Patents

Literature

145 results about "Flue-gas stack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

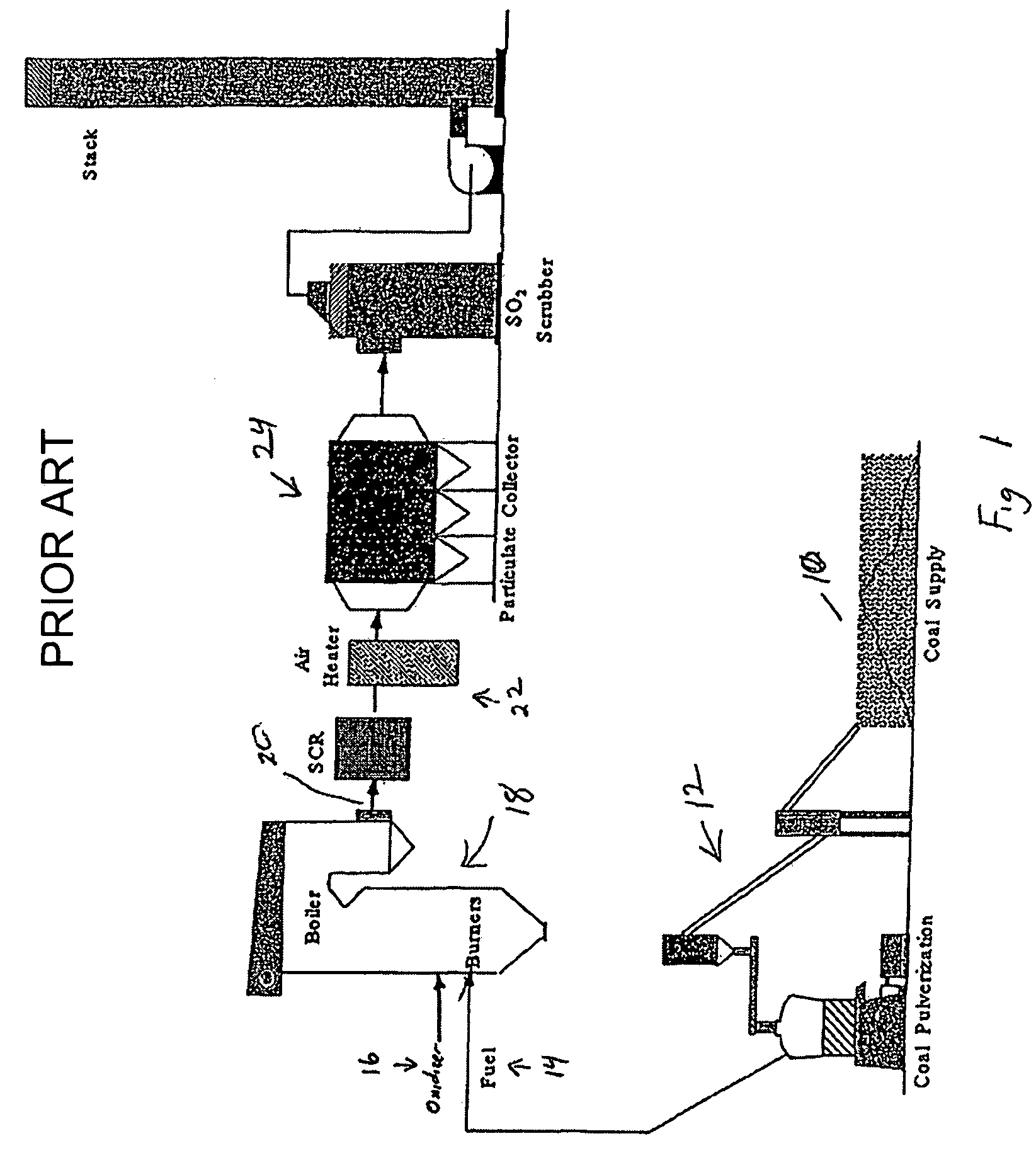

A flue-gas stack, also known as a smoke stack, chimney stack or simply as a stack, is a type of chimney, a vertical pipe, channel or similar structure through which combustion product gases called flue gases are exhausted to the outside air. Flue gases are produced when coal, oil, natural gas, wood or any other fuel is combusted in an industrial furnace, a power plant's steam-generating boiler, or other large combustion device. Flue gas is usually composed of carbon dioxide (CO₂) and water vapor as well as nitrogen and excess oxygen remaining from the intake combustion air. It also contains a small percentage of pollutants such as particulate matter, carbon monoxide, nitrogen oxides and sulfur oxides. The flue gas stacks are often quite tall, up to 400 metres (1300 feet) or more, so as to disperse the exhaust pollutants over a greater area and thereby reduce the concentration of the pollutants to the levels required by governmental environmental policy and environmental regulation.

Flue gas mercury control

ActiveUS8080088B1Enhance particulate collectionReducing fly ash resistivityGas treatmentIsotope separationActivated carbonHalogen

An adsorbent composition for removing mercury from a flue gas stream, and a method of its use. The composition is a powdered activated carbon having at least one of a halogen-containing component and an alkaline component dispersed thereon. A flow agent can be composited with the material to maintain flowability in situ.

Owner:SRINIVASACHAR SRIVATS

Mercury sorbent delivery system for flue gas

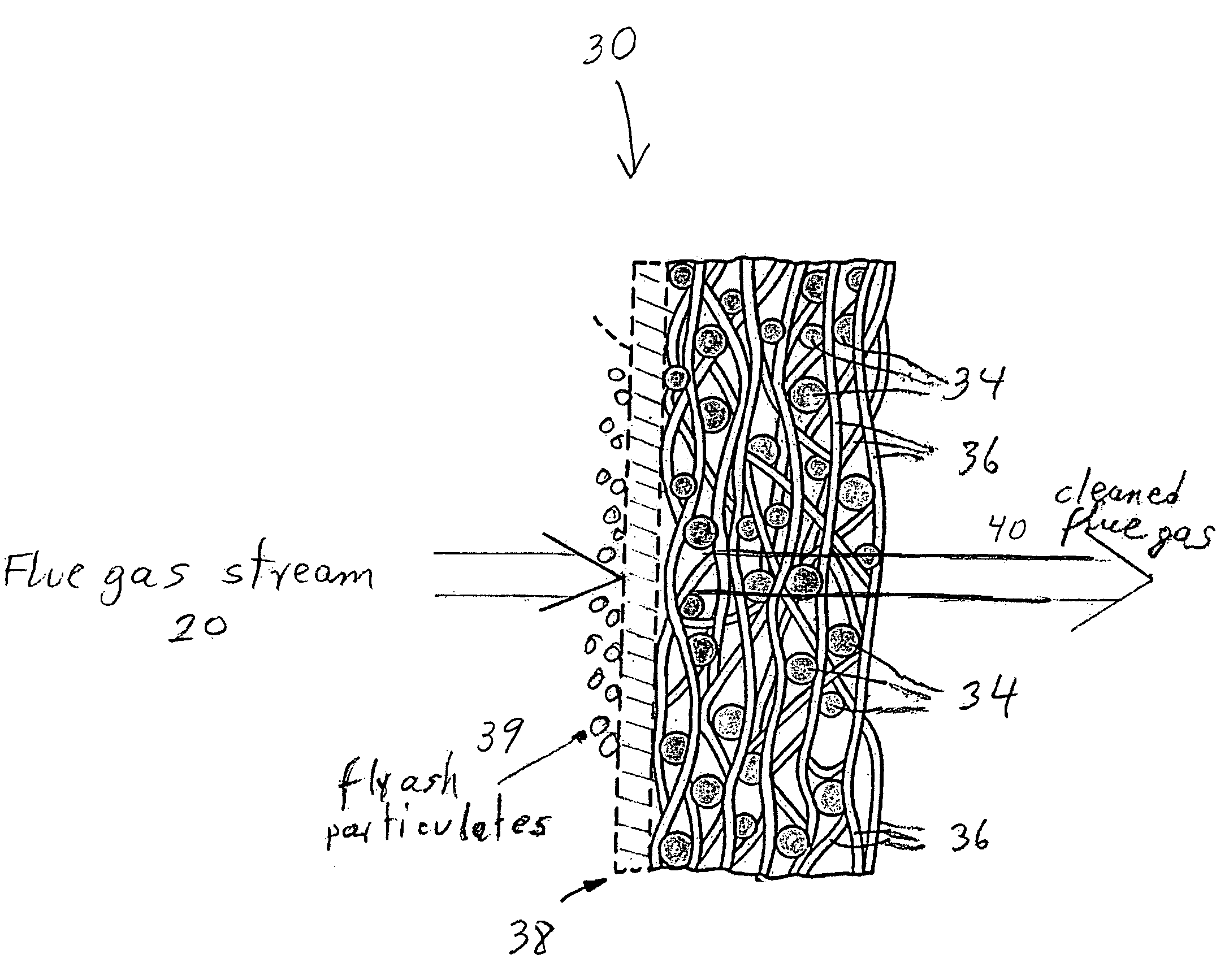

The invention presents a device for the removal of elemental mercury from flue gas streams utilizing a layer of activated carbon particles contained within the filter fabric of a filter bag for use in a flue gas scrubbing system.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

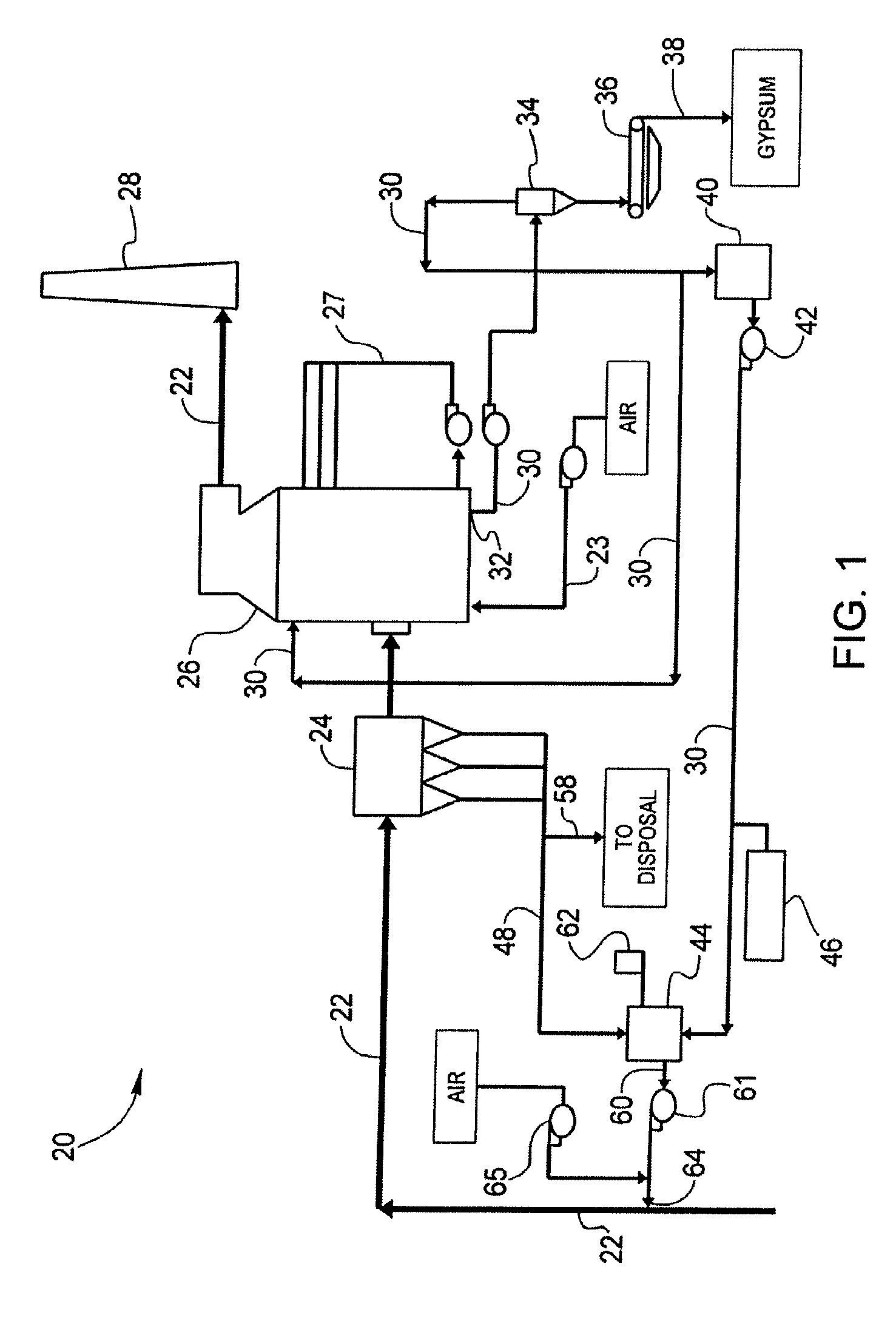

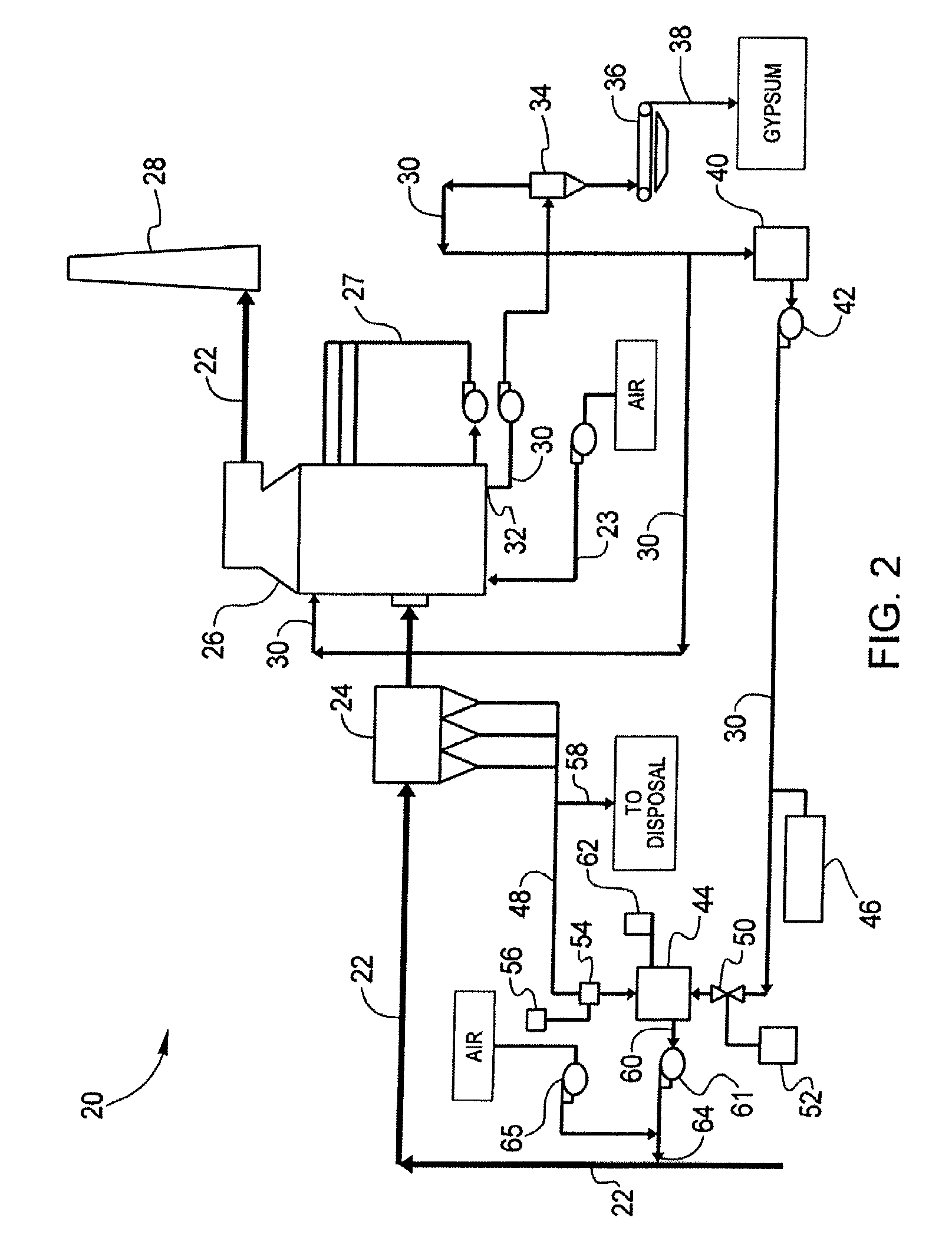

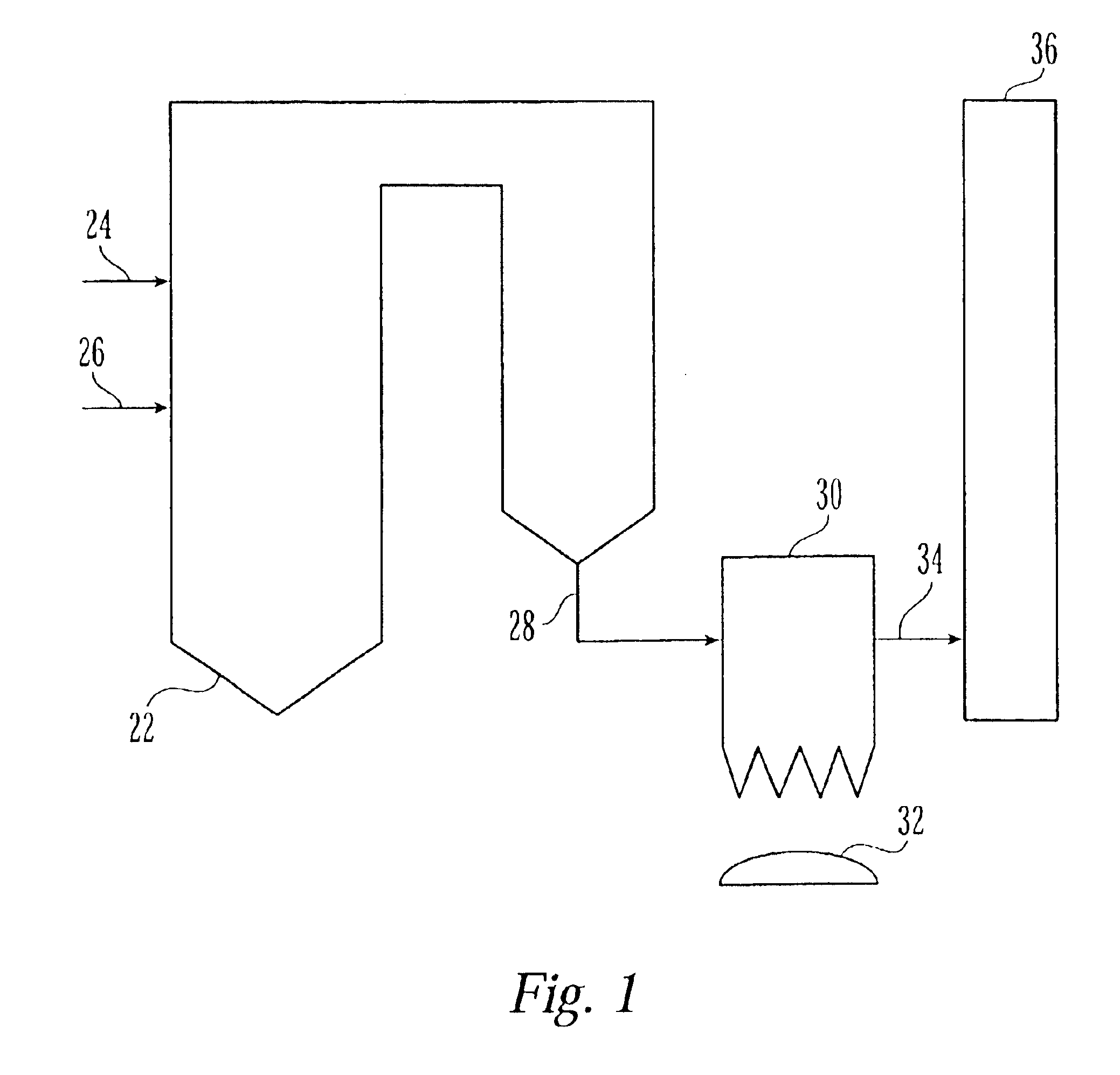

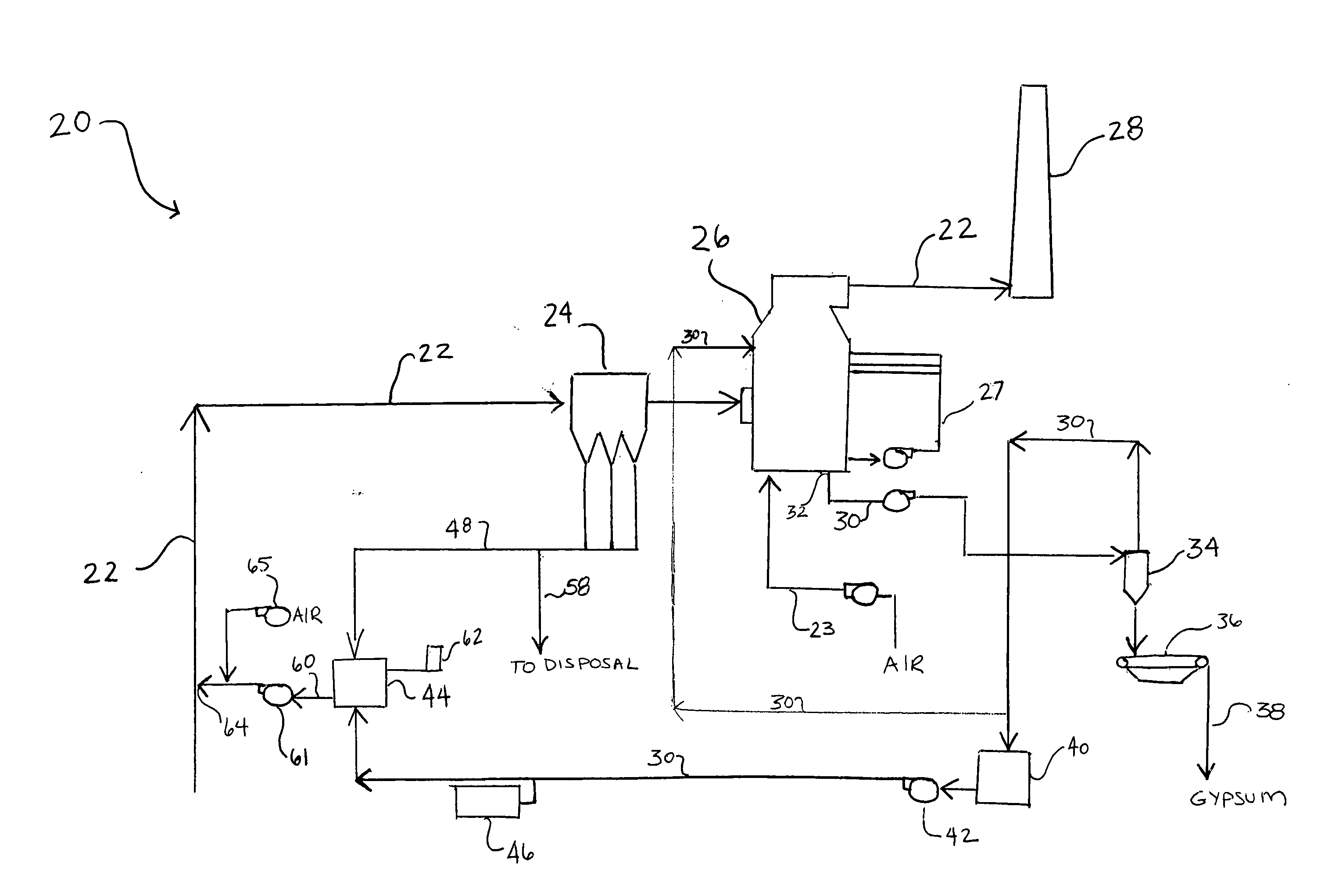

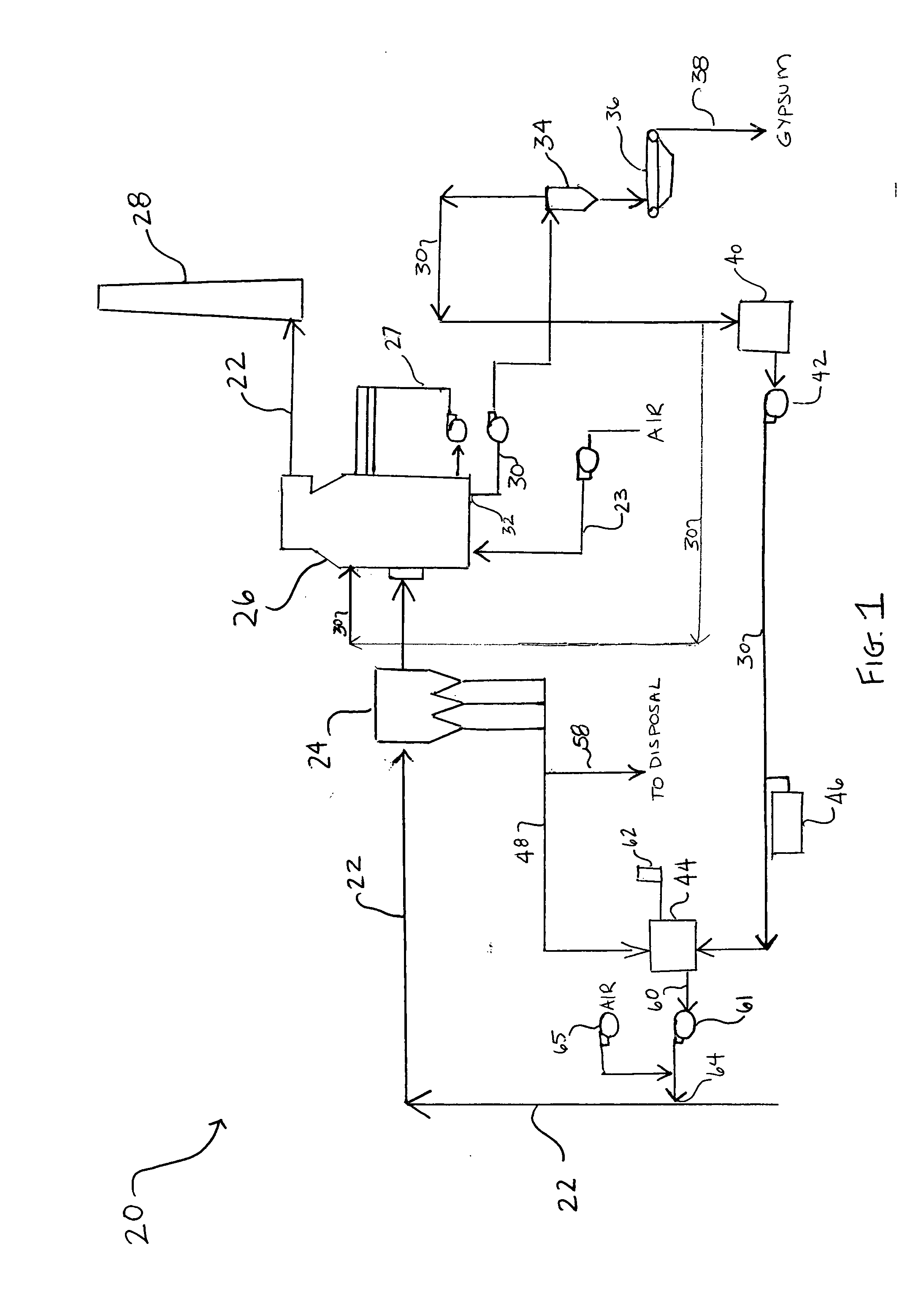

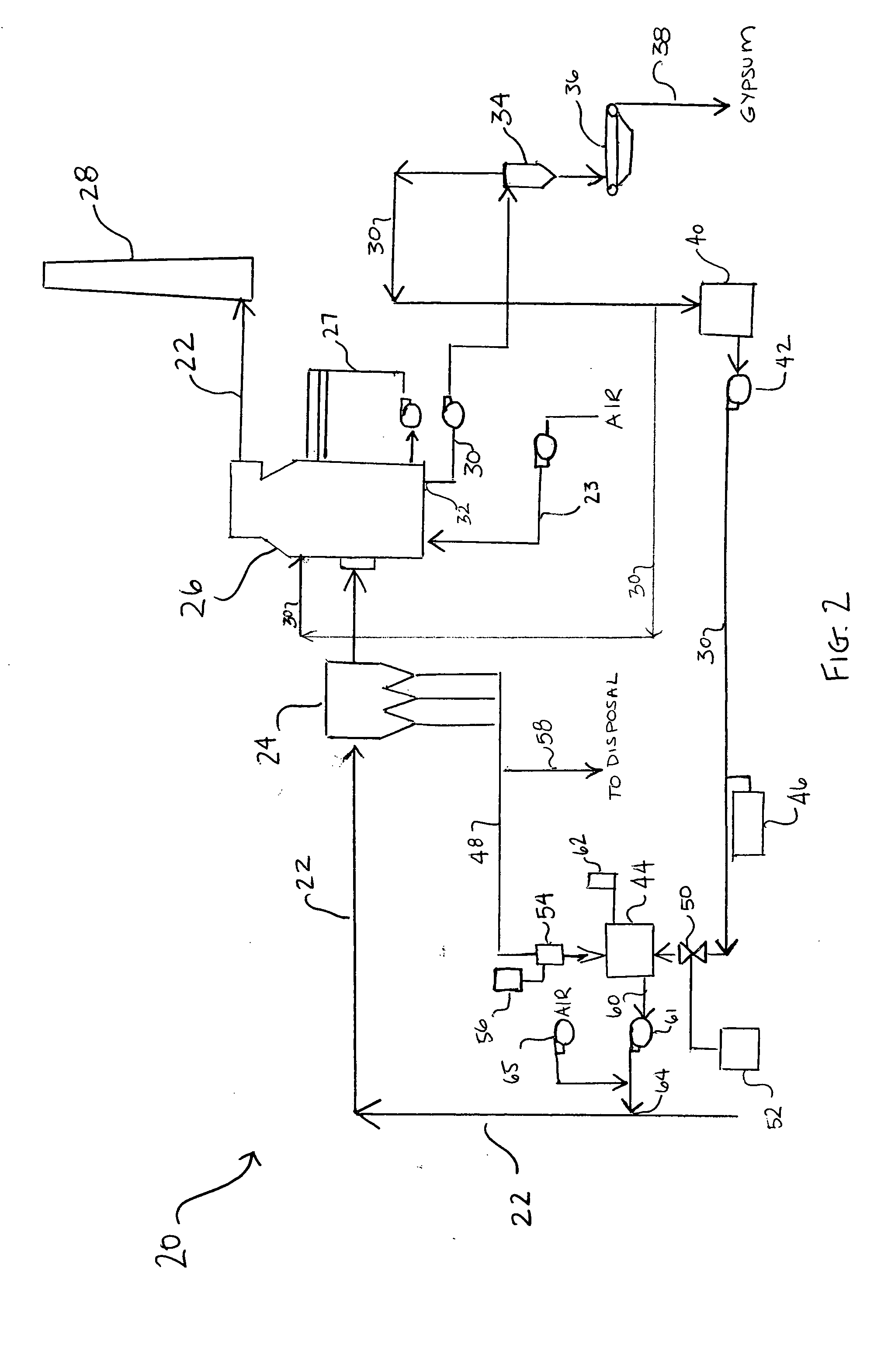

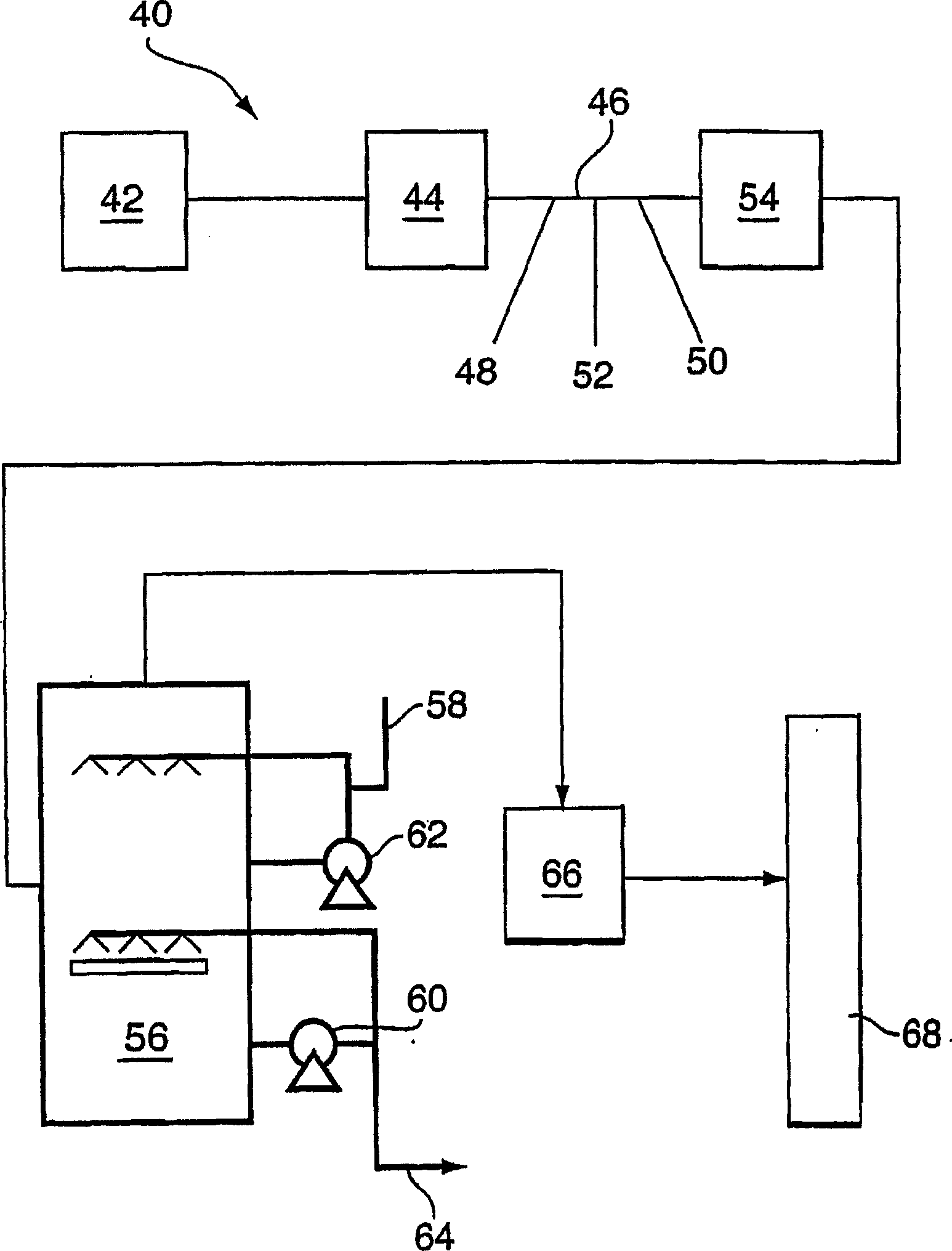

Reduced liquid discharge in wet flue gas desulfurization

One aspect of the invention relates to a method for removing contaminants from a flue gas stream (22). The method includes: removing fly ash from a flue gas stream (22) utilizing a particle collector (24); contacting the flue gas stream with an alkaline reagent in a wet scrubber (26); discharging a purge liquid (30) from the wet scrubber (26); and, combining at least a portion of the purge liquid with at least a portion of fly ash circulating within a dry circulating fluid bed scrubber (48) to form moistened fly ash (60).

Owner:GENERAL ELECTRIC TECH GMBH

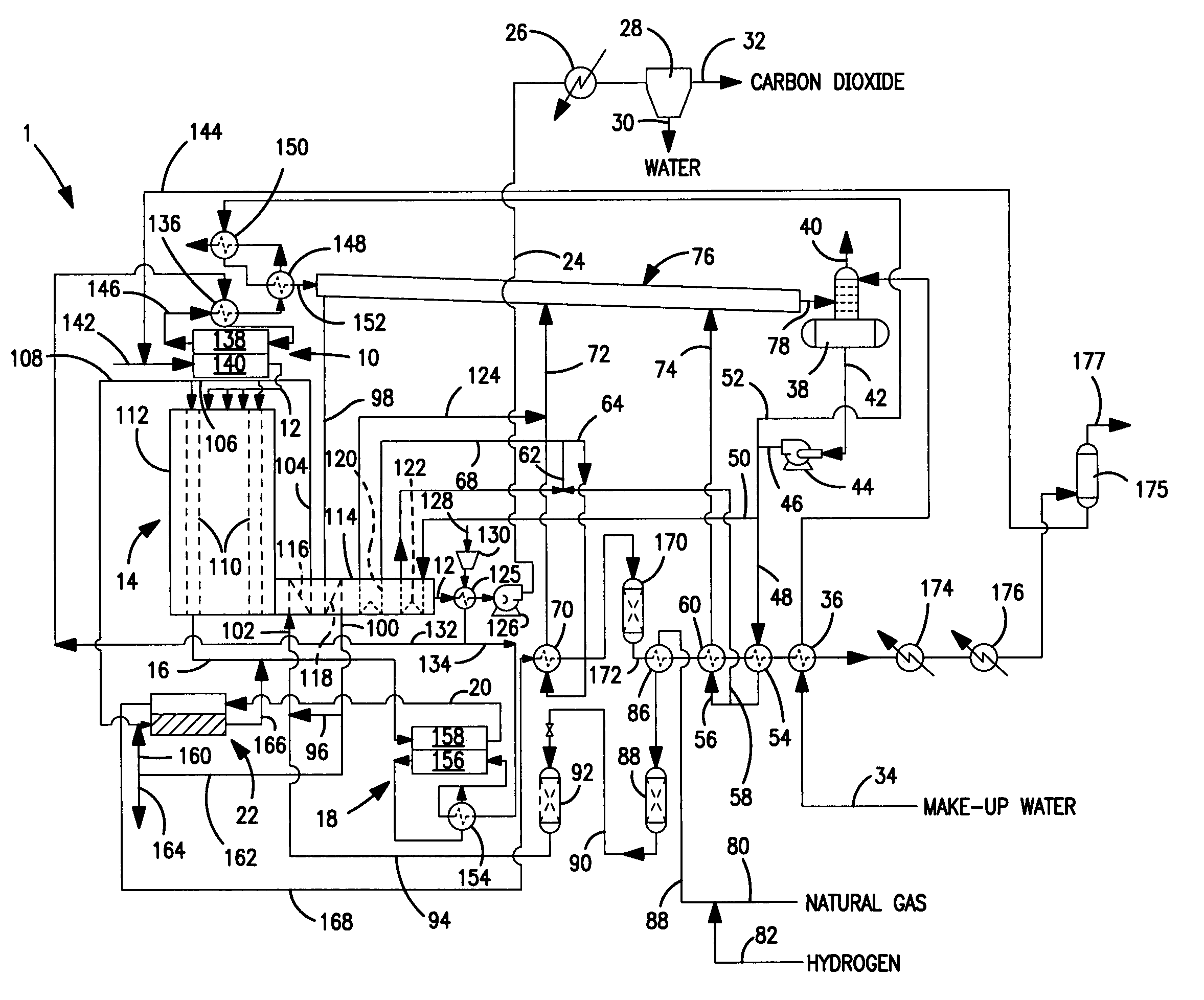

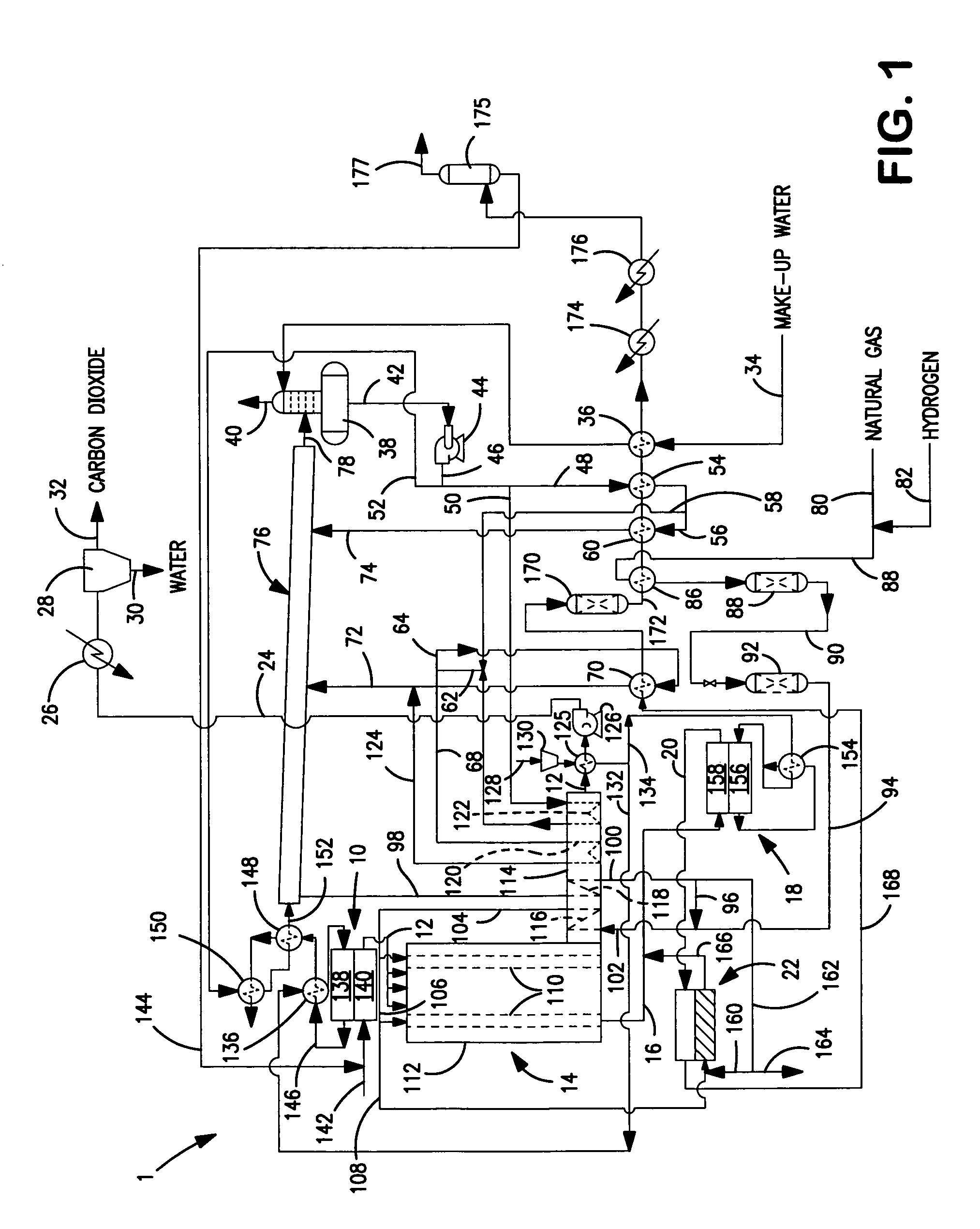

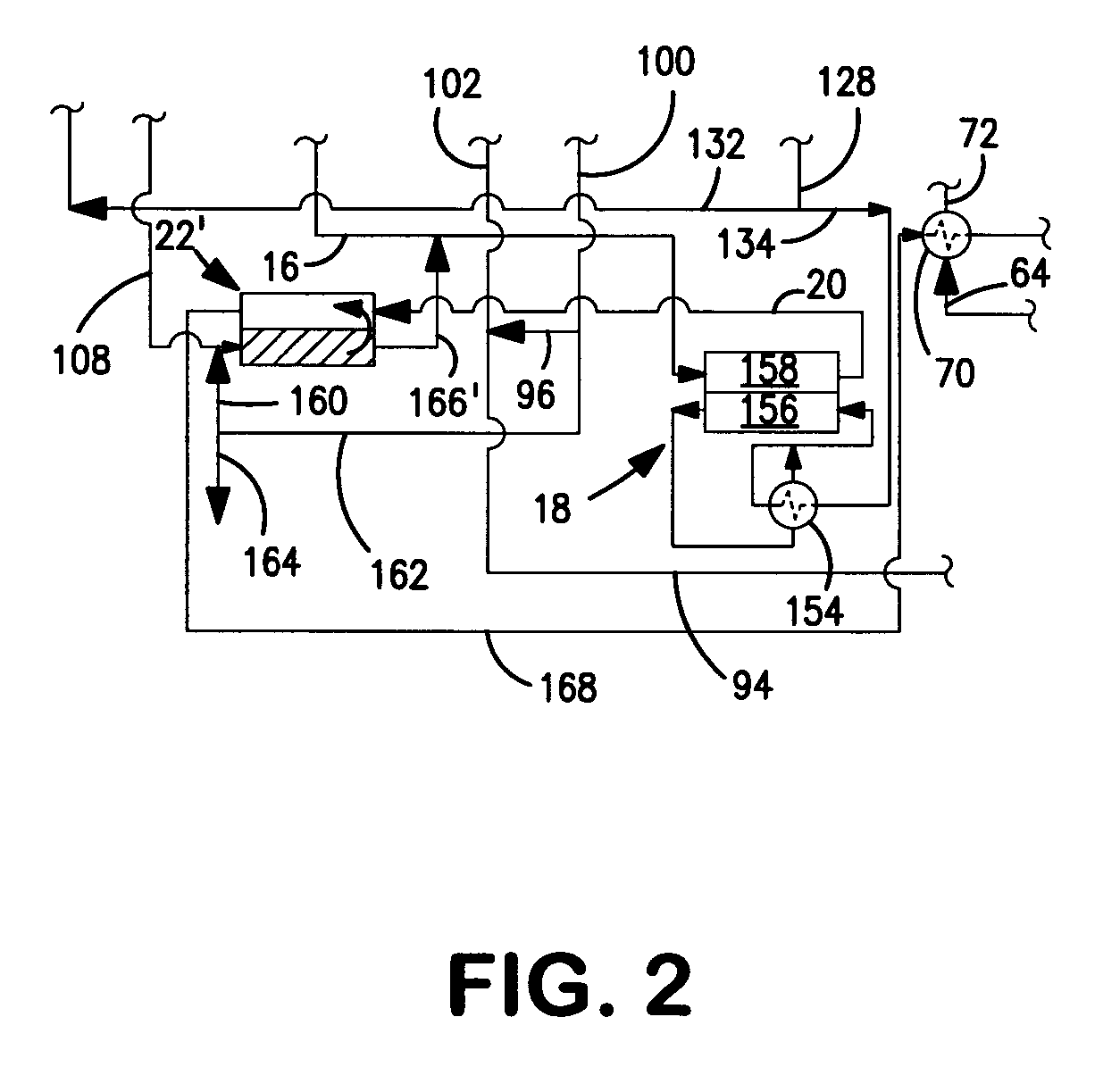

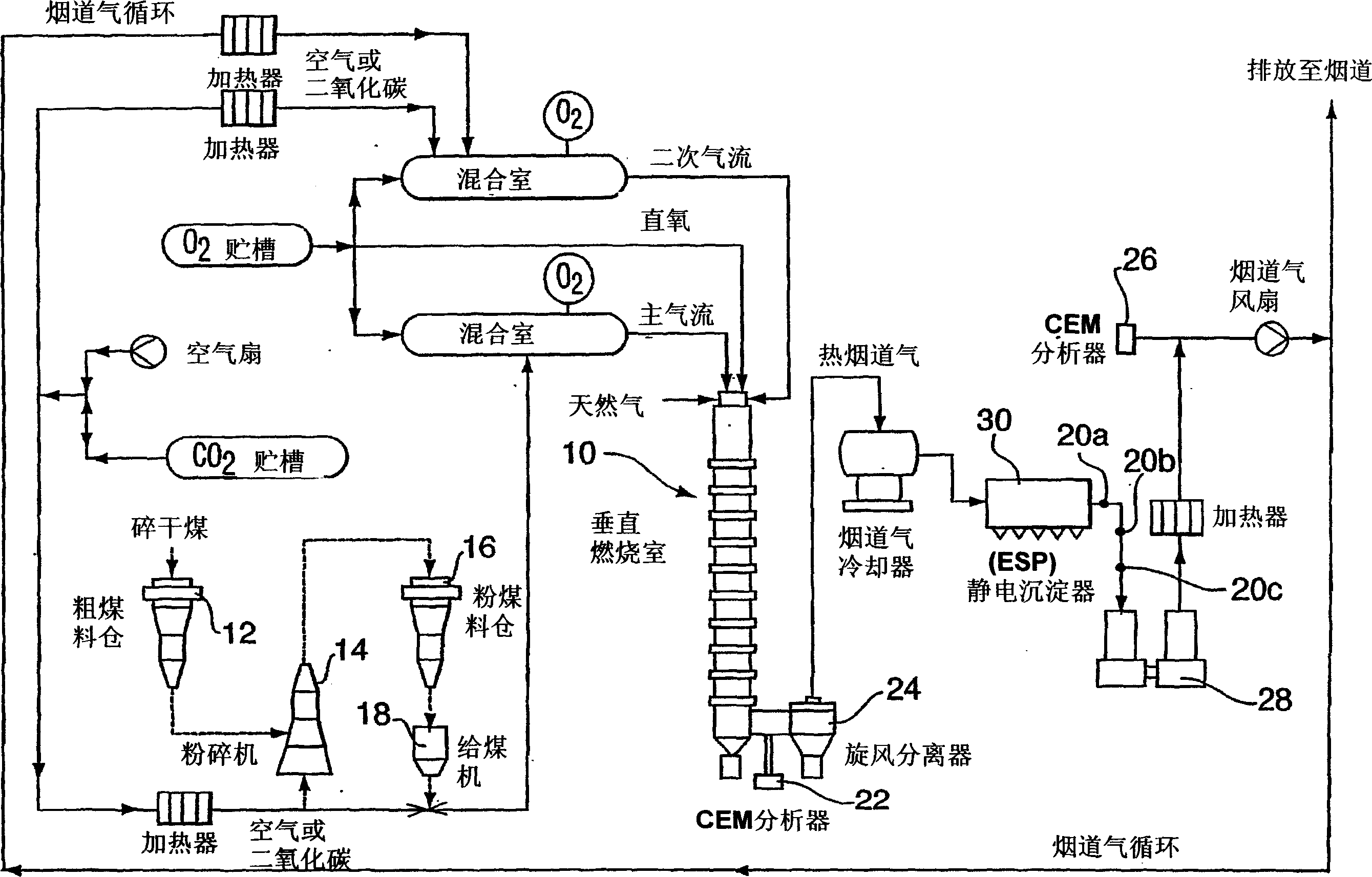

Synthesis gas and carbon dioxide generation method

A method of generating a synthesis gas product stream and carbon dioxide in which a fuel is combusted in an oxygen transport membrane combustor to produce a flue gas stream containing the carbon dioxide and water. Reforming duty is divided between a combined reforming process and a gas heated reformer to produce the product stream. The flue gas stream is used to supply heat to a primary, steam methane reforming stage of the combined reforming process. Residual methane, produced in the primary stage, is reacted in a secondary stage having an oxygen transport membrane reactor. Heat produced in the secondary stage is supplied to the gas heated reactor to support its operation. The flue gas stream is cooled and water is separated therefrom to produce the carbon dioxide at a concentration of at least 85 mol percent.

Owner:PRAXAIR TECH INC

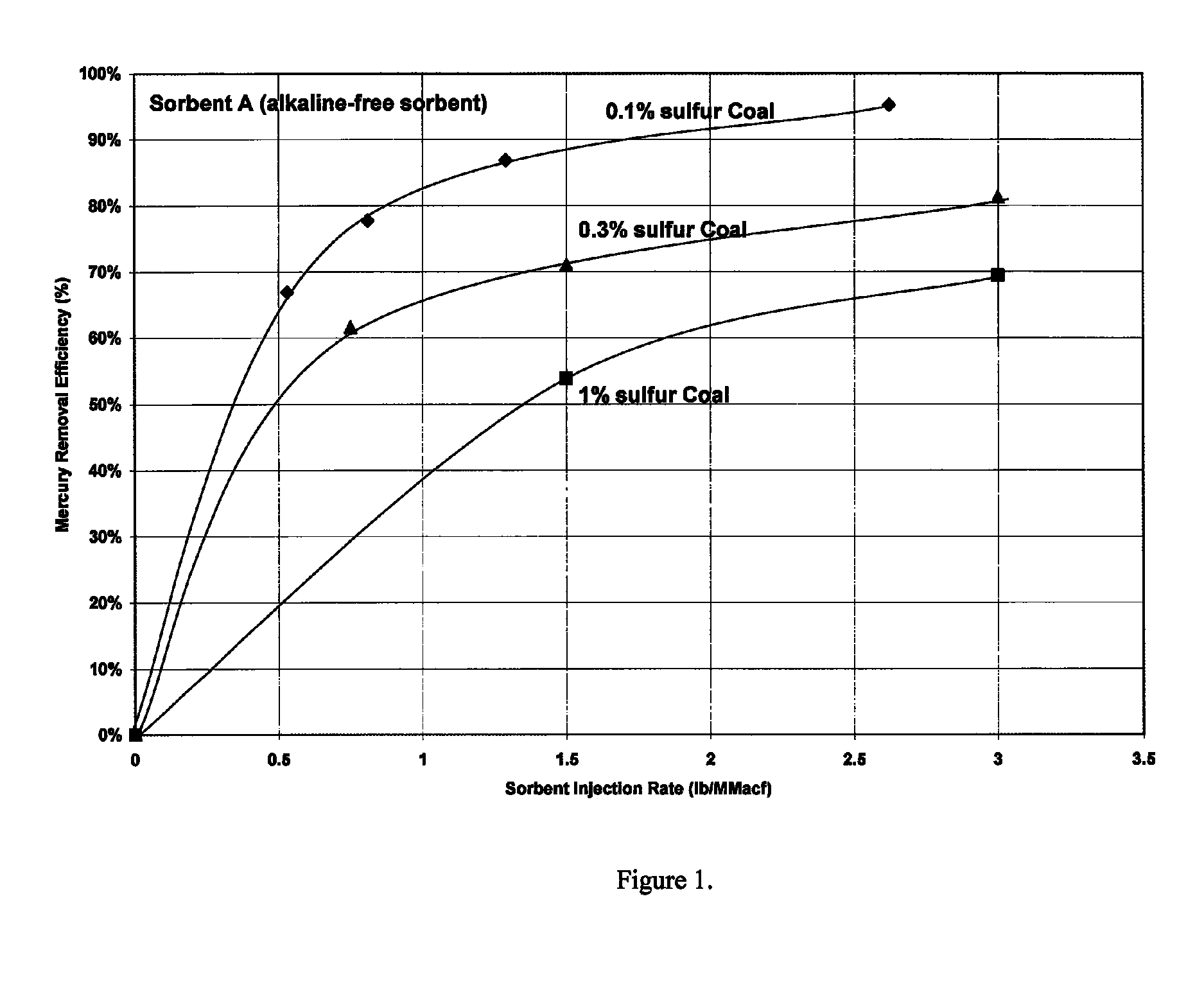

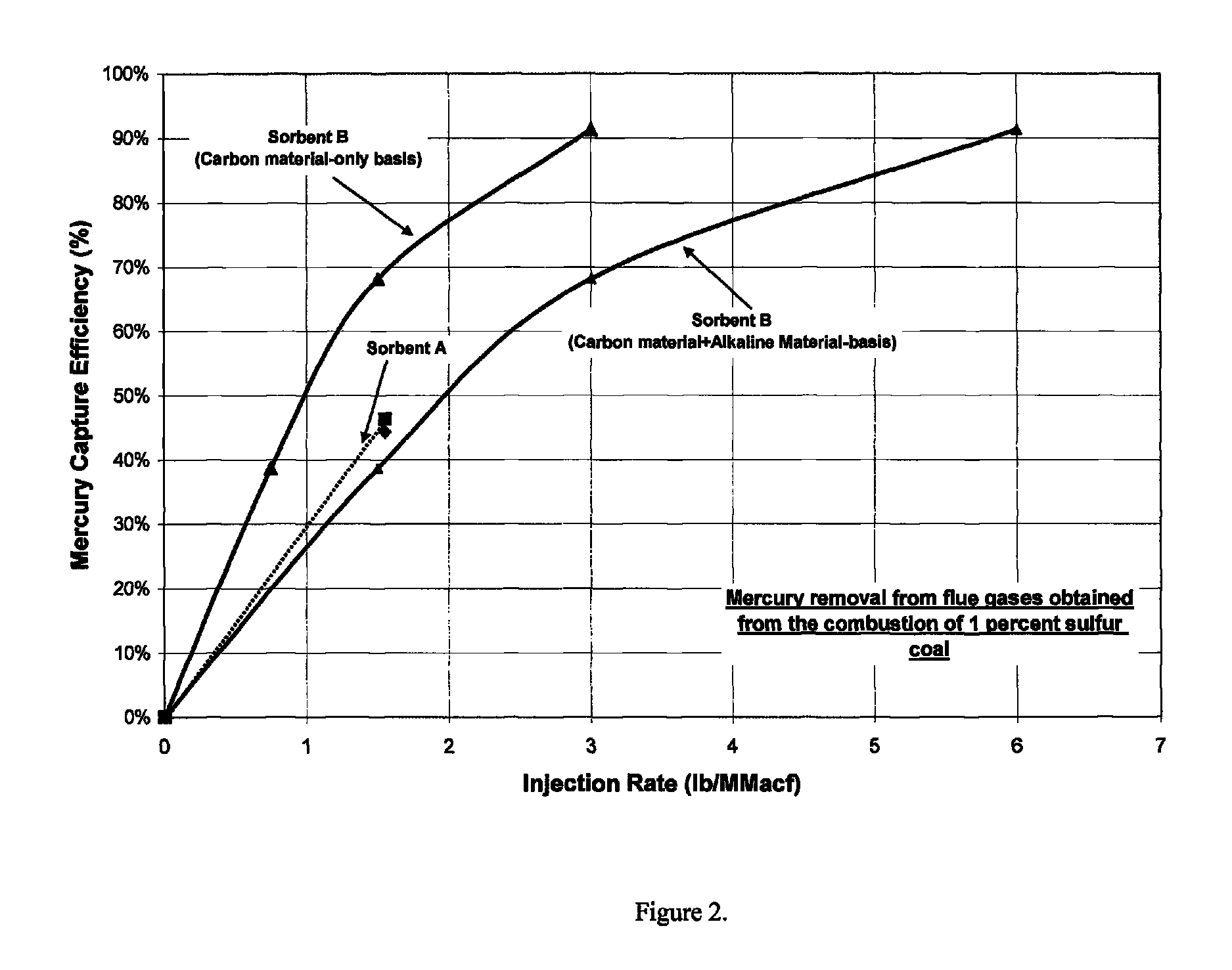

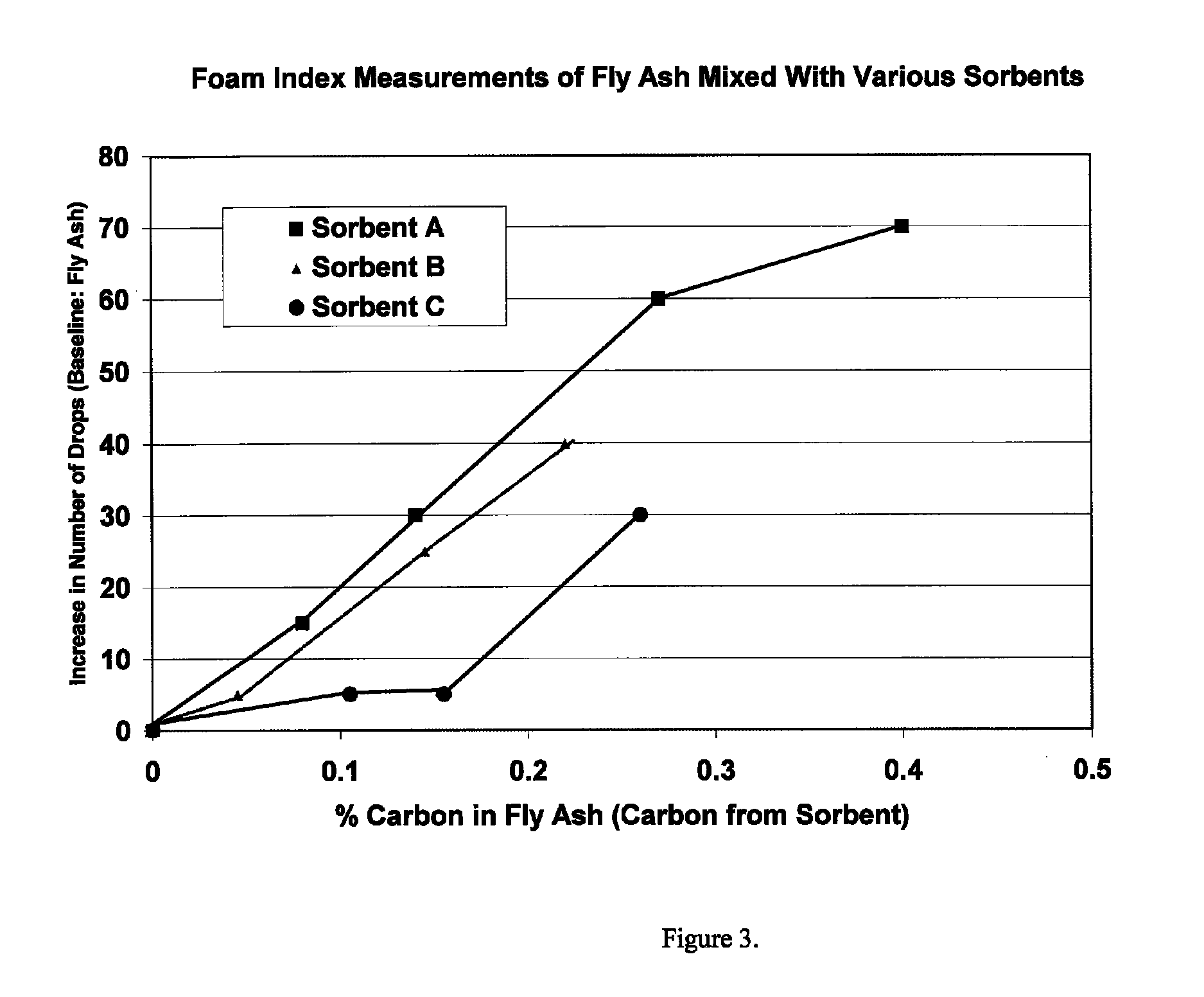

Mercury removal from flue gas streams using treated sorbents

ActiveUS8551431B1Disadvantages can be reduced eliminatedProblems can be reduced eliminatedGas treatmentMolecular sieve catalystsHalogenFlue gas

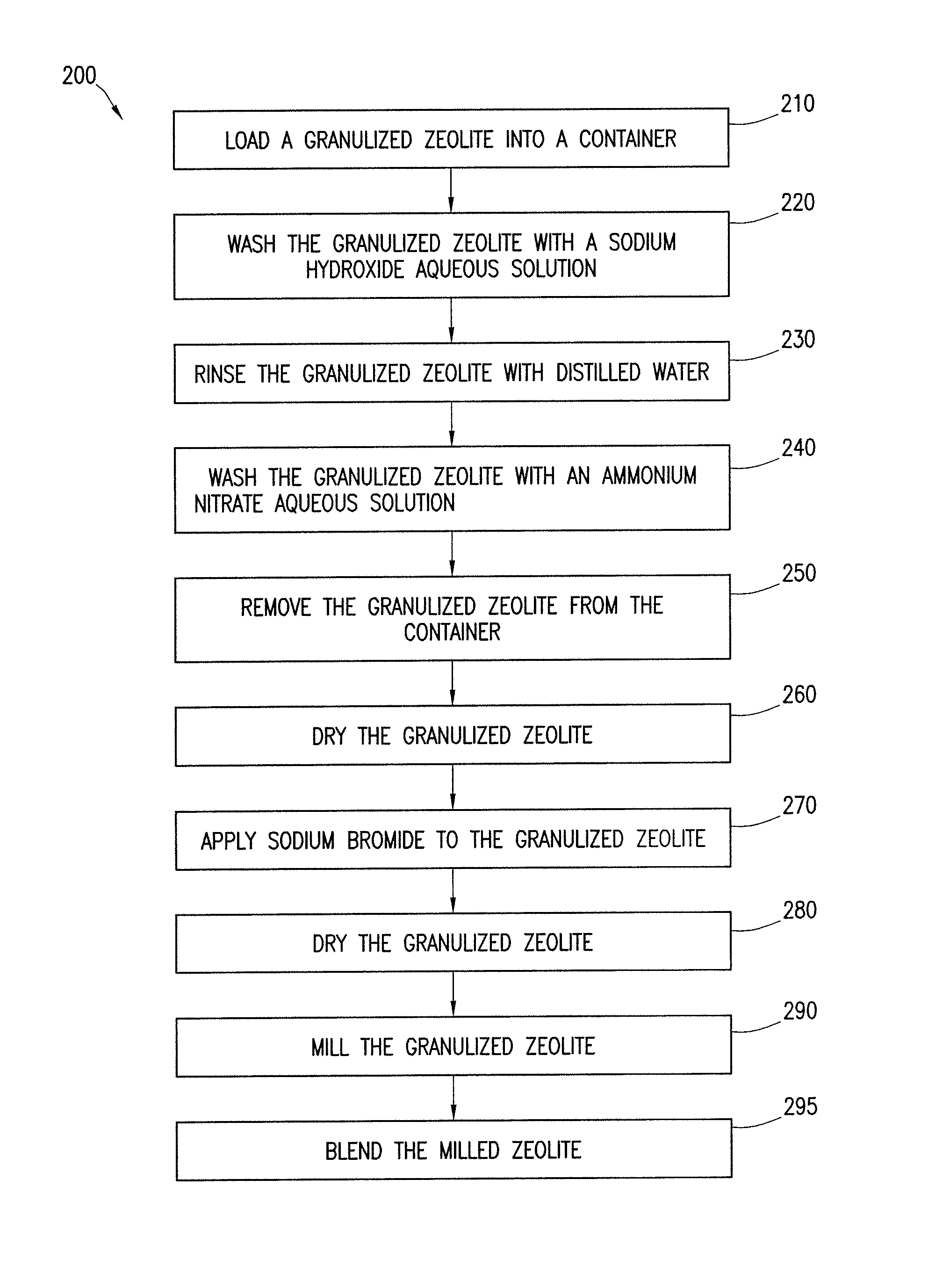

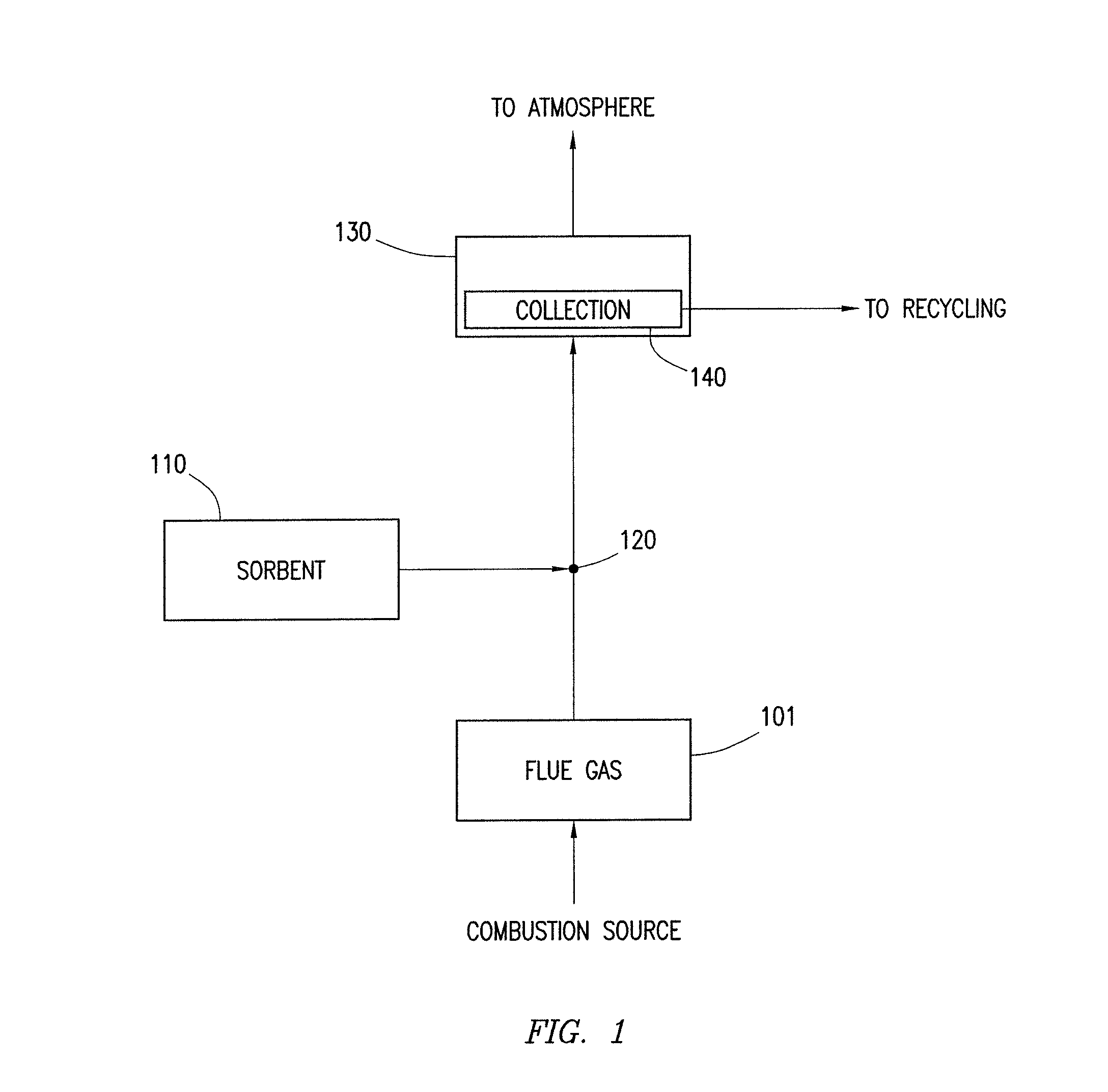

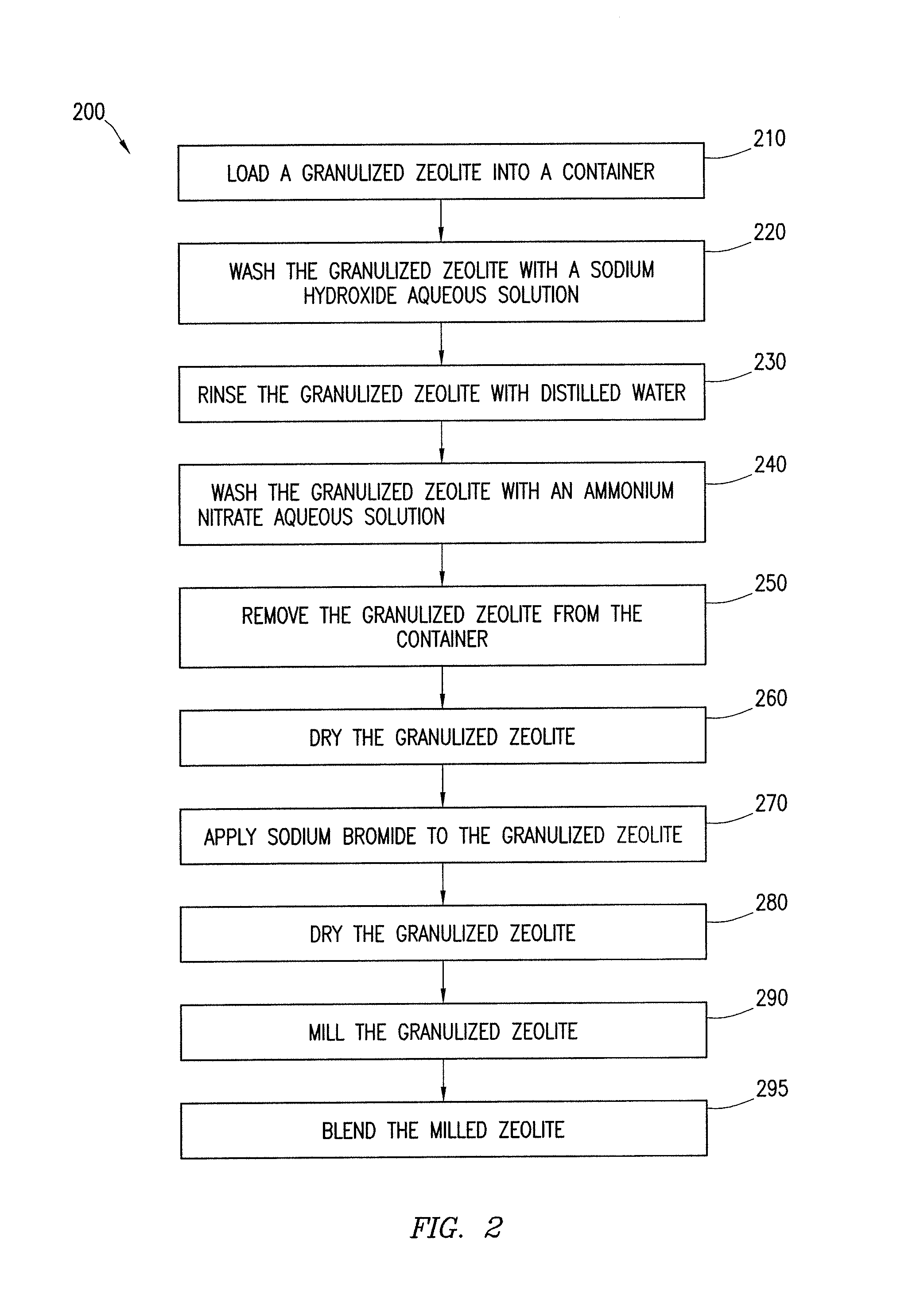

A method for modifying the properties of a sorbent comprising washing a sorbent with a washing solution so as to achieve an exchange of ions between the sorbent and the washing solution, and applying a halogen compound to the sorbent that has been washed with the washing solution to achieve a predetermined concentration of the halogen on the sorbent.

Owner:CABOT NORIT AMERICAS

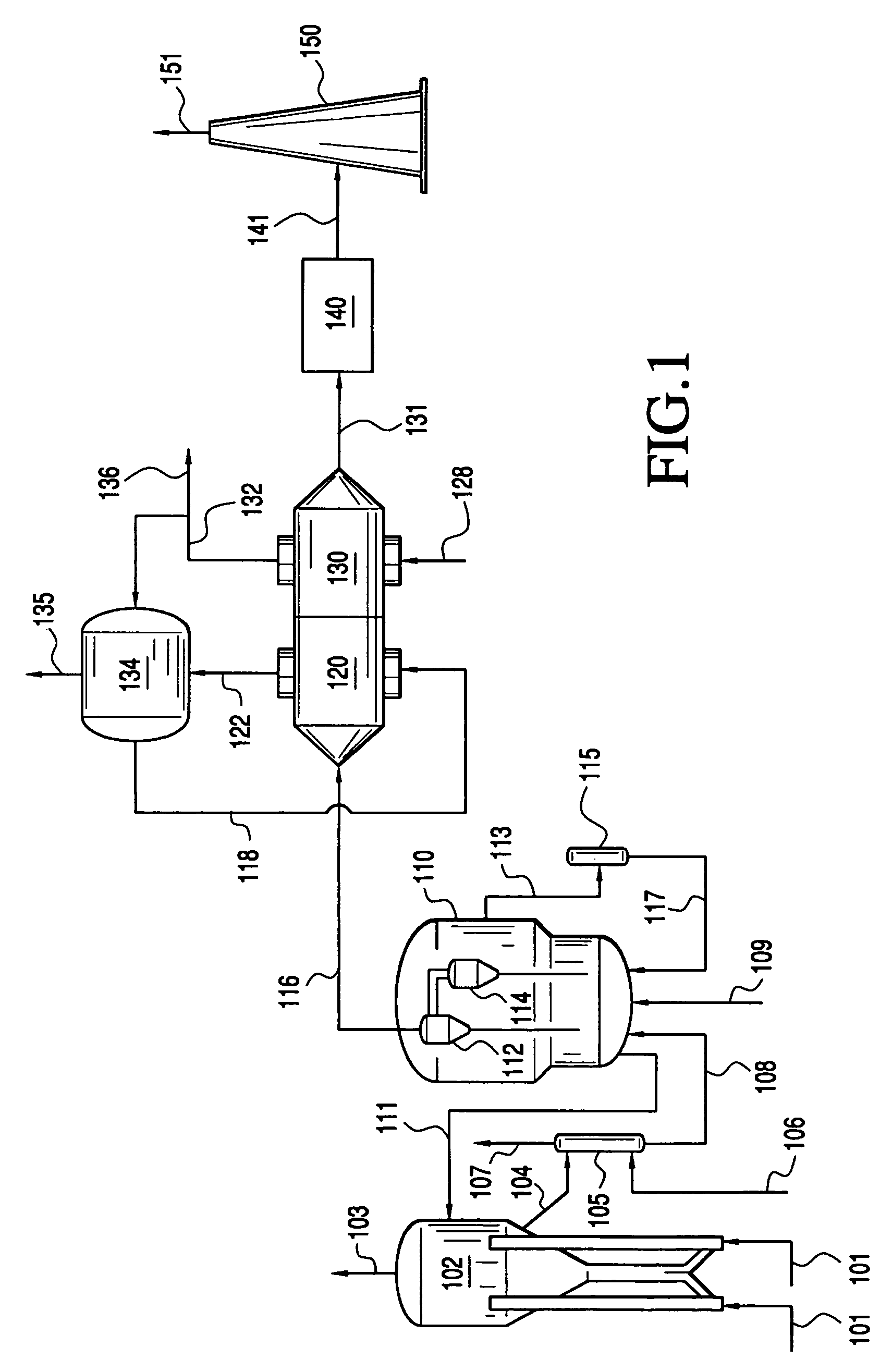

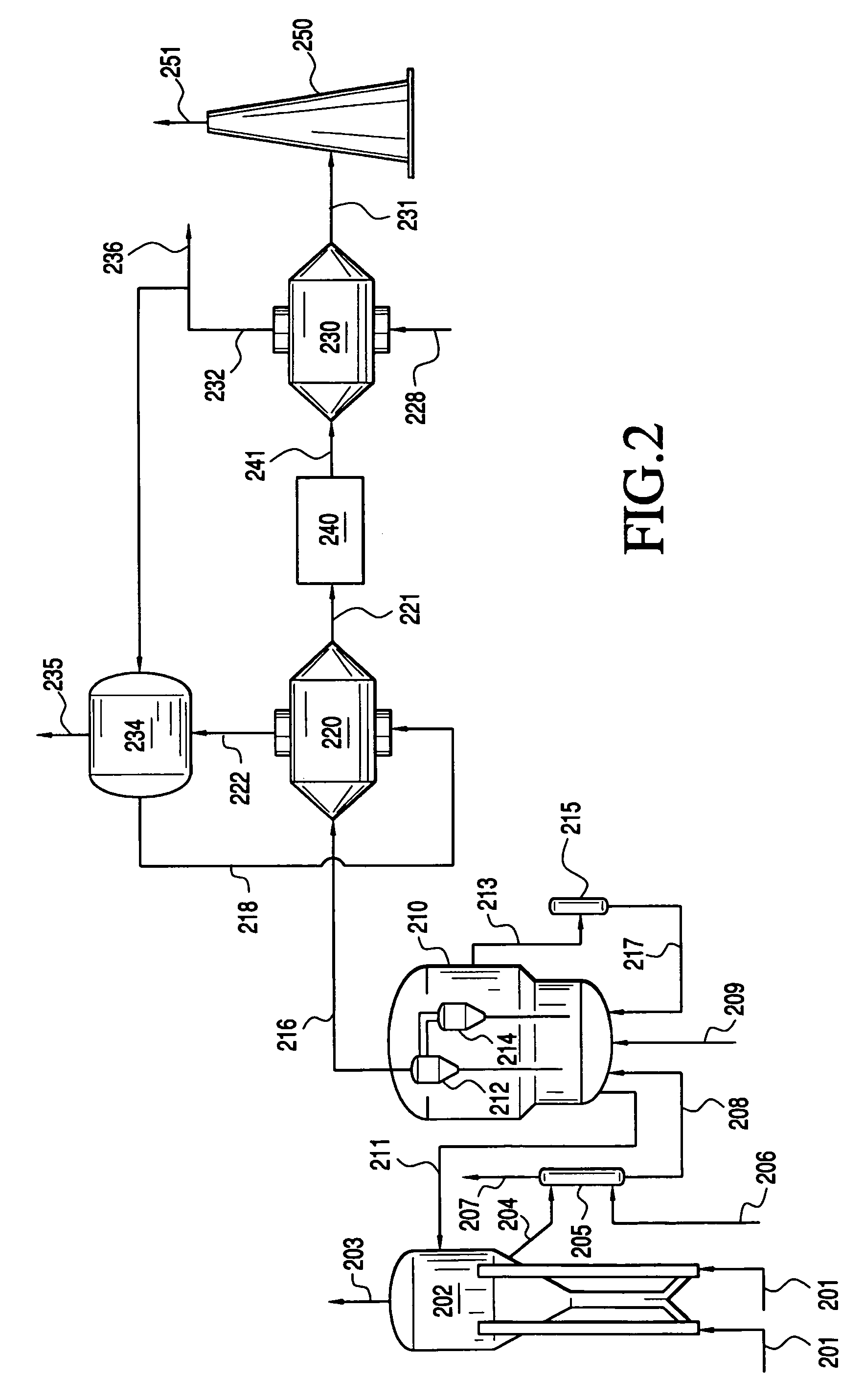

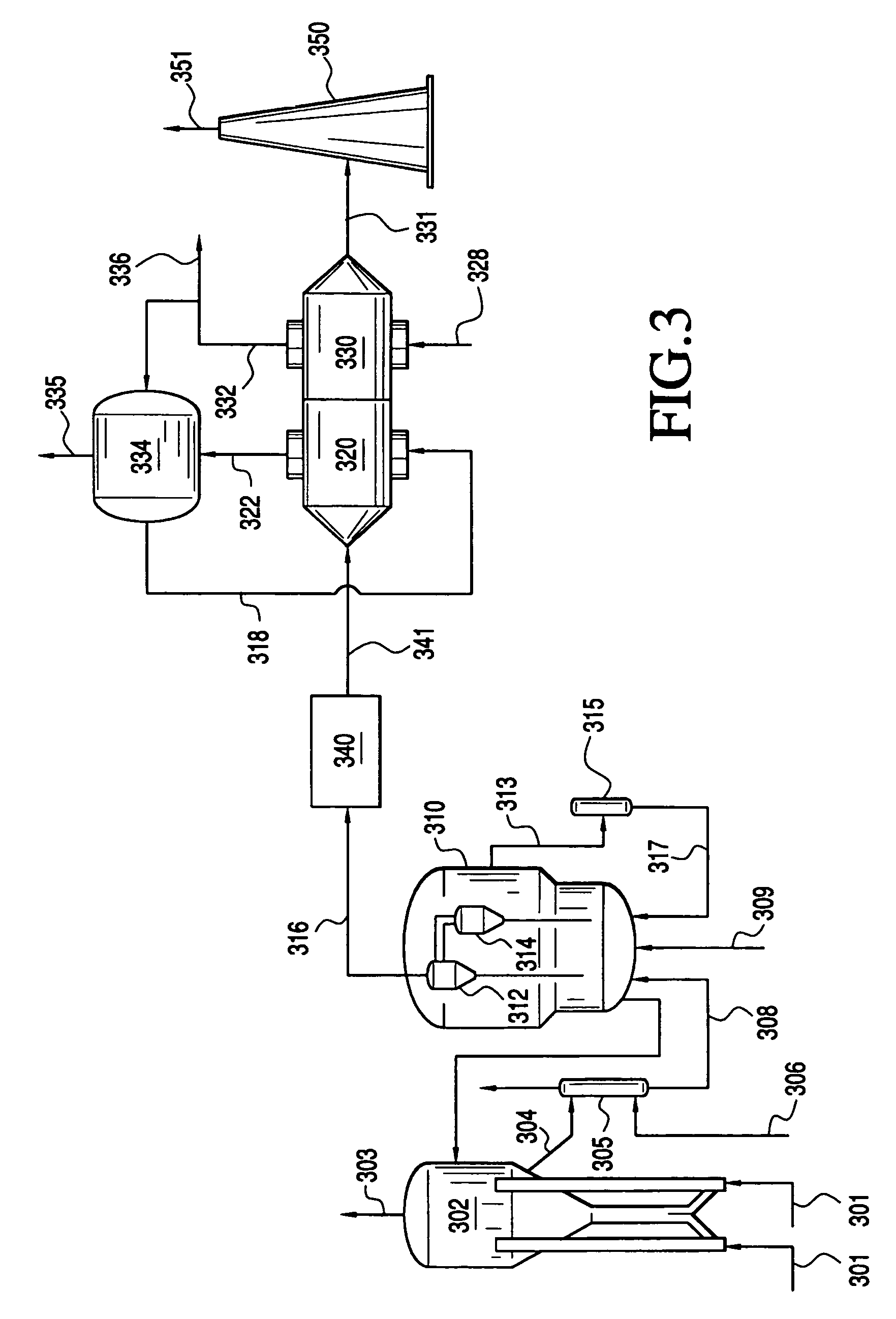

Carbon Dioxide Absorber And Regeneration Assemblies Useful For Power Plant Flue Gas

ActiveUS20110005395A1Limit and prevents any localized overheatingUniform bed temperatureGas treatmentEmission preventionSorbentCo2 absorption

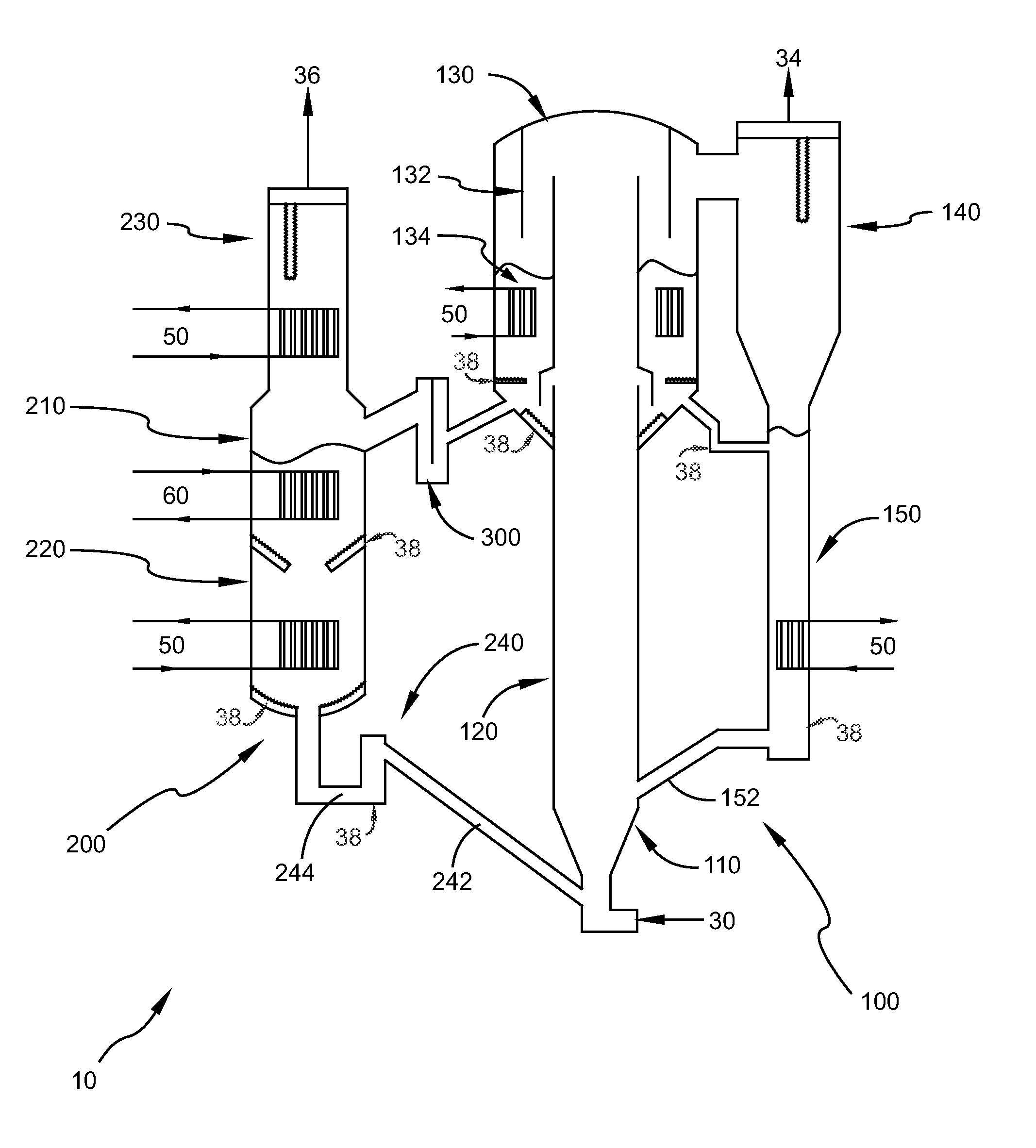

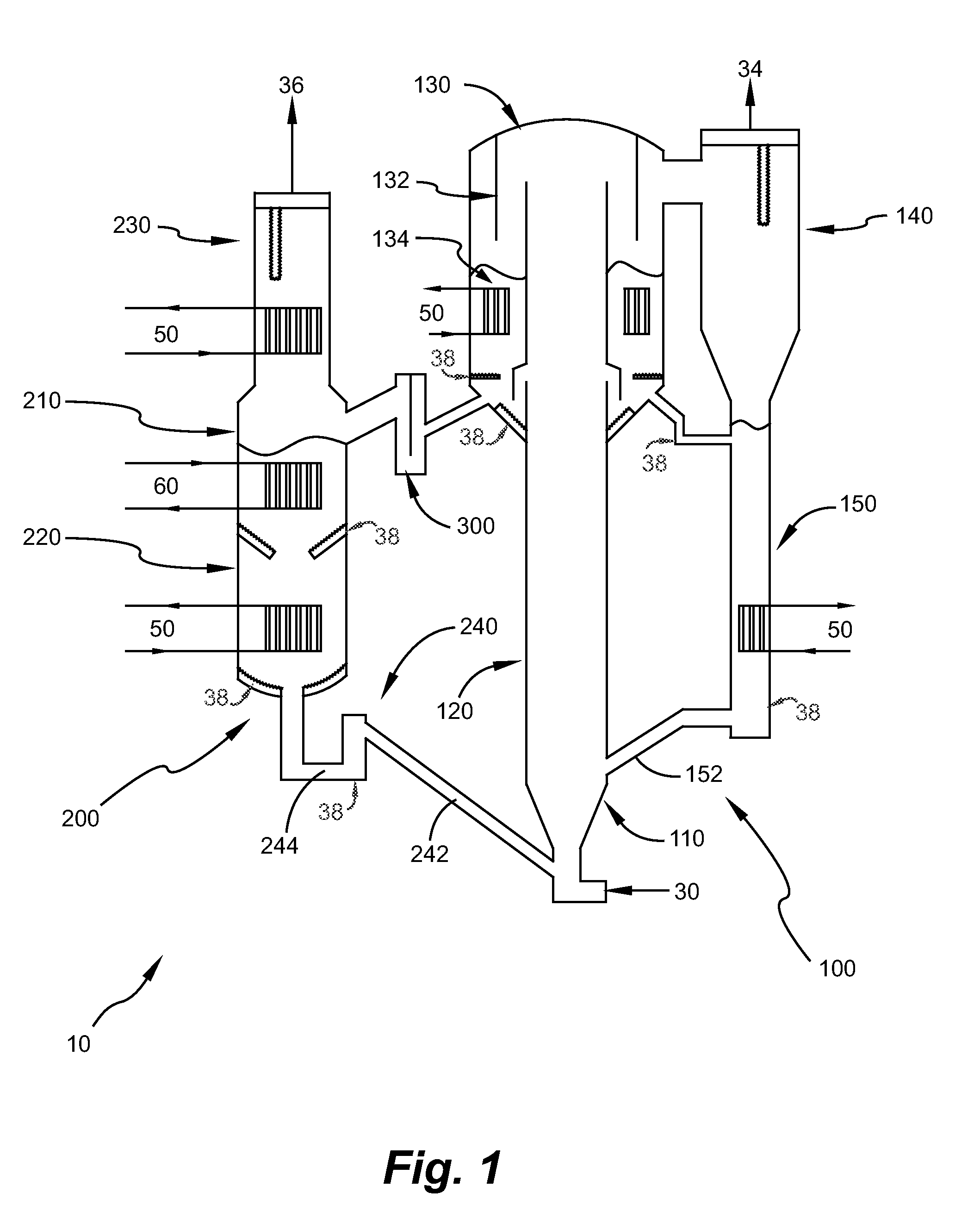

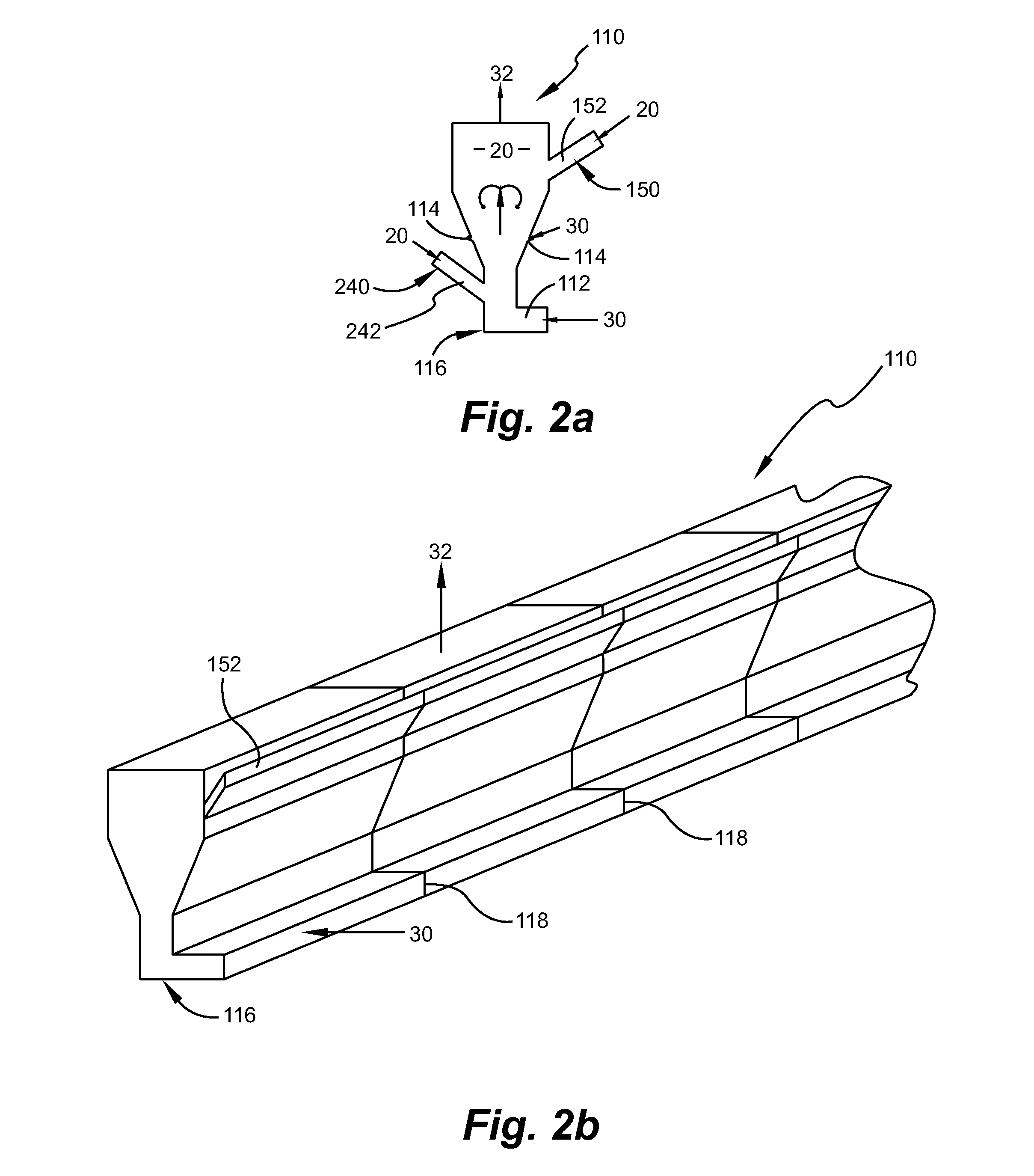

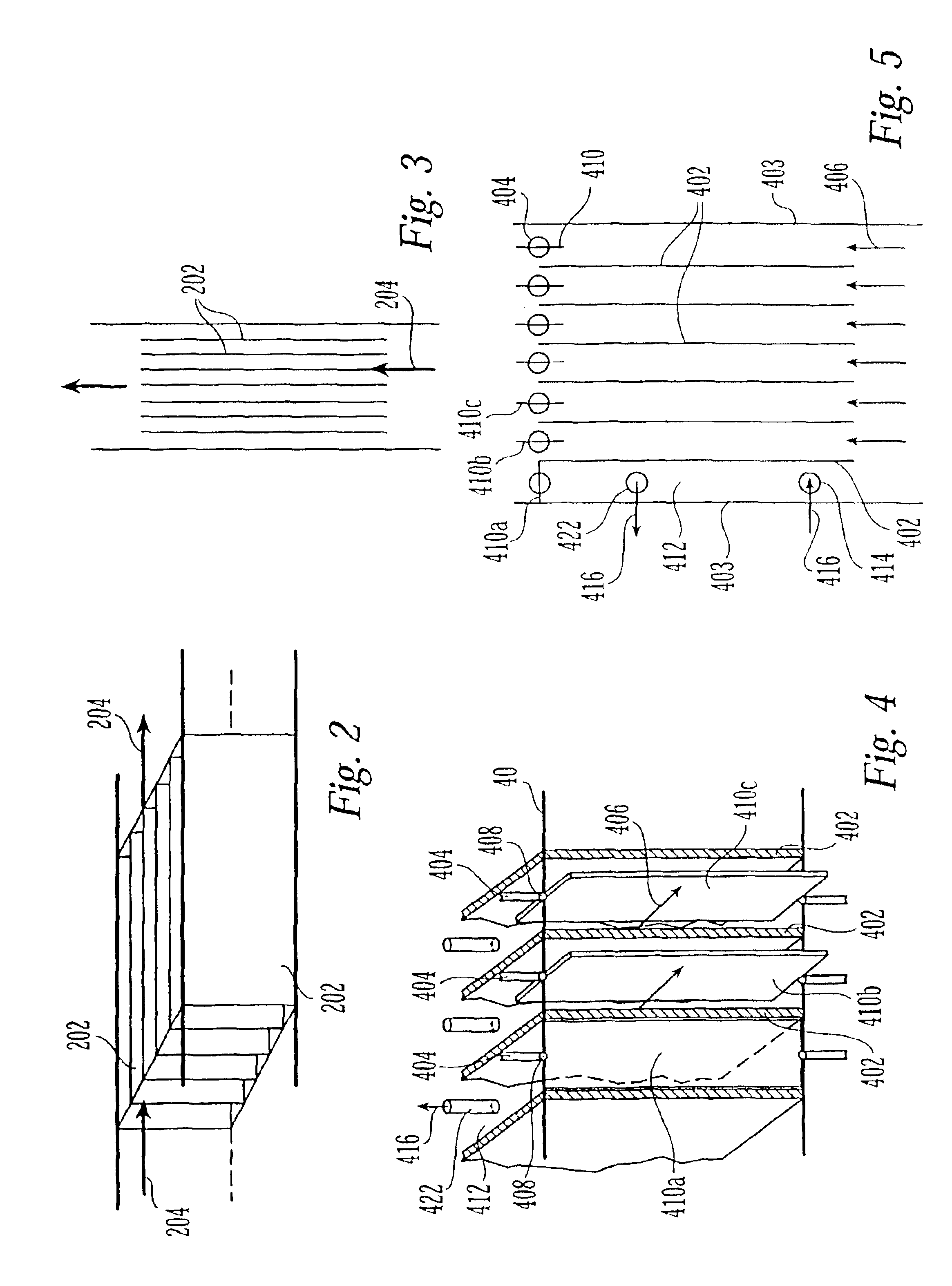

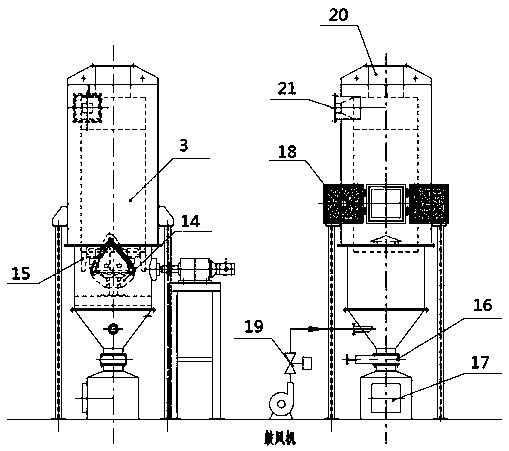

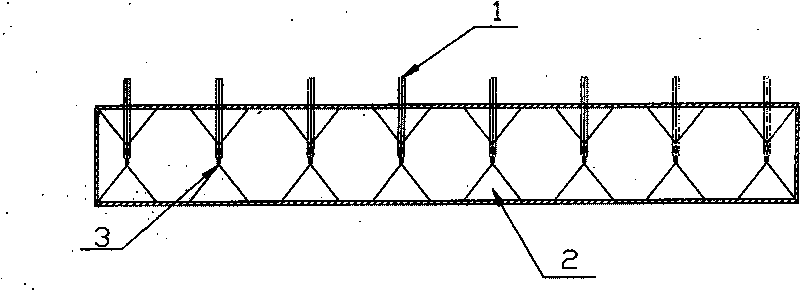

Disclosed are apparatus and method to treat large amounts of flue gas from a pulverized coal combustion power plant. The flue gas is contacted with solid sorbents to selectively absorb CO2, which is then released as a nearly pure CO2 gas stream upon regeneration at higher temperature. The method is capable of handling the necessary sorbent circulation rates of tens of millions of lbs / hr to separate CO2 from a power plant's flue gas stream. Because pressurizing large amounts of flue gas is cost prohibitive, the method of this invention minimizes the overall pressure drop in the absorption section to less than 25 inches of water column. The internal circulation of sorbent within the absorber assembly in the proposed method not only minimizes temperature increases in the absorber to less than 25° F., but also increases the CO2 concentration in the sorbent to near saturation levels. Saturating the sorbent with CO2 in the absorber section minimizes the heat energy needed for sorbent regeneration. The commercial embodiments of the proposed method can be optimized for sorbents with slower or faster absorption kinetics, low or high heat release rates, low or high saturation capacities and slower or faster regeneration kinetics.

Owner:THE SOUTHERN CO

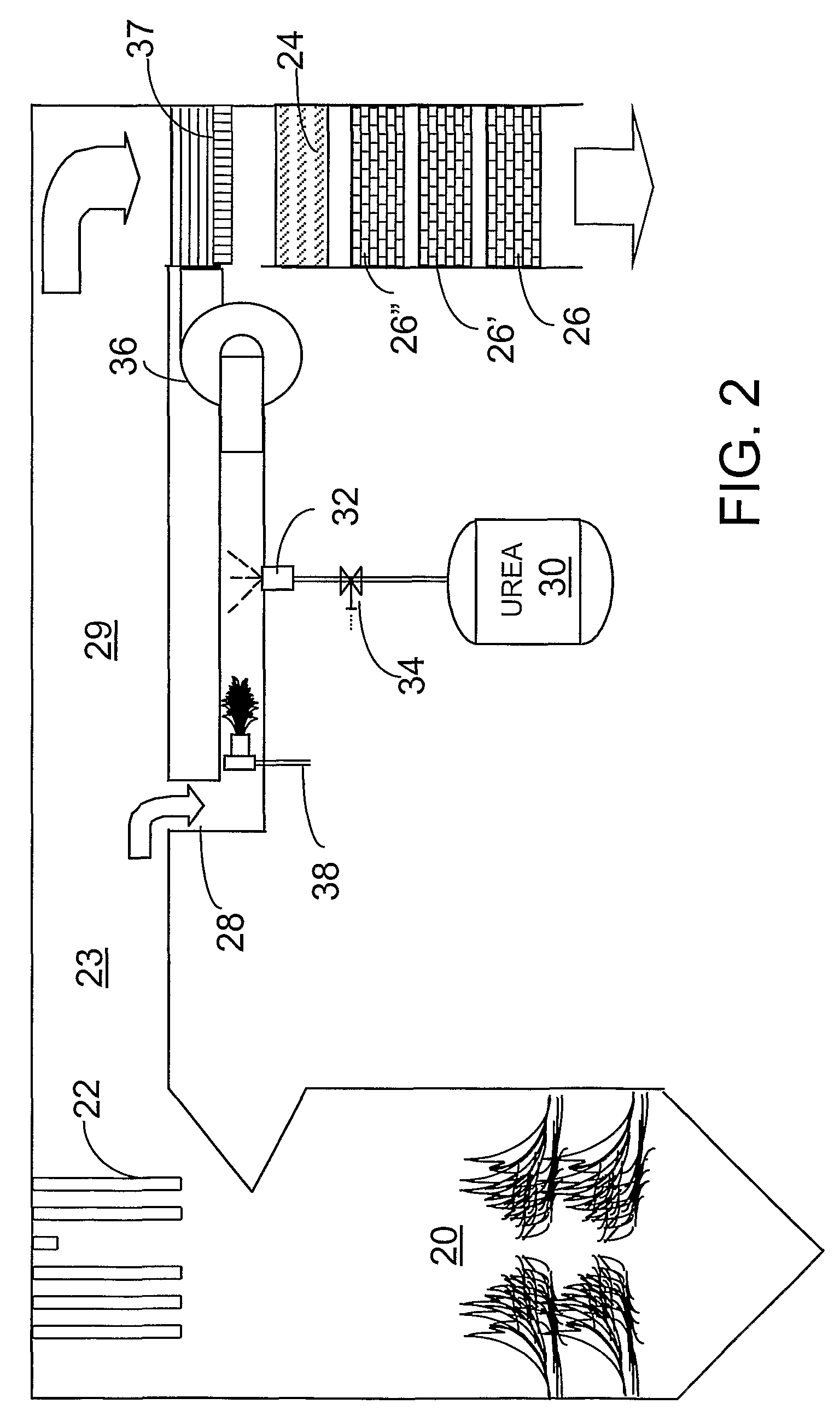

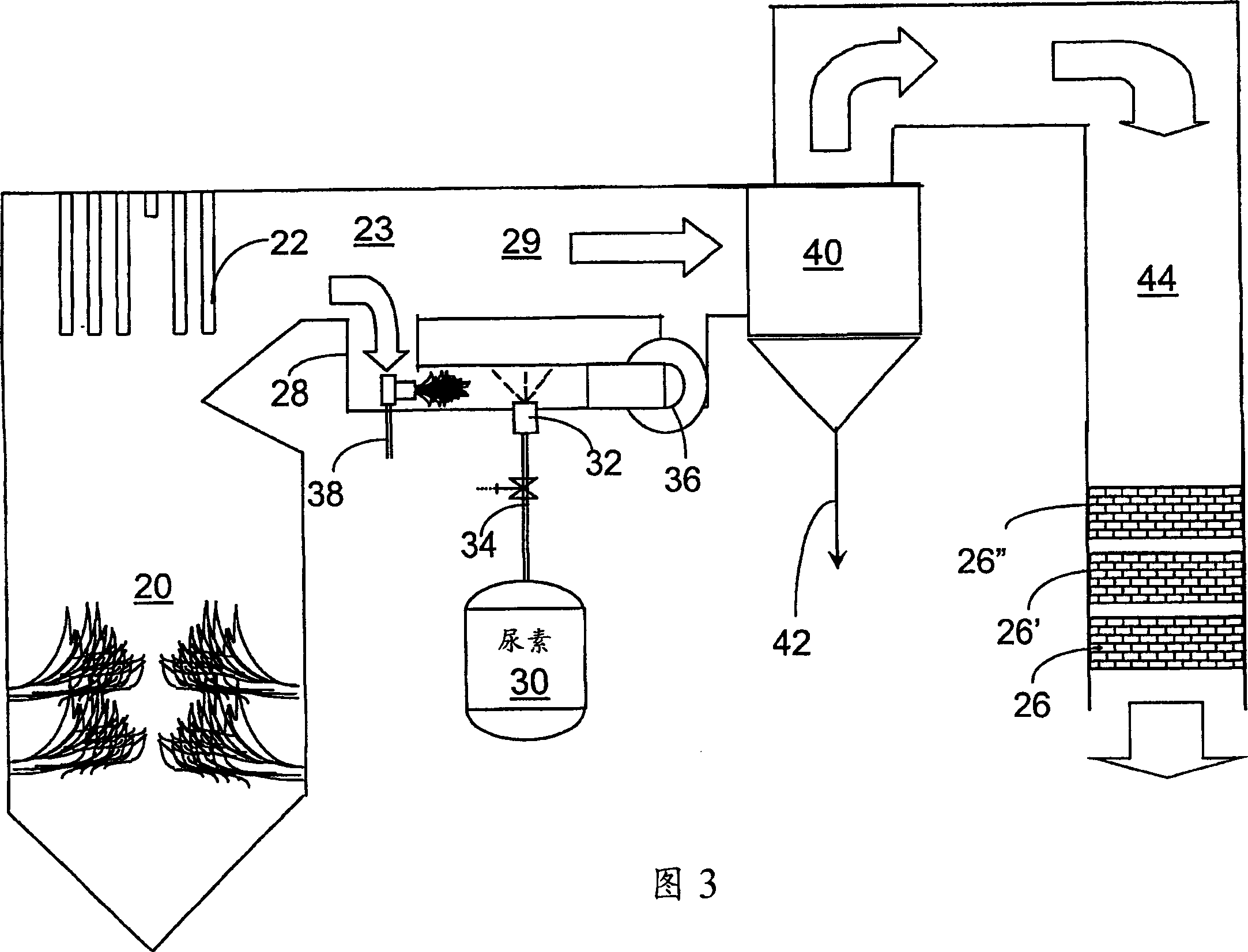

SELECTIVE CATALYTIC REDUCTION OF NOx ENABLED BY SIDESTREAM UREA DECOMPOSITION

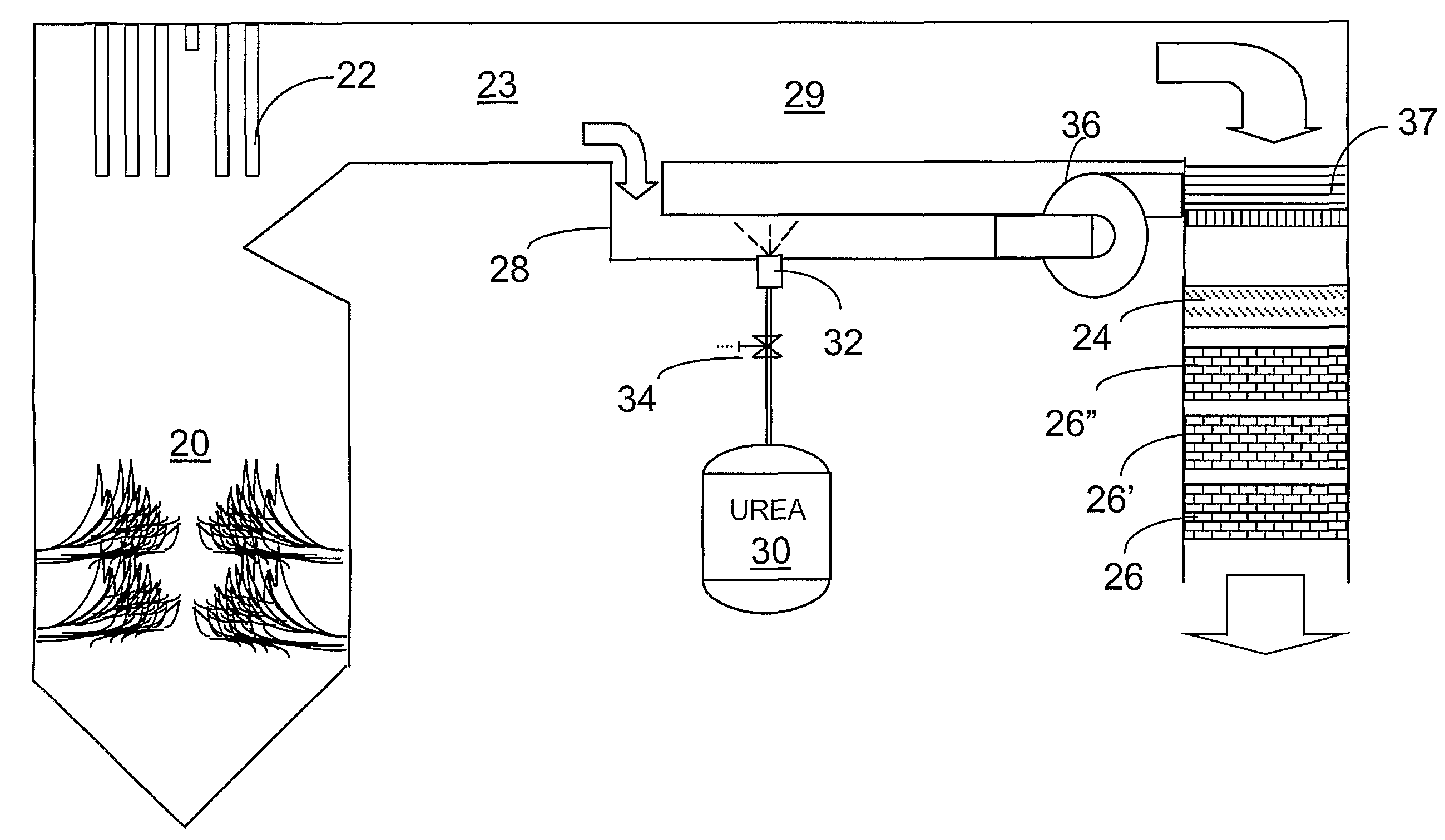

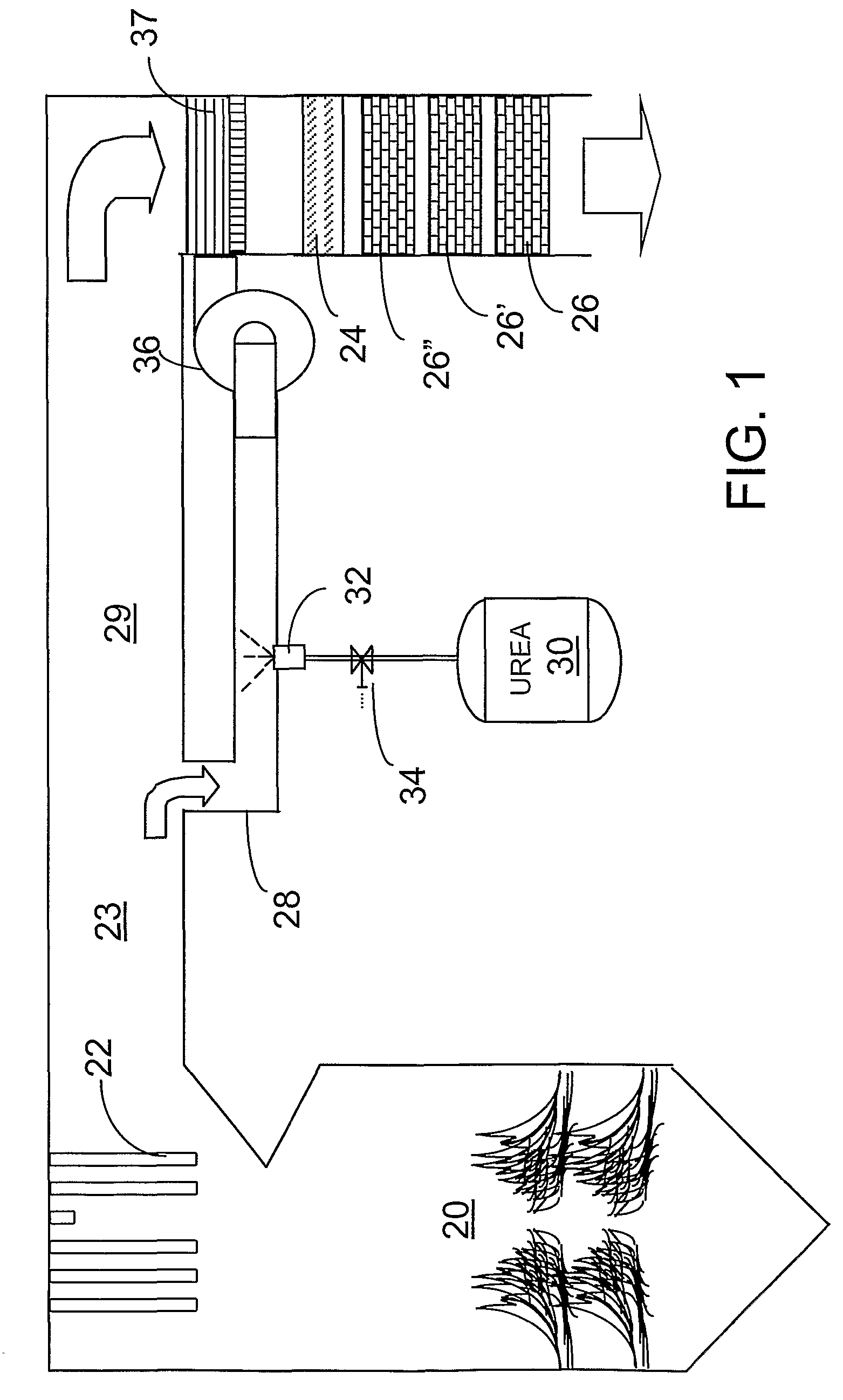

ActiveUS20060115402A1Well mixedAccurate temperatureCombination devicesNitrogen compoundsParticulatesSuperheater

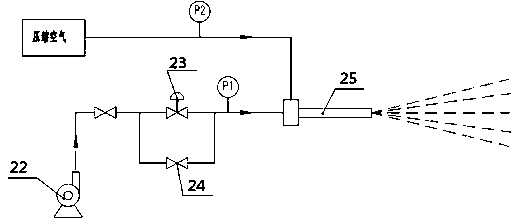

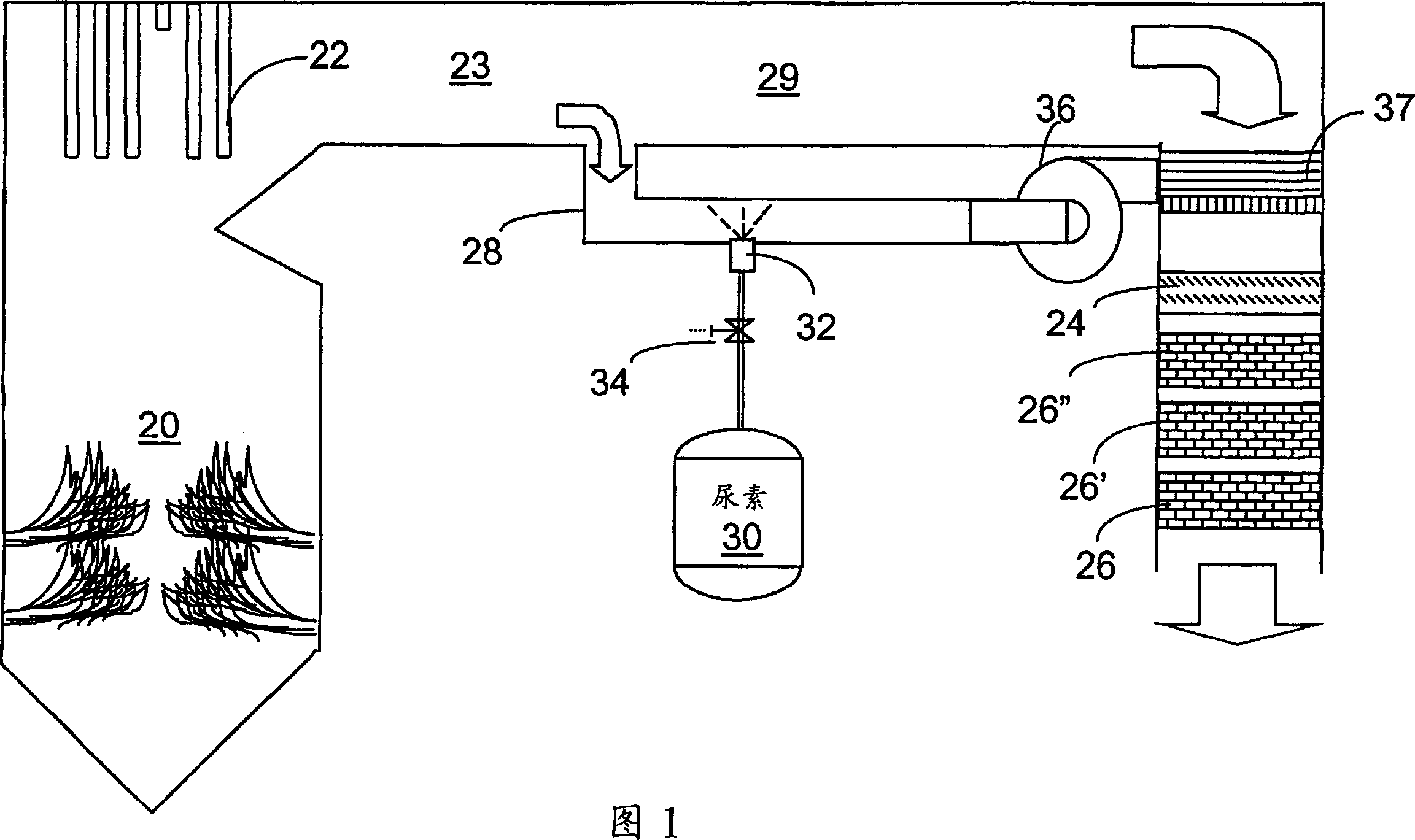

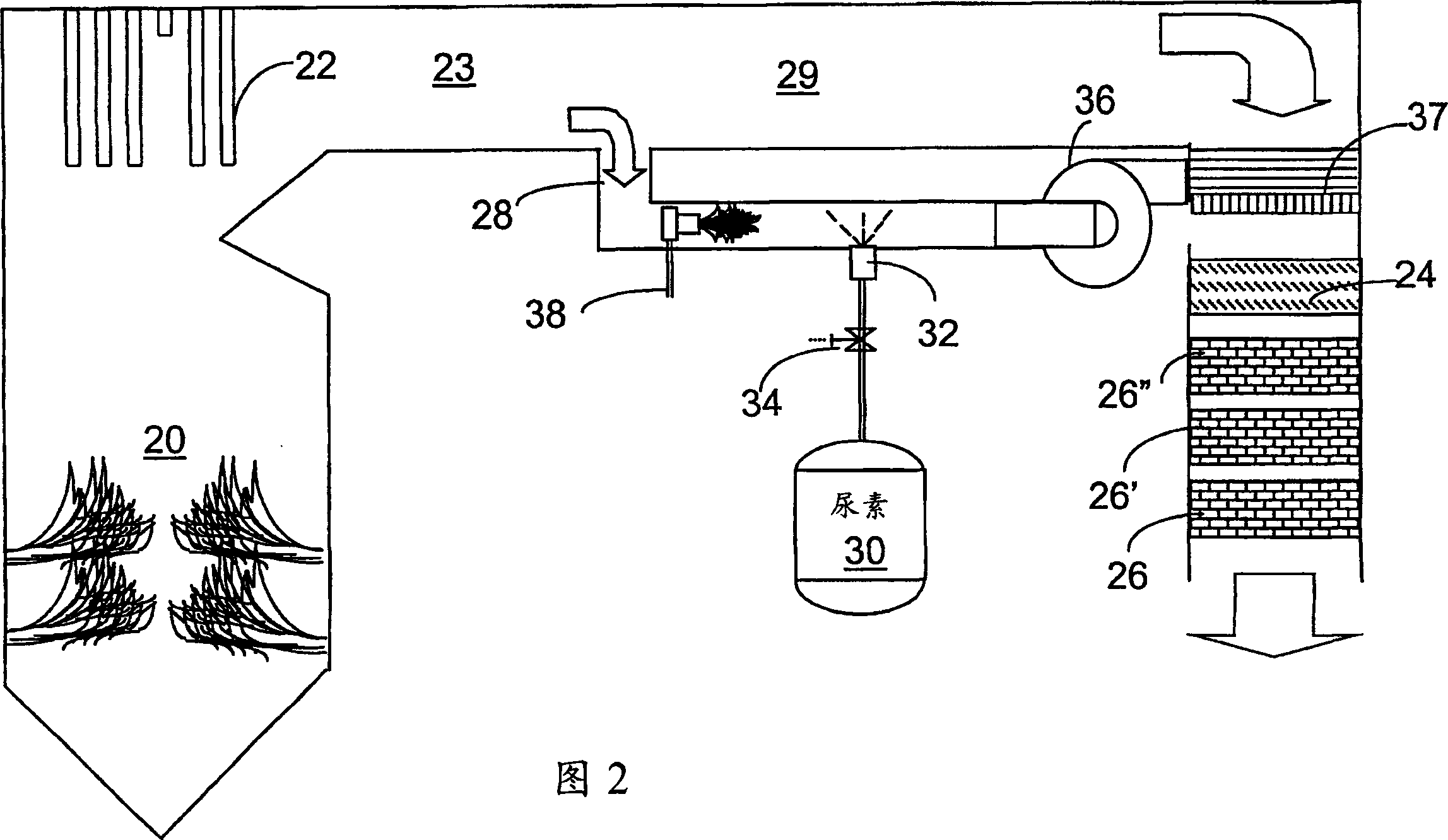

A preferred apparatus arrangement utilizes the enthalpy of the flue gas, which can be supplemented if need be, to convert urea (30) into ammonia for SCR. Urea (30), which decomposes at temperatures above 140.degree. C., is injected (32) into a flue gas stream split off (28) after a heat exchanger (22), such as a primary superheater or an economizer. Ideally, the side stream would gasify the urea without need for further heating; but, when heat is required it is far less than would be needed to heat either the entire effluent (23) or the urea (30). This side stream, typically less than 3% of the flue gas, provides the required temperature and residence time for complete decomposition of urea (30). A cyclonic separator can be used to remove particulates and completely mix the reagent and flue gas. This stream can then be directed to an injection grid (37) ahead of SCR using a blower (36). The mixing with the flue gas is facilitated due to an order of magnitude higher mass of side stream compared to that injected through the AIG in a traditional ammonia-SCR process.

Owner:FUEL TECH

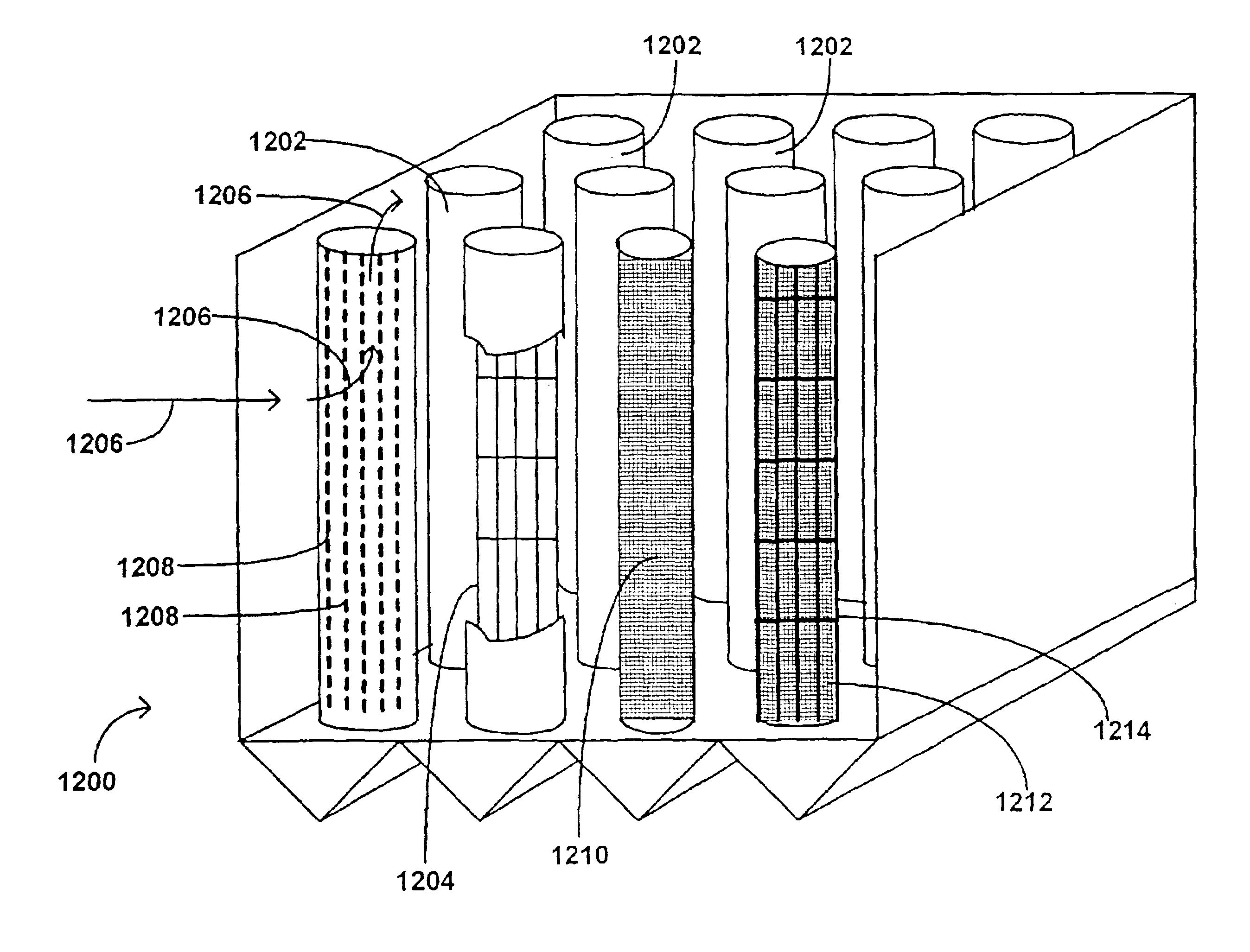

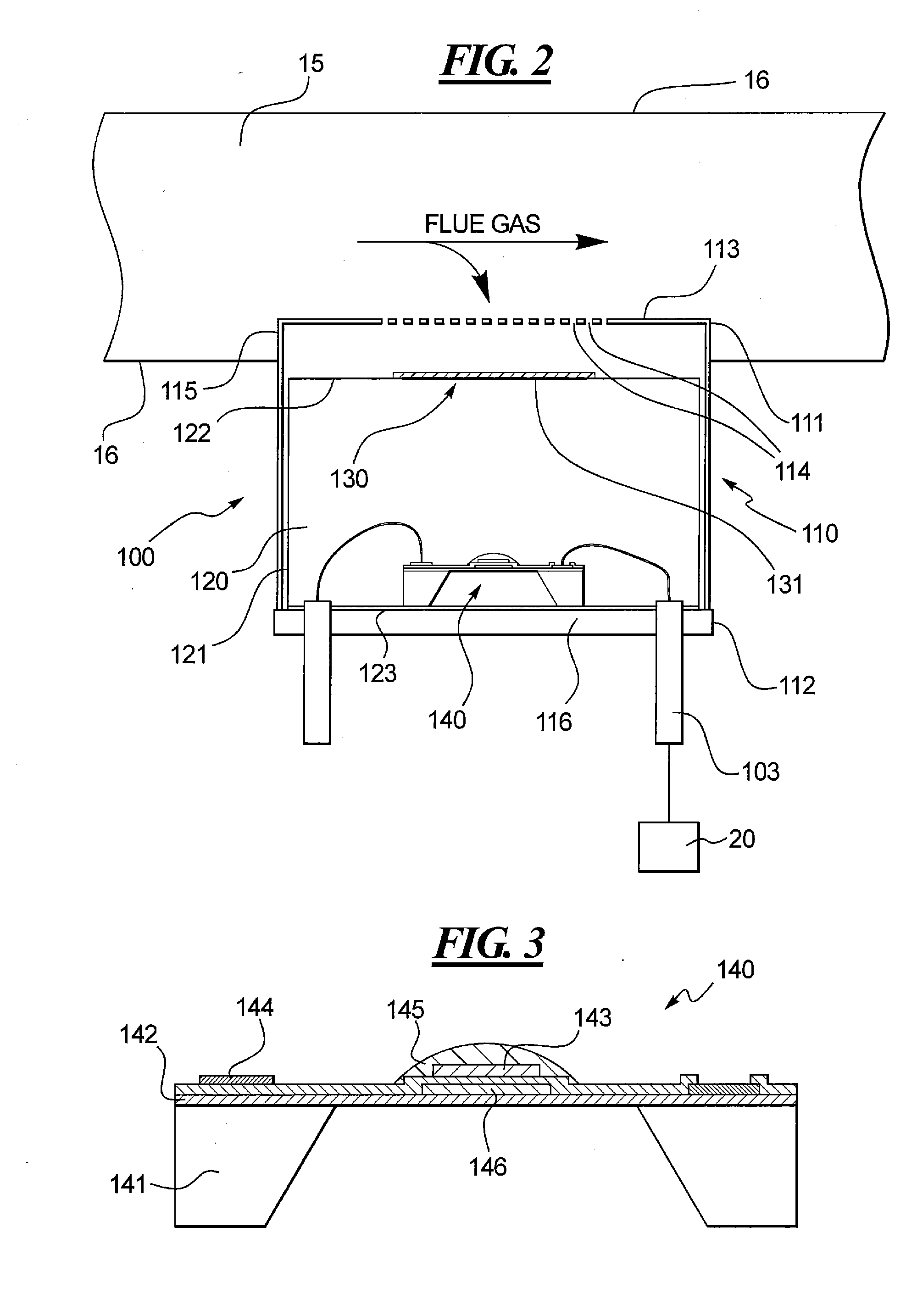

Method and apparatus for removing vapor phase contaminants from a flue gas stream

The present invention provides a method and apparatus for removing trace contaminants from a gas stream or flue gas. In one embodiment, the present invention an apparatus for removing a trace contaminant from a gas stream, comprising a gas duct configured to receive a gas stream comprising a trace contaminant; a plurality of substrates disposed within the gas duct; a trace contaminant sorbent disposed on at least a portion of each of the substrates; an isolation device for separating the portion of each of the substrates from the gas stream; and a regenerator for regenerating the trace contaminant sorbent. In another embodiment, the present invention provides a method for removing a trace contaminant from a gas stream.

Owner:ELECTRIC POWER RES INST INC

Process for controlling the moisture concentration of a combustion flue gas

InactiveUS20070243119A1Reduce concentrationReducing the moisture of the flue gasUsing liquid separation agentHydrogen sulfidesSprayerWater vapor

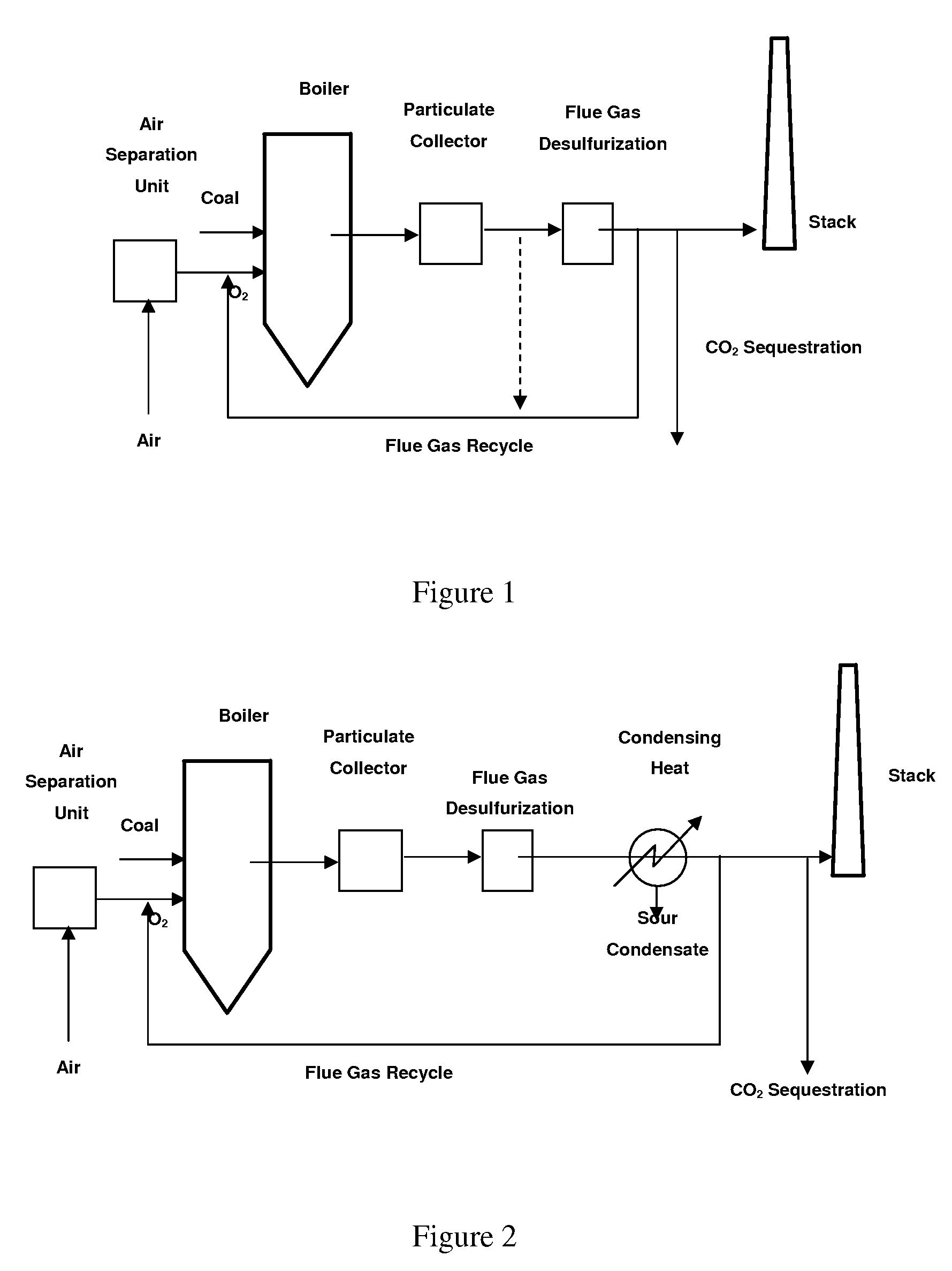

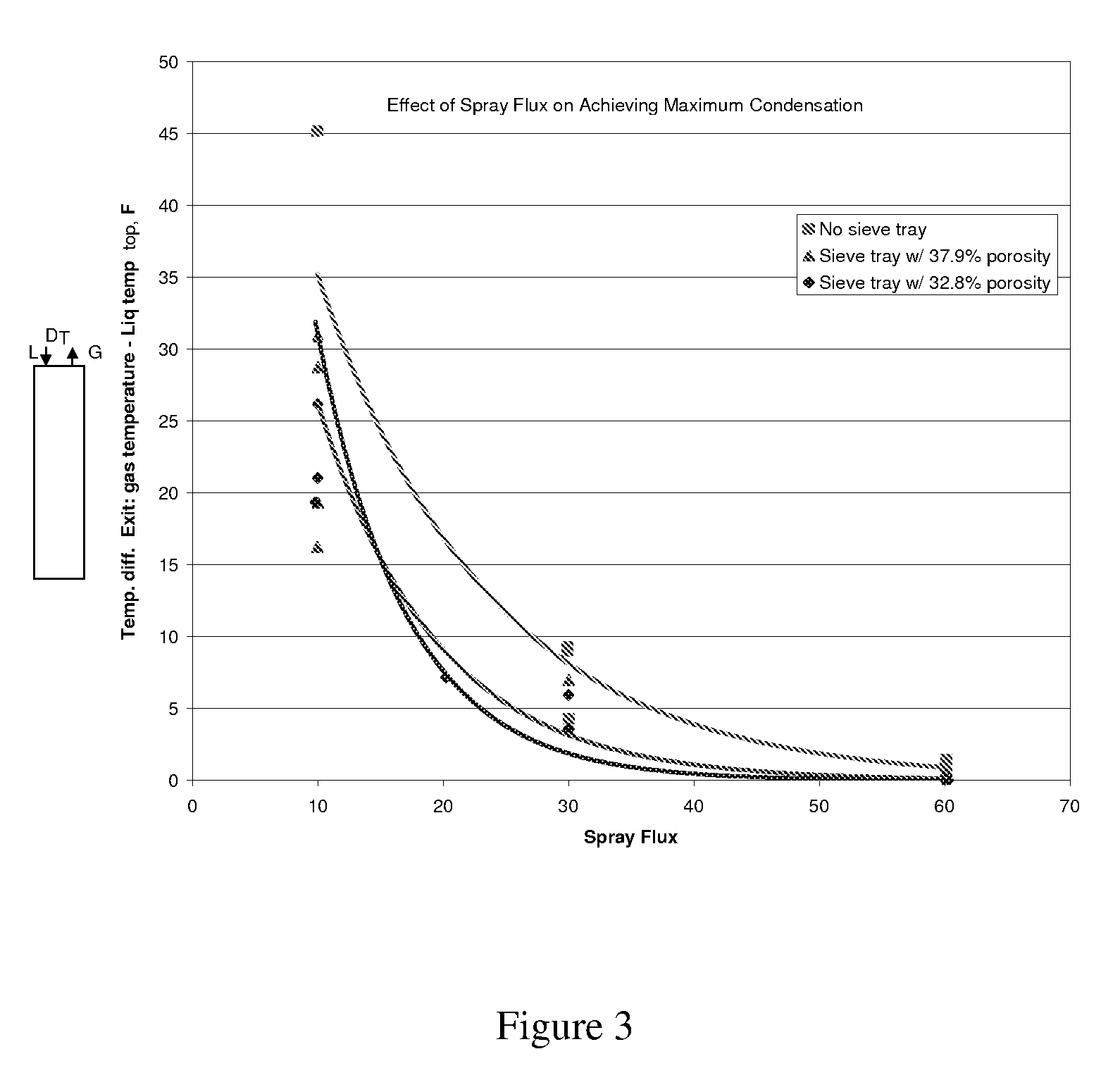

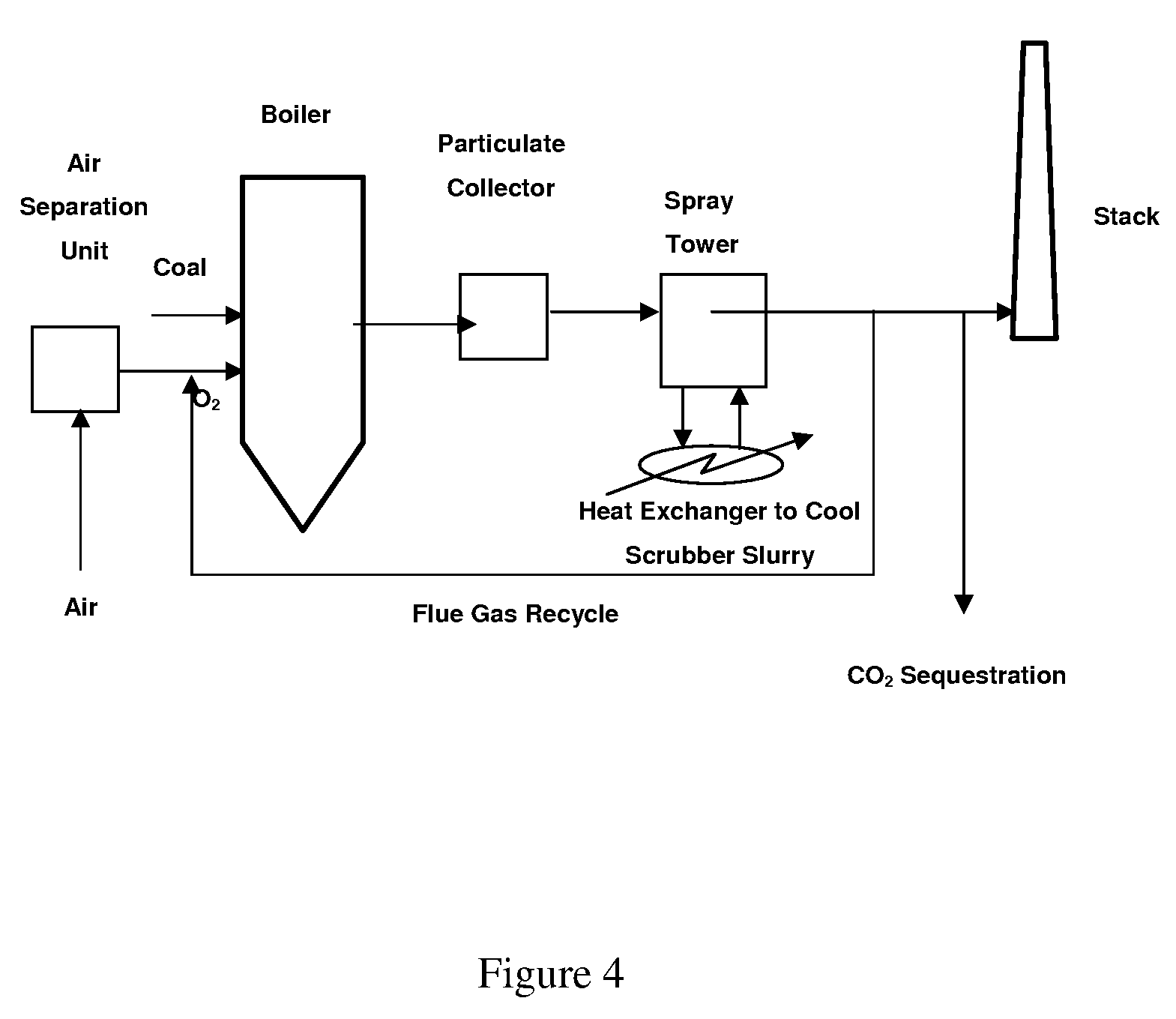

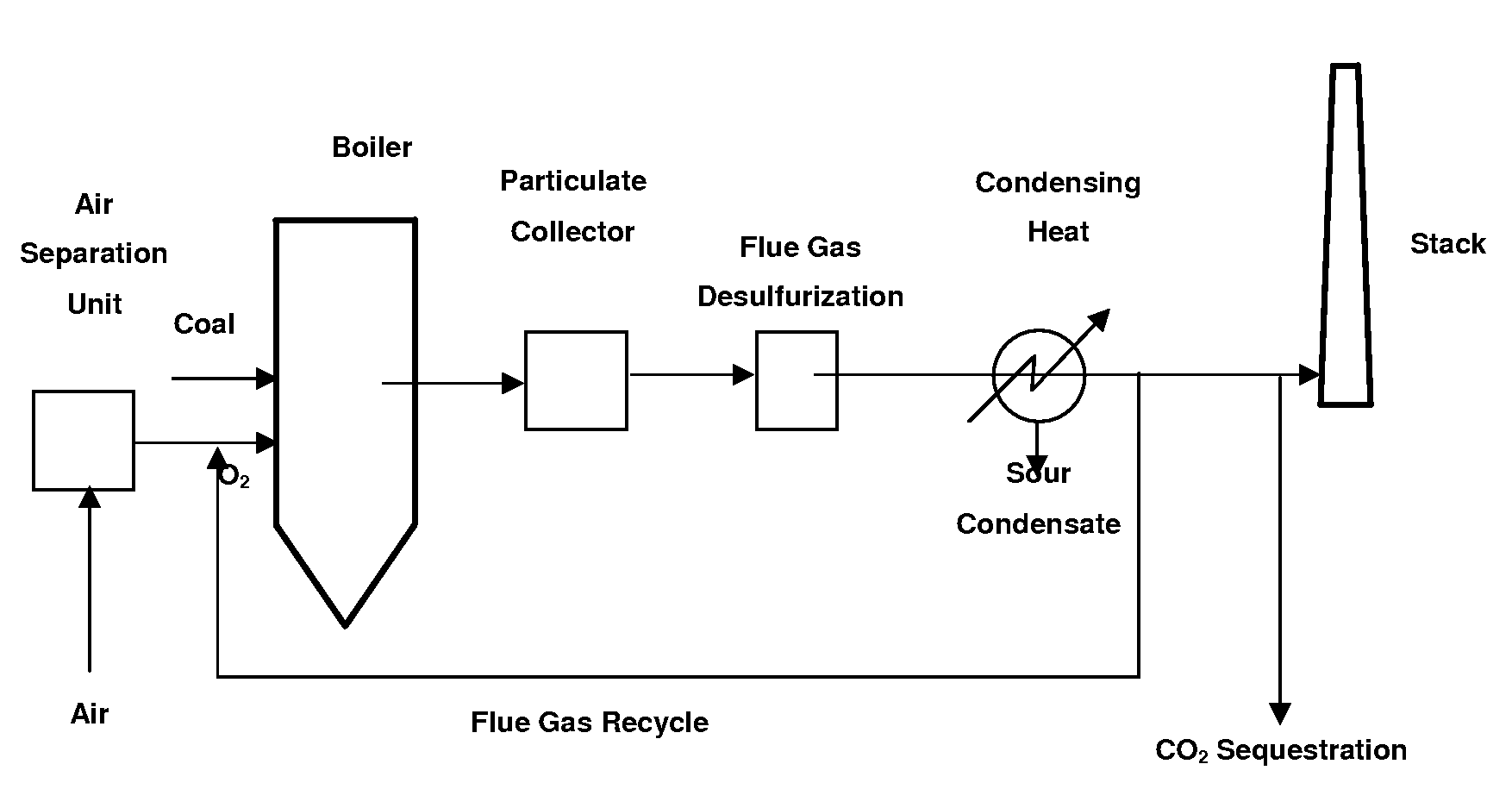

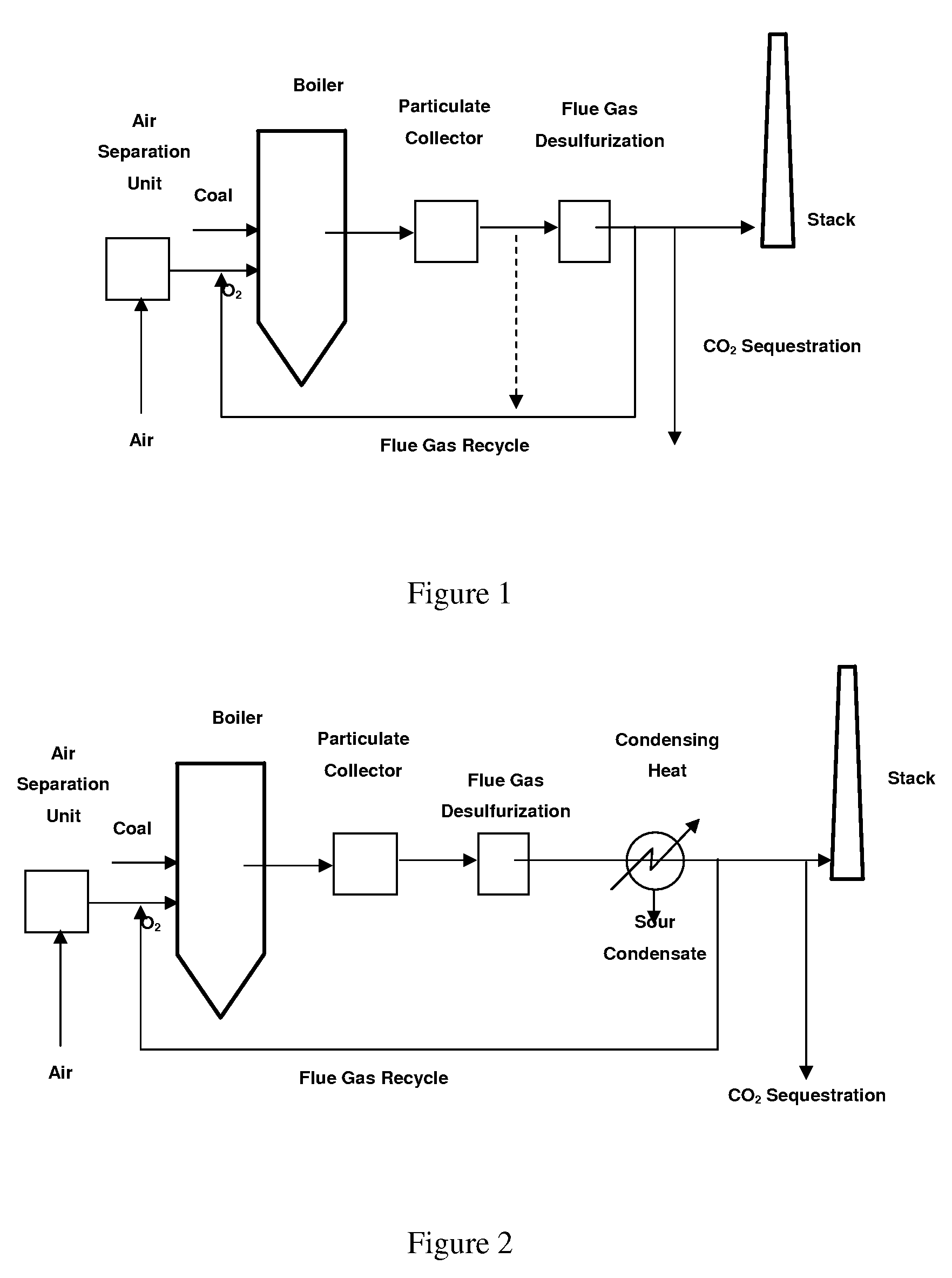

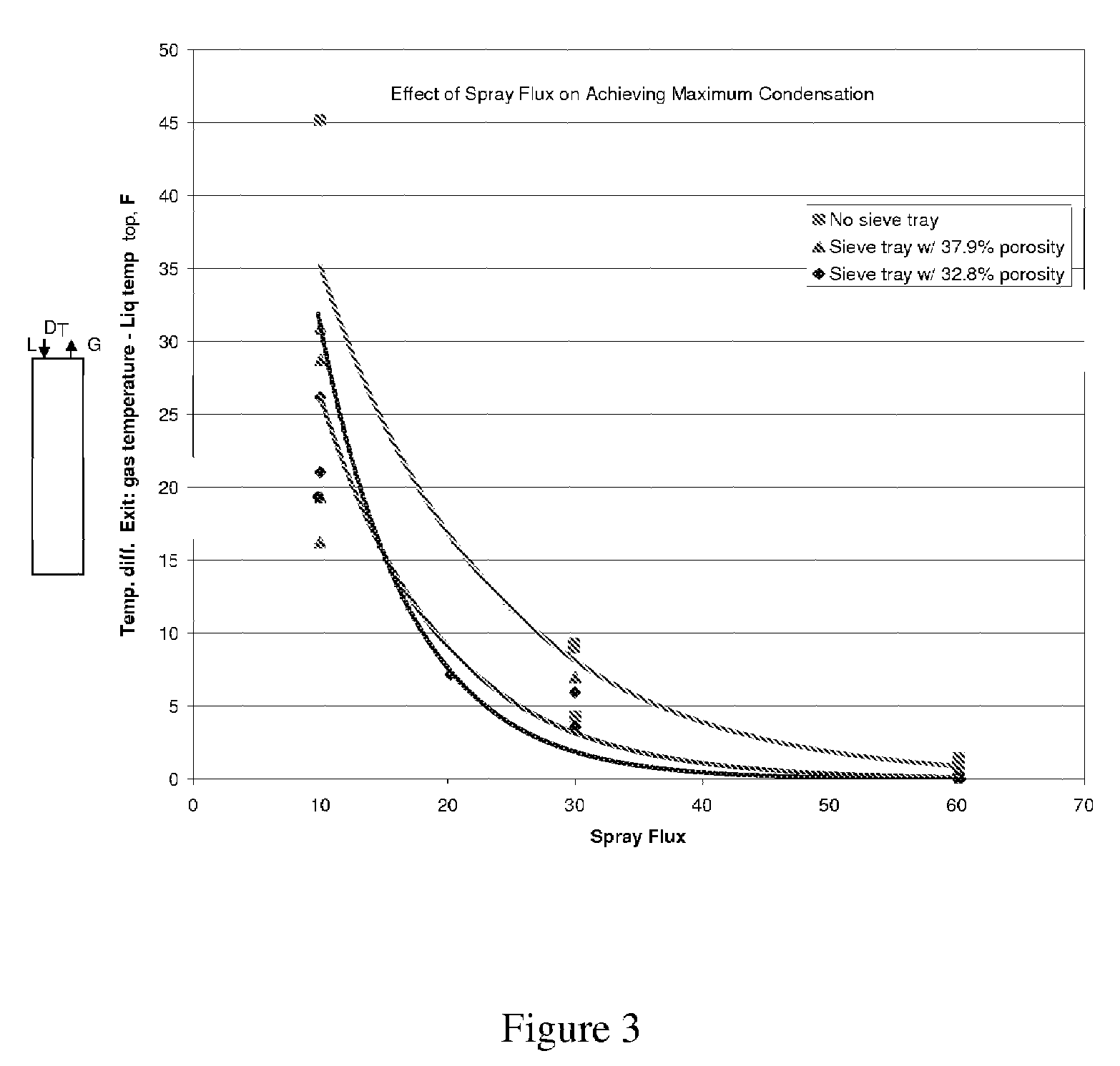

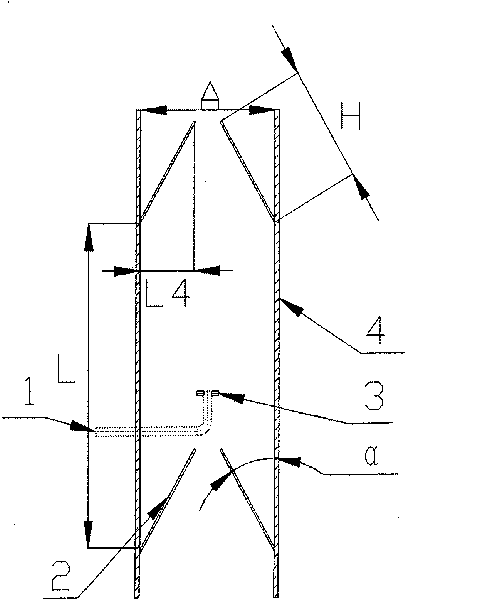

The invention is related to a system for removal of moisture and contaminants from recirculated flue gas which is used for combustion in fossil fuel power plants. The system includes a spray tower having an inlet at one end of the housing and an outlet at an opposite end of the housing for channeling the flue gas into and out of the housing. Sprayers are located in the housing for spraying the flue gas with a liquid reagent to remove contaminants, including SO2, from the flue gas. A heat exchanger is integrally connected to the housing. The heat exchanger cools the liquid reagent before the reagent is sprayed onto the flue gas stream. The sprayers quench the flue gas stream with the cooled liquid reagent. The cooling of the liquid reagent to a temperature below the flue gas water vapor dew point improves the condensation of the water vapor in the flue gas during the spraying process. The flue gas exits the system with a lower moisture content and is redirected to burner for combustion. As a result, the efficiency the combustion process will improve with less moisture in the flue gas.

Owner:THE BABCOCK & WILCOX CO

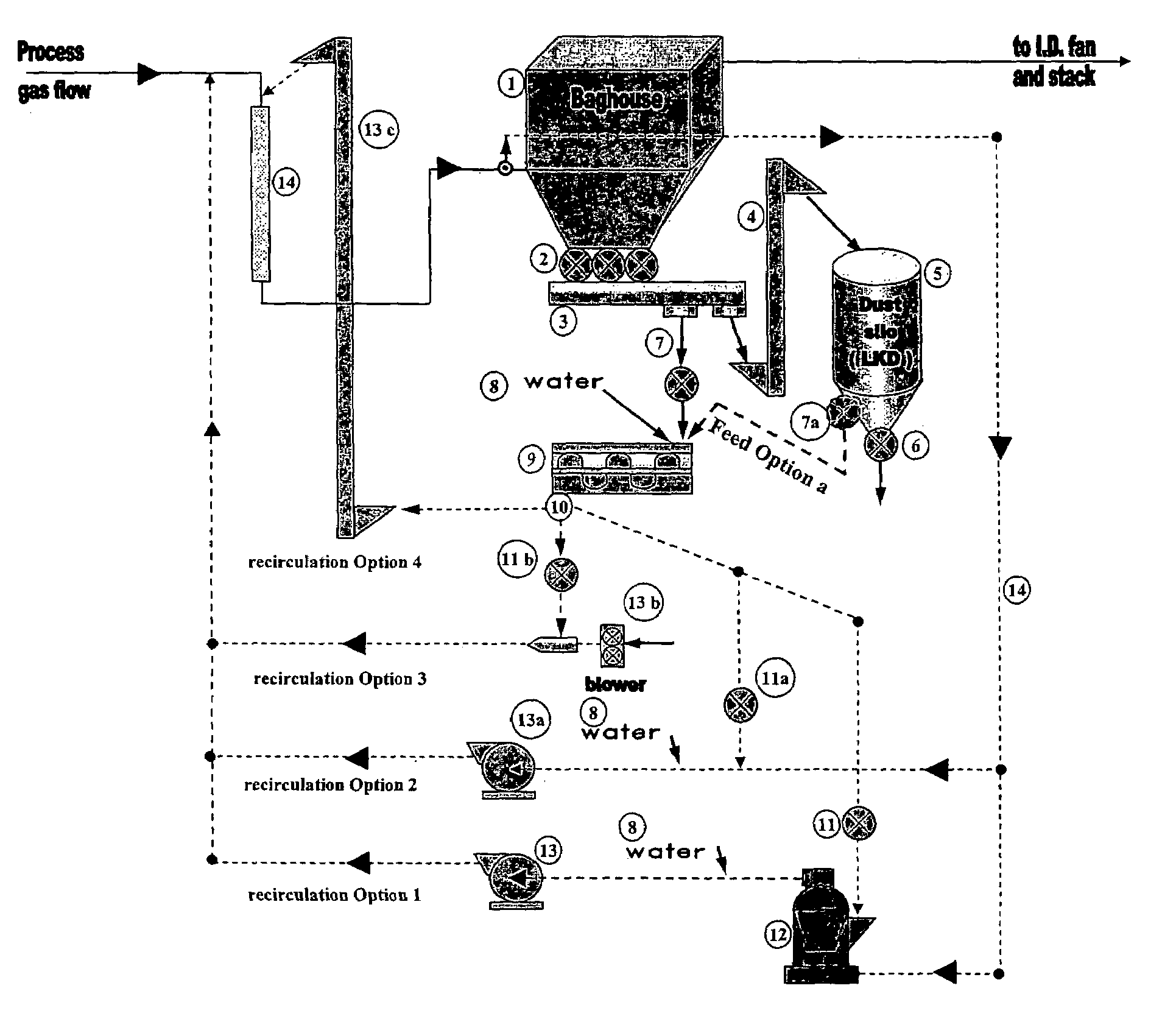

Hydrated lime kiln dust recirculation method for gas scrubbing

ActiveUS7141093B2Effectively self-cleaningEffective sorbentGas treatmentIsotope separationSorbentFlue gas

Owner:GRAYMONT PA INC

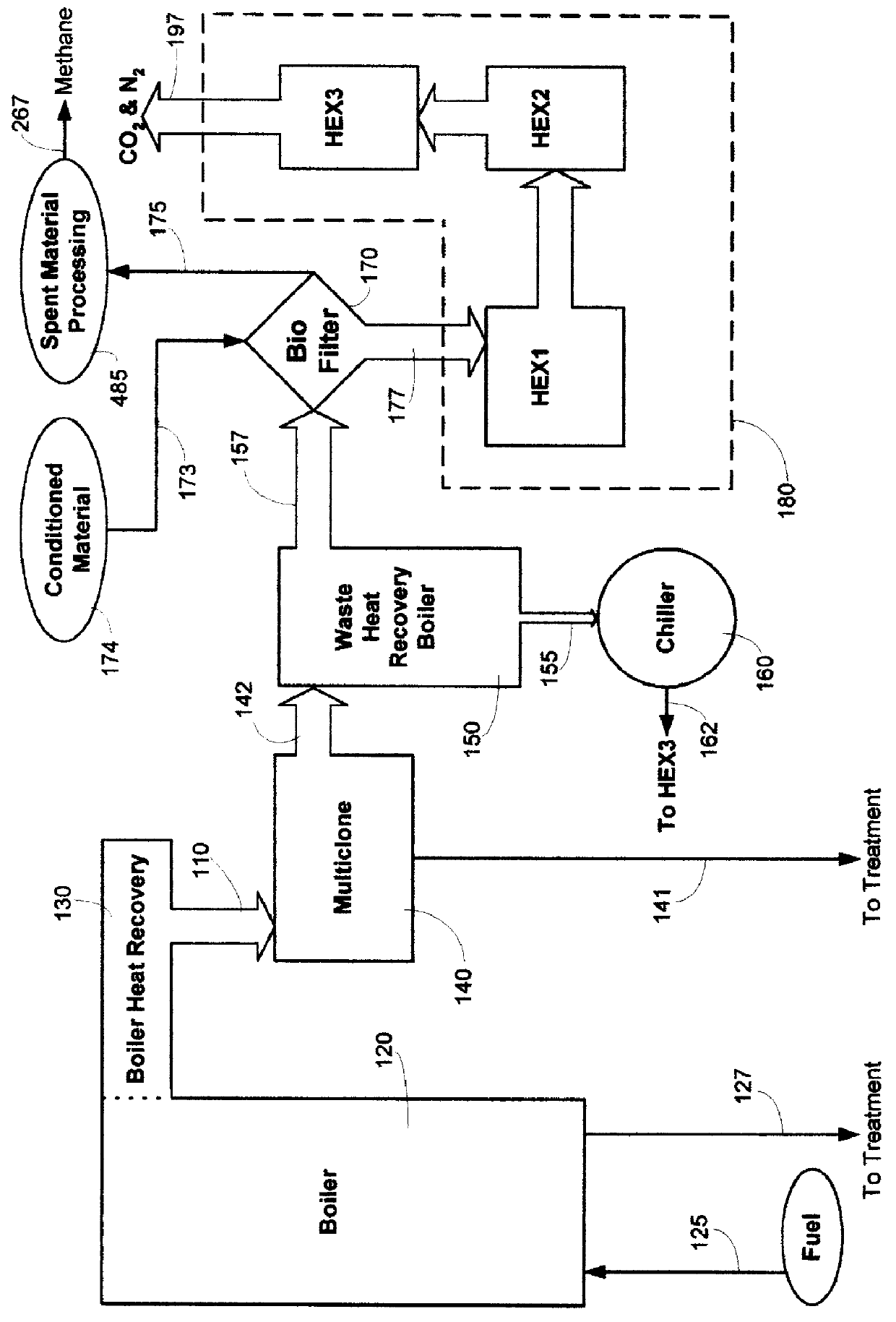

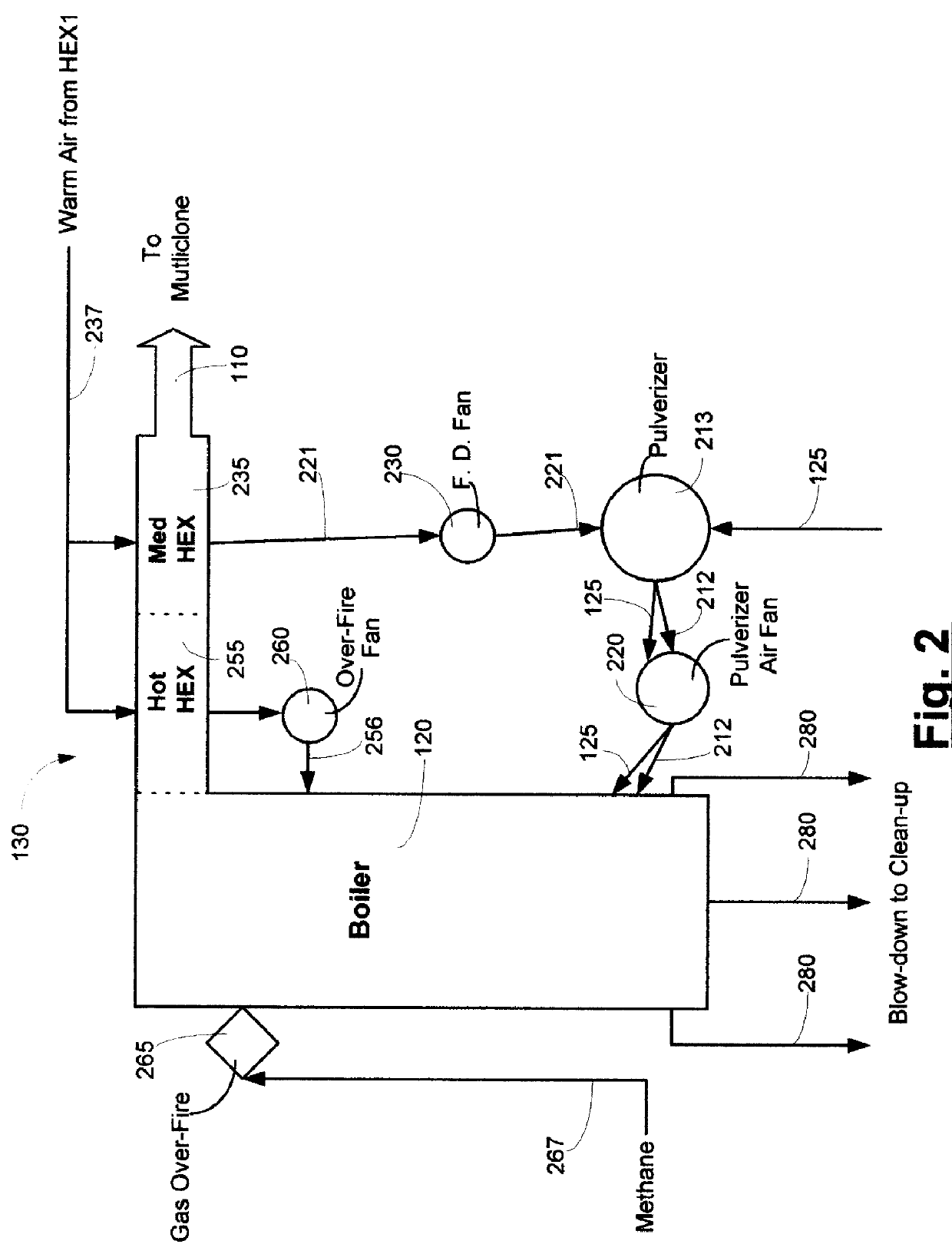

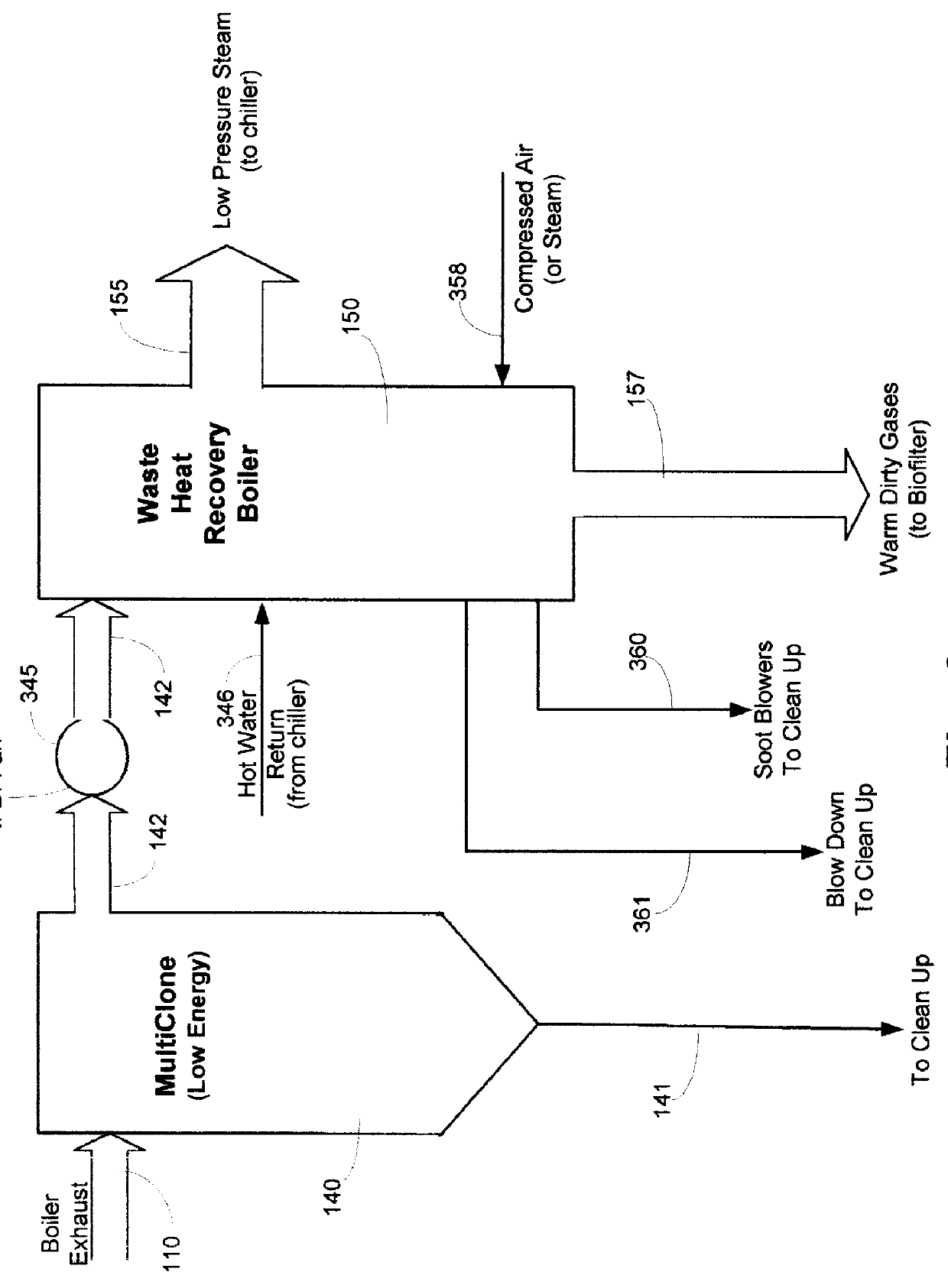

Moving bed biofilter and condenser for flue gas pollutant removal and collection

InactiveUS6117672ALow costReduce water consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid wasteCombustion chamber

A system for removing particulate, sulfur dioxide, nitrogenous oxides and other condensables from the flue gas of a coal, lignite, or other solid fuel combustor. The system can combine biomass filtration, anaerobic digestion, steam absorption refrigeration, and heat exchangers to minimize parasitic energy consumption, solid and liquid waste disposal and interference with combustion efficiency, while achieving near total reduction of contaminants without regard to sulfur or ash content of fuel. Gases at the exit of a multiclone of a fuel-combustor enter a waste heat boiler, generating low pressure steam that drives a steam absorption chiller. The flue gas which still contains small particulate material pass through a moving belt system conveying a mat of chopped biomass that can be impregnated with bacteria that feed on nitrogenous oxides. The mat is sufficiently thick and moist to entrap the remaining solids and smoke in the exhaust stream. The particulate-free flue gas passes through a staged heat exchanger which can utilize ambient air, pond water, and the refrigerated water from the steam absorption chiller to condense the water vapor in the exhaust stream. Sulfur oxides exits the flue gas stream with the condensed water vapor which can be processed in an anaerobic digester. Methanogenic bacteria within the digester can convert the mat and the acidic condensate into a biogas, a combination of methane and carbon dioxide, and plant growth media.

Owner:TECHN INFORMATION

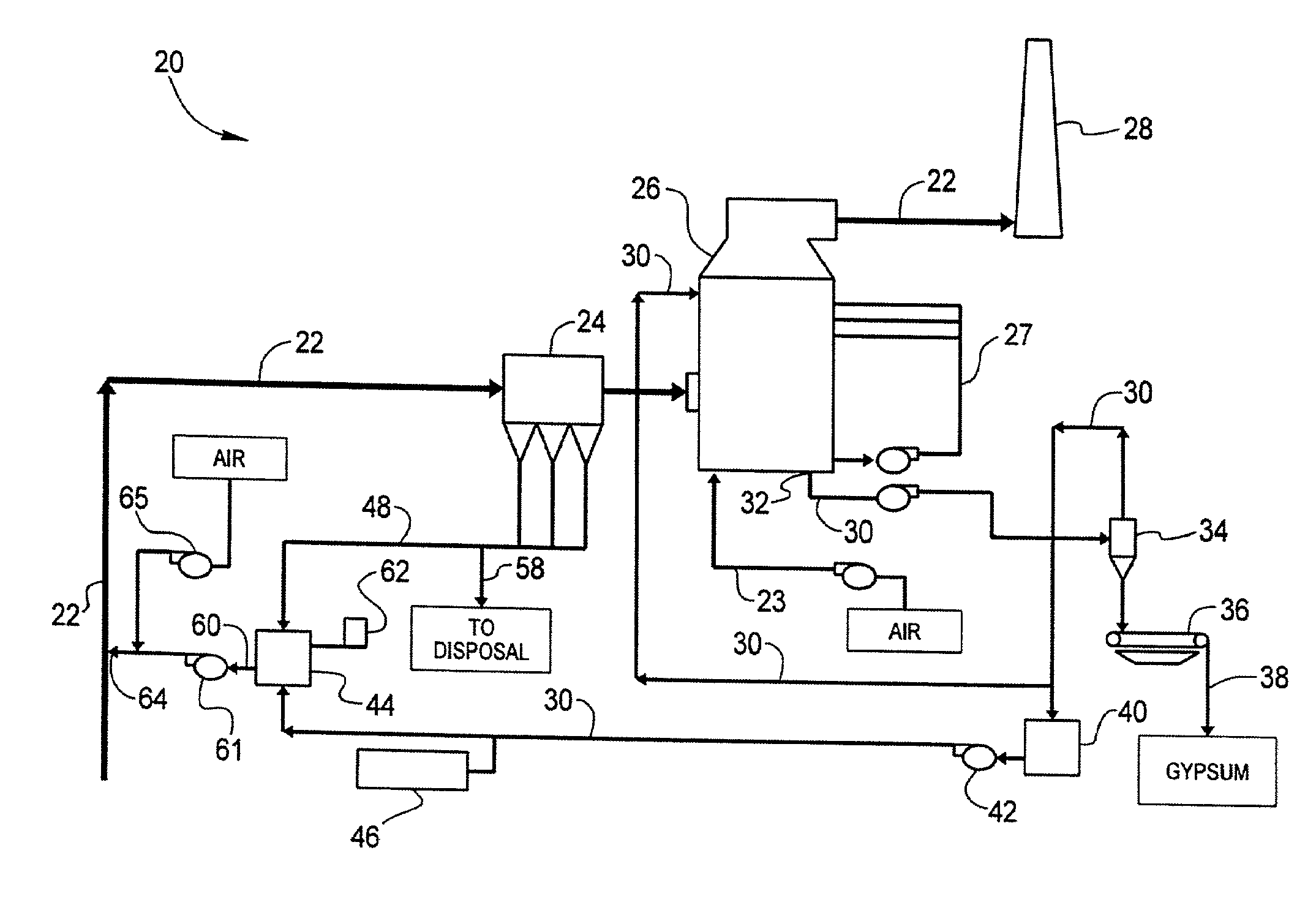

Reduced liquid discharge in wet flue gas desulfurization

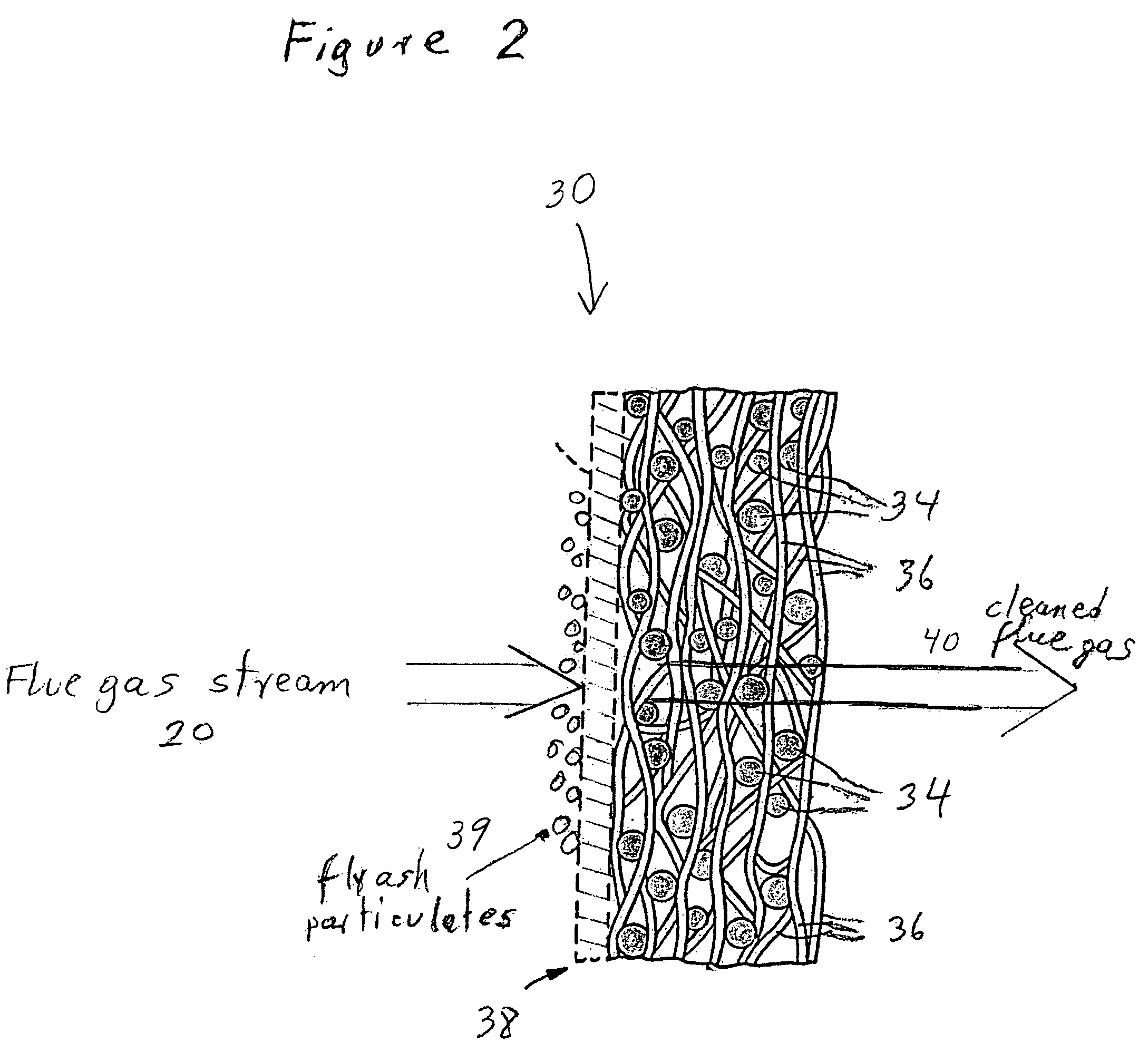

ActiveUS20080011158A1Reduce amountCombination devicesDispersed particle filtrationFlue-gas stackFly ash

One aspect of the invention relates to a method for removing contaminants from a flue gas stream (22). The method includes: removing fly ash from a flue gas stream (22) utilizing a particle collector (24); contacting the flue gas stream with an alkaline reagent in a wet scrubber (26); discharging a purge liquid (30) from the wet scrubber (26); combining at least a portion of the purge liquid (30) with at least a portion of the fly ash (48) to form moistened fly ash (60); and injecting at least a portion of the moistened fly ash (60) into the flue gas stream (22) upstream of the particle collector (24), whereby the moistened fly ash (60) removes at least a portion of contaminants present in the flue gas stream (22).

Owner:GENERAL ELECTRIC TECH GMBH

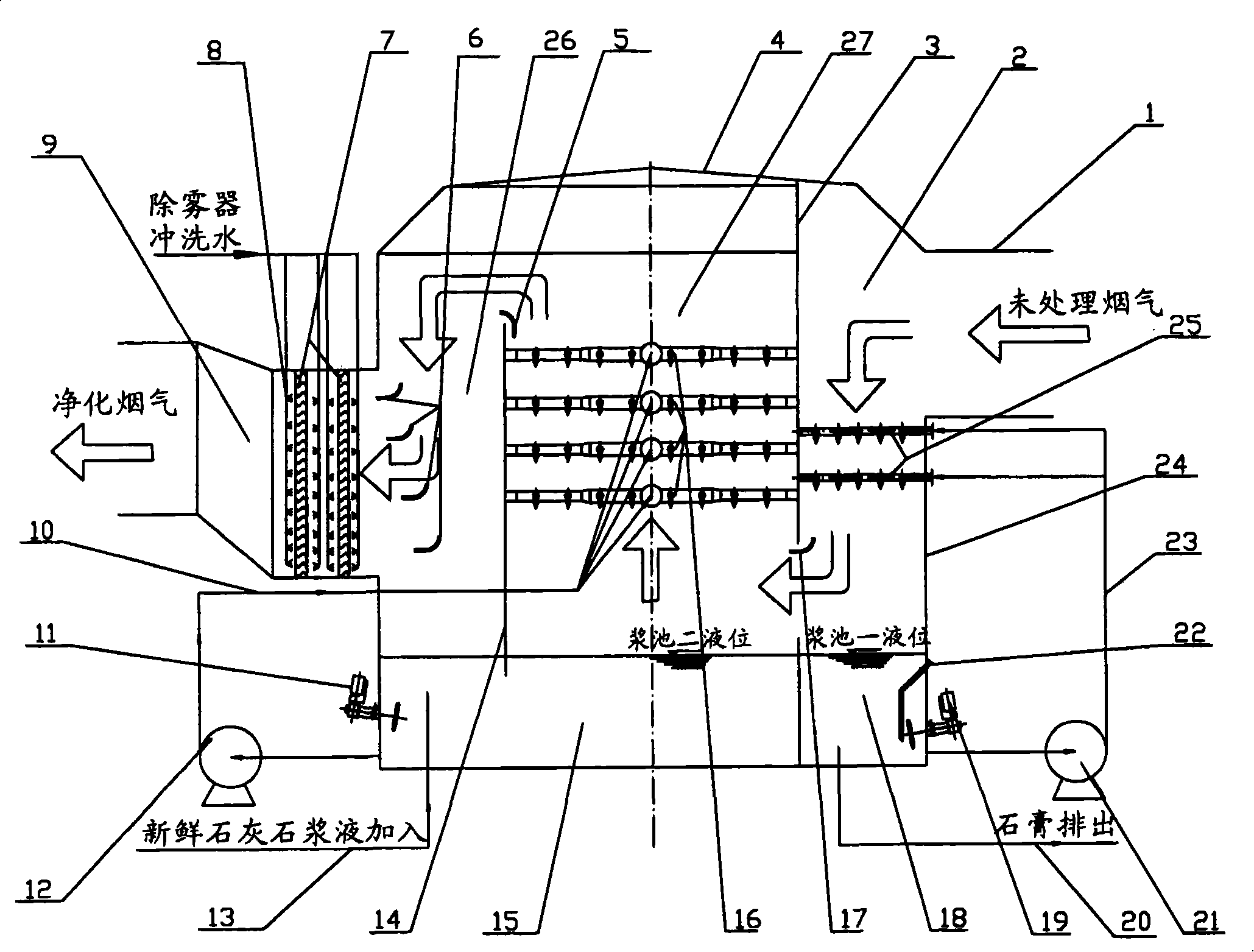

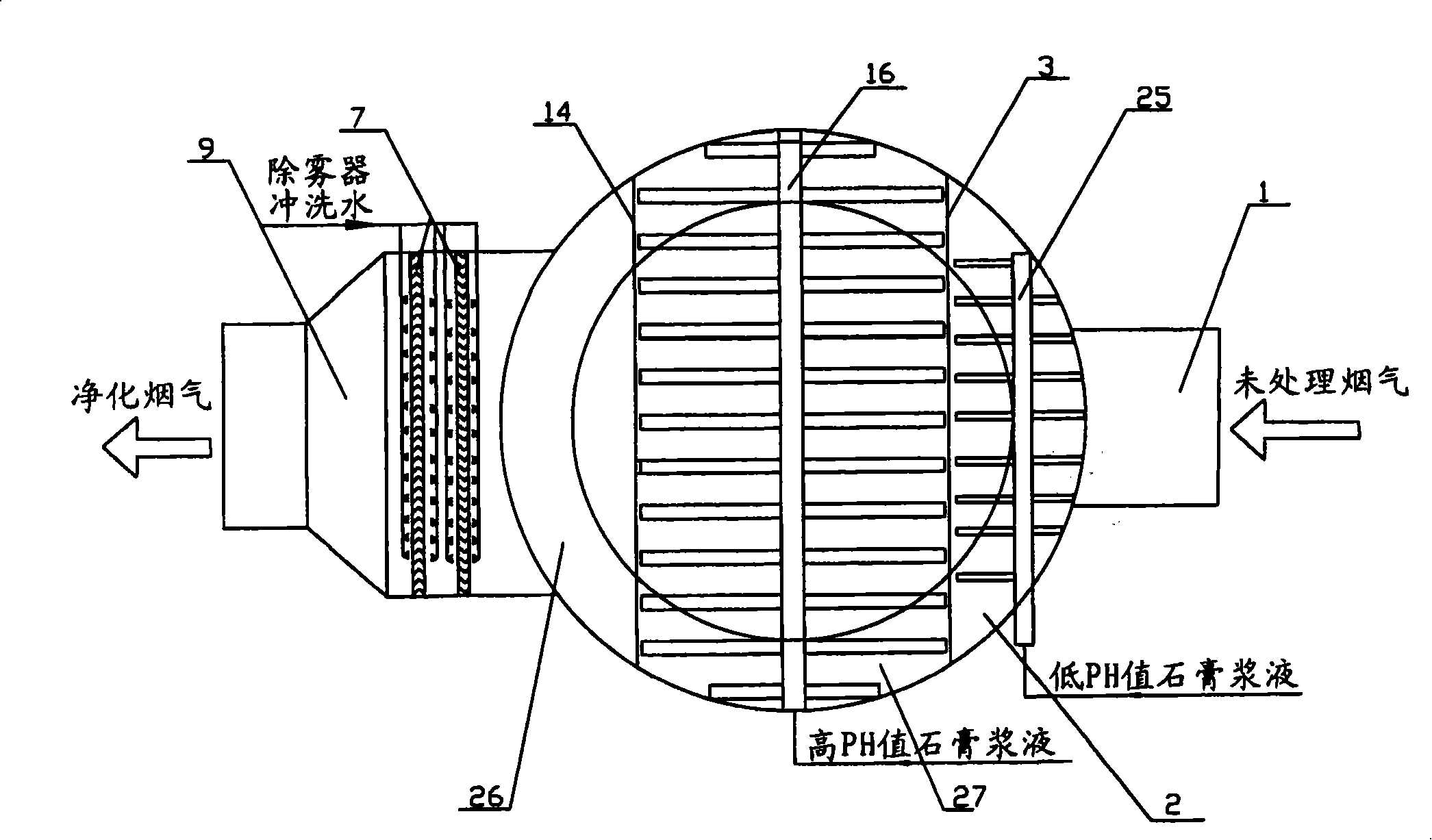

A spray tower for flue gas desulfurization and its running method

ActiveCN101161332ASmall footprintReduced support structureDispersed particle separationFlue gasEngineering

The present invention relates to a cylindrical spraying tower for eliminating the sulfur dioxide in the flue gas and a method for eliminating the sulfur dioxide in the flue gas with the spraying tower thereof, wherein the spraying tower is provided with two vertical clapboards and is provided with a defroster at the outlet, the clapboard is provided with an opening thereby dividing the absorbing area to three areas and dividing the serous fluid tank into two sections. The flue gas contacts with the spraying serous fluid concurrently and then countercurrent in the area of the absorbing area and is discharged through the defroster. The excellent desulfurizing effect is realized and the method is especially suitable for the wet limestone gypsum flue gas desulfurization technique of the large-scale thermal power plant with the power more than 300MW.

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

Flue gas purification method

InactiveCN1720091AEfficient capturePromote oxidationDispersed particle separationAir quality improvementPurification methodsSorbent

The present invention provides a method of scrubbing SOx, NOx compounds and other air toxins from a flue gas stream. In the method, two distinct unit operations are amalgamated to scrub SOx, NOx and other air toxins compounds from a flue gas stream. More specifically, there is a dry scrubbing operation and a wet scrubbing operation. The dry injection scrubbing operation involves contacting a flue gas stream containing SOx and NOx compounds with a sorbent for removing substantially all of the SOx and NOx compounds present in the stream. The second wet scrubbing operation involves contacting the stream to remove any residual SOx, NOx compounds, and other air toxins remaining in the stream.

Owner:AIRBORNE CLEAN ENERGY

Continuous pyrolysis incineration device for full-scale electronic and electrical product waste

ActiveCN105509062AGuaranteed incineration temperatureGuaranteed incineration efficiencyEmission preventionCombustion technology mitigationEnergy recoverySolvent

The invention relates to a continuous pyrolysis incineration device for full-scale electronic and electrical product waste. The continuous pyrolysis incineration device structurally comprises a feeder, a pulley feed hopper, a pyrolysis gasifier, a pyrolysis gas flue, a combustion furnace, a G-L air heat exchanger, a quenching absorption tower, a bypass flue, a chimney exhaust port, a cat ladder, an activated carbon storage tank and a chimney. The continuous pyrolysis incineration device has the advantages that dangerous electronic and electrical product waste, medical waste, organic waste and other kinds of dangerous combustible solid waste with a certain heat value are treated through a pyrolysis incineration technology, pyrolysis and high-temperature incineration technologies are combined in an optimized mode, low-temperature gas and high-temperature melt are combined together, waste incineration is conducted in the steps of pyrolysis, premixing and incineration, the synthetic technological process and technological conditions of pyrolysis incineration, energy recovery and flue gas cleaning are achieved and have perspectiveness, the overall technology has the outstanding harmless characteristic, compatibility and resourcezation are remarkable, material applicability is high, no hazardous reaction medium or poisonous and harmful solvent is involved in the process, and nature greenization can be achieved.

Owner:NANJING UNIV OF TECH

Selective catalytic reduction of NO, enabled by side stream urea decomposition

A preferred process arrangement utilizes the enthalpy of the flue gas, which can be supplemented if need be, to convert urea ( 30 ) into ammonia for SCR. Urea ( 30 ), which decomposes at temperatures above 140 ° C., is injected ( 32 ) into a flue gas stream split off ( 28 ) after a heat exchanger ( 22 ), such as a primary superheater or an economizer. Ideally, the side stream would gasify the urea without need for further heating; but, when heat is required it is far less than would be needed to heat either the entire effluent ( 23 ) or the urea ( 30 ). This side stream, typically less than 3% of the flue gas, provides the required temperature and residence time for complete decomposition of urea ( 30 ). A cyclonic separator can be used to remove particulates and completely mix the reagent and flue gas. This stream can then be directed to an injection grid ( 37 ) ahead of SCR using a blower ( 36 ). The mixing with the flue gas is facilitated due to an order of magnitude higher mass of side stream compared to that injected through the AIG in a traditional ammonia-SCR process.

Owner:FUEL TECH

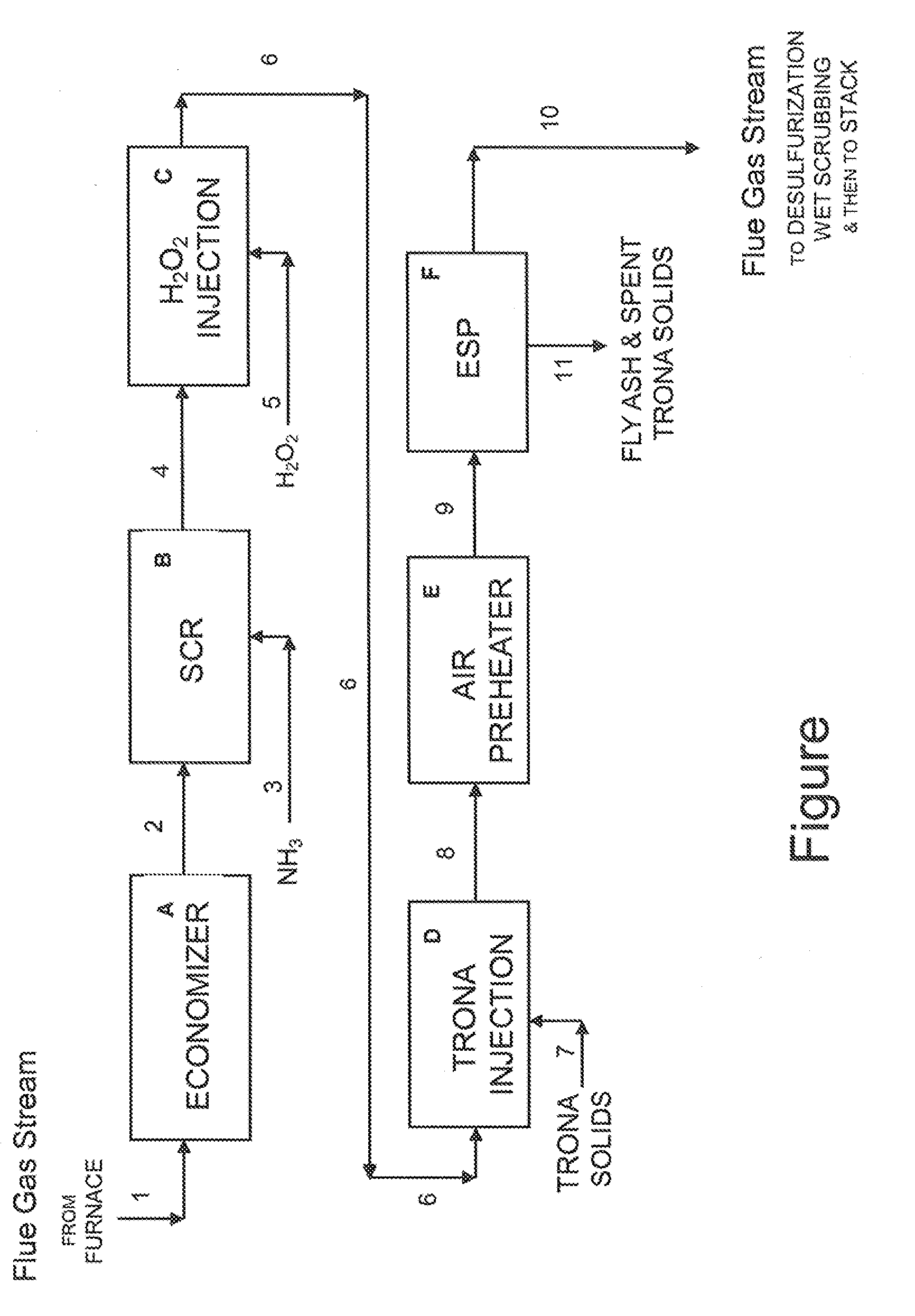

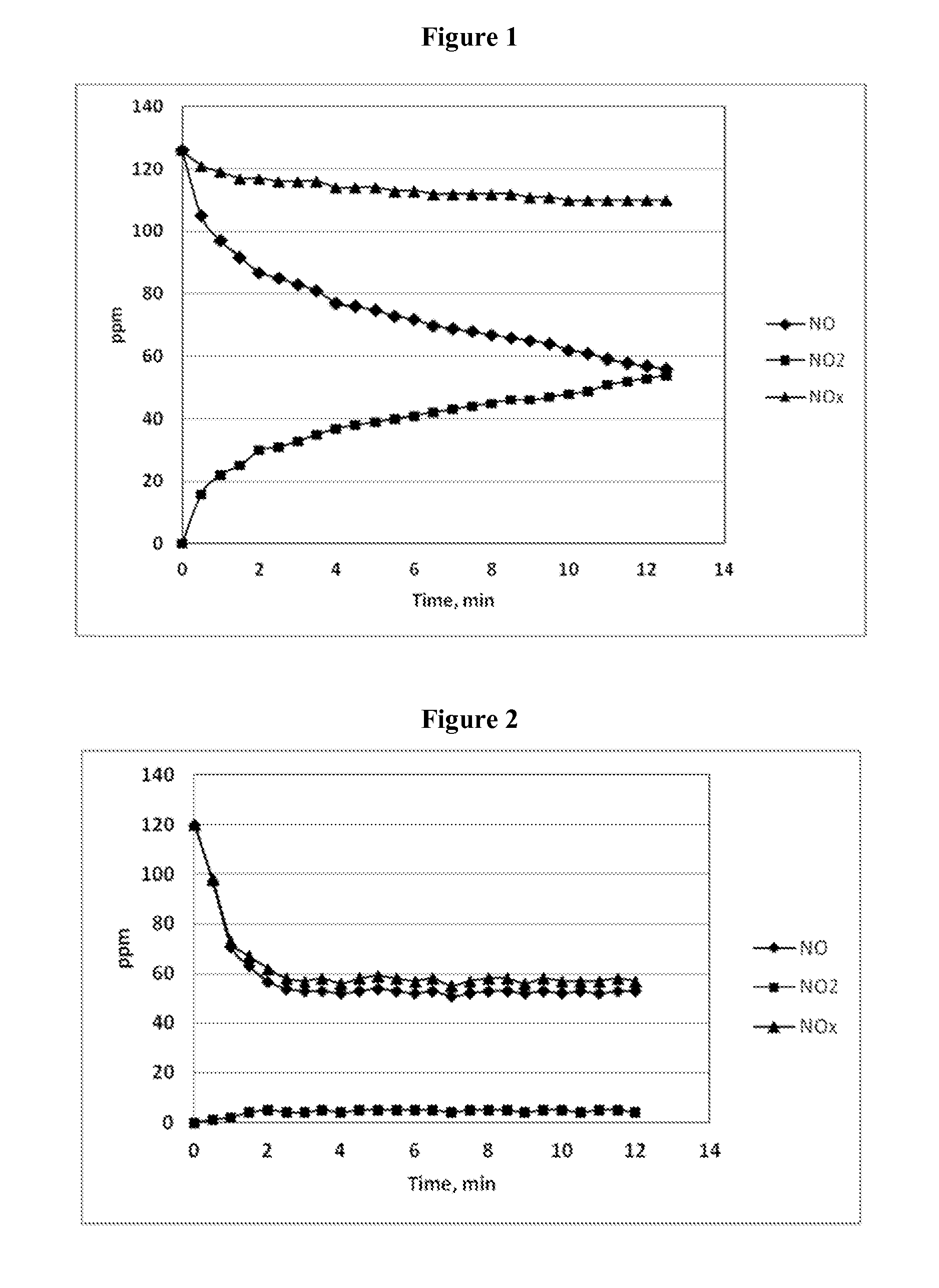

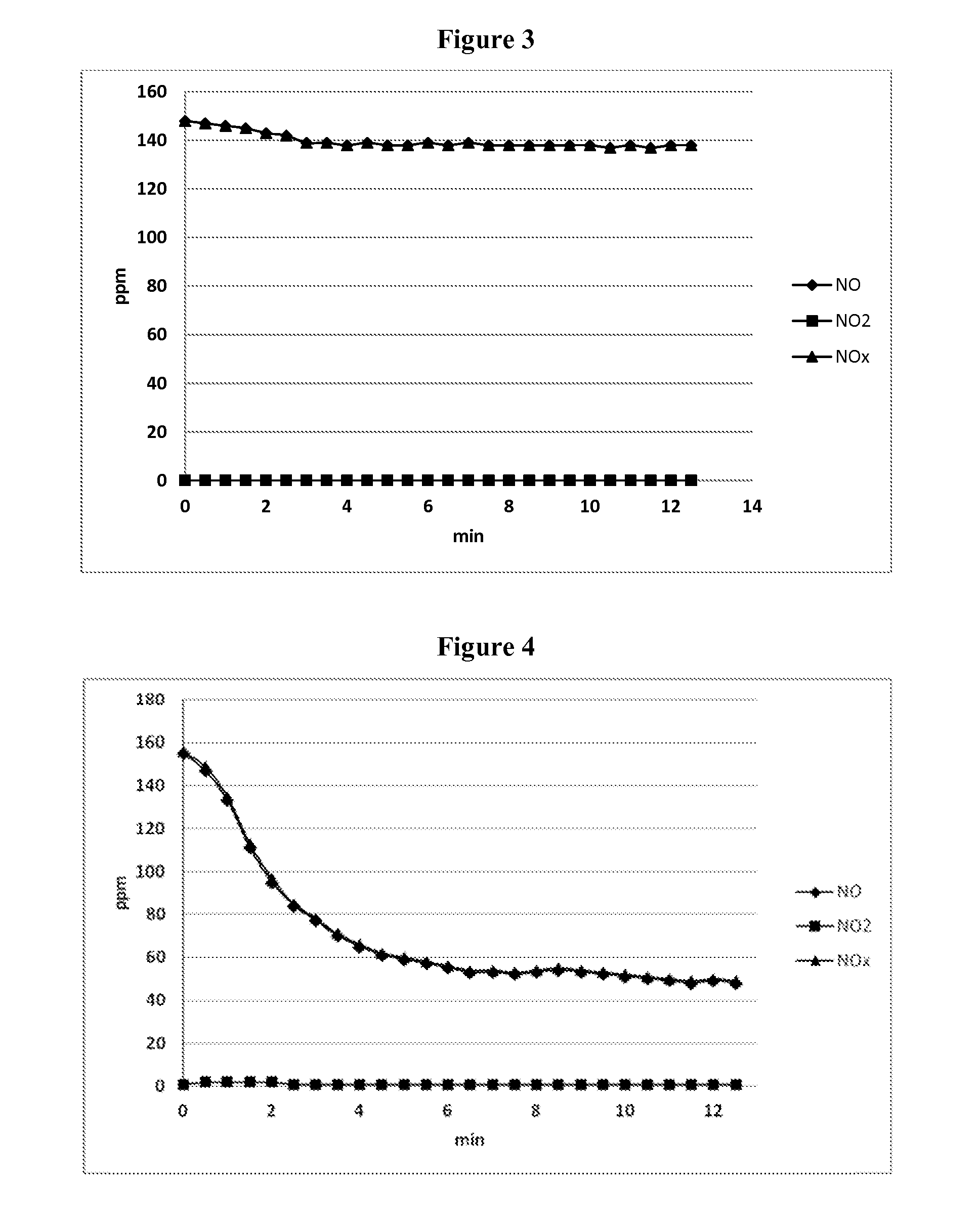

COMBUSTION FLUE GAS NOx TREATMENT

ActiveUS20100290965A1Reduce NOxReduce the concentration of nitrogen oxidesNitrous oxide captureCombination devicesFlue gasFlue-gas stack

Combustion flue gas containing NOX and SOX is treated to remove NOX in a multistep system in which NOX is reduced in the flue gas stream via selective catalytic reduction or selective non-catalytic reduction with ammonia or an ammonia-forming compound, followed treatment with hydrogen peroxide to remove residual ammonia and, optionally, treatment with an alkali reagent to reduce residual NOX in the flue gas stream. The NOX-depleted flue gas stream may also be subjected to a desulfurization treatment for removal of SOX.

Owner:PEROXYCHEM LLC

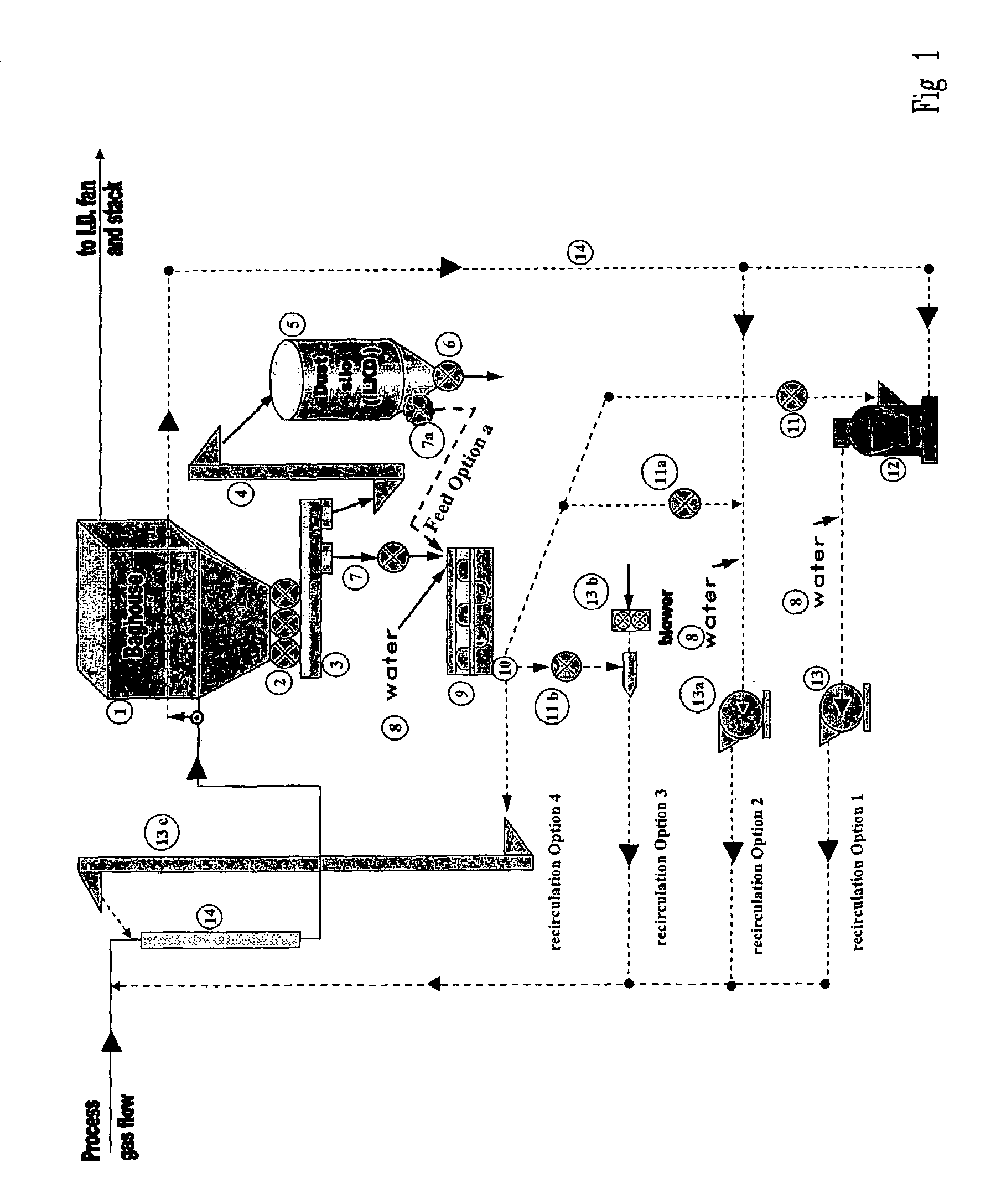

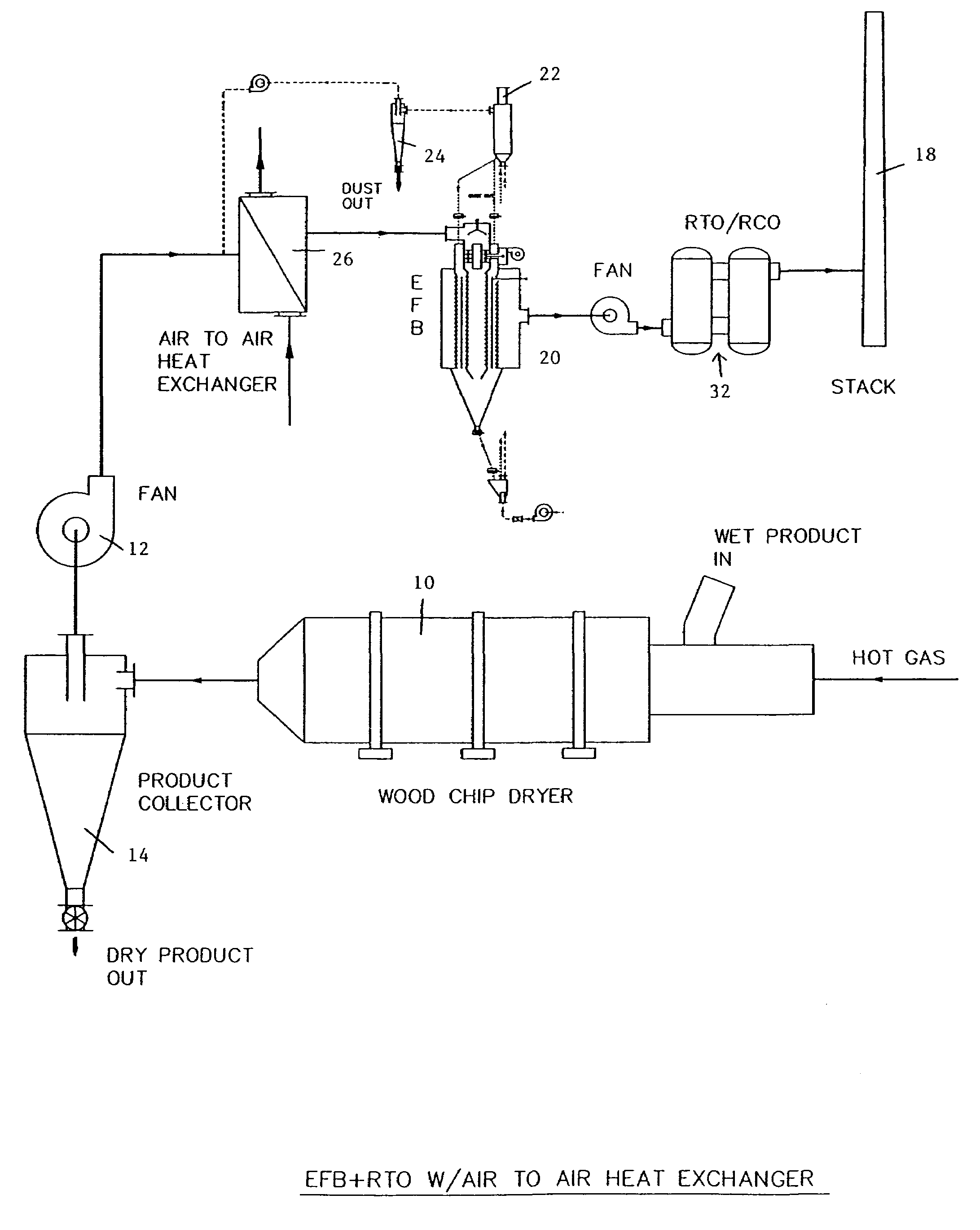

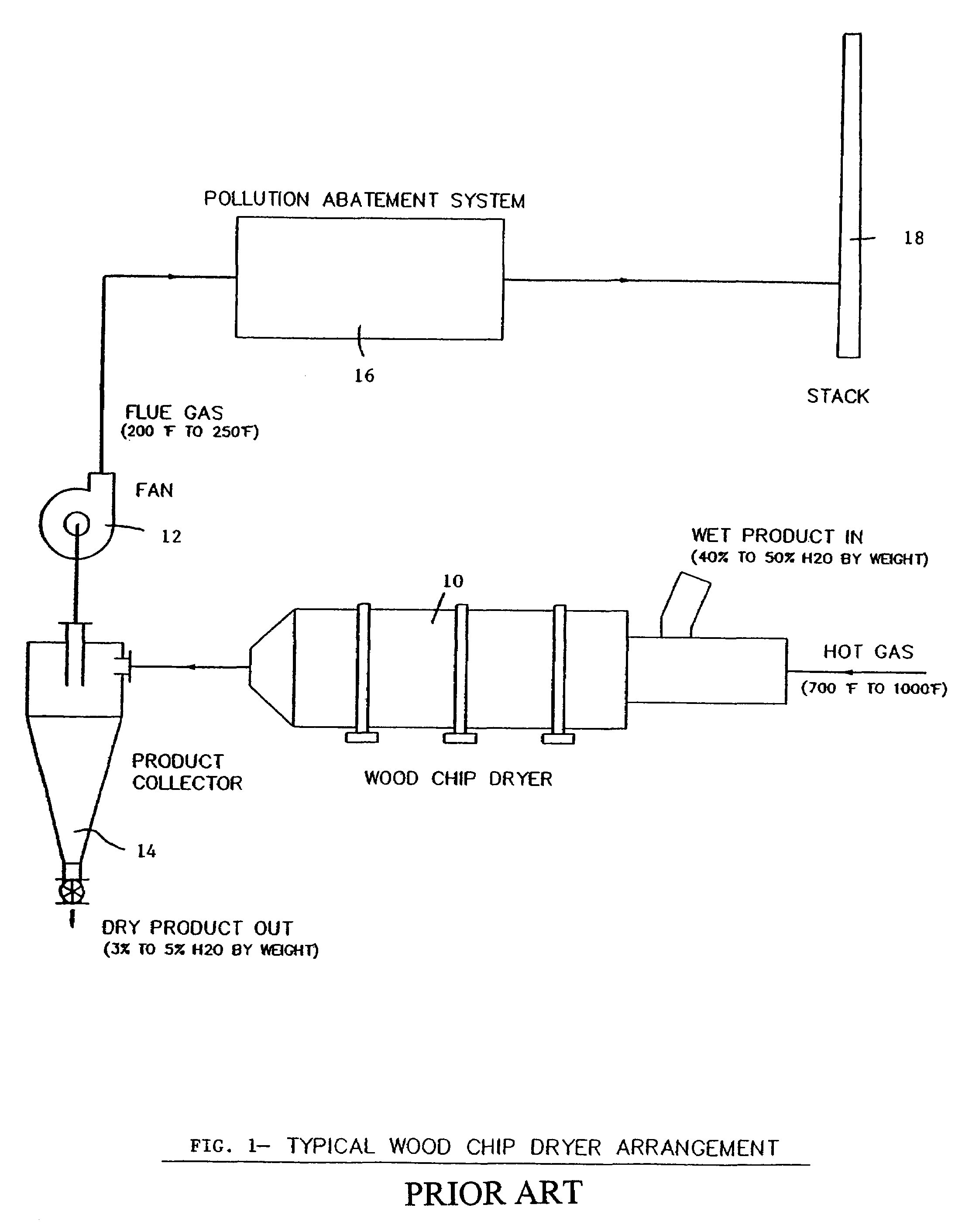

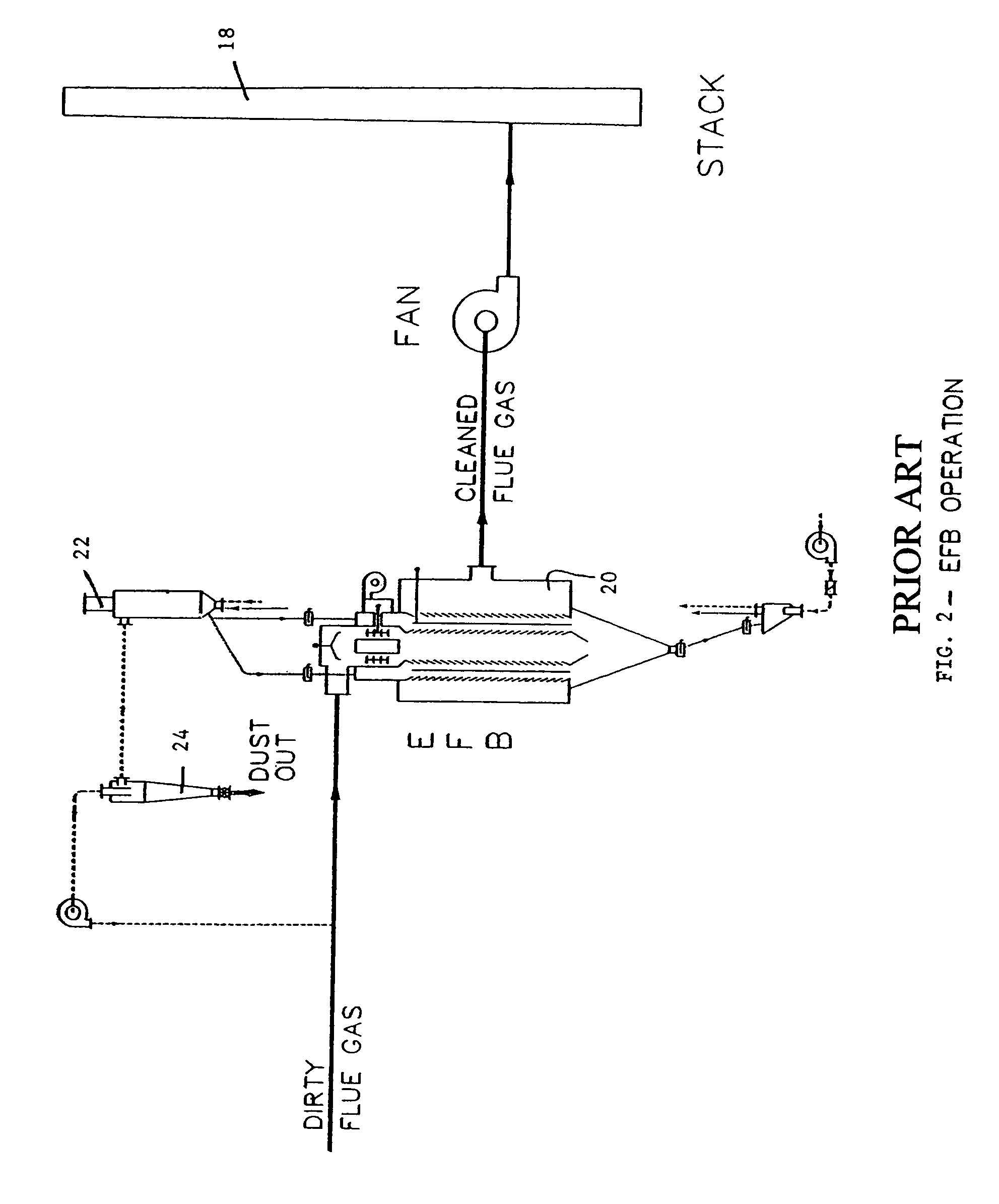

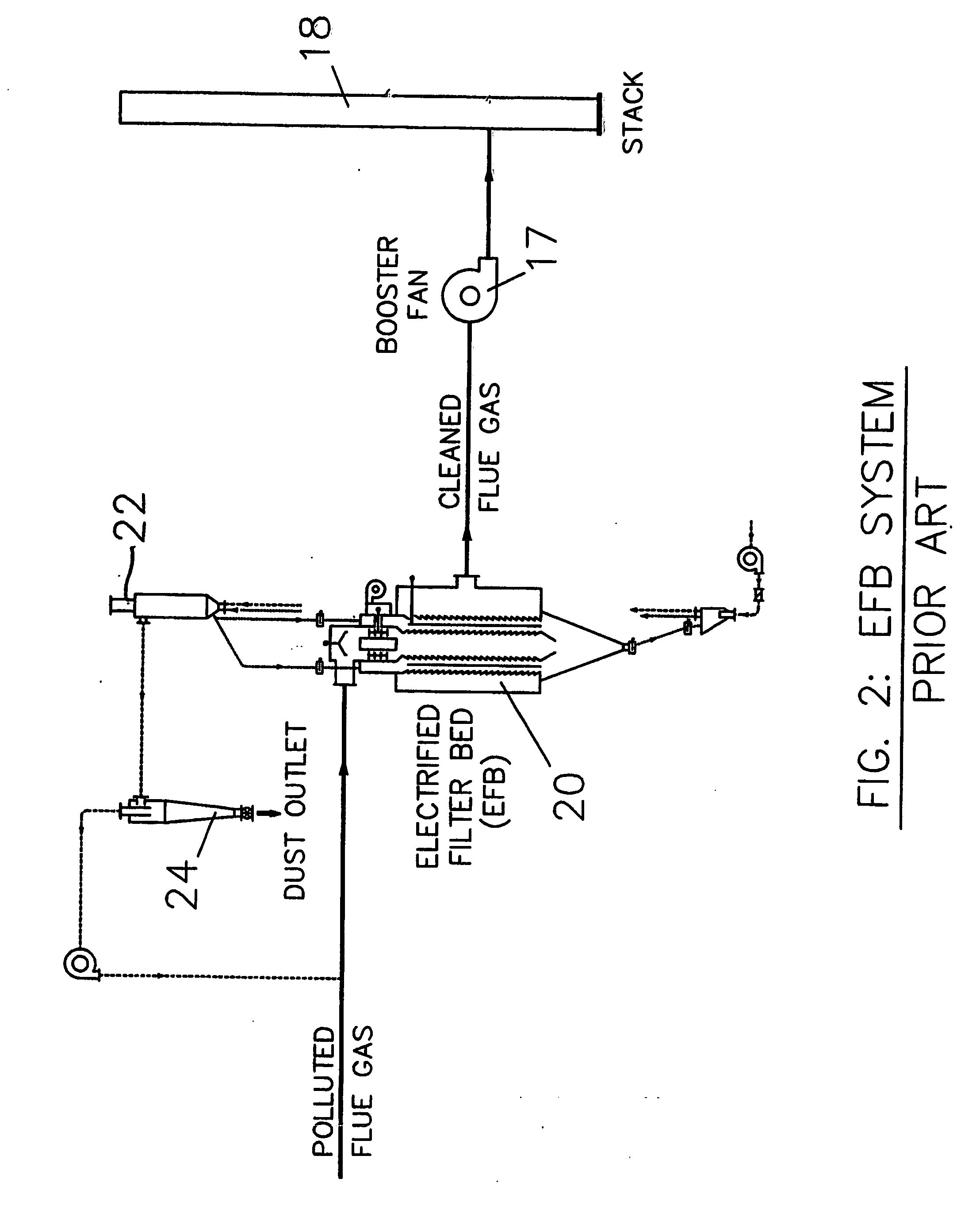

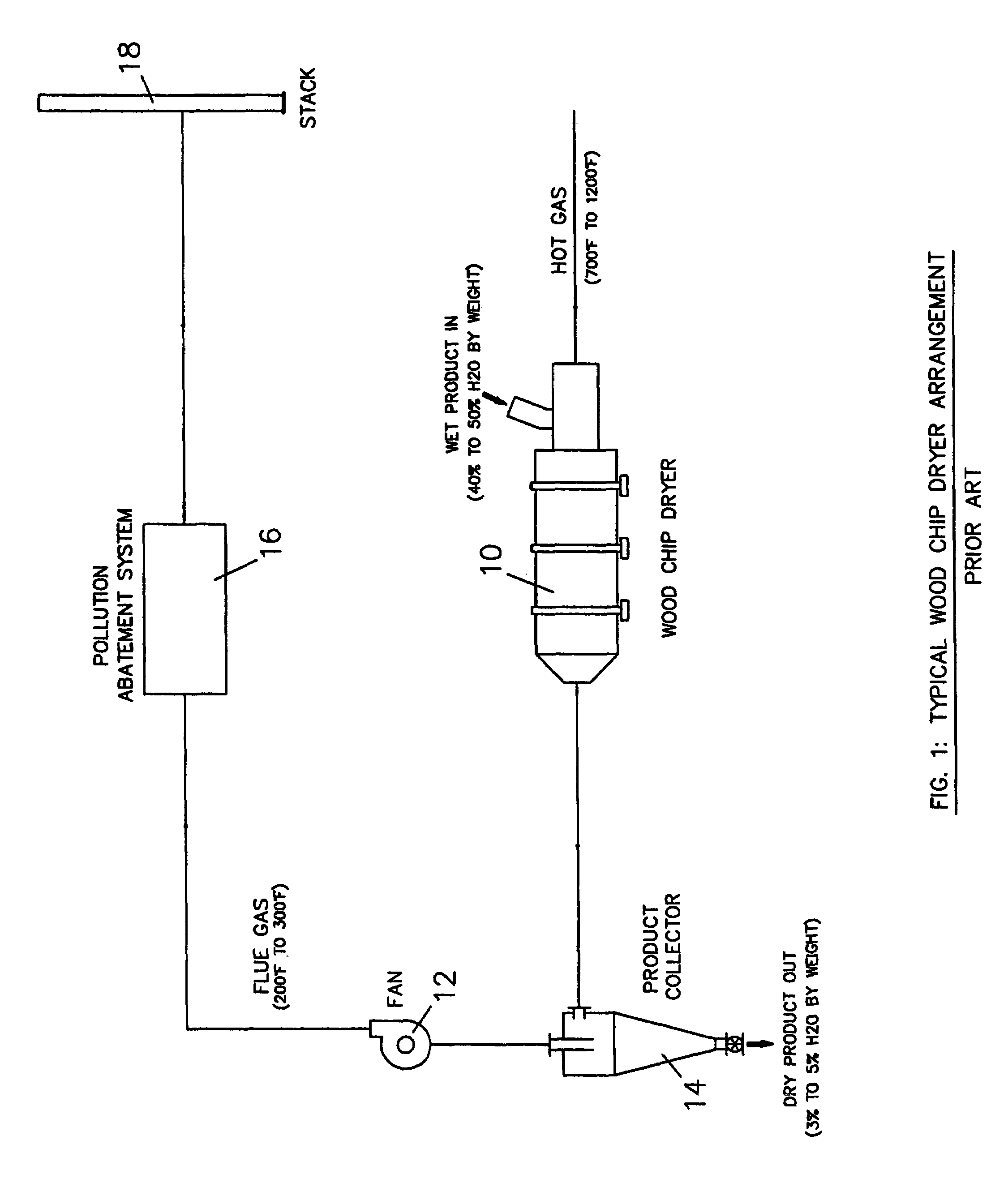

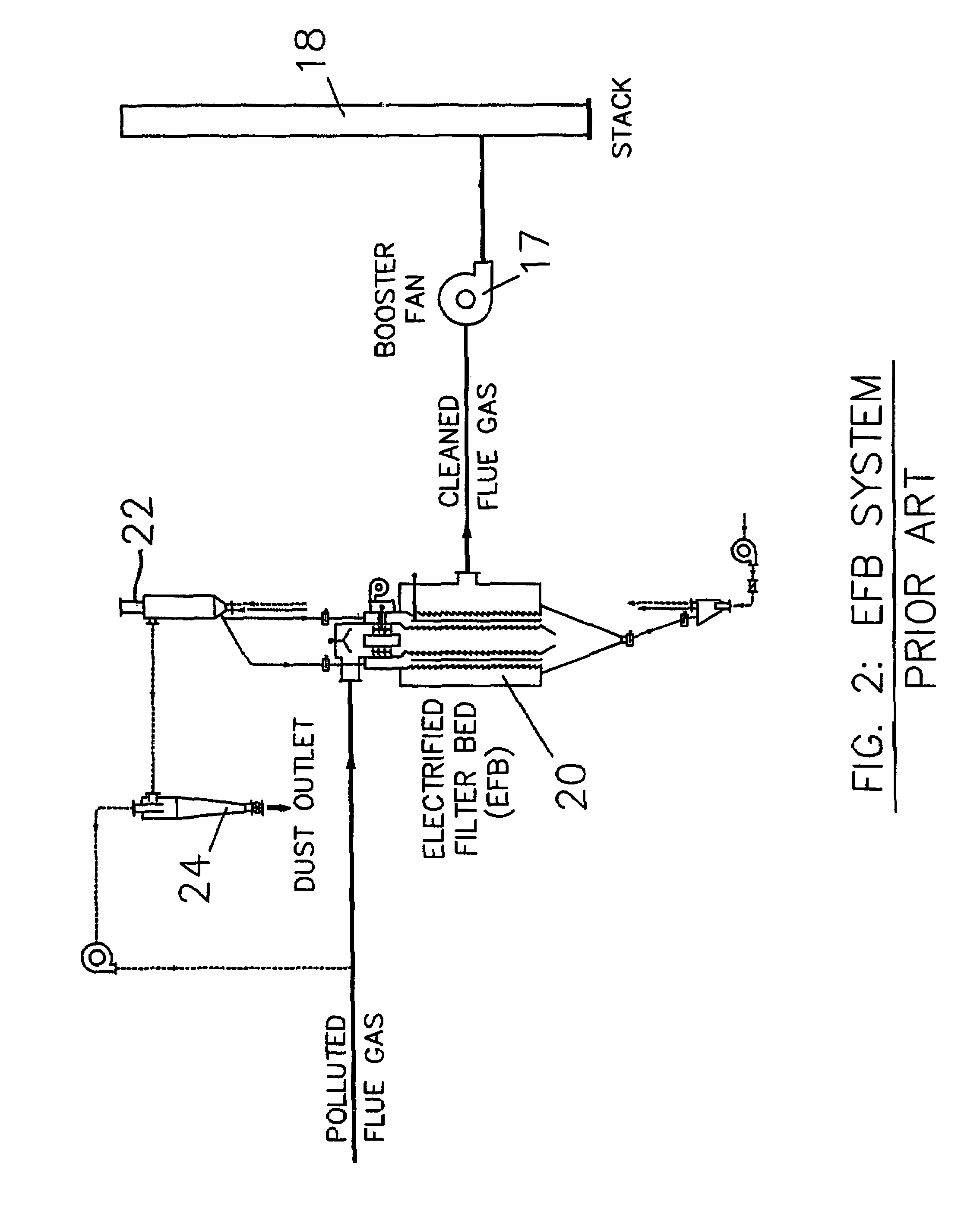

Apparatus and method using an electrified filter bed for removal of pollutants from a flue gas stream

InactiveUS6974494B1Avoid pollution control issueReduce decreaseElectrostatic separationFlue gasSolid particle

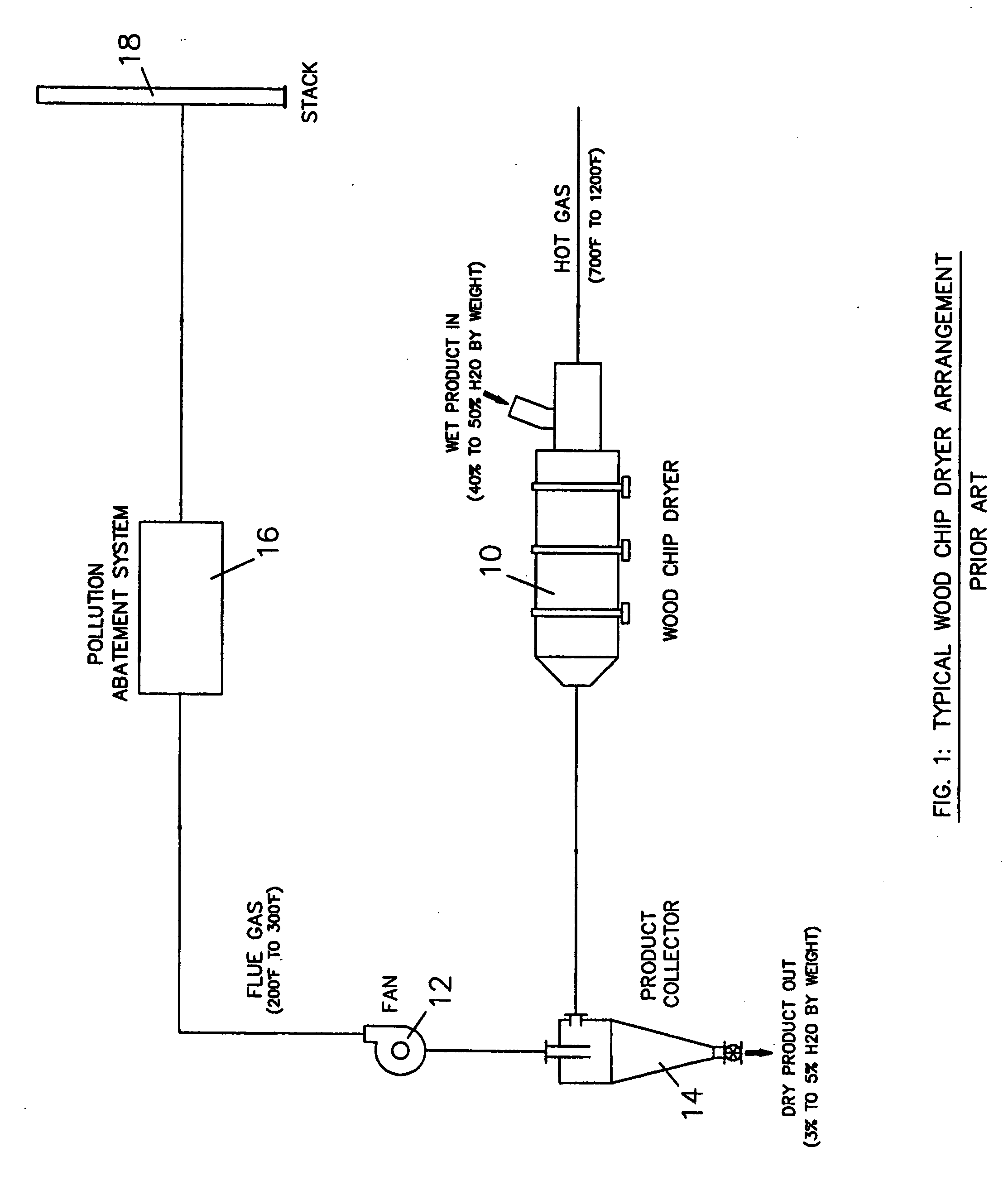

Pollutants in a flue gas stream from a dryer of products, such as wood chips, are removed by a pollution abatement system that includes an electrified filter bed unit for removing solid particulates. To prevent deteriorated operation of the electrified filter bed unit due to condensation of volatile organic compounds, the flue gas stream is heated, prior to admission to the electrified filter bed unit, to a temperature sufficient to convert condensable liquid aerosols to a gaseous state. The electrified filter bed unit then removes solid particulate selectively without collecting condensable organics. After the flue gas stream has passed through the electrified filter bed unit, gaseous pollutants can be removed by an oxidation process, for example.

Owner:ZAHEDI KARIM

Heat recovery technique for catalyst regenerator flue gas

ActiveUS7404891B2Effective recoveryIncrease heightThermal non-catalytic crackingCatalytic crackingFlue gasProcess engineering

A technique for recovering heat from a high temperature effluent stream from catalyst regeneration or the like, comprising processes and means for: (a) passing the effluent stream in heat exchange relationship in a steam generator with boiler feed water to produce high pressure steam and partially cool the effluent stream; (b) passing the partially cooled effluent stream from the steam regenerator in heat exchange relationship to preheat high pressure boiler feed water and further cool the effluent stream; and (c) passing the preheated boiler feed water to the steam generator. The apparatus and processes for thermal energy recovery may be used to treat hot regenerator effluent from FCC or OTO-type processes, thereby producing a cooled flue gas stream to discharge to ambient atmosphere.

Owner:EXXONMOBIL CHEM PAT INC

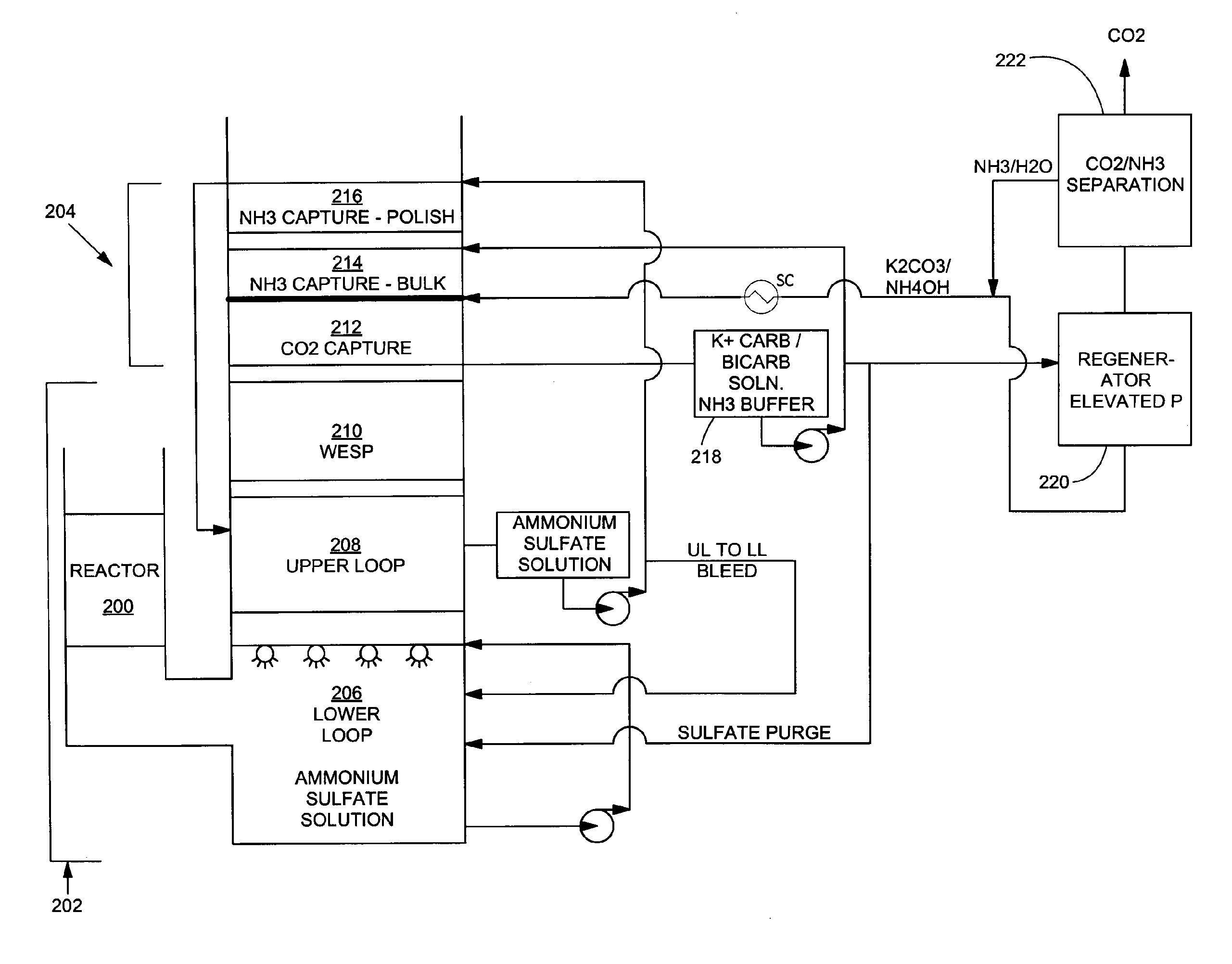

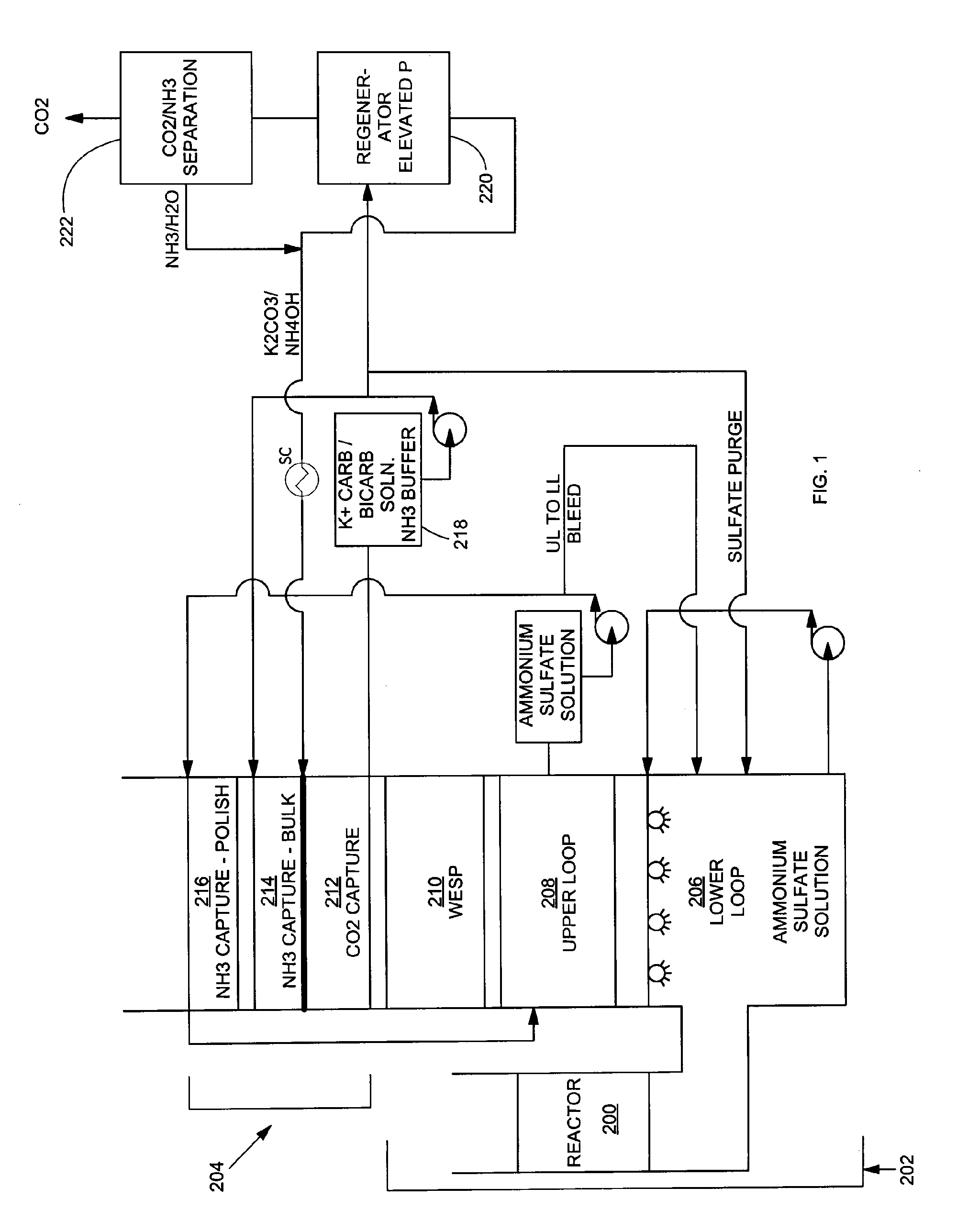

Removal of carbon dioxide from flue gas streams using mixed ammonium/alkali solutions

A process for removing carbon dioxide from a gas stream by scrubbing the carbon dioxide from the gas stream with a mixture of ammonium and alkali carbonates such as sodium carbonate and / or potassium carbonate. Using the mixed alkali carbonate solution as the CO2 scrubbing solution offers the opportunity for both low regeneration energy and low ammonia volatility while still maintaining a high rate of CO2 hydration.

Owner:POWERSPAN CORP

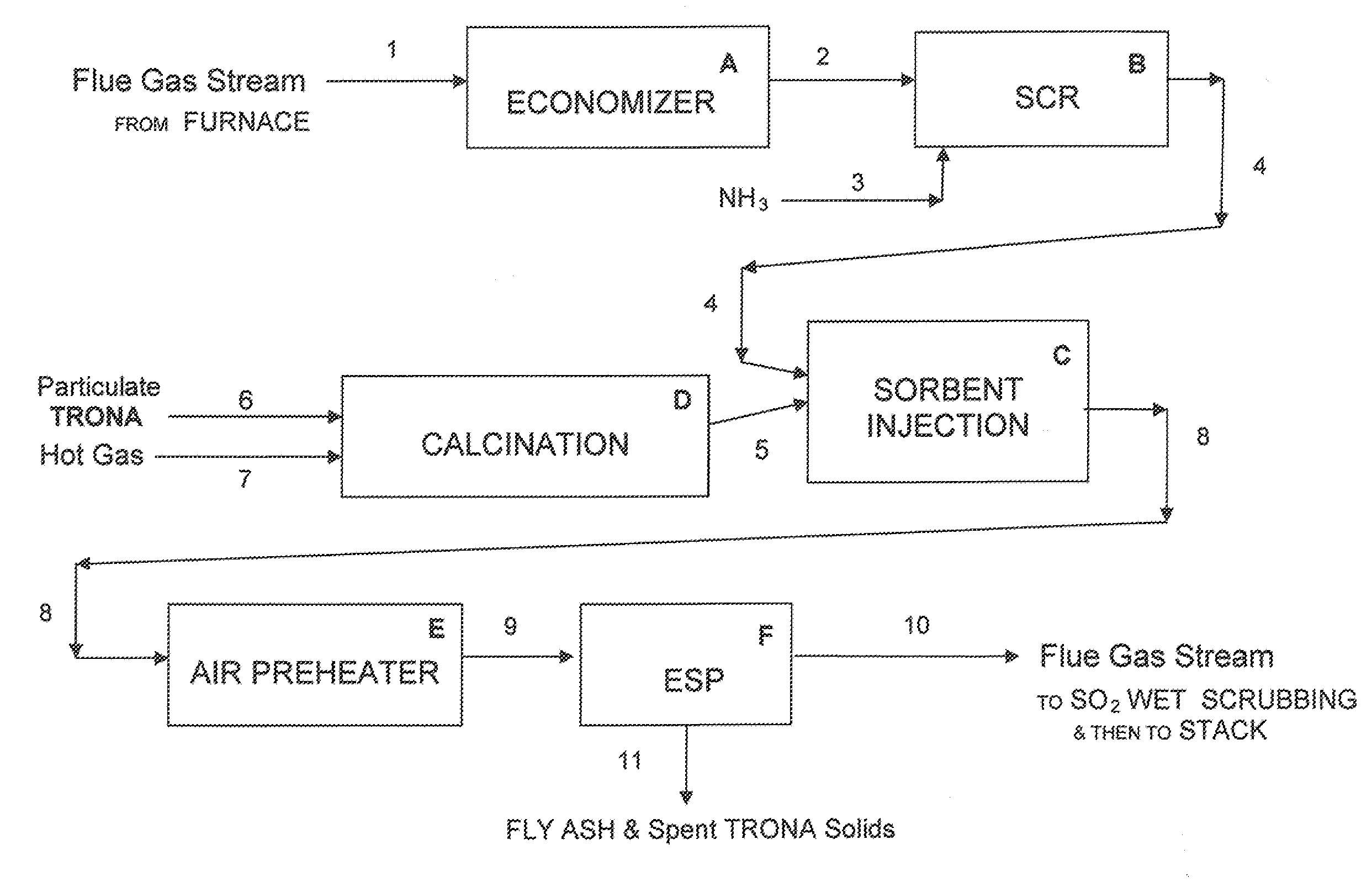

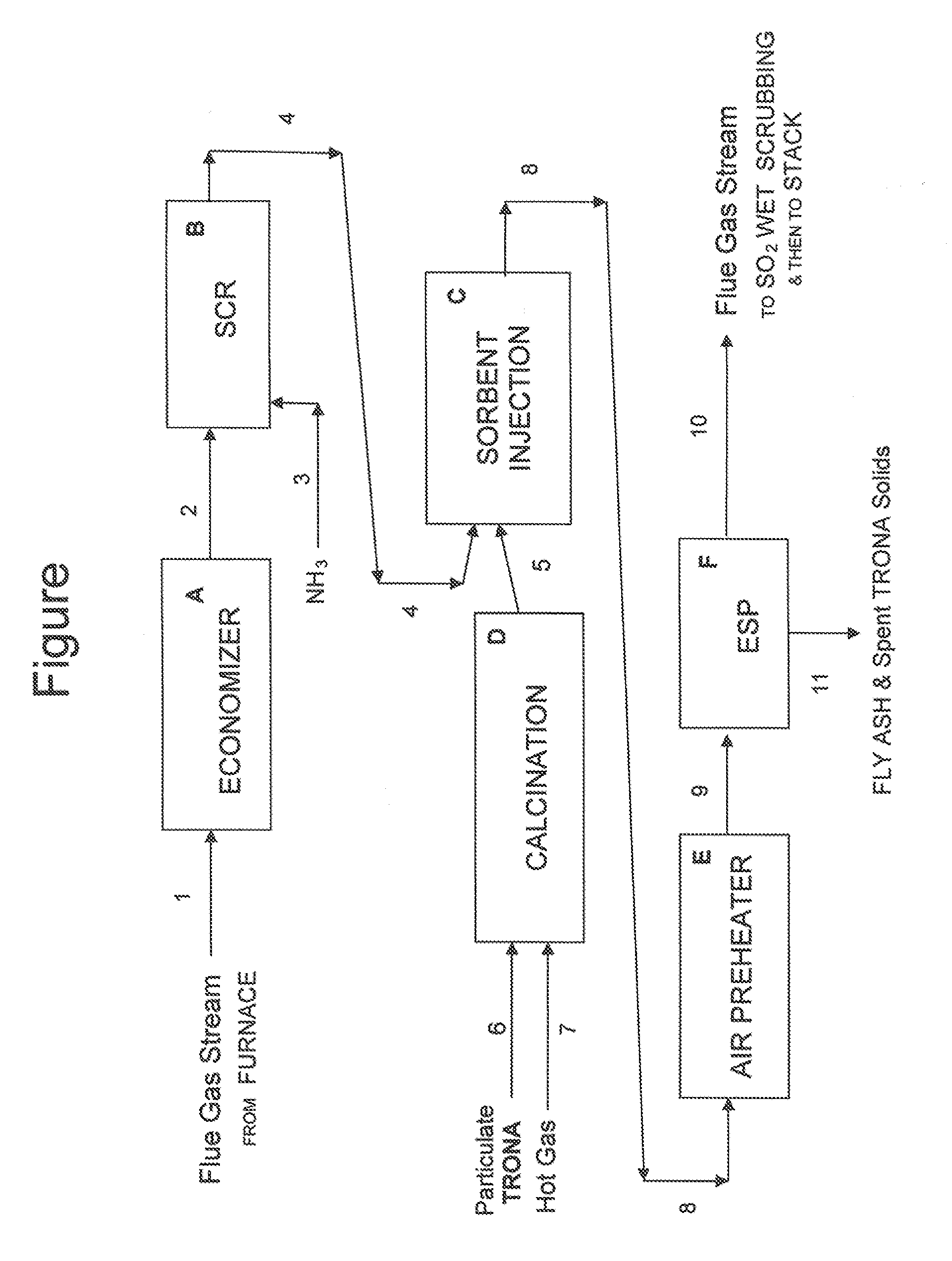

COMBUSTION FLUE GAS SOx TREATMENT VIA DRY SORBENT INJECTION

Combustion flue gas containing SOX is treated to remove SOX using a dry particulate sorbent injection procedure in which a sodium-based sorbent precursor is calcined immediately prior to its introduction into the flue gas stream, to activate the sorbent for reaction with SOX. The sorbent precursor is a NaHCO3-containing compound, and trona is preferred as the sorbent precursor.

Owner:TRONOX ALKALI WYOMING CORP

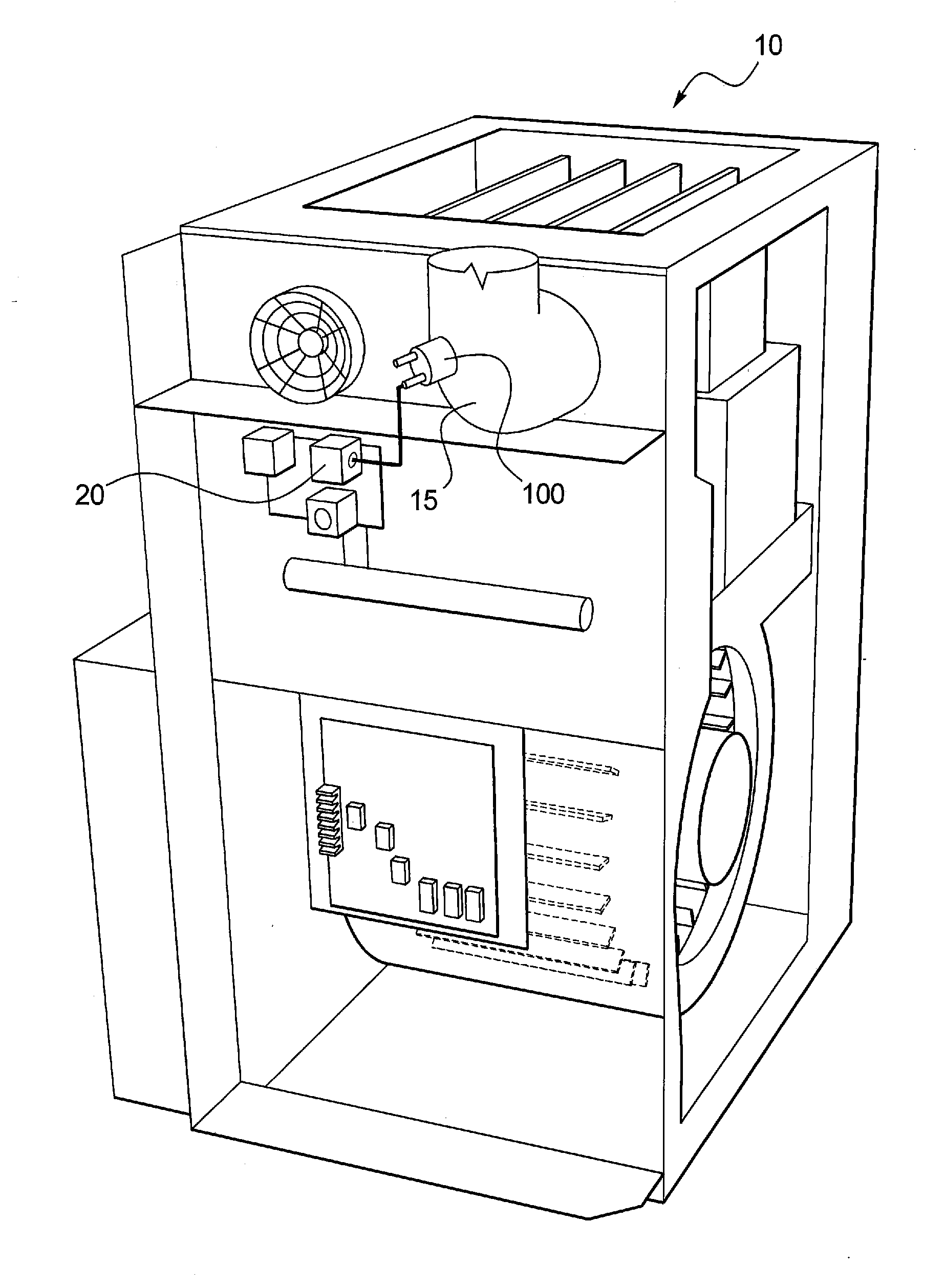

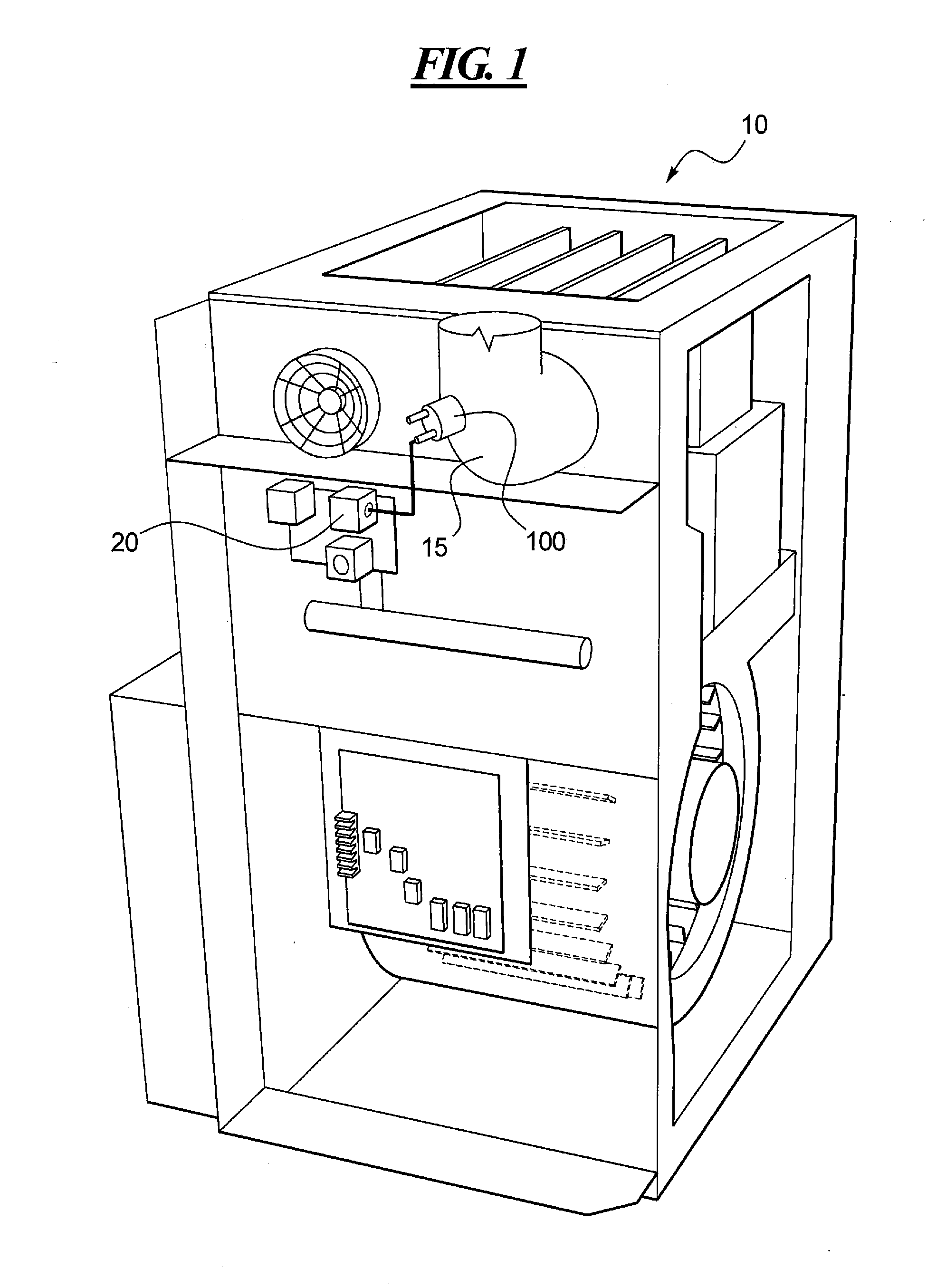

Apparatus and method using an electrified filter bed for removal of pollutants from a flue gas stream

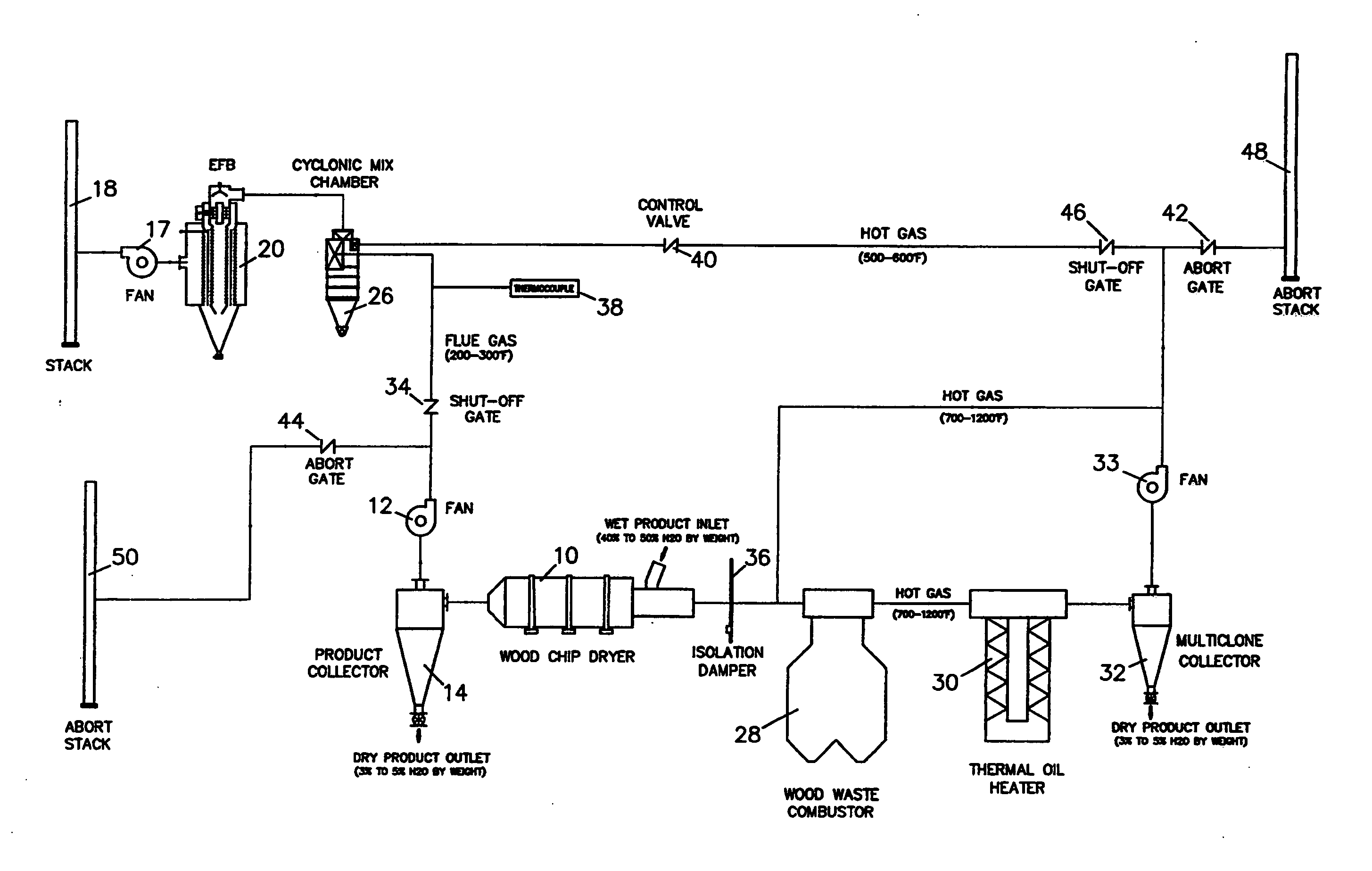

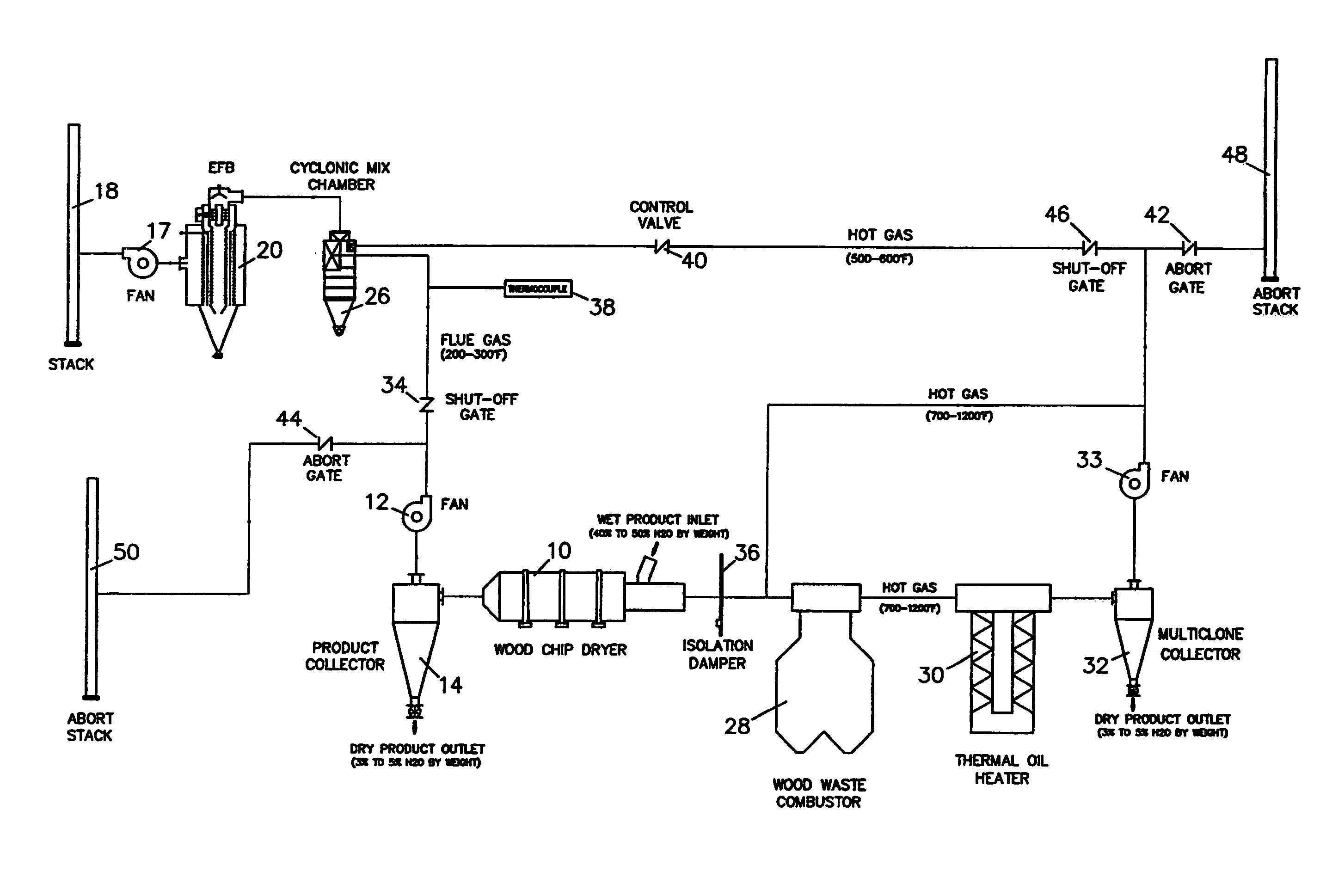

InactiveUS20070214676A1Free of materialRapidly preheatedDrying using combination processesDrying solid materials with heatWhirlwindPollution

A pollution abatement apparatus comprises an electrified filter bed preceded by a cyclonic mix chamber to remove wood fines and fly ash in a flue gas stream from a wood chip dryer heated by hot gas from an energy system that includes a wood waste combustor. The cyclonic mix chamber has dual inlets, one supplied with flue gas from the dryer and the other supplied with hot gas from the energy system.

Owner:EFB

Apparatus and method using an electrified filter bed for removal of pollutants from a flue gas stream

InactiveUS7318288B2Free of materialRapidly preheatedDrying using combination processesDrying solid materials with heatWhirlwindPollution

Owner:EFB

Flue Gas Sensor With Water Barrier Member

An improved flue gas sensor of a combustion device is disclosed. The flue gas sensor may include a housing and a gas detector disposed within the housing, wherein the gas detector detects or measures at least one gas in a flue gas stream of the combustion device. The housing may also include a water barrier member through which the at least one gas comes into contact with the gas detector. By keeping water and water vapor away from the gas detector, premature failure of the flue gas sensor caused by corrosion may be prevented.

Owner:CARRIER CORP

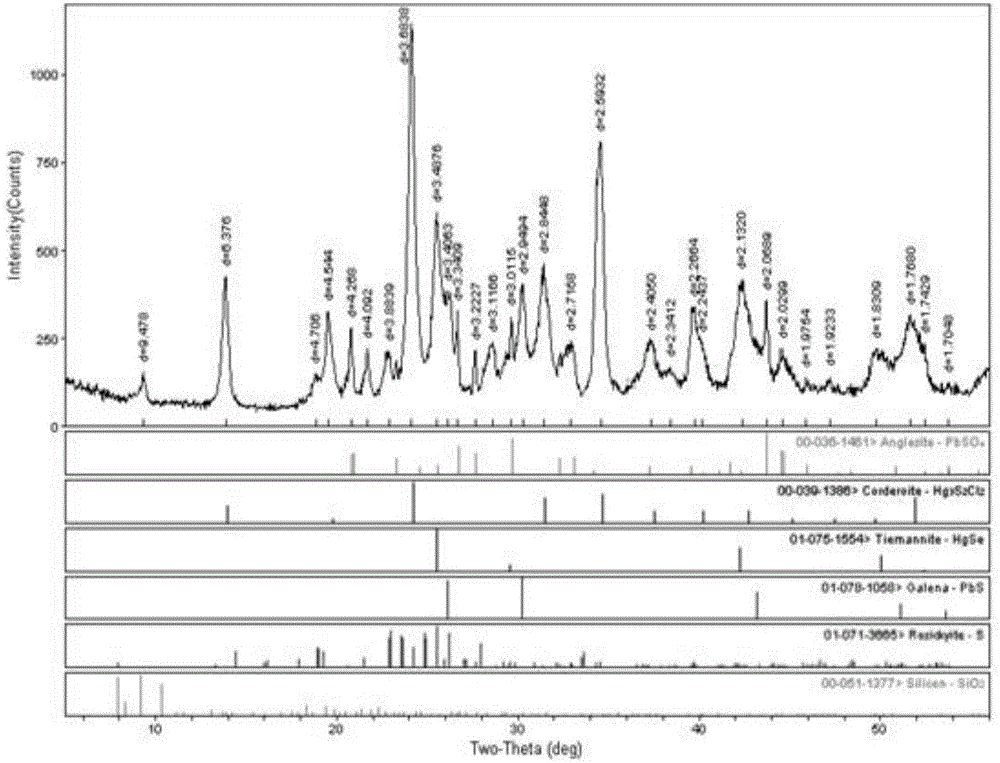

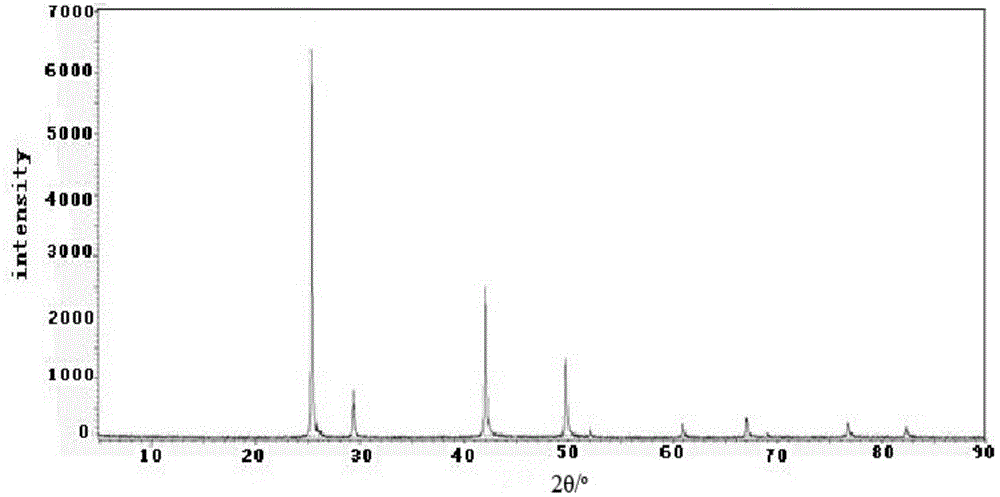

Method for recovering selenium, mercury, gold and silver from acid sludge

ActiveCN104805297AHigh recovery rateReduce pollutionProcess efficiency improvementBinary selenium/tellurium compoundsTube furnaceFlue gas

The invention discloses a method for recovering selenium, mercury, gold and silver from acid sludge. The method comprises the steps: (1) putting the acid sludge, generated from a sulfide ore roasting flue gas acid preparing process, into a tubular furnace, and carrying out roasting treatment under the condition of a protective atmosphere, so as to obtain roasting slag and flue gas containing gaseous mercury selenide; (2) cooling the flue gas, so as to cool the gaseous mercury selenide in the flue gas into solid-state mercury selenide and recover selenium and mercury from the acid sludge; (3) extracting gold and silver from the roasting slag obtained in the step (1) by adopting a cyanidation method, so as to recover gold and silver from the acid sludge. According to the method, the solid-state mercury selenide with high added value is obtained by adopting a protective atmosphere roasting process, and gold and silver are recovered by adopting the cyanidation method, so that the method has the advantages of brief flow, high product added value, high purity, high valuable element recovery ratio and little environmental pollution.

Owner:西安西北有色地质研究院有限公司

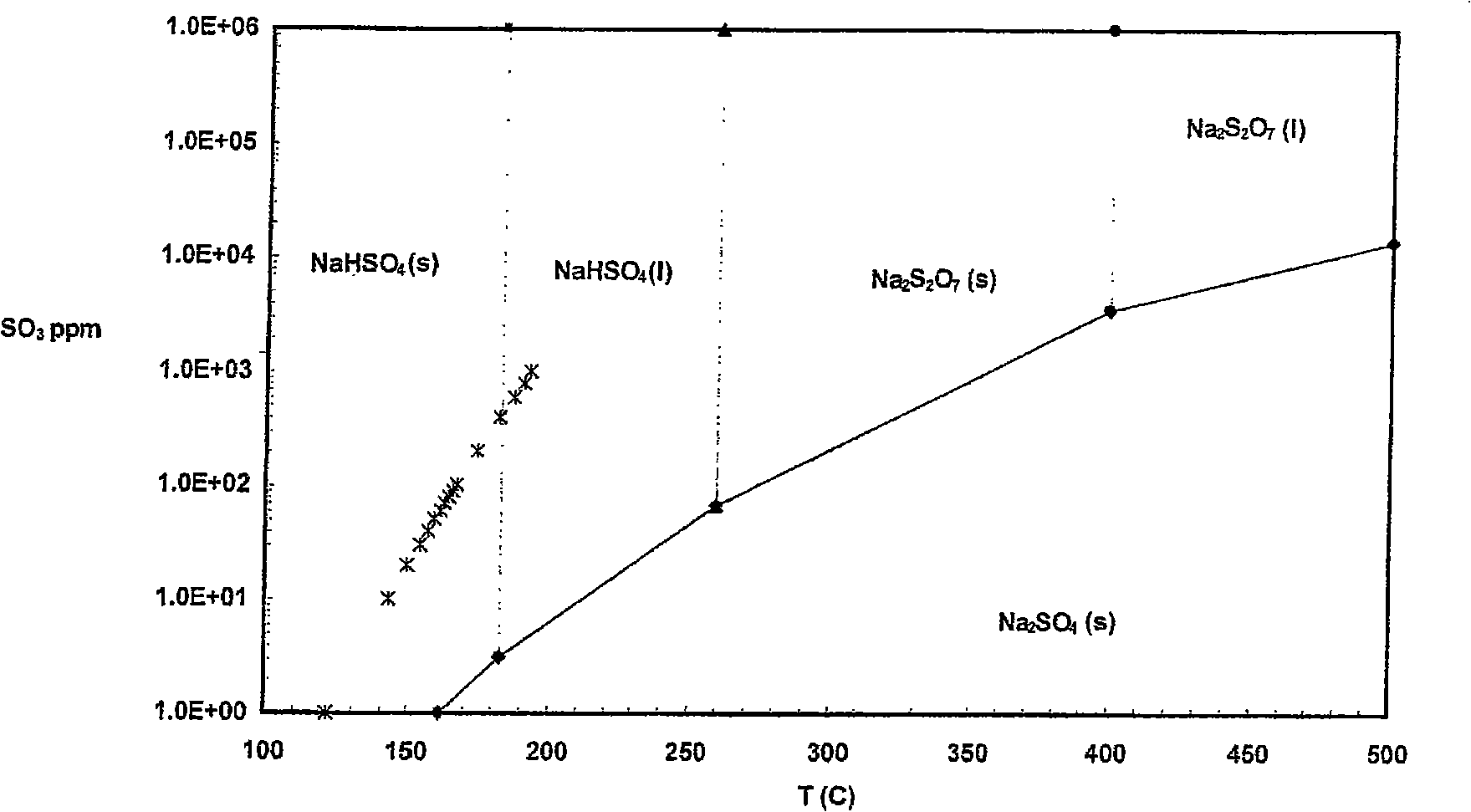

Sulfur trioxide removal from a flue gas stream

A method of removing SO3 from a flue gas stream having increased amounts of SO3 formed by a NOx removal system, includes injecting a sorbent composition into the flue gas stream. The sorbent composition includes an additive and a sodium sorbent such as mechanically refined trona or sodium bicarbonate. The additive is selected magnesium carbonate, calcium carbonate, magnesium hydroxide, calcium hydroxide, and mixtures thereof. The concentration of the SO3 in the flue gas stream is reduced and the formation of a liquid phase NaHSO4 reaction product is minimized.

Owner:SOLVAY CHEM INC

Process for controlling the moisture concentration of a combustion flue gas

InactiveUS7585476B2Reduce concentrationReducing the moisture of the flue gasUsing liquid separation agentHydrogen sulfidesWater vaporMoisture

Owner:THE BABCOCK & WILCOX CO

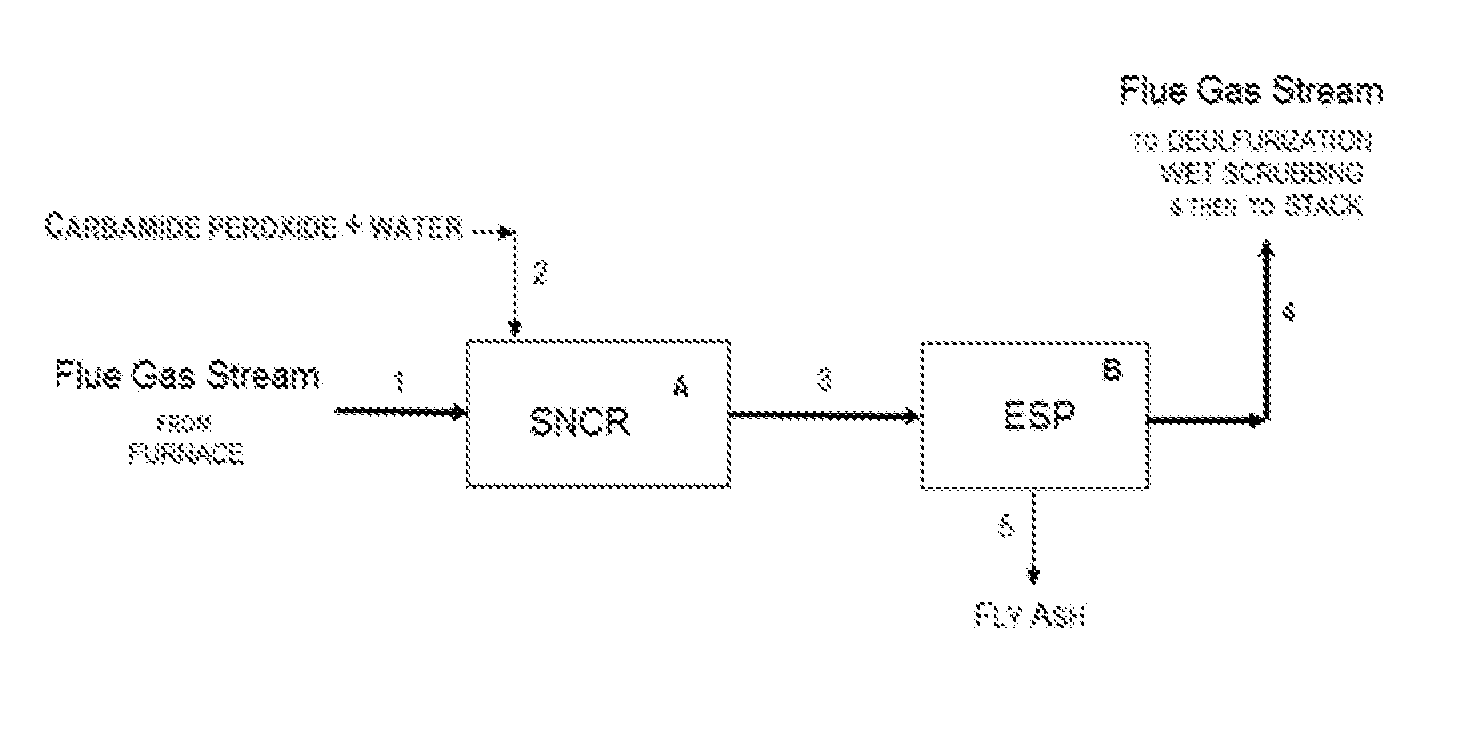

Treatment of nitrogen oxides in flue gas streams

A method for removing nitrogen oxides in stationary source combustion flue gas streams includes introducing a reagent or a mixture comprising carbamide peroxide and water as a reducing agent.

Owner:EVONIK OPERATIONS GMBH

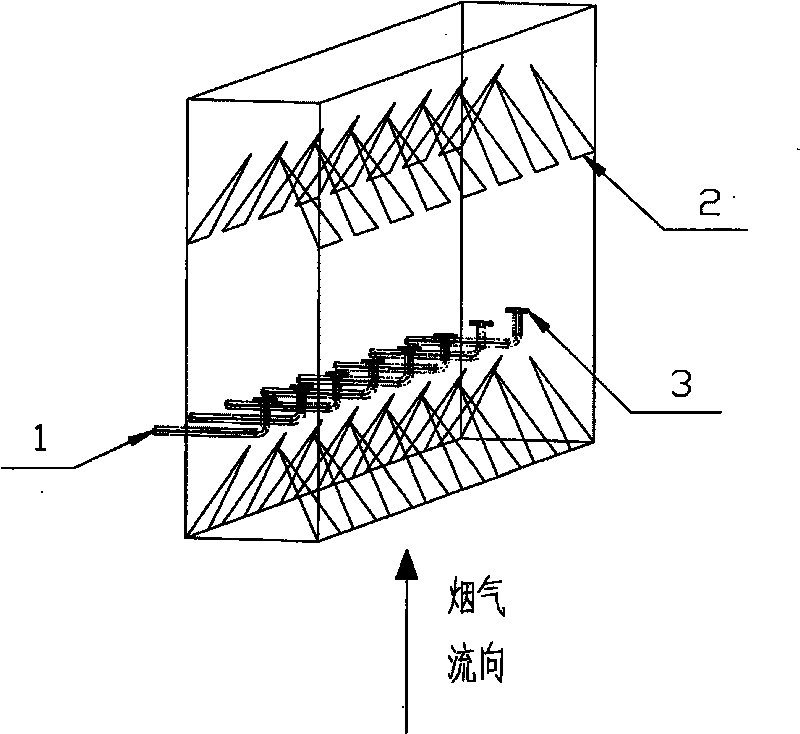

Ammonia spraying and mixing system for coal-fired flue gas SCR denitration technology

InactiveCN101708430AIncrease mixing intensityImprove the mixing effectLighting and heating apparatusDispersed particle separationStreamflowReducing agent

The invention discloses an ammonia spraying and mixing system for the coal-fired flue gas SCR denitration technology and relates to a system used for spraying reducing agent ammonia and strengthening the mixture of ammonia and flue gas. The ammonia spraying and mixing system comprises 5-20 reducing agent ammonia jet tubes with independent flow control systems and longitudinal vortex generation elements, wherein the tail end of each reducing agent ammonia jet tube is provided with a two-way nozzle which is vertical and symmetric to the flue gas stream, each longitudinal vortex generation element is a triangle, a trapezoid, a half round or a half ellipse, each longitudinal vortex generation element is connected with the flue wall and forms 30-60 degrees angle with the flue gas stream so as to form longitudinal vortex of which downstream is stable, increase the intensity of turbulent flow and enhance the mixture of reducing agent ammonia and glue gas. The device has the following advantages: 1) the stable longitudinal vortex is formed, the mixing intensity of vortex is increased, and the mixing effect of ammonia and nitrogen is optimized; 2) the number of the ammonia jet tubes is reduced, the ammonia-spraying regulation difficulty is lowered; and 3) pressure breakdown caused by the system is relatively small and the energy loss is reduced.

Owner:ZHEJIANG UNIV

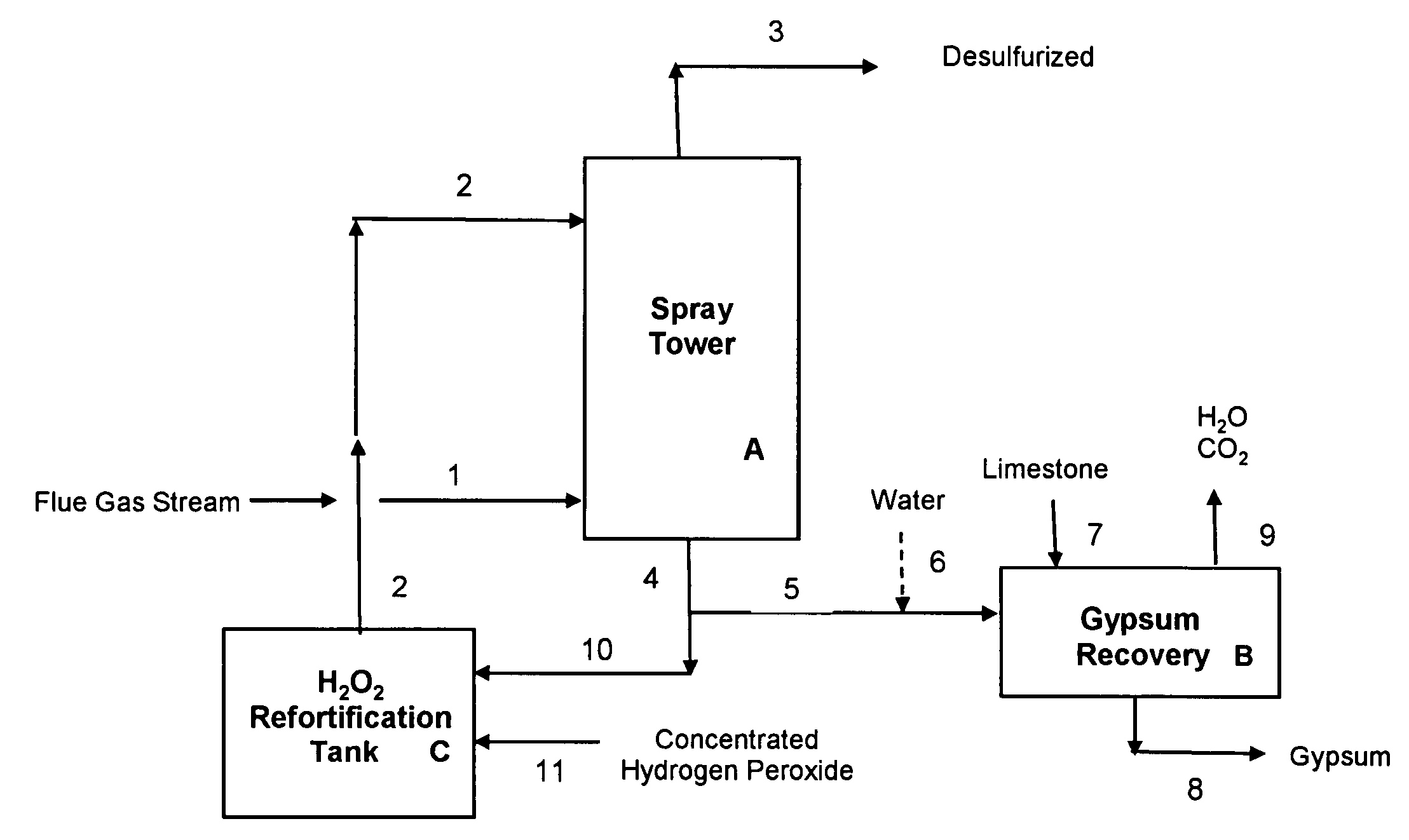

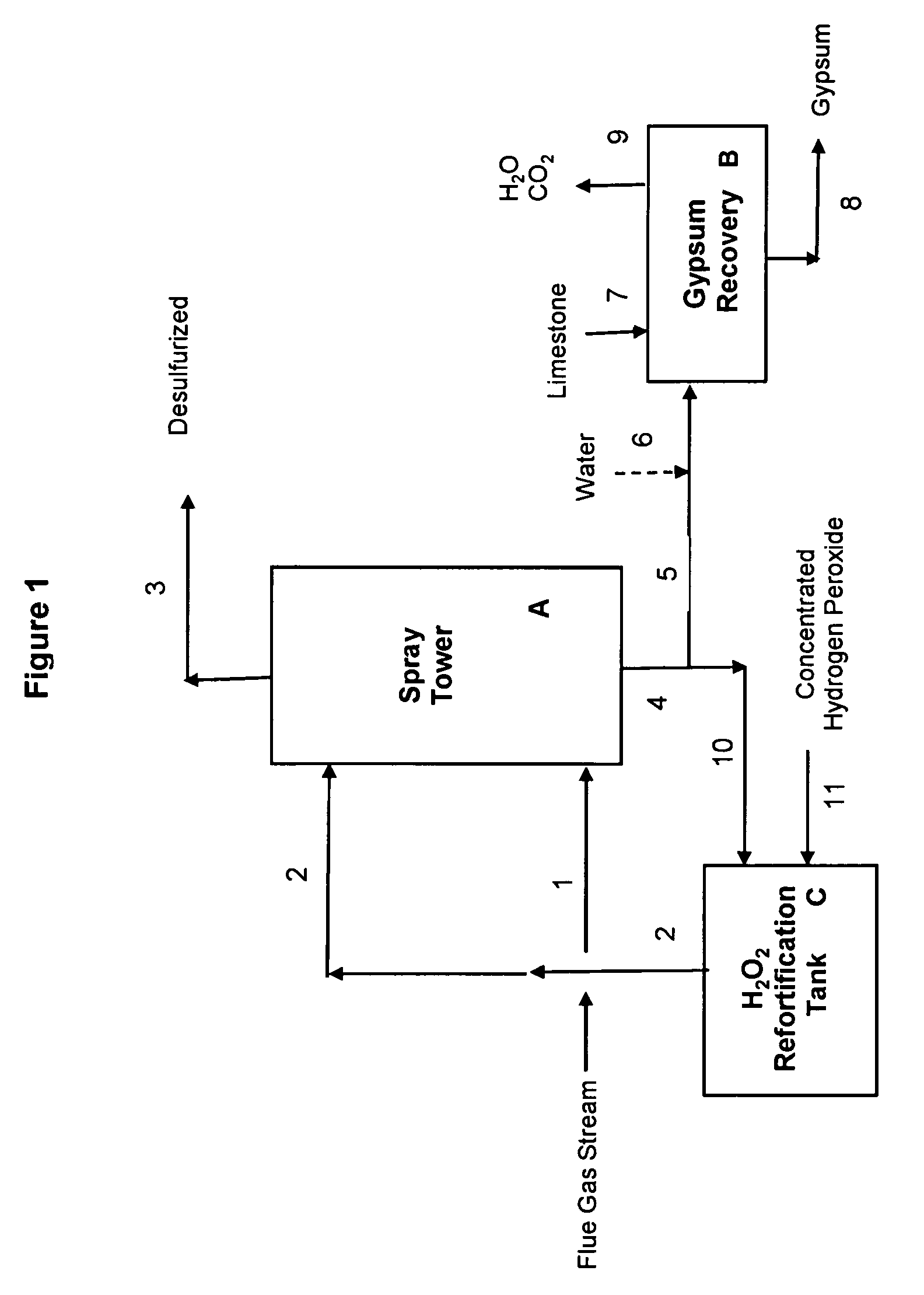

Flue gas desulfurization process utilizing hydrogen peroxide

InactiveUS7998446B2Sulfur-dioxide/sulfurous-acidCalcium/strontium/barium compoundsFlue gasFlue-gas stack

A flue gas desulfurization process in which a SO2-containing flue gas stream is contacted with a recirculating stream of an aqueous medium containing concentrated sulfuric acid and hydrogen peroxide, to yield a desulfurized flue gas stream and to produce additional sulfuric acid in the aqueous medium. A portion of the recirculating aqueous sulfuric acid stream is diverted for recovery of the additional sulfuric acid as gypsum in a neutralization step, and the process parameters are adjusted so that the heat of reaction generated during the neutralization step is sufficient to evaporate the free water that is present and yield a gypsum product that is substantially dry.

Owner:PEROXYCHEM LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com