Straw incinerator

An incinerator and straw technology, applied in the field of straw incinerators, can solve the problems of hindering the popularization and application of straw incineration, low power generation efficiency, low calorific value of straw, etc. The effect of high incineration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

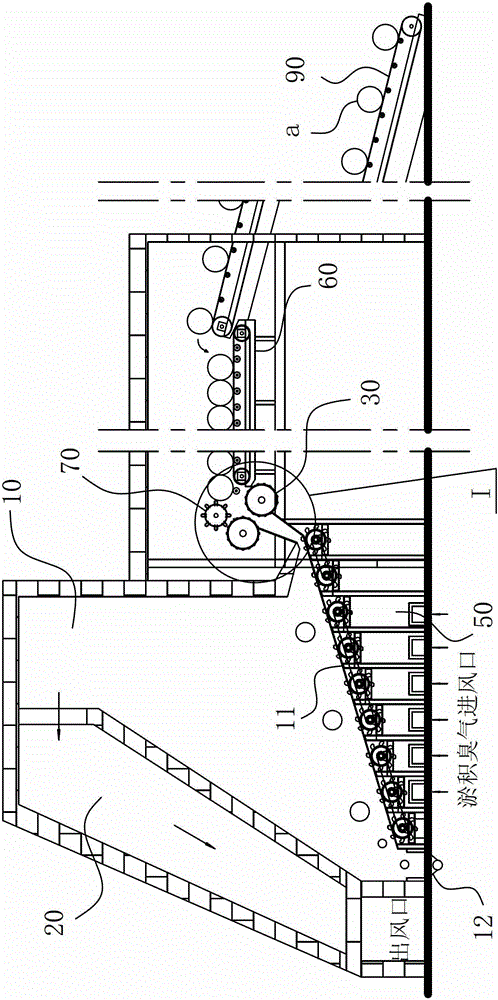

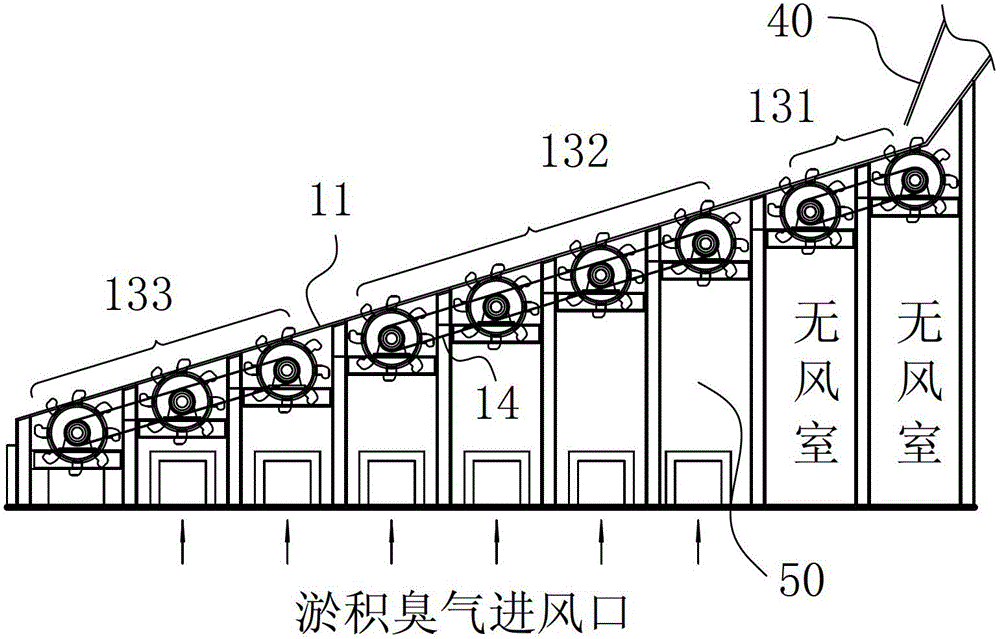

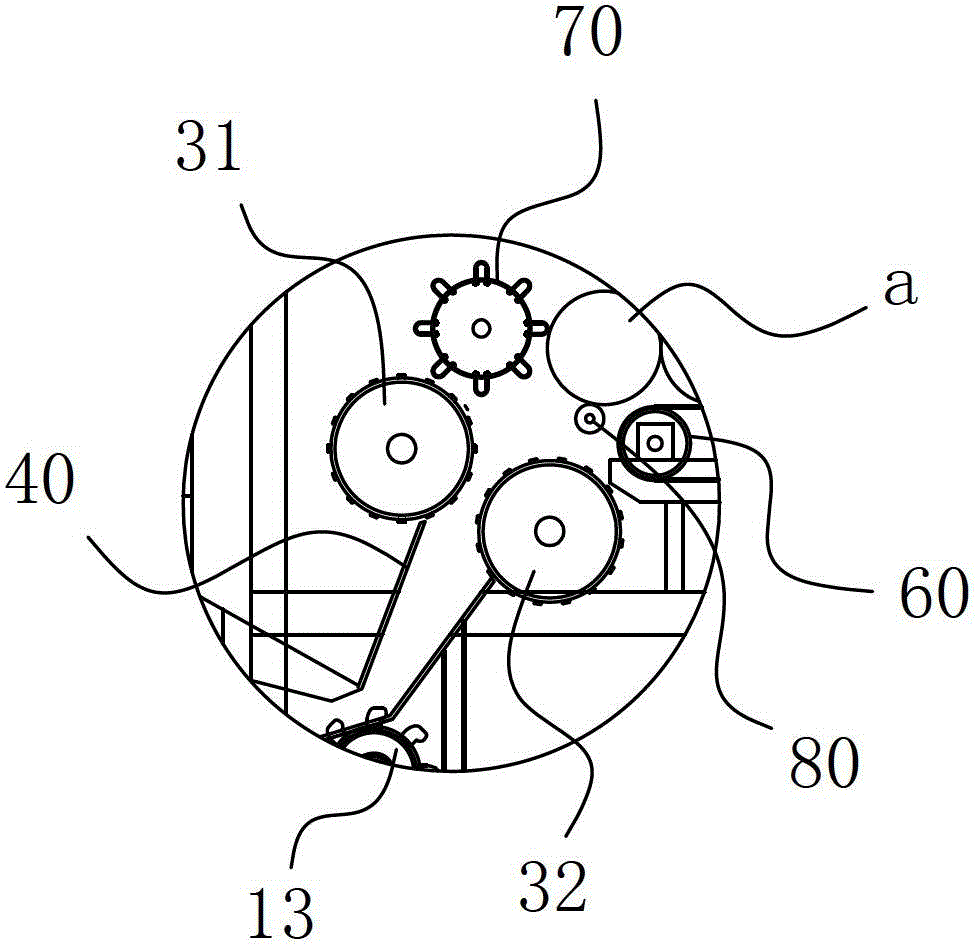

[0010] A straw incinerator comprises a combustion chamber 10 and a flue 20 for extracting heat energy in the combustion chamber 10, the combustion chamber 10 is provided with a delivery platform 11 for burning and transporting molded straw; the straw incinerator also Comprise rigid extruding unit 30, rigid extruding unit 30 comprises the two extruding parts that mutually constitute extruding fit, and described at least one extruding part is pressure roller; The extruding gap of described rigid extruding unit 30 and straw The thickness to be extruded is consistent, and its outlet conveying path points to the table where the feeding end of the conveying platform 11 is located, actually as Figure 1-4 shown.

[0011] As a further preferred solution of the present invention: the outlet end of the flue 20 is connected to the air inlet chamber of the external combustion furnace, and the flue 20 communicates with the combustion chamber 10 through the vent at the top of the combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com