Technology for incinerating volatile organic gases and circulating fluidized bed incinerator utilizing technology

A volatile organic, circulating fluidized bed technology, which is applied to the field of circulating fluidized bed incinerators and their incineration processes, can solve the problems of low volatile organic gas concentration, low incineration air volume requirements, and large required fluidization wind speed. , to achieve the effect of reducing fluidizing air volume, reducing operating costs, and low fluidizing air speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

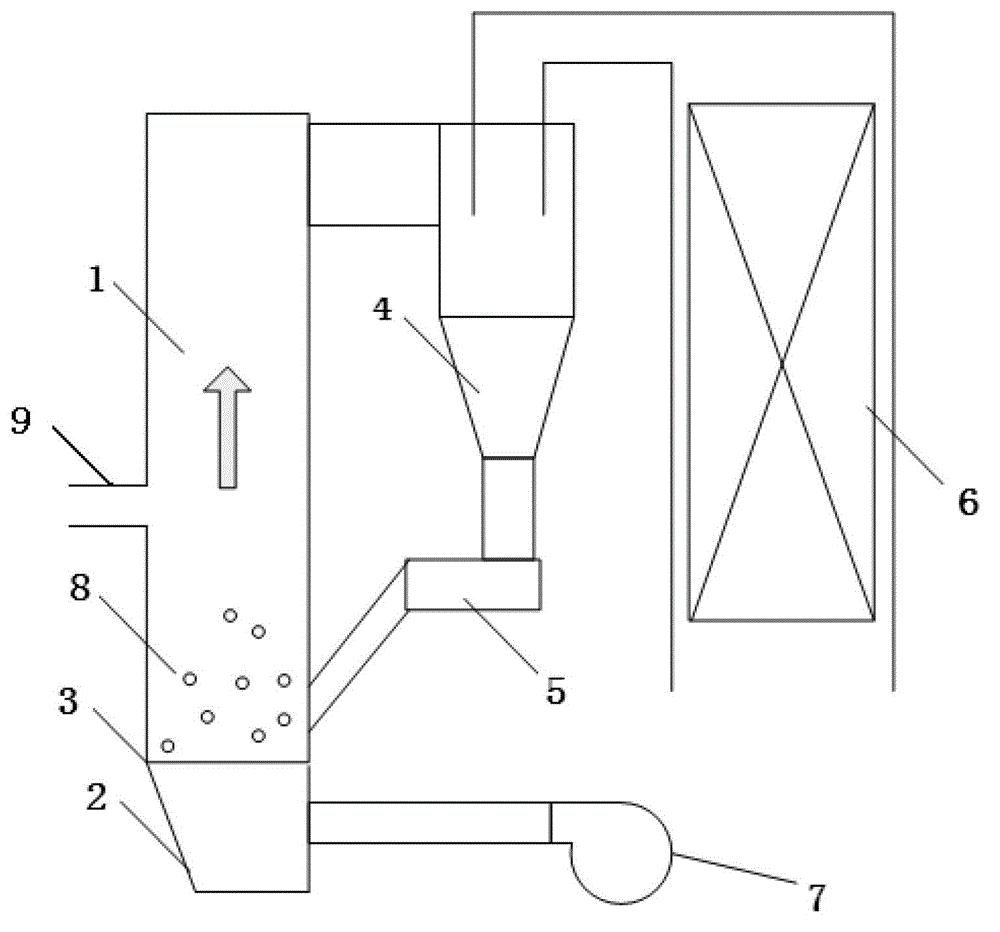

[0033] Attached below figure 1 , to further illustrate the structure and operation process of the circulating fluidized bed volatile organic gas incinerator of the present invention.

[0034] Such as figure 1 As shown, the circulating fluidized bed volatile organic gas incinerator of the present invention includes: a furnace 1, an air chamber 2 positioned at the bottom of the furnace 1, a gas inlet 9 arranged in the middle of the furnace, and a separator communicated with the top of the furnace 1 4. The separator 4 has a top outlet and a bottom outlet, a tail flue 6 communicating with the top outlet, a return pipe 5 for connecting the bottom outlet and the furnace, an air distribution plate 3, and an air distribution plate 3 between the bottom of the furnace and the air chamber. The chamber 2 is externally connected with a fluidizing fan 7 through a pipeline.

[0035] A layer of aluminum oxide hollow balls 8 with a thickness of 400 mm is laid on the bottom of the furnace 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com