ArH cleaning method for carbon pollution on surface of optical element

A technology for optical components and carbon pollution, applied in optical components, optics, instruments, etc., can solve the problems of low efficiency of hydrogen atom clearing, achieve the effects of avoiding adverse effects, improving cleaning efficiency, and maintaining particle activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

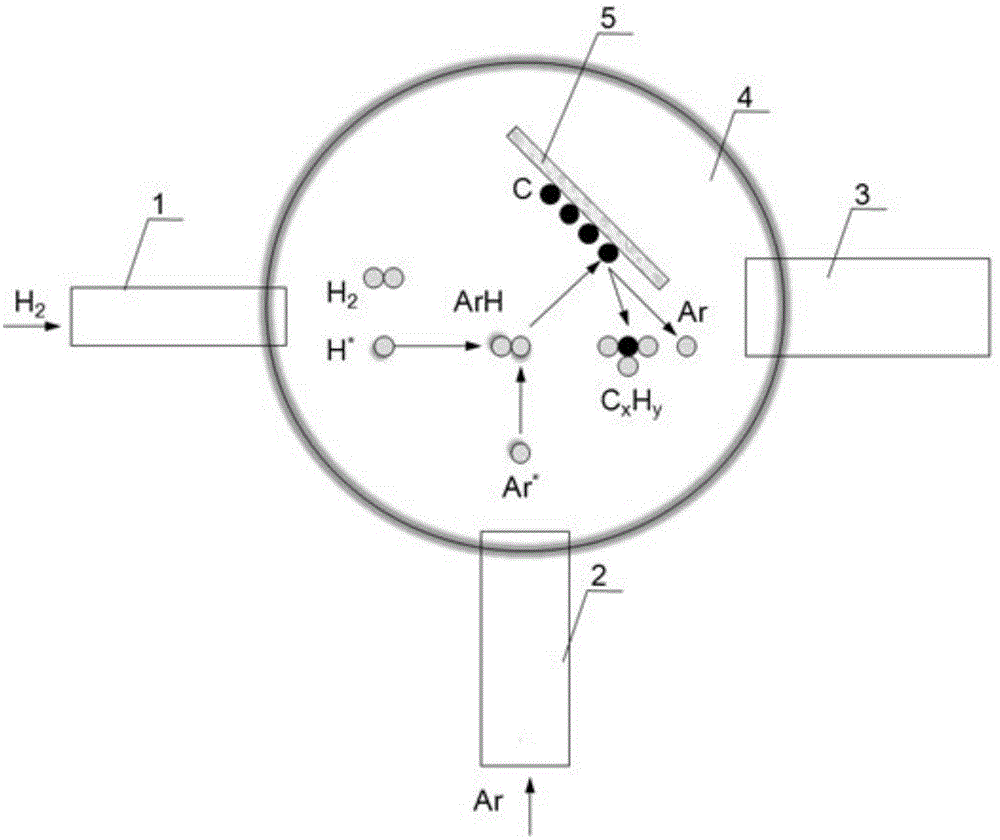

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, the cleaning method of the present invention is specifically described by taking the cleaning of carbon contamination on the surface of the Mo / Si multilayer film of the EUV optical element as an example.

[0017] The specific implementation process of the ArH cleaning method for carbon contamination on the surface of optical components is as follows:

[0018] In the first step, the optical element sample 5 contaminated by carbon exposure is placed in the cleaning chamber 4, and the vacuum pump 3 is used to make the cleaning chamber 4 reach a vacuum degree of 10 -5 above mbar.

[0019] The second step is to start the radio frequency plasma emitter 2, the radio frequency is 13.56MHz, and the argon gas is fed in, and the supply flow rate is 2 sccm, so that the whole cleaning chamber 4 is filled with excited argon particles, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com