Continuous pyrolysis incineration device for full-scale electronic and electrical product waste

A technology for electronic appliances and waste, which is applied in the field of continuous pyrolysis and incineration devices for full-scale electronic and electrical waste, can solve problems such as inability to atomize, poor atomization, and inability to ensure stable atomization effects, so as to ensure safe combustion, Combustion method safety, improve work efficiency and the effect of working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

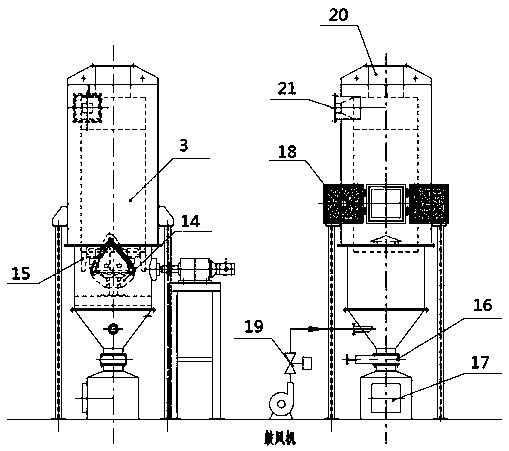

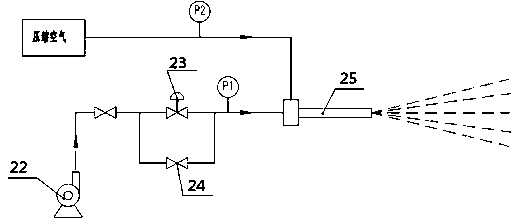

[0030] control figure 1 , a full-scale continuous pyrolysis incineration device for electronic and electrical waste, its structure includes a feeder 1, a feed hopper 2, a pyrolysis gasifier 3, a pyrolysis gas flue 4, a combustion furnace 5, and a G-L air heat exchanger 6 , quenching absorption tower 7, forward and bypass flue 8, bag filter 9 pyrolysis gasification furnace operating platform and ladder 10, activated carbon storage tank 11, chimney 12; among them, feeder 1 and pyrolysis gasification furnace 3 Adjacent to each other, the feed hopper 2 is placed above the pyrolysis gasifier 3 and fixedly connected on the top of the latter through mechanical components, and one end of the pyrolysis gas flue 4 is connected to the side opening of the pyrolysis gasifier 3 at the top of the latter , one end is connected with the combustion furnace 5 at the top opening of the latter, the pyrolysis gas flue 4 stands side by side with the combustion furnace 5, the pyrolysis gasification f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com