Method for recovering selenium, mercury, gold and silver from acid sludge

A technology for recovering selenium and acid sludge, applied in the field of recovering selenium, gold, silver, and mercury from acid sludge, can solve the problems of low recovery rate of valuable elements, complicated process, affecting product purity, etc., and achieve high added value of products. , the process is short, the effect of low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment includes the following steps:

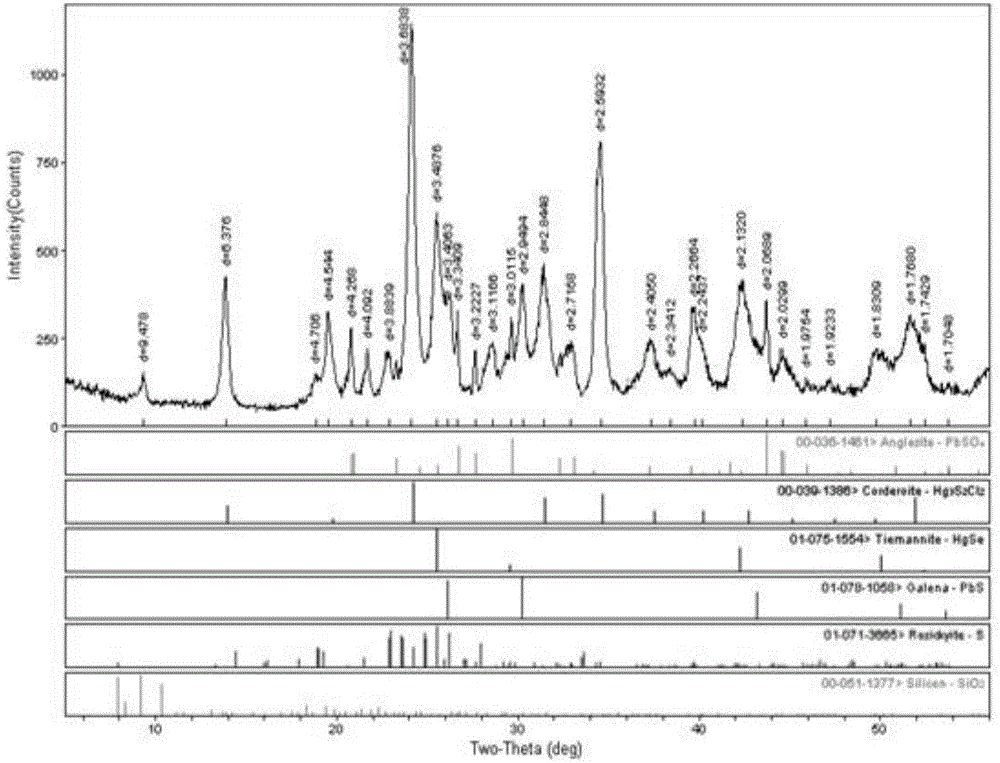

[0022] Step 1, place the 80g acid mud produced in the process of making acid from sulfide ore roasting flue gas in a tube furnace, and carry out roasting treatment under protective atmosphere conditions to produce 6.0g roasting slag and flue gas containing gaseous mercuric selenide; The temperature of the roasting treatment is 560°C, the time is 120min, and the protective atmosphere is a nitrogen atmosphere; the mass content of selenium in the acid mud is 16.28%, the mass content of mercury is 60%, and the mass content of gold is 11.22g / t, the mass content of silver is 366.5g / t;

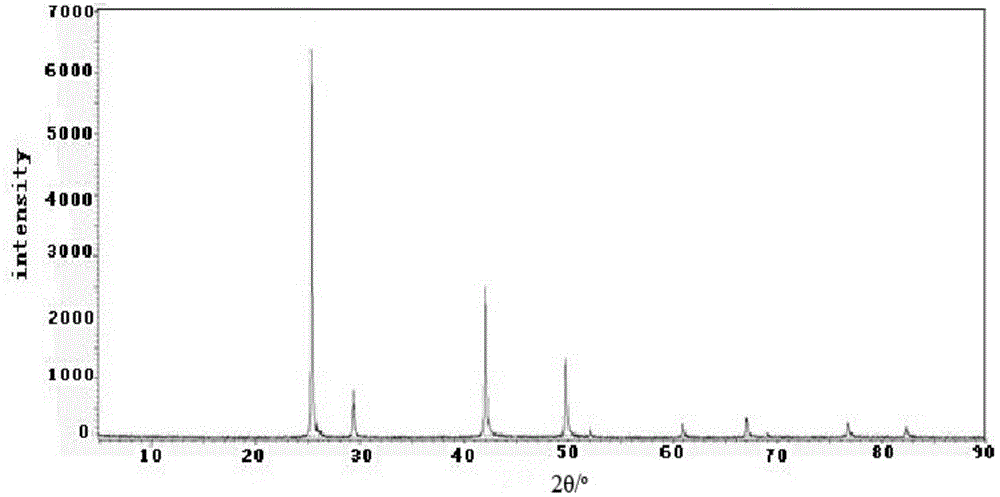

[0023] Step 2, cooling the flue gas described in step 1, cooling the gaseous mercuric selenide in the flue gas into solid mercuric selenide, realizing the recovery of selenium and mercury in the acid mud; the specific mode of the cooling treatment is: Pass the flue gas into water to cool and precipitate the gaseous mercury selenide in the flue ...

Embodiment 2

[0028] This embodiment includes the following steps:

[0029] Step 1, place the 160g acid mud produced in the acid production process with sulfide ore roasting flue gas in a tube furnace, and carry out roasting treatment under protective atmosphere conditions to produce 12.5g roasted slag and flue gas containing gaseous mercuric selenide; The temperature of the roasting treatment is 580°C, the time is 100min, and the protective atmosphere is an argon atmosphere; the mass content of selenium in the acid mud is 16.28%, the mass content of mercury is 60%, and the mass content of gold is 11.22g / t, the mass content of silver is 366.5g / t;

[0030] Step 2, cooling the flue gas described in step 1, cooling the gaseous mercuric selenide in the flue gas into solid mercuric selenide, realizing the recovery of selenium and mercury in the acid mud; the specific mode of the cooling treatment is: Pass the flue gas into water to cool and precipitate the gaseous mercury selenide in the flue ...

Embodiment 3

[0035] This embodiment includes the following steps:

[0036] Step 1, place 100g of acid mud produced in the process of producing acid from sulfide ore roasting flue gas in a tube furnace, and carry out roasting treatment under protective atmosphere conditions to produce 20g of roasted slag and flue gas containing gaseous mercury selenide; The temperature of roasting treatment is 540 ℃, and the time is 140min, and described protective atmosphere is argon gas atmosphere; The mass content of selenium in the described acid mud is 5.6%, and the mass content of mercury is 15.8%, and the mass content of gold is 4.5g / t, the mass content of silver is 101.7g / t;

[0037]Step 2, cooling the flue gas described in step 1, cooling the gaseous mercuric selenide in the flue gas into solid mercuric selenide, realizing the recovery of selenium and mercury in the acid mud; the specific mode of the cooling treatment is: Pass the flue gas into water to cool and precipitate the gaseous mercury se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com