A spray tower for flue gas desulfurization and its running method

A spray tower and flue gas technology, applied in the field of flue gas purification, can solve the problems of high equipment investment and operating costs, complex spray tower system, large slurry circulation volume, etc., achieve low construction cost, prolong residence time, reduce The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

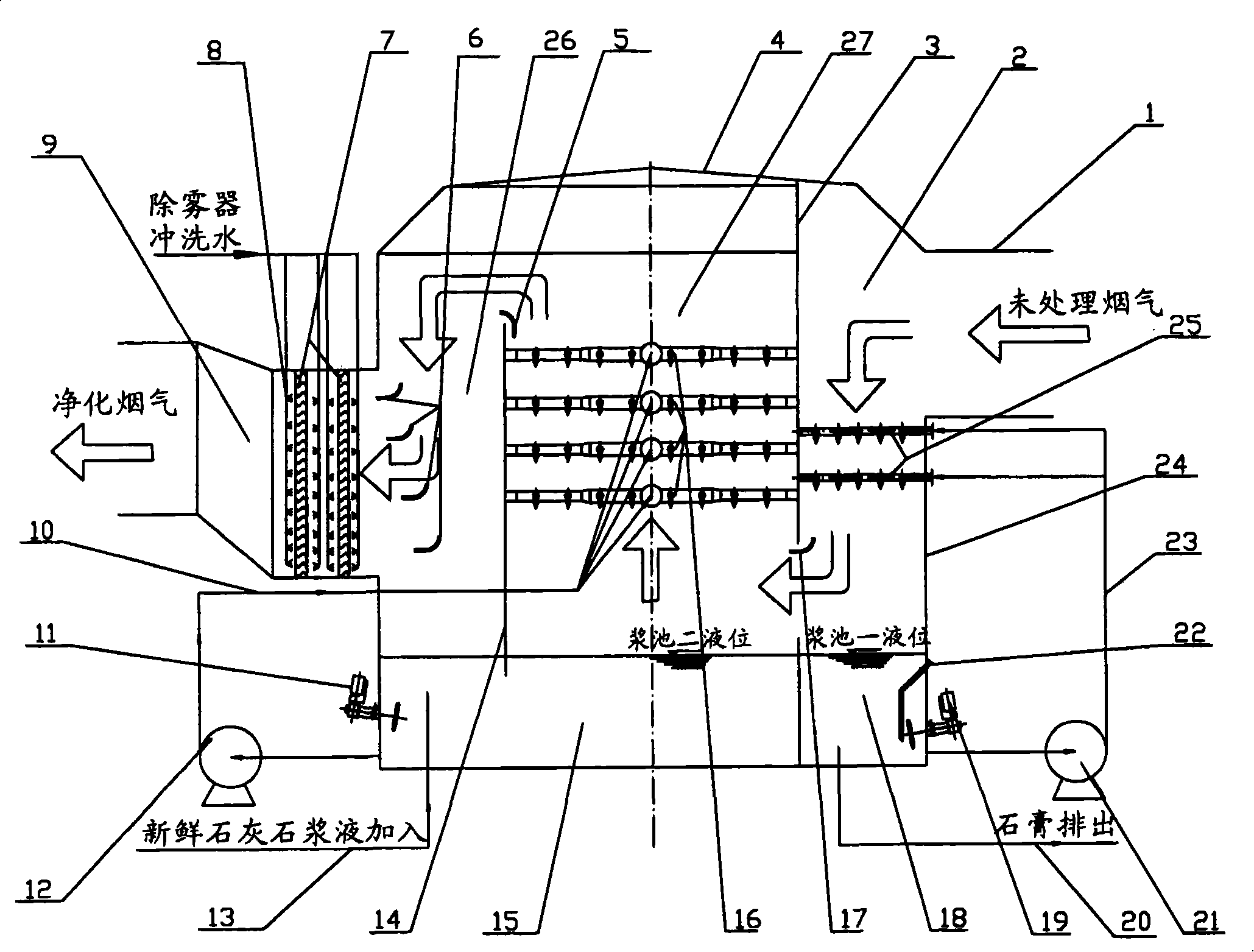

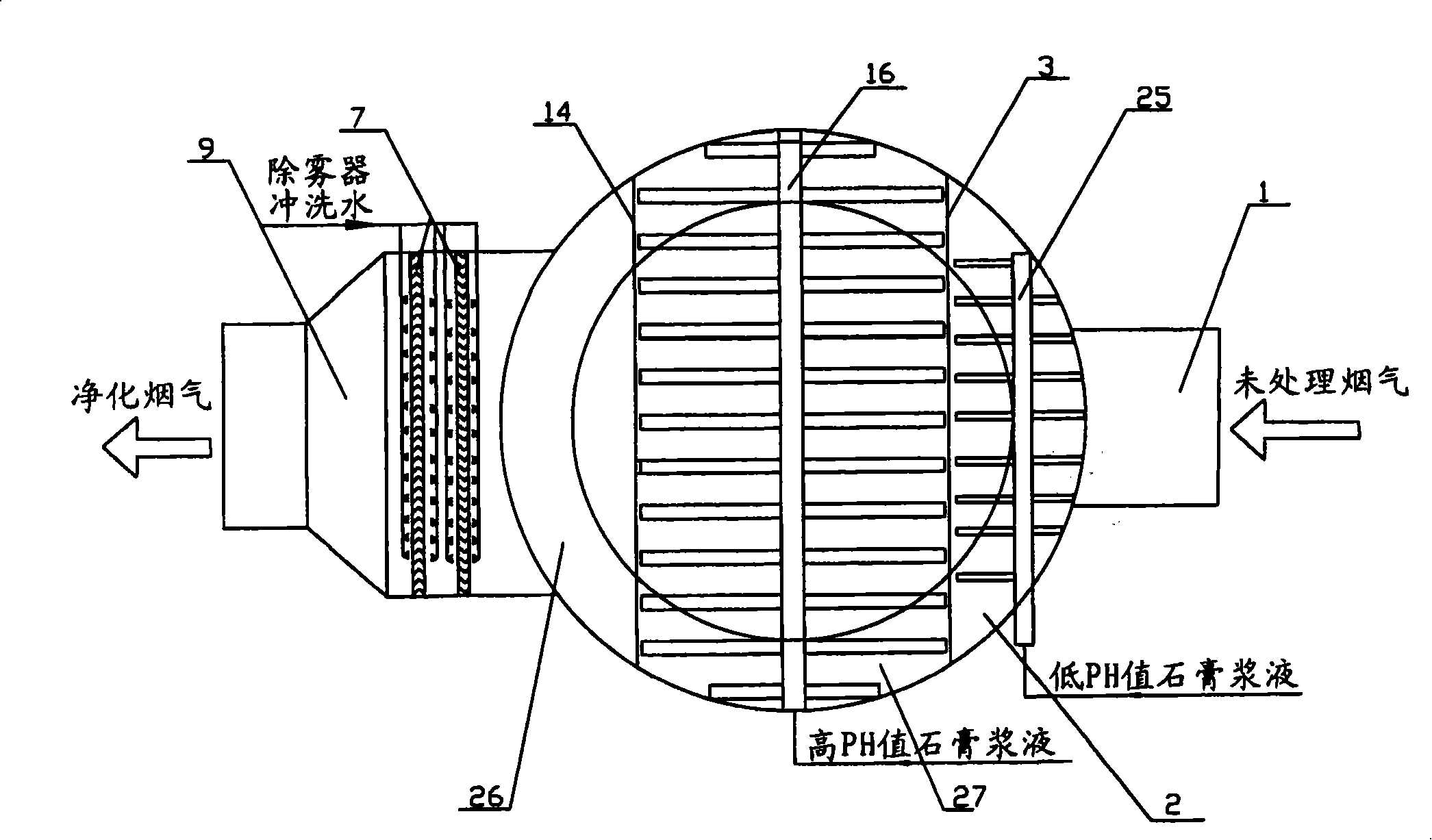

[0029] A spray tower for the flue gas desulfurization device of a 600MW coal-fired generator set, with a flue gas flow rate of 2 million standard cubic meters per hour, and a sulfur dioxide content of 2000 ppm in the flue gas. The absorbent used is limestone powder passing 90% of 325 mesh.

[0030] The spray tower is composed of a tower body 24, a tower top 4, a flue gas inlet 1, and a flue gas outlet 9. The diameter of the tower body 24 is 21.28 meters, the gypsum slurry level in the slurry pool is 4.3 meters, and the height of the tower top is 21.9 meters. The upper edge of the flue gas inlet 1 is level with the top of the spray tower, and the size of the flue gas inlet 1 is 4890H×14670L. A mist eliminator 8 is installed in the flue gas outlet 9. The size of the mist eliminator 8 is 9550H×17210L×5000W. The demister is provided with four spray layers to prevent fouling. The flue gas outlet 9 is equipped with a demister. The lower edge of the mister area is 1 meter higher than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com