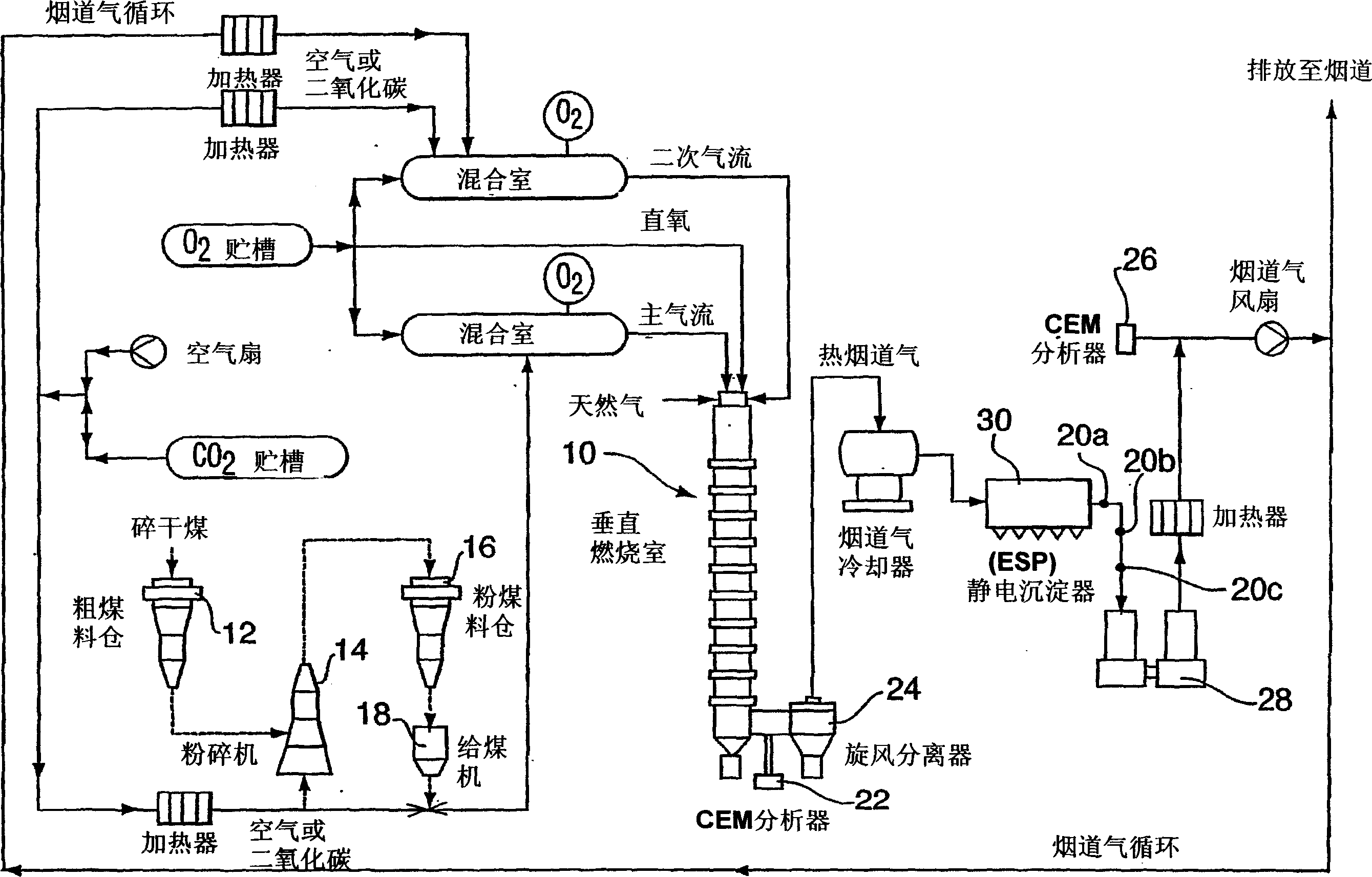

Flue gas purification method

A flue and airflow technology, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of complexity of smoke flow control, low efficiency of sulfur trioxide or sulfuric acid aerosol removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Inject NaHCO at a rate of 6.6 kg / hr at 150C over a short period of time (5 minutes) at all three ports 20a, 20b, 20c 3 , to observe it for SO 2 and NO x concentration effect. This was followed by a 1 hour continuous injection at port 20a after the short injection.

[0055] Sodium carbonate (Na 2 CO 3 ) aqueous solution was used as the wash solution and was added during the test to maintain the solution pH at approximately 7.

[0056] Table 3 - Flue gas composition before injection

[0057] Note that all concentrations are reported on a volumetric and dry basis.

[0058] Injection of sodium bicarbonate started at 0240 pm at port 20c (0.5 sec residence time) followed by ports 20b and 20a for 5 min each. Table 4 summarizes the flue gas composition at the time of injection.

[0059] Table 4 - During short-term (5min) sorbent injection,

[0060] Table 5 - At 1 hour sorbent injection at port 20a, at combustion

[0061] NaHCO 3 Injection i...

Embodiment 2

[0068] This test is performed by injecting NaHCO at three ports at a flow rate of 5.5kg / hr and an injection temperature of 150°C 3 conduct. The injection time at each port lasted 1 hour. Pre-filled wash solution: 1 kg of Na dissolved in 1871 water 2 CO 3 , 29kg of Na 2 SO 4 and 19kg of Na 2 SO 3 . The pH of the prepared solution was about 10.6.

[0069] Start injecting NaHCO at port 20c 3 , and subsequently at ports 20b and 20a. Immediately after each injection is complete, the filter downstream of the injection port CEM system is changed to ensure an accurate readout of the flue gas composition.

[0070] Table 8 - Flue gas composition before injection

[0071] NaHCO injection started at 1237am at port 20c (0.5sec residence time) 3 , followed by 20a, each port lasted 60min. Table 9 summarizes the flue gas composition at the time of injection.

[0072] Table 9 - Flue gas composition during injection

[0073] As can be seen from the data shown ab...

Embodiment 3

[0075] In this example, NaHCO was performed at three ports at a flow rate of 7.7 kg / hr and an injection temperature of 150°C. 3 Injection. The injection time at each port lasted 1 hour. Pre-filled wash solution: 1 kg of Na dissolved in 1871 water 2 CO 3 , 29kg of Na 2 SO 4 and 19kg of Na 2 SO 3 . The pH of the prepared solution was about 10.6.

[0076] Start injecting NaHCO at port 20c 3 , followed by 20a.

[0077] Table 10 - Average Injection Temperature (°C)

Port 20a

Port 20b

Port 20c

upstream

downstream

upstream

downstream

upstream

downstream

155±3

132±5

157±1

133±0

157±5

139±5

[0078] Table 11 - Flue gas composition before injection

combustion chamber outlet

Scrubber inlet

O 2 (%)

2.14±0.33

4.38±0.19

CO 2 (%)

15.95±0.29

14.23±0.45

CO (ppm)

10±85

28±5

NO x (ppm)

545±1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com