COMBUSTION FLUE GAS NOx TREATMENT

a technology of combustion flue gas and nox treatment, which is applied in the direction of hydrogen sulfides, dissolving, and separation processes, can solve the problems of large failure of wet scrubbing desulfurization techniques used for so/sub>x /sub>removal from combustion flue gas, presence of pollutants in the combustion flue gas stream, etc., and achieves the reduction of nox concentration, nox concentration, and residual ammonia concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

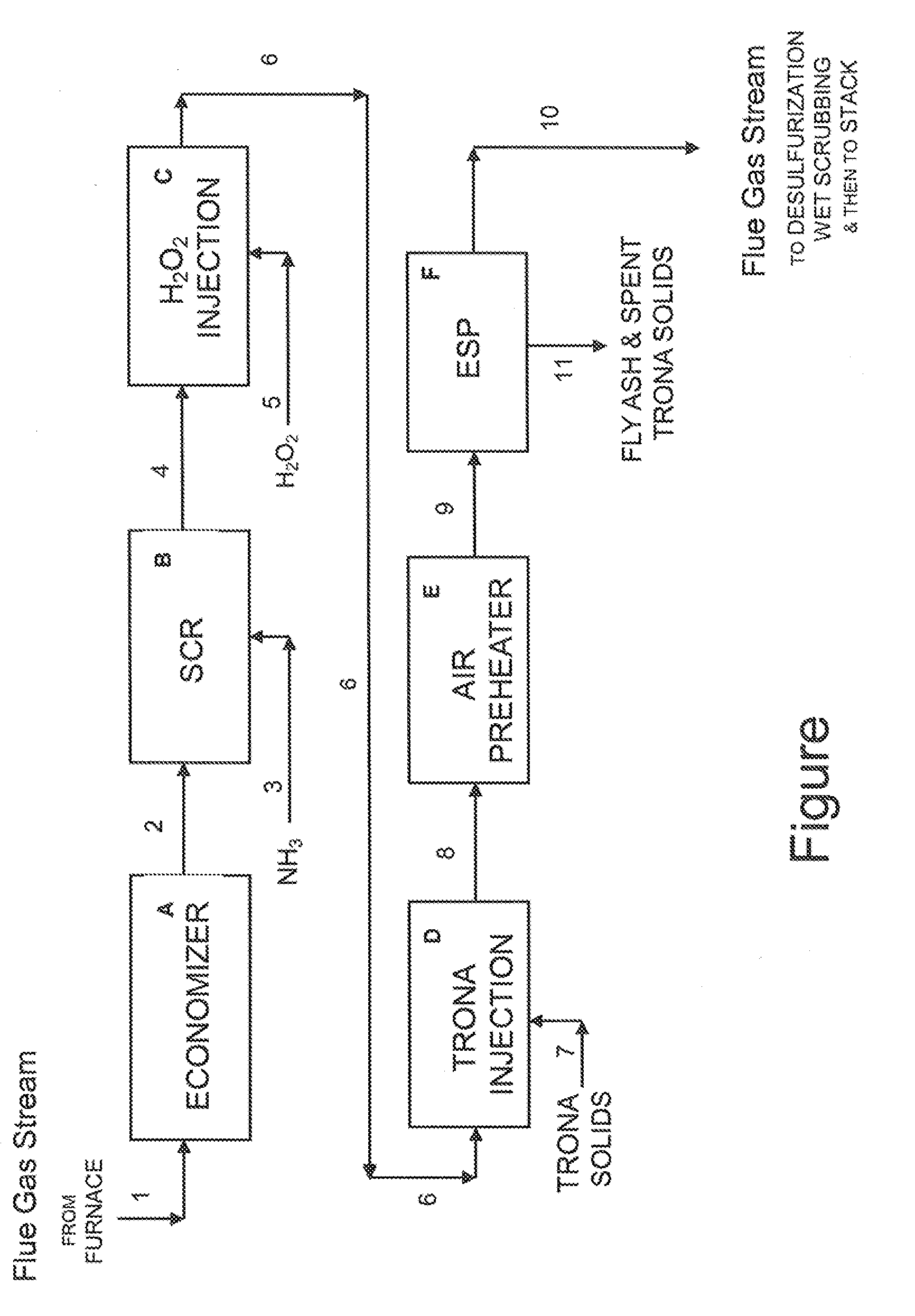

[0108]The Example illustrates the application of a preferred embodiment of the present invention to the NOX and SOX treatment of a flue gas stream from a combustion boiler utilizing high sulfur coal. The process is operated continuously, and normal steady state conditions are assumed for purposes of the Example. The FIGURE illustrates a schematic flow diagram of this preferred embodiment; reference numerals and letters in the FIGURE are included in the process description which follows. References to gaseous component concentrations in percentage (%), parts per million (ppm) or parts per billion (ppb) refer to such concentrations on a volume basis.

[0109]The coal used in the combustion unit of this Example is high sulfur coal containing 2 wt % sulfur. The combustion furnace is operated with preheated air, and it is assumed that there is 1% conversion of the sulfur in the coal to SO3 in flue gas from the combustion unit. The exit combustion flue gas stream 1 contains about 900 parts p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com