Patents

Literature

35results about How to "Reduce NOx concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

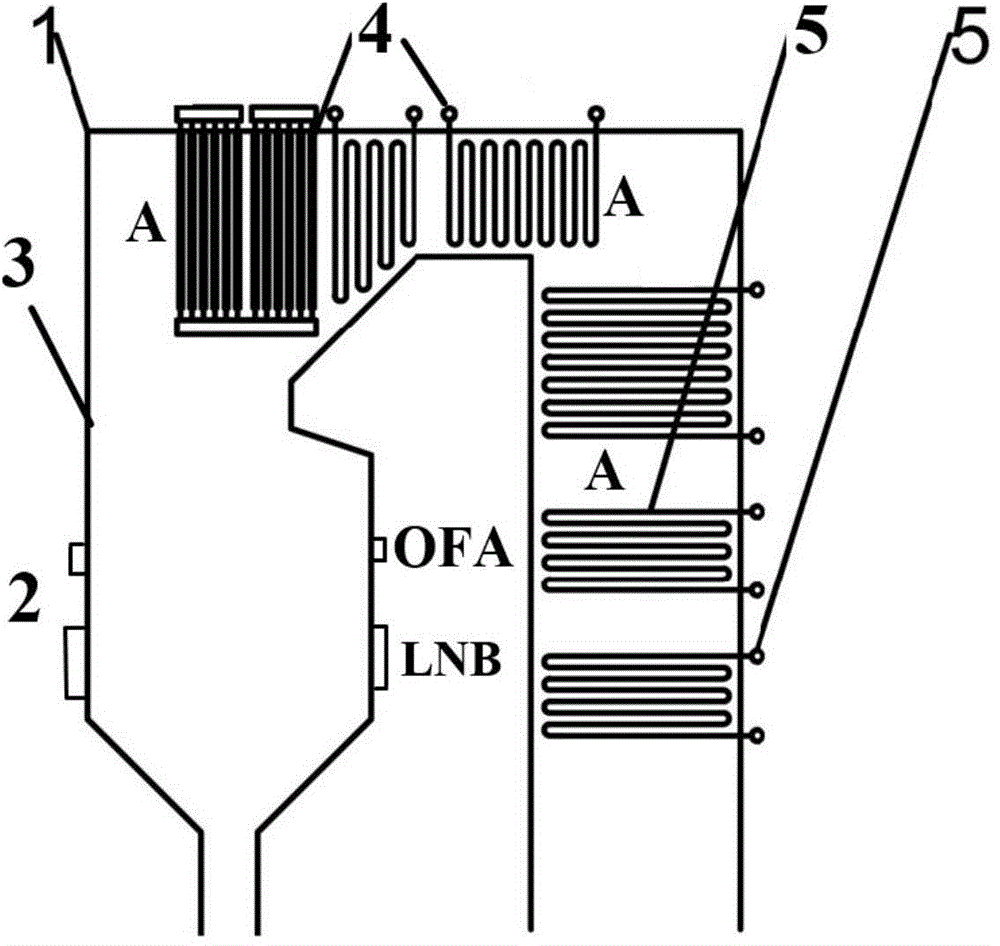

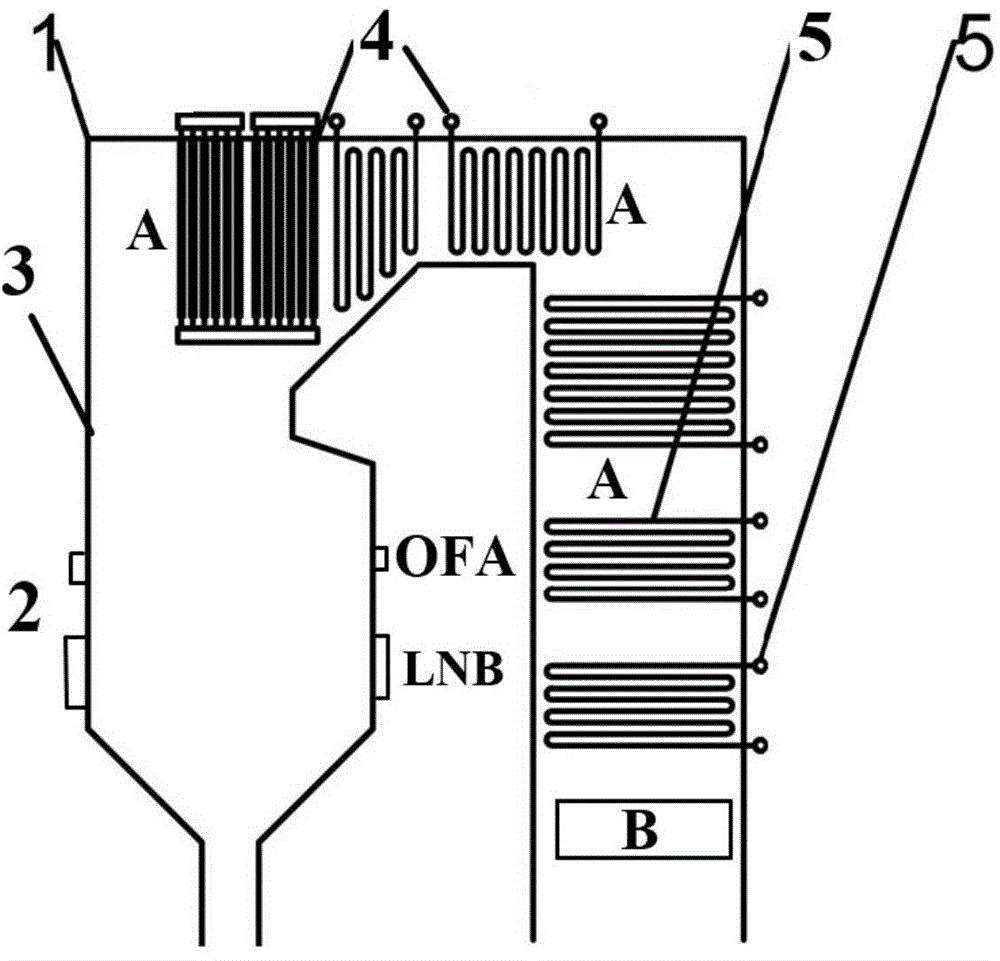

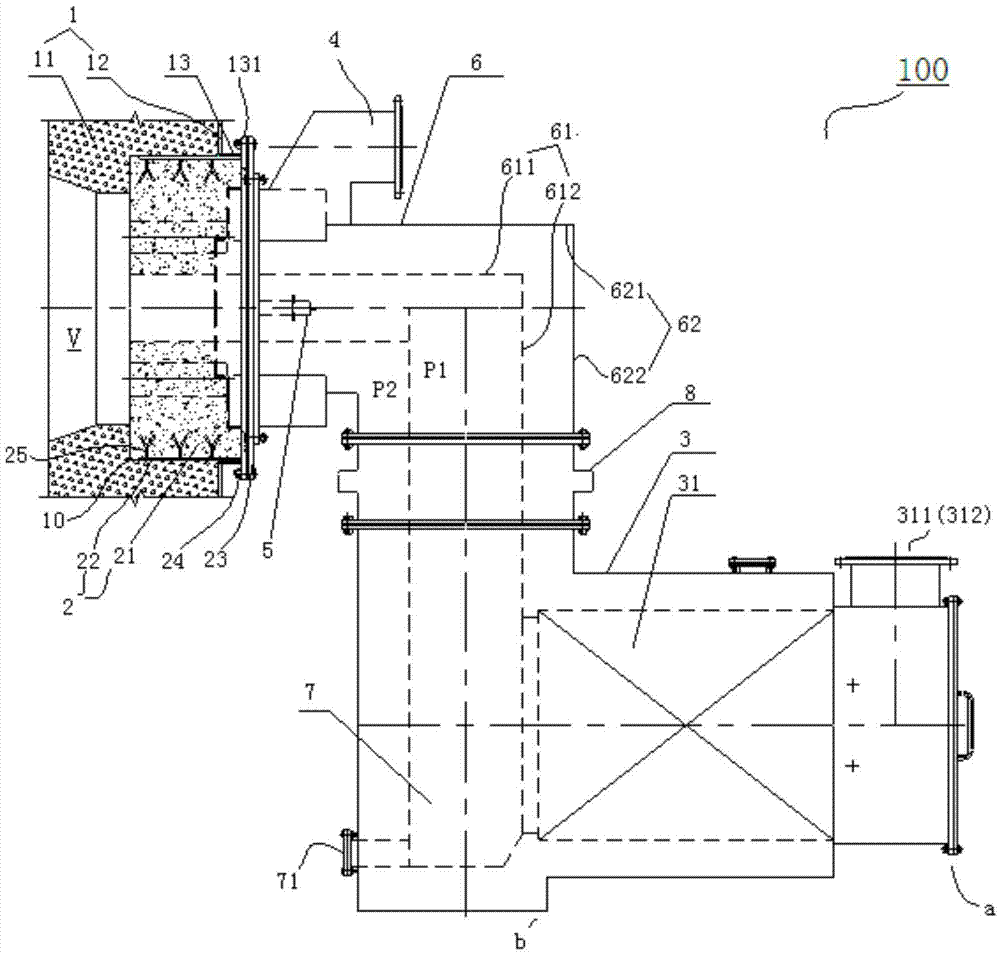

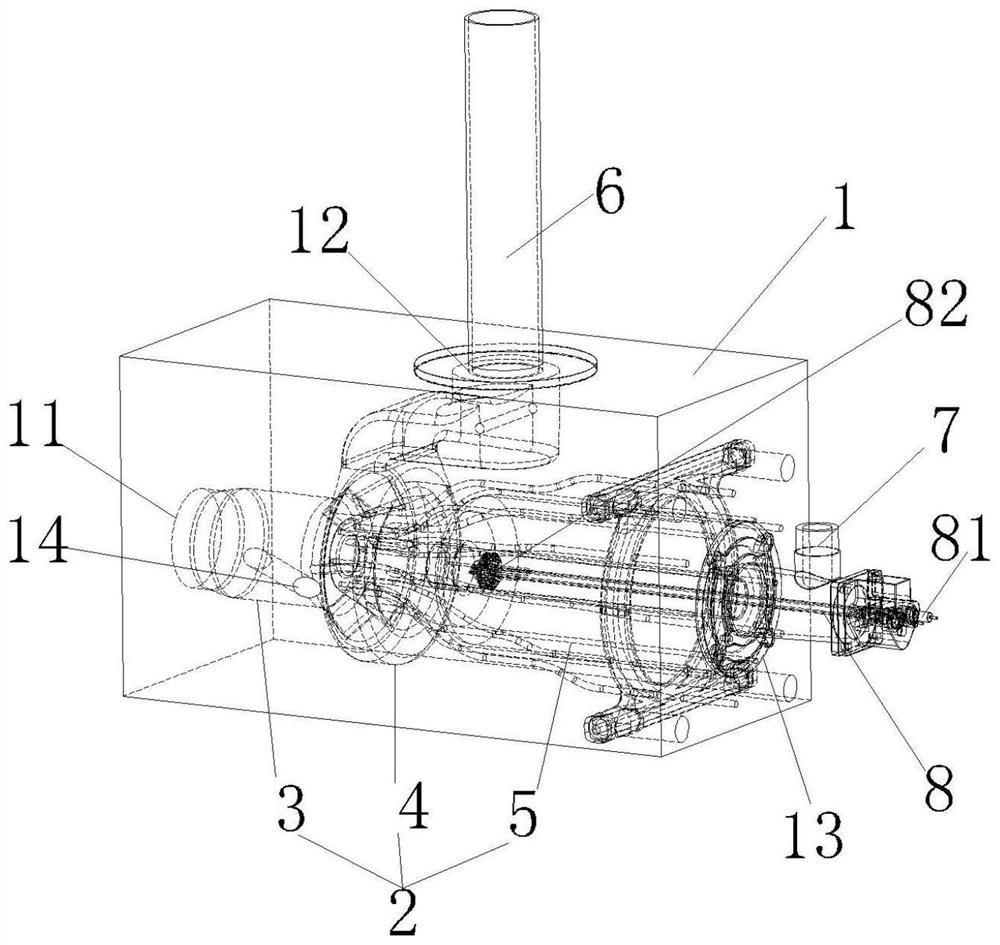

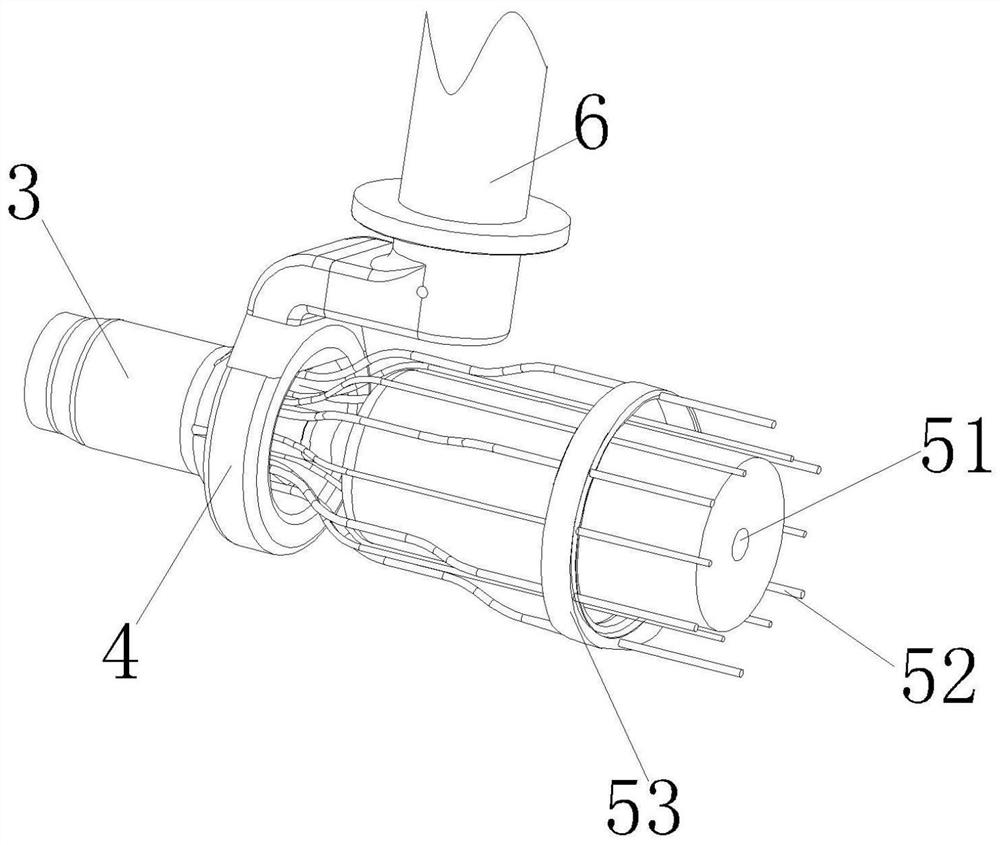

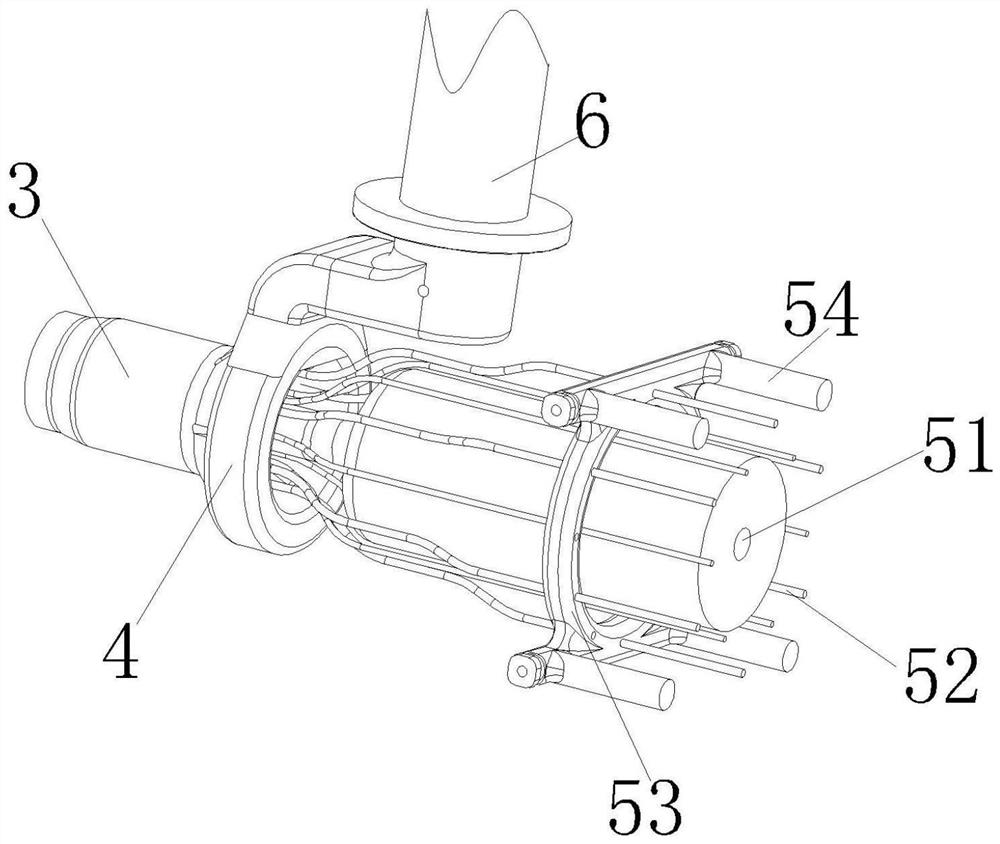

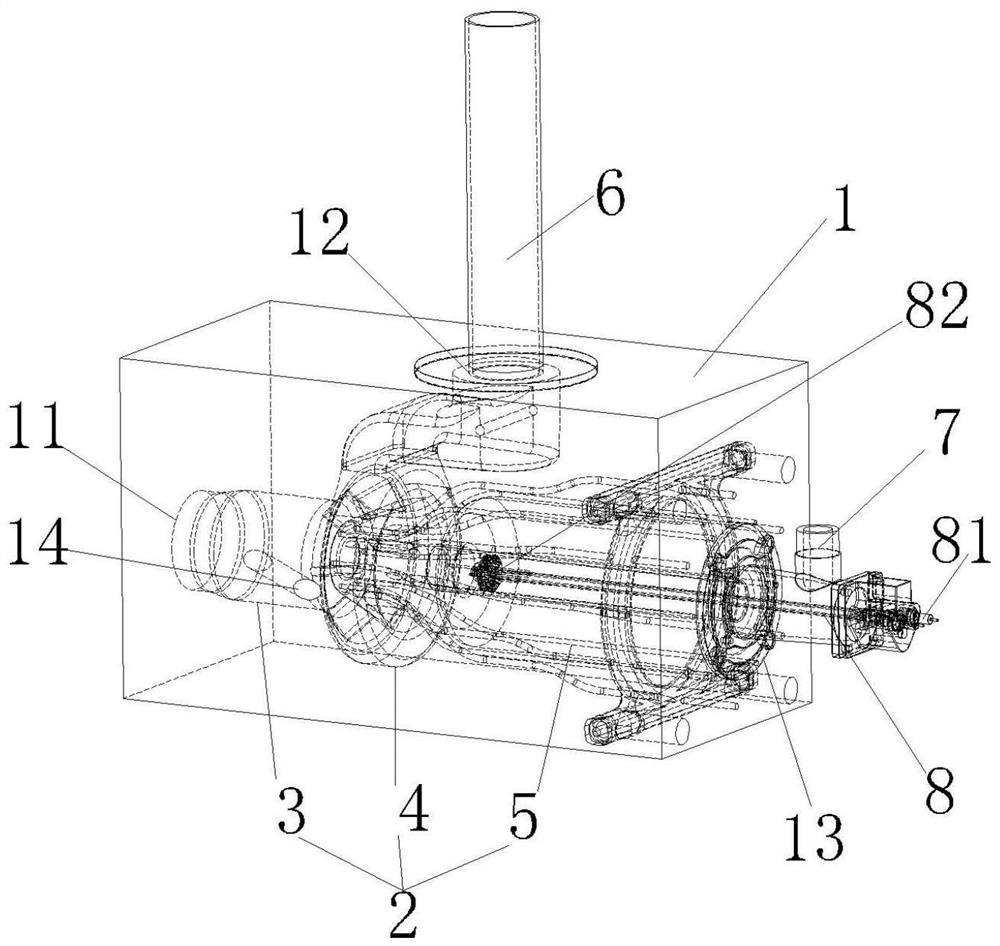

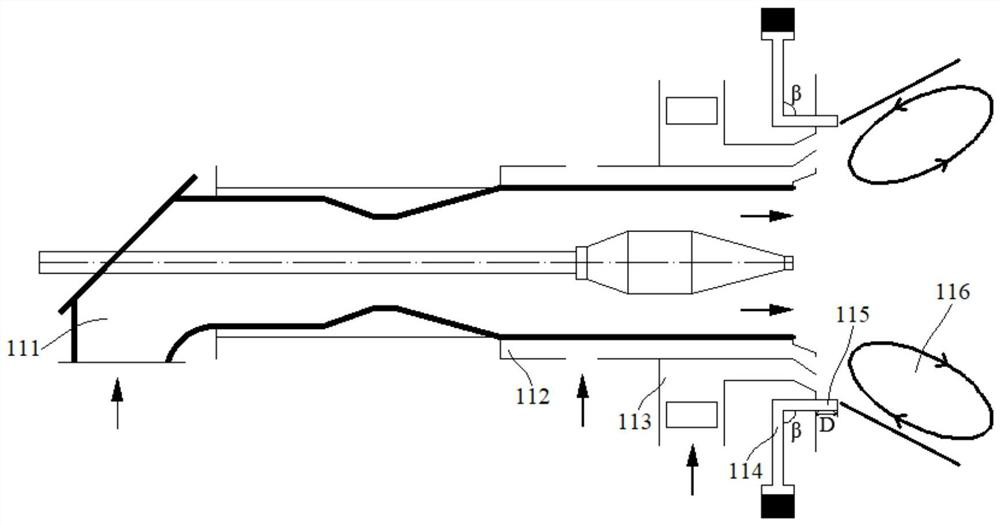

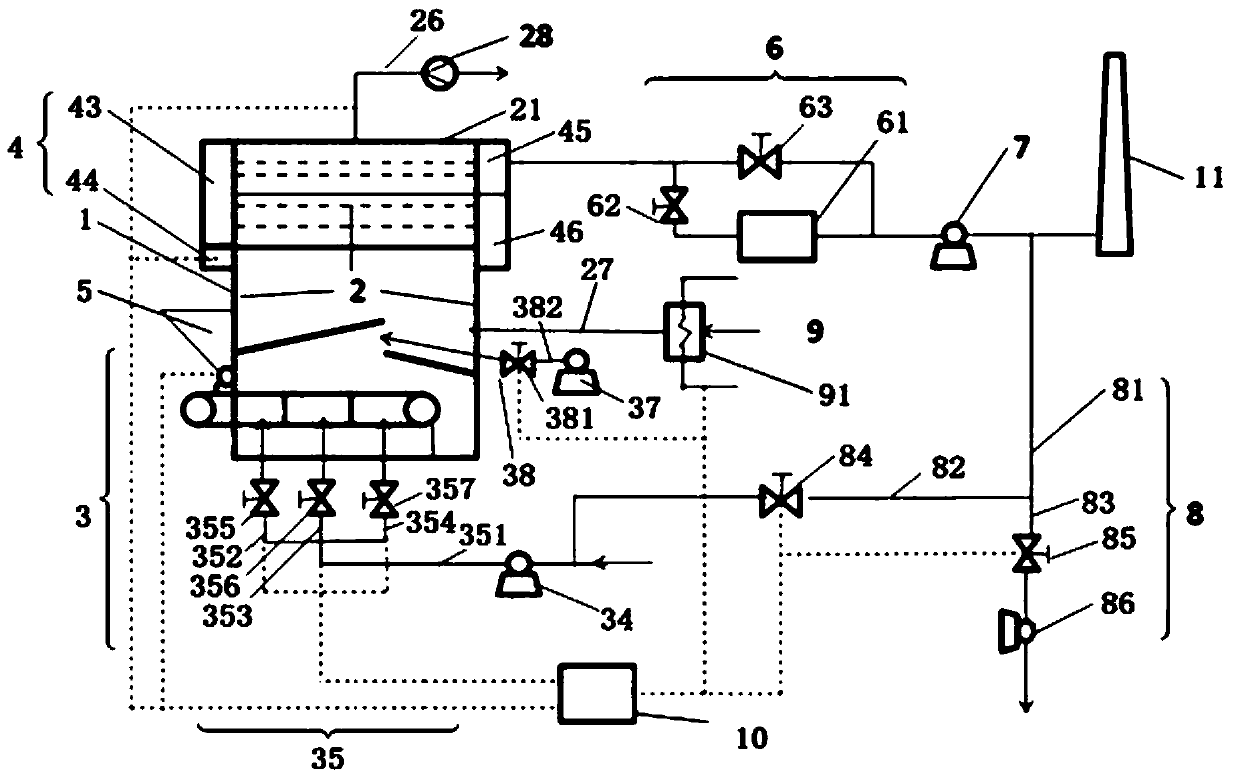

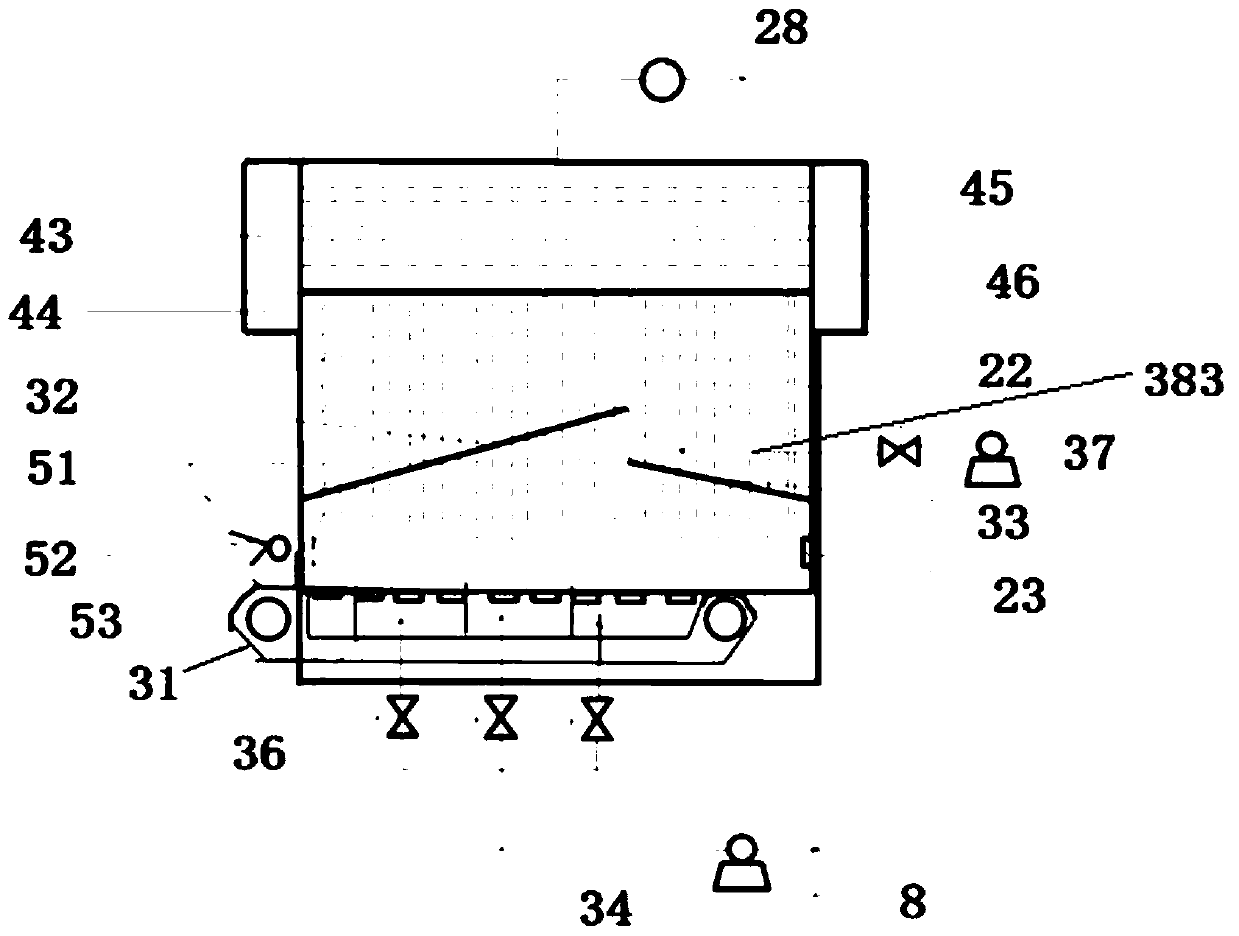

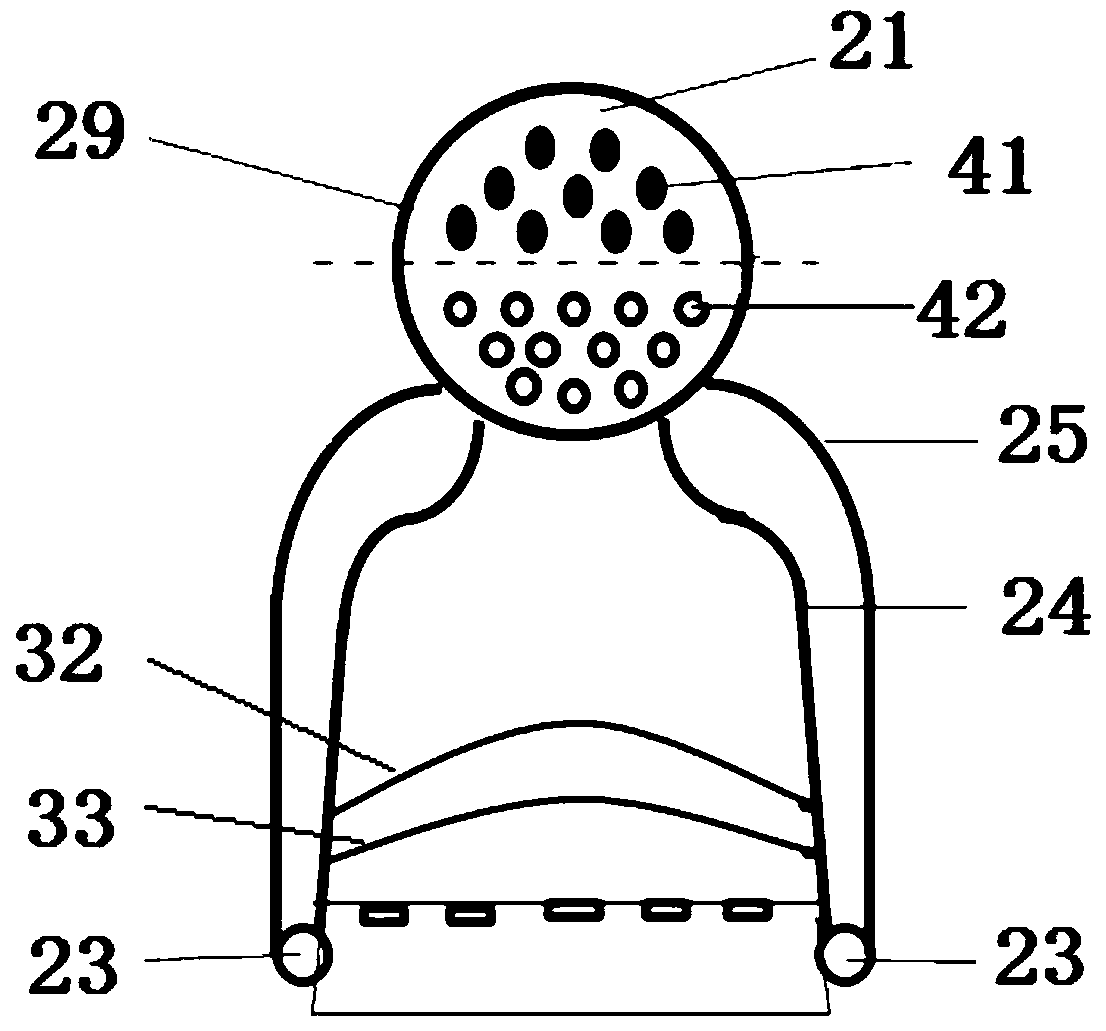

Pulverized coal fired boiler with ultralow nitric oxide emission

ActiveCN104896470AEmission reductionReduce NOx concentrationDispersed particle separationCombustion apparatusLow nitrogenNitric oxide

The invention provides a pulverized coal fired boiler with ultralow nitric oxide emission, and belongs to the technical field of coal-fired power generation and environmental protection. The pulverized coal fired boiler comprises a hearth, a boiler burner, a boiler internal water-cooled wall heating surface, a screen type heating surface and a convection heating surface, wherein the boiler burner is provided with a reducing agent generating device and can generate CO which is the reducing agent; NO and CO carry out reduction reaction and flue gas denitration is implemented; the boiler burner comprises a low-nitrogen burner (LNB) and over fire air (OFA); by the low-nitrogen burner, deep air classification is implemented so as to reduce the original production of the NO; the molar ratio of the CO which is the reducing agent to the NO is adjusted by the over fire air (OFA); and catalyst layers are respectively adhered to the boiler internal water-cooled wall heating surface, the screen type heating surface and the convection heating surface along a smoke flowing direction, or independent catalyst layers are arranged on a tail-end flue. The pulverized coal fired boiler with ultralow nitric oxide emission is simple in structure and runs stably; denitration reaction can be finished without the aid of amino reducing agents, the denitration efficiency is high, and the denitration cost is reduced obviously; and the pulverized coal fired boiler with ultralow nitric oxide emission can be in different scale grades.

Owner:HUANENG CLEAN ENERGY RES INST

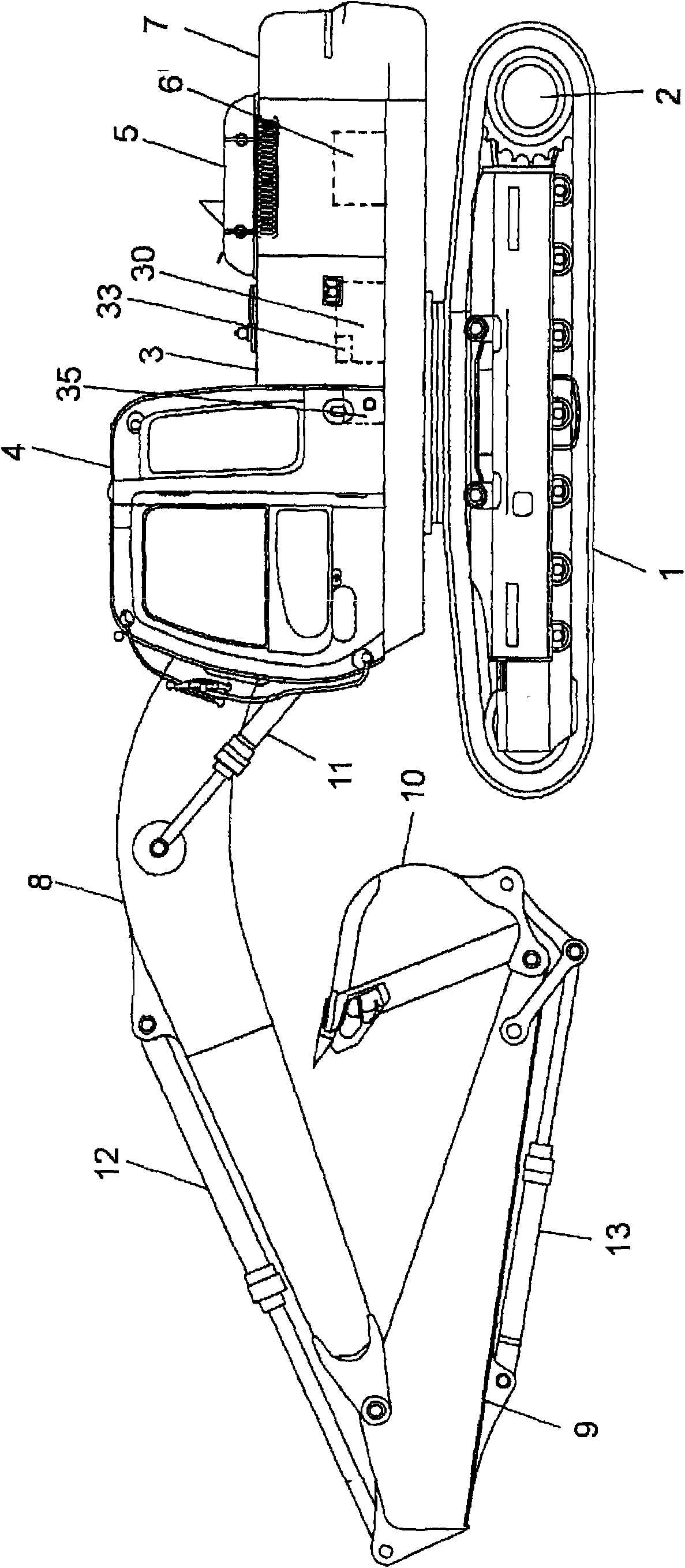

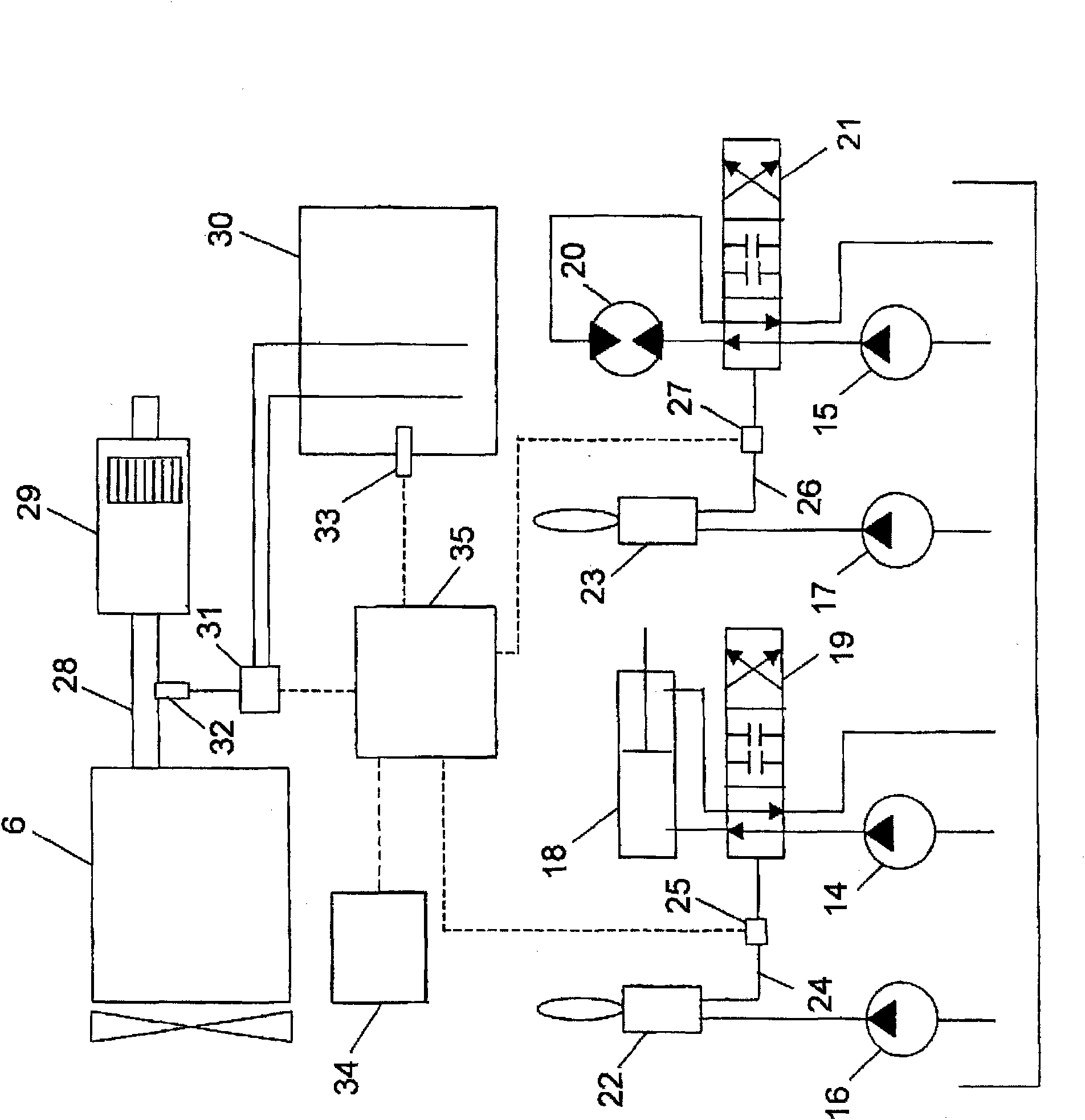

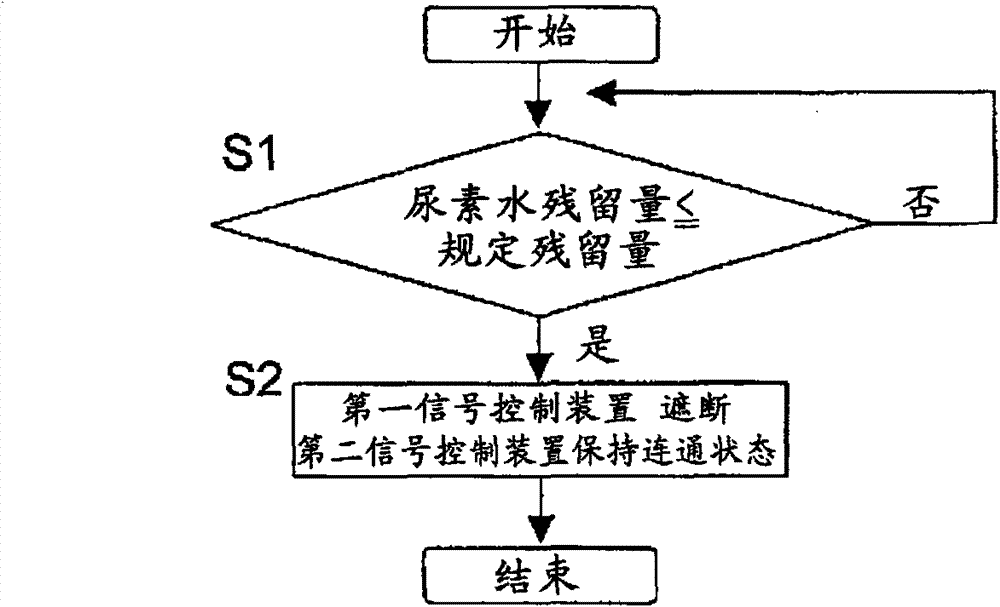

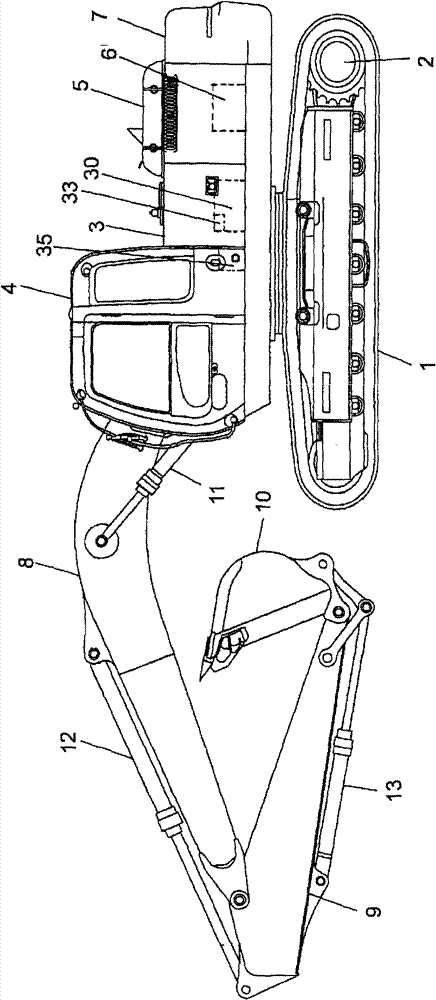

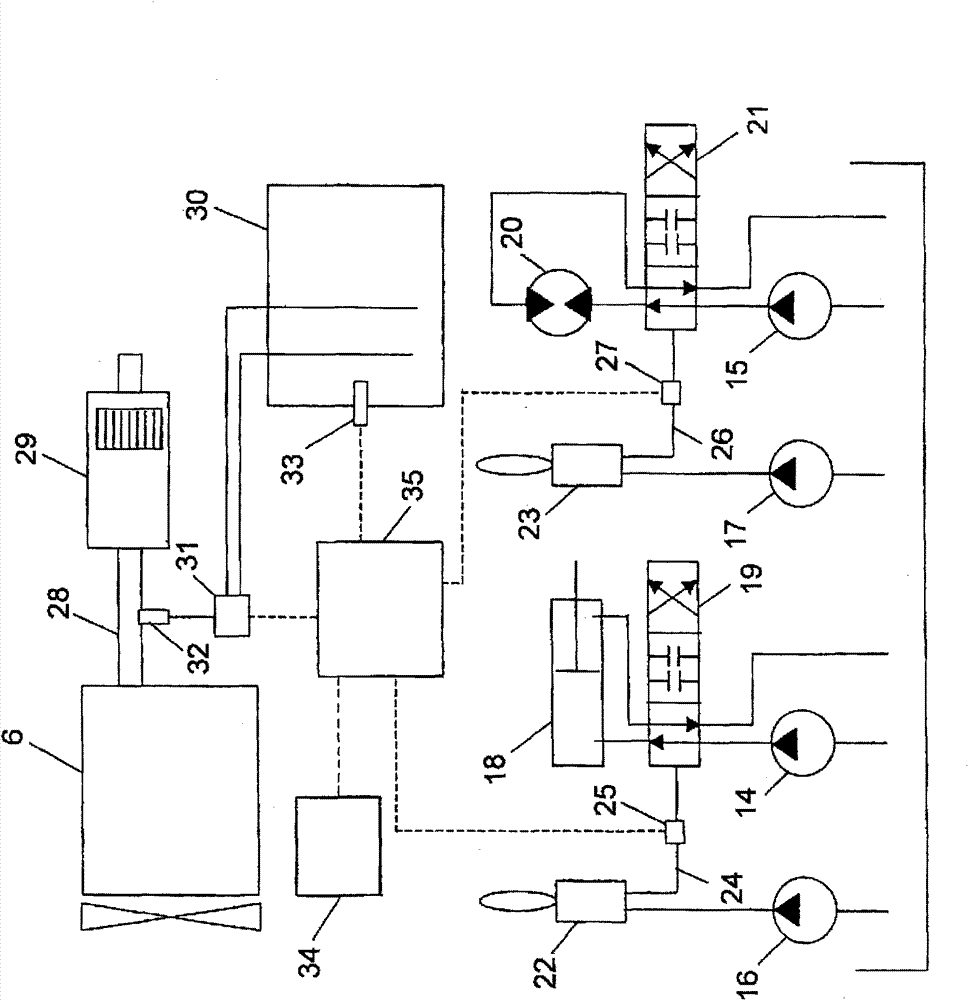

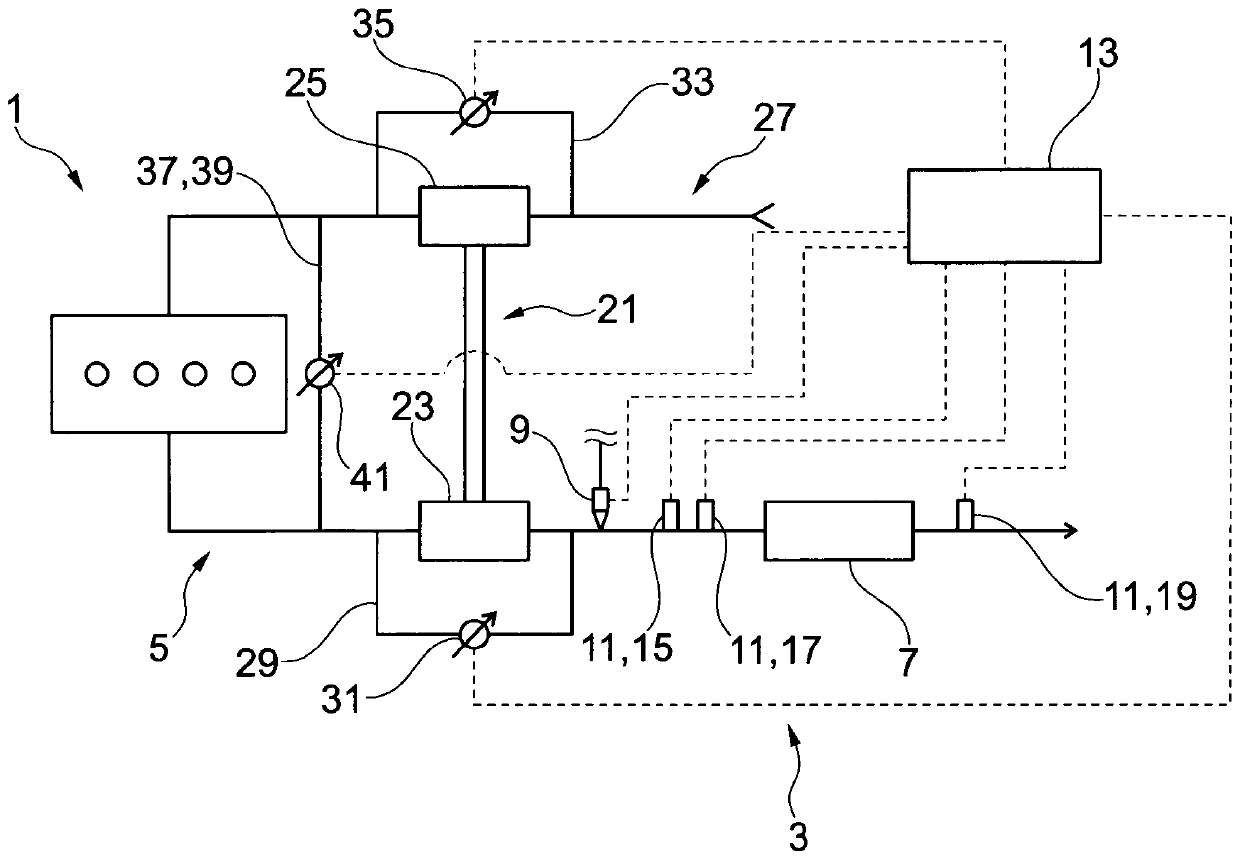

Construction machine

ActiveCN101680209ADegree of inhibition reductionImprove reliabilityInternal combustion piston enginesExhaust apparatusHydraulic motorHydraulic cylinder

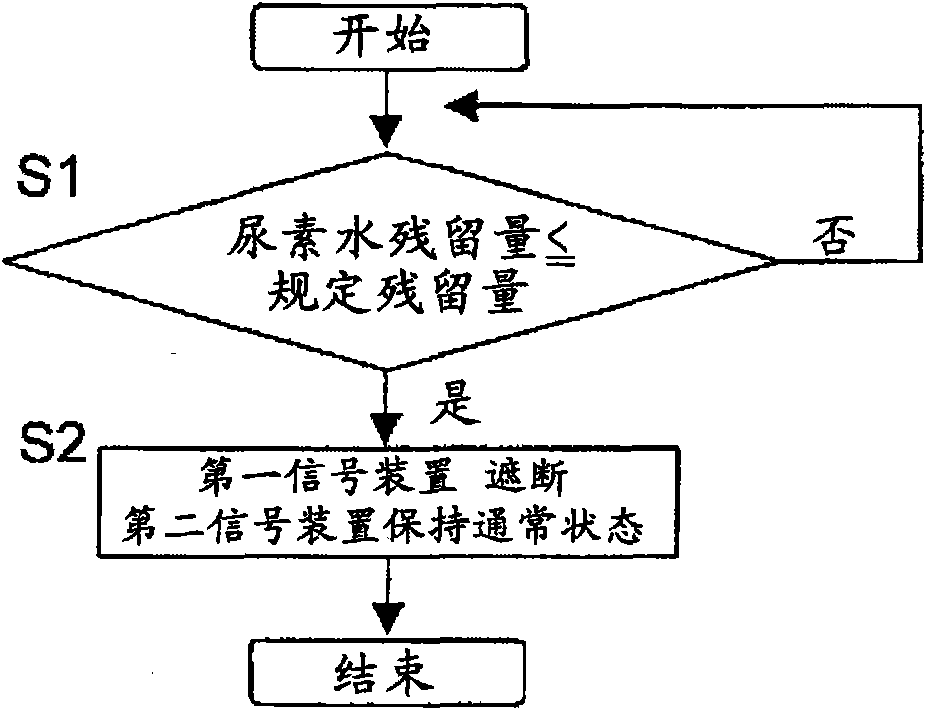

To provide a construction machine which can attain required operation with no trouble even when a residual quantity of a reducing agent is decreased. [MEANS FOR SOLVING PROBLEMS] A hydraulic shovel composed of an engine, a plurality of actuators including a hydraulic cylinder (18) and a hydraulic motor (20), and an exhaust gas processing unit for purifying nitrogen oxides in exhaust gas from the engine is provided. It includes an actuator operation control means which performs both of the regulation control for regulating operation of the hydraulic cylinder (18) such that a front working machine driven through the hydraulic cylinder (18) becomes difficult to excert its function when the residual quantity of a reducing agent in a reducing agent storage tank (30) detected by a reducing agent residual quantity detector (33) is below a predetermined level, and the sustention control for sustaining operation of the hydraulic motor (20) so that the function of a traveling body (1) and a turning body (3) driven through the hydraulic motor (20) can be exhibited.

Owner:NIHON KENKI CO LTD

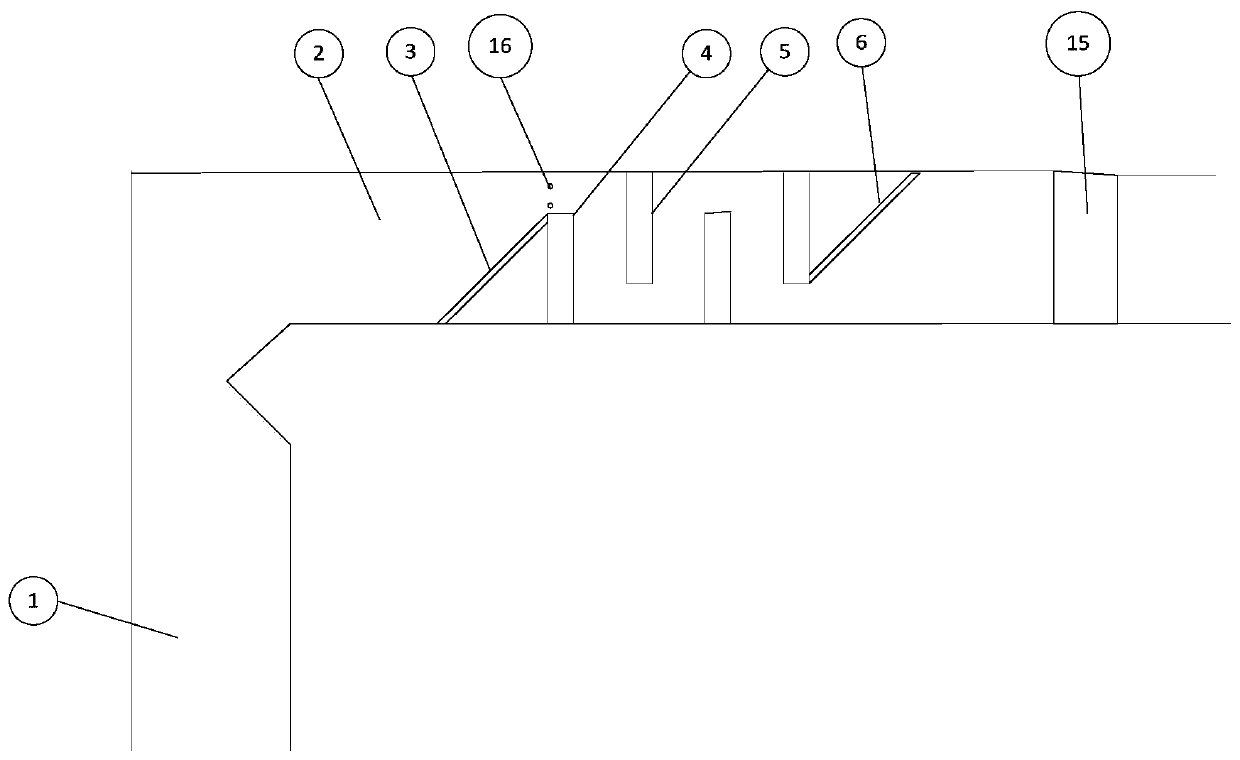

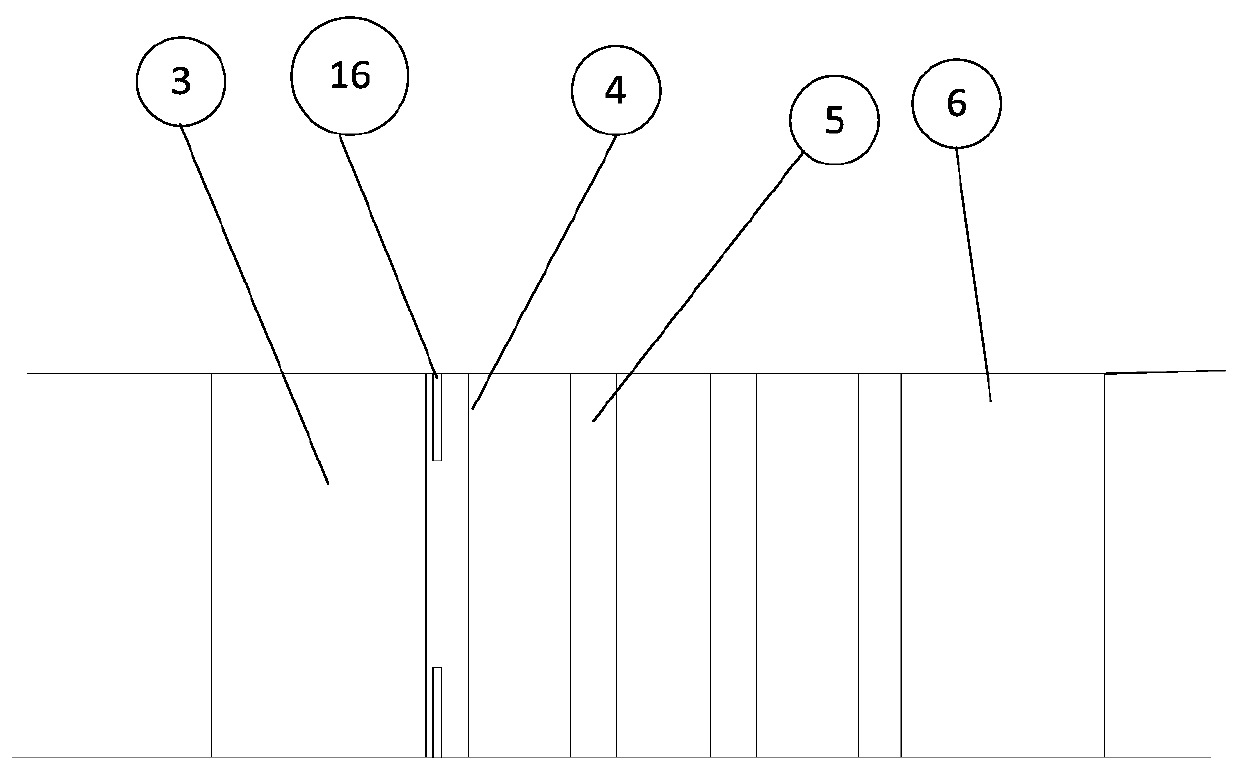

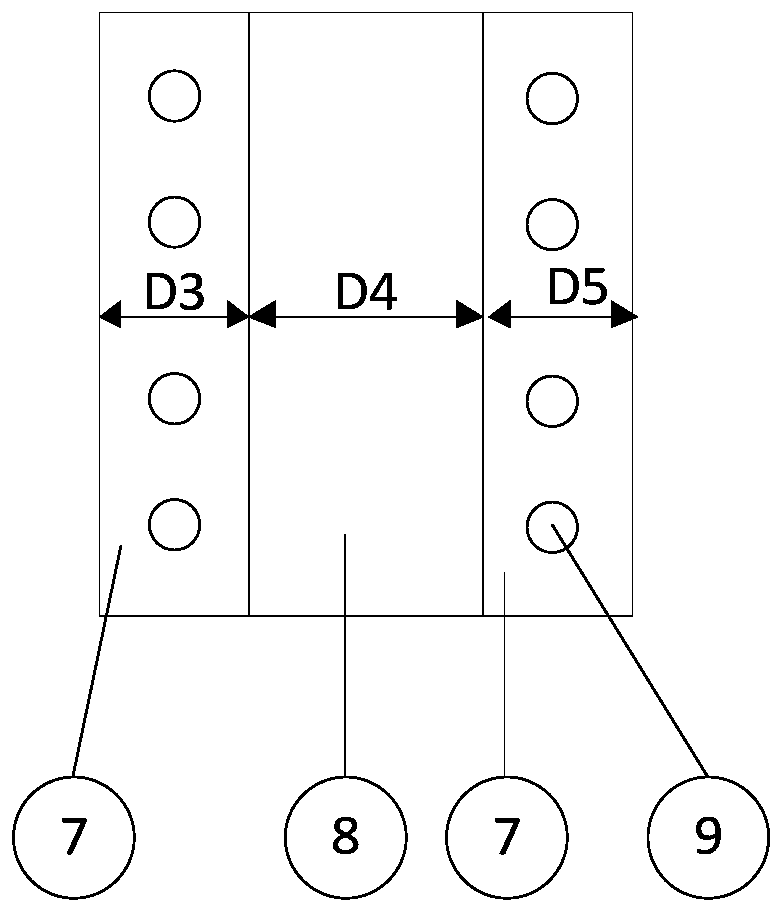

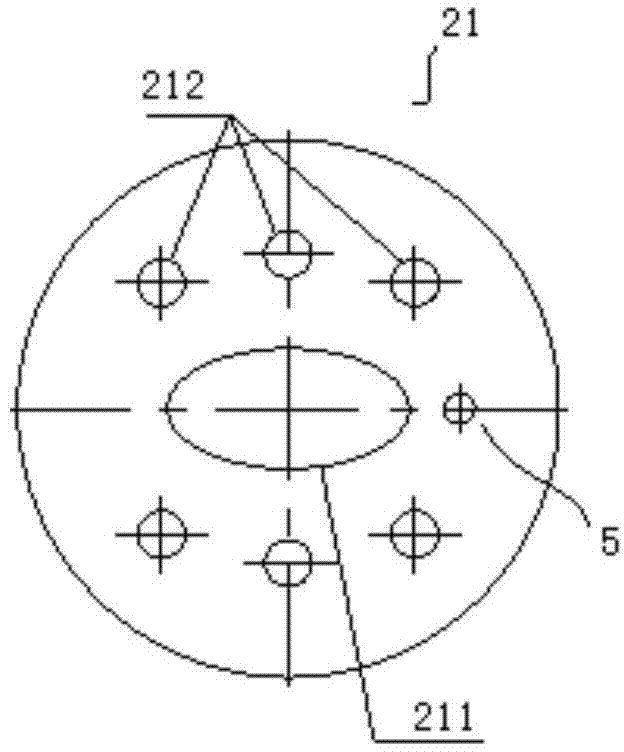

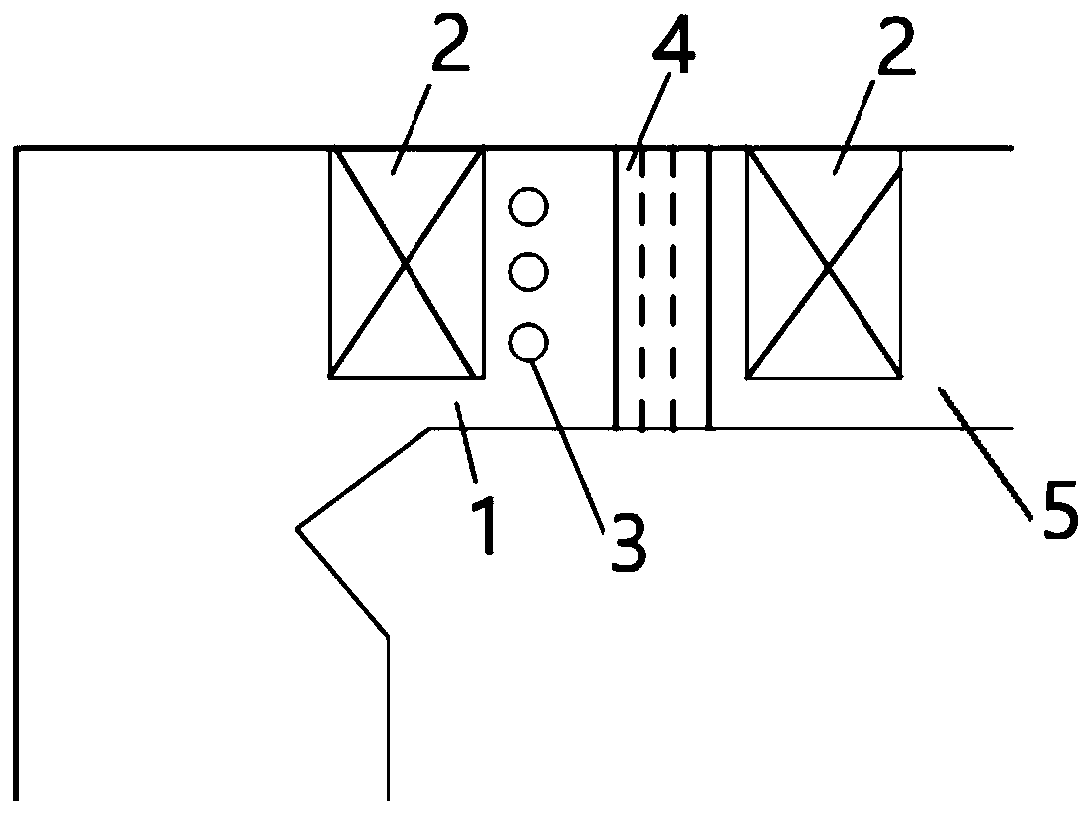

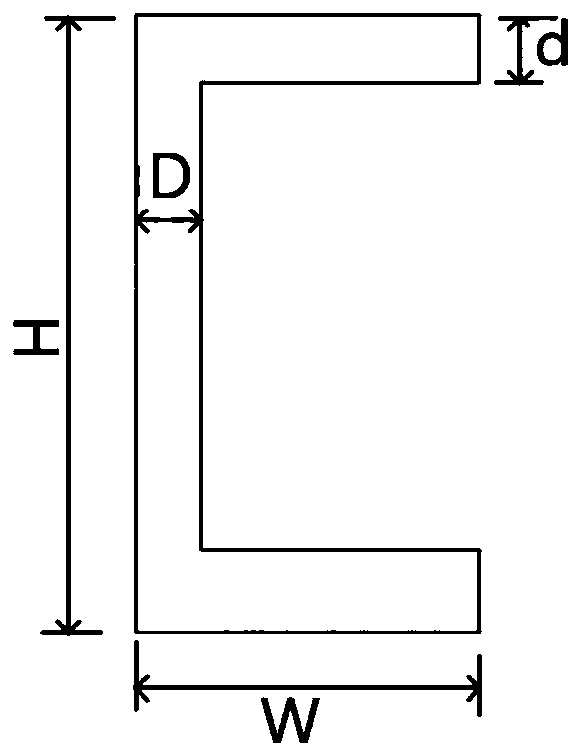

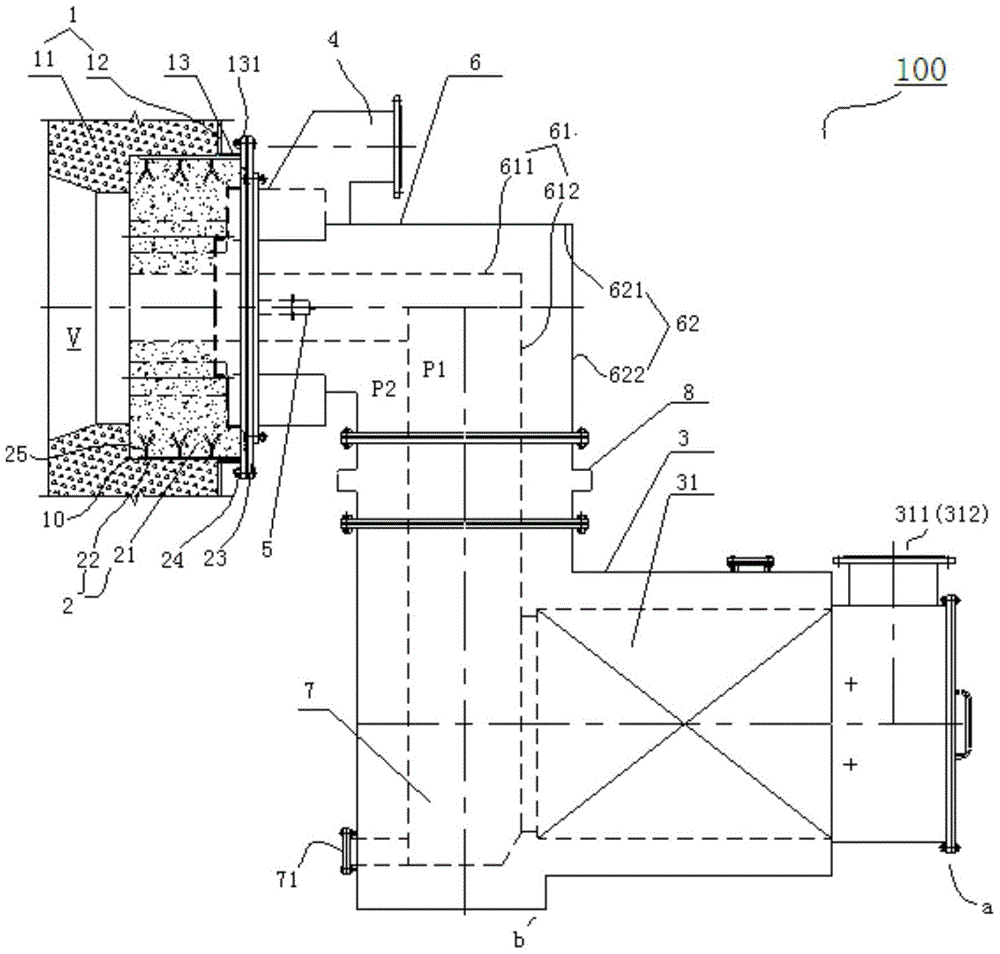

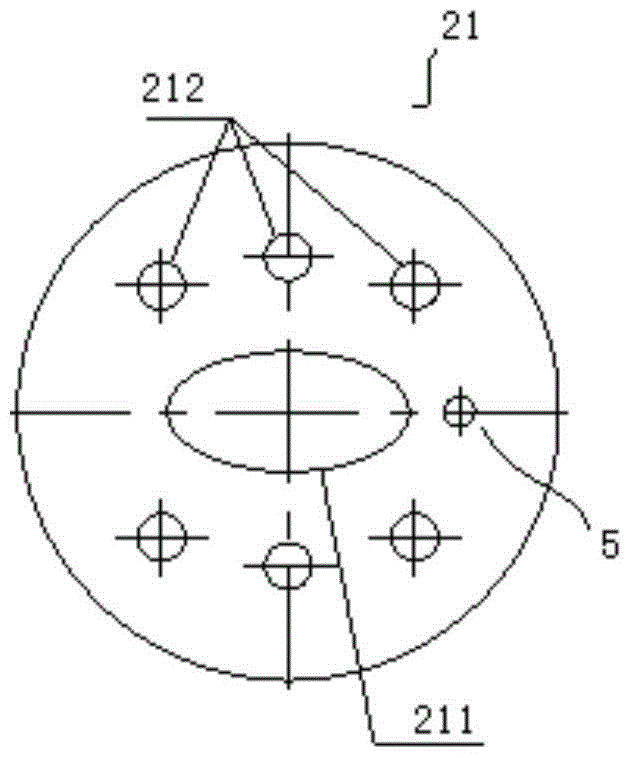

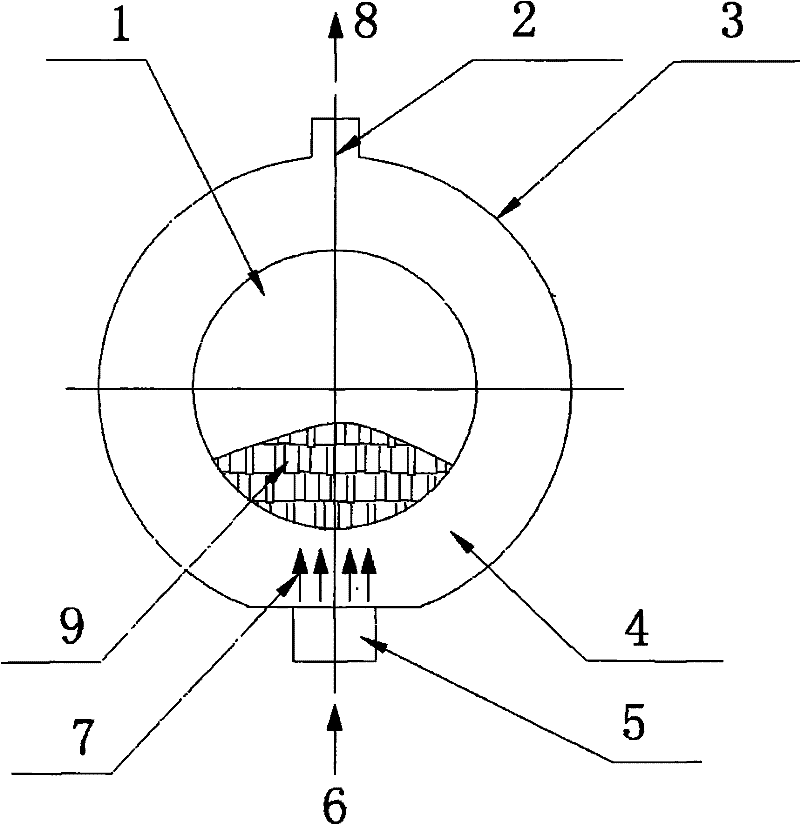

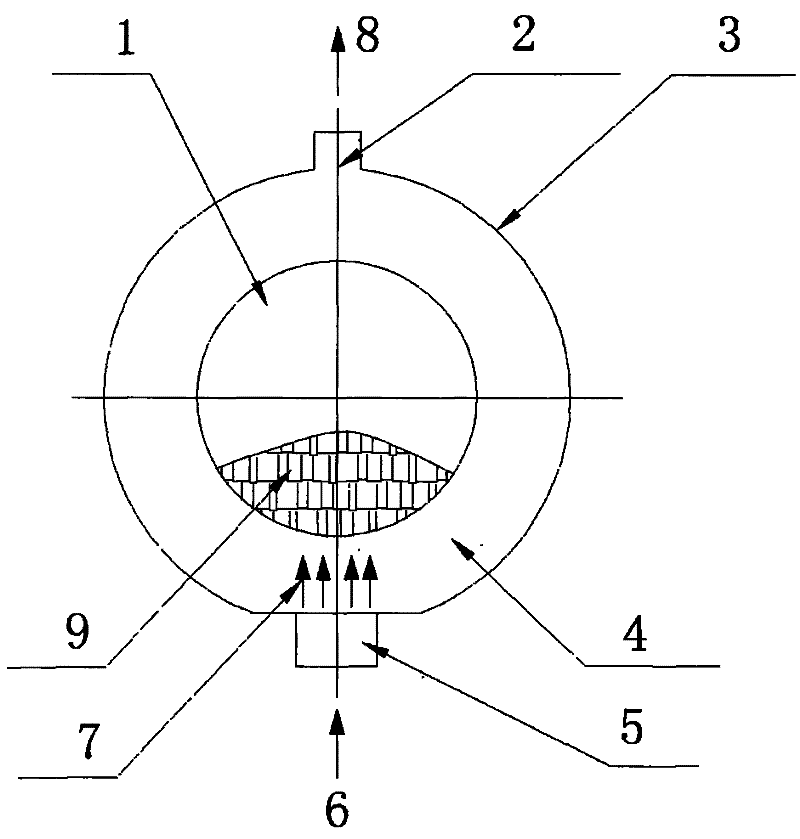

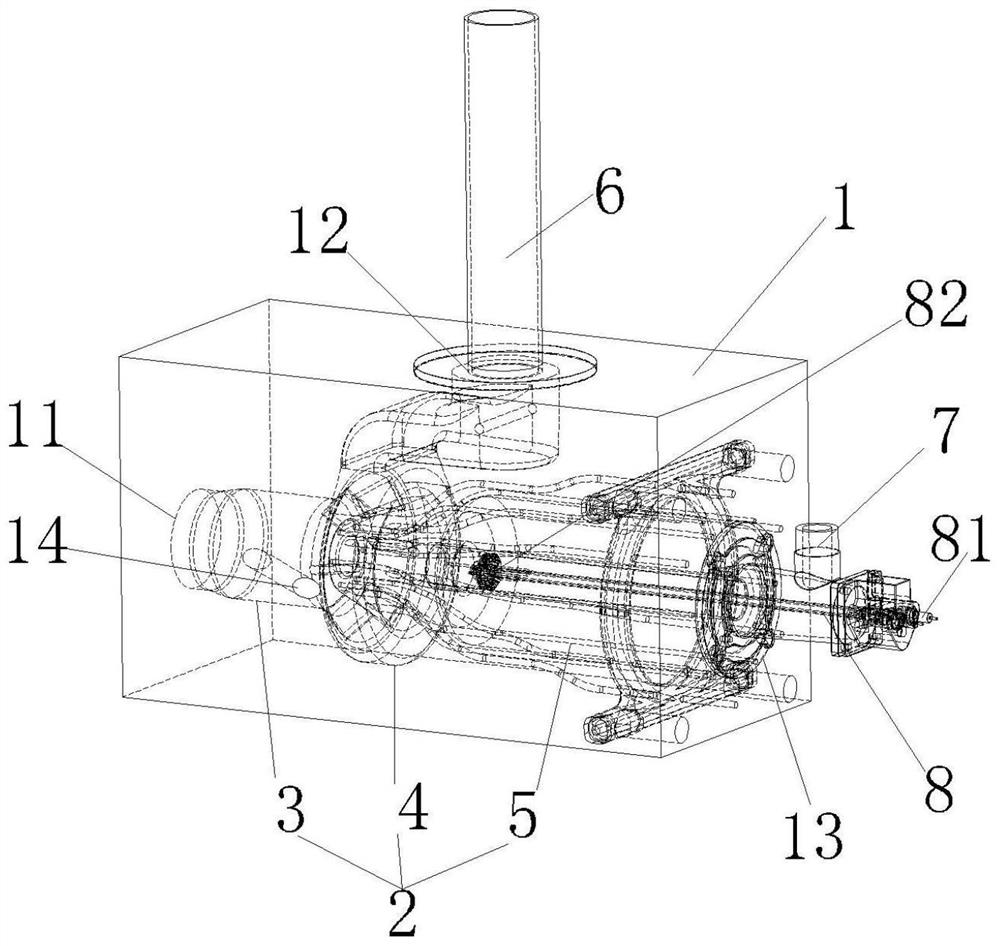

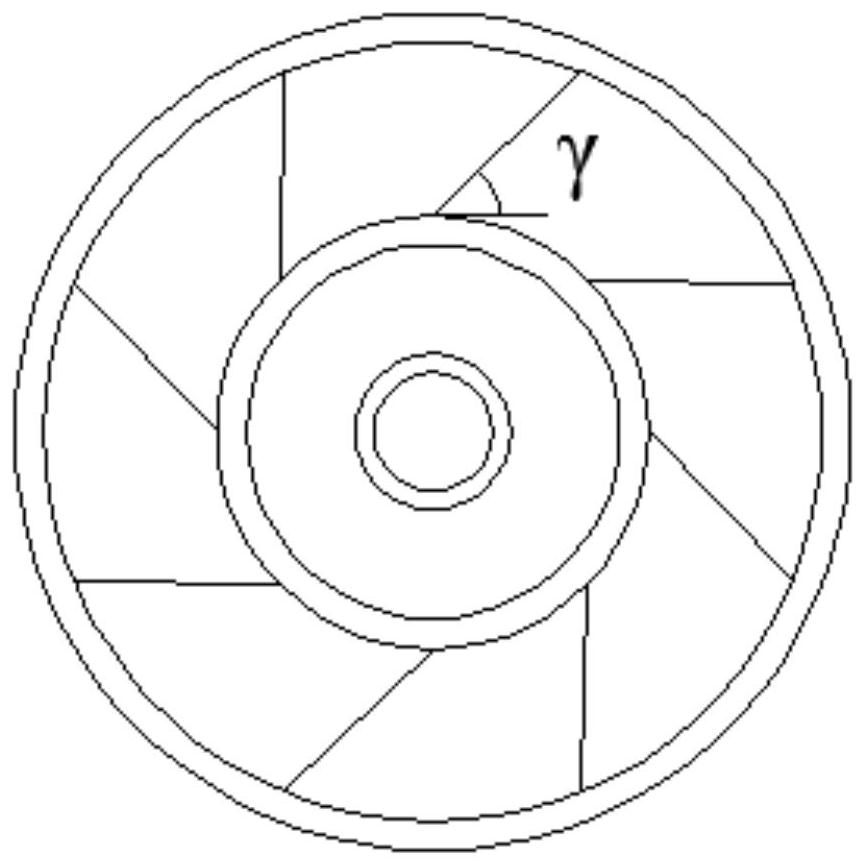

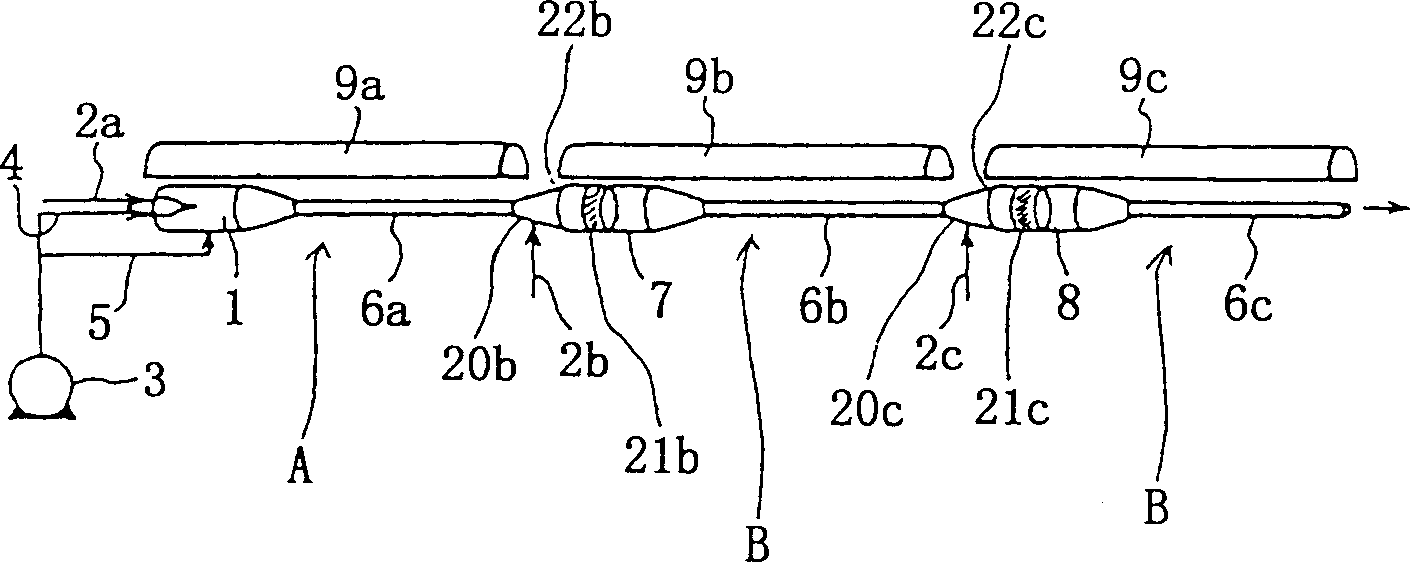

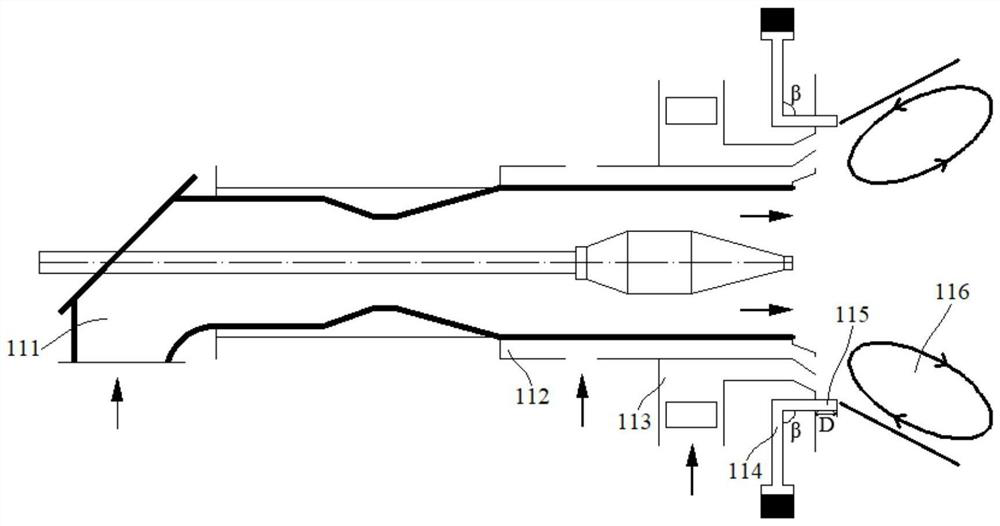

Overfiring air port, method for manufacturing air port, boiler, boiler facility, method for operating boiler facility and method for improving boiler facility

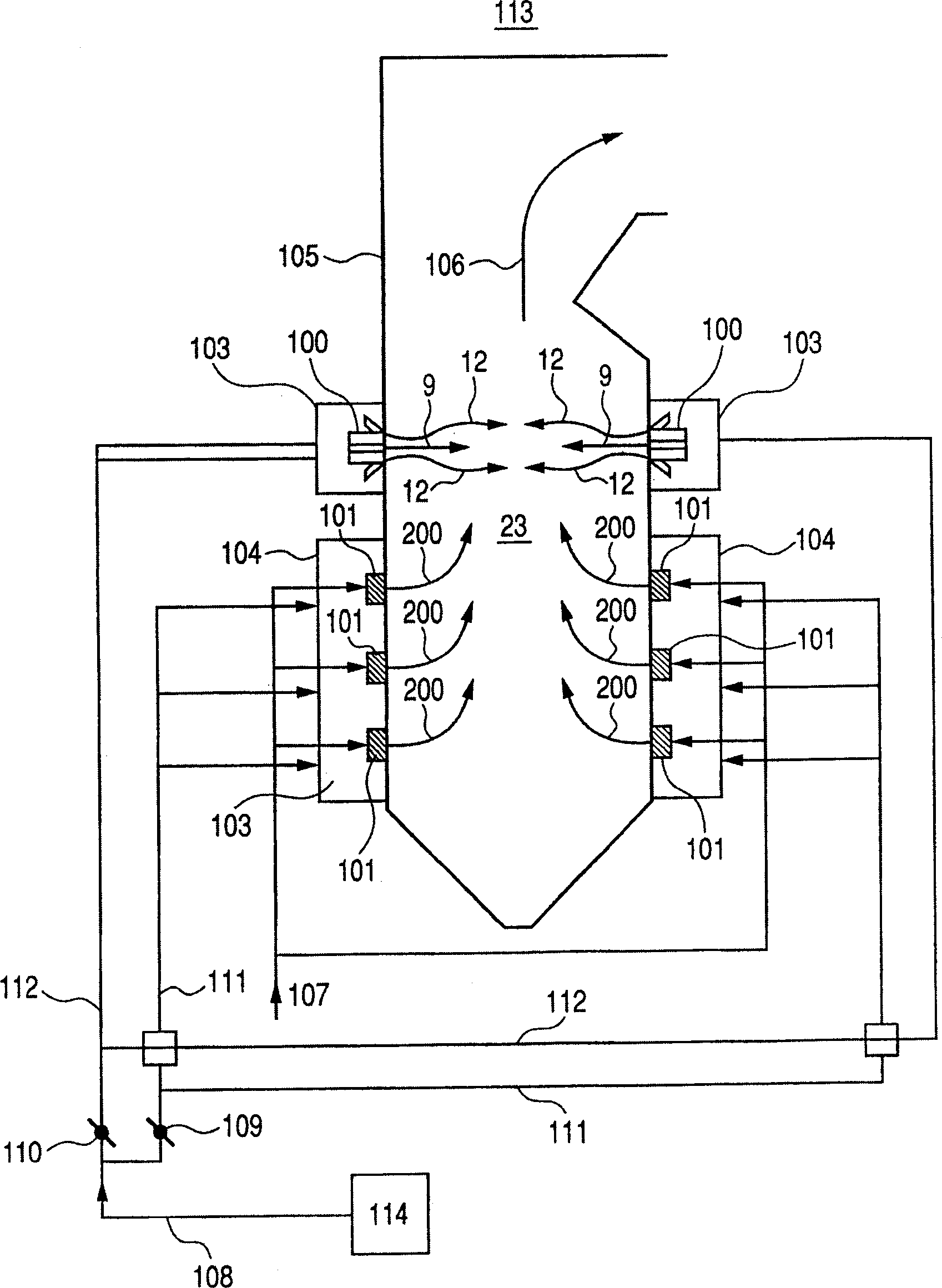

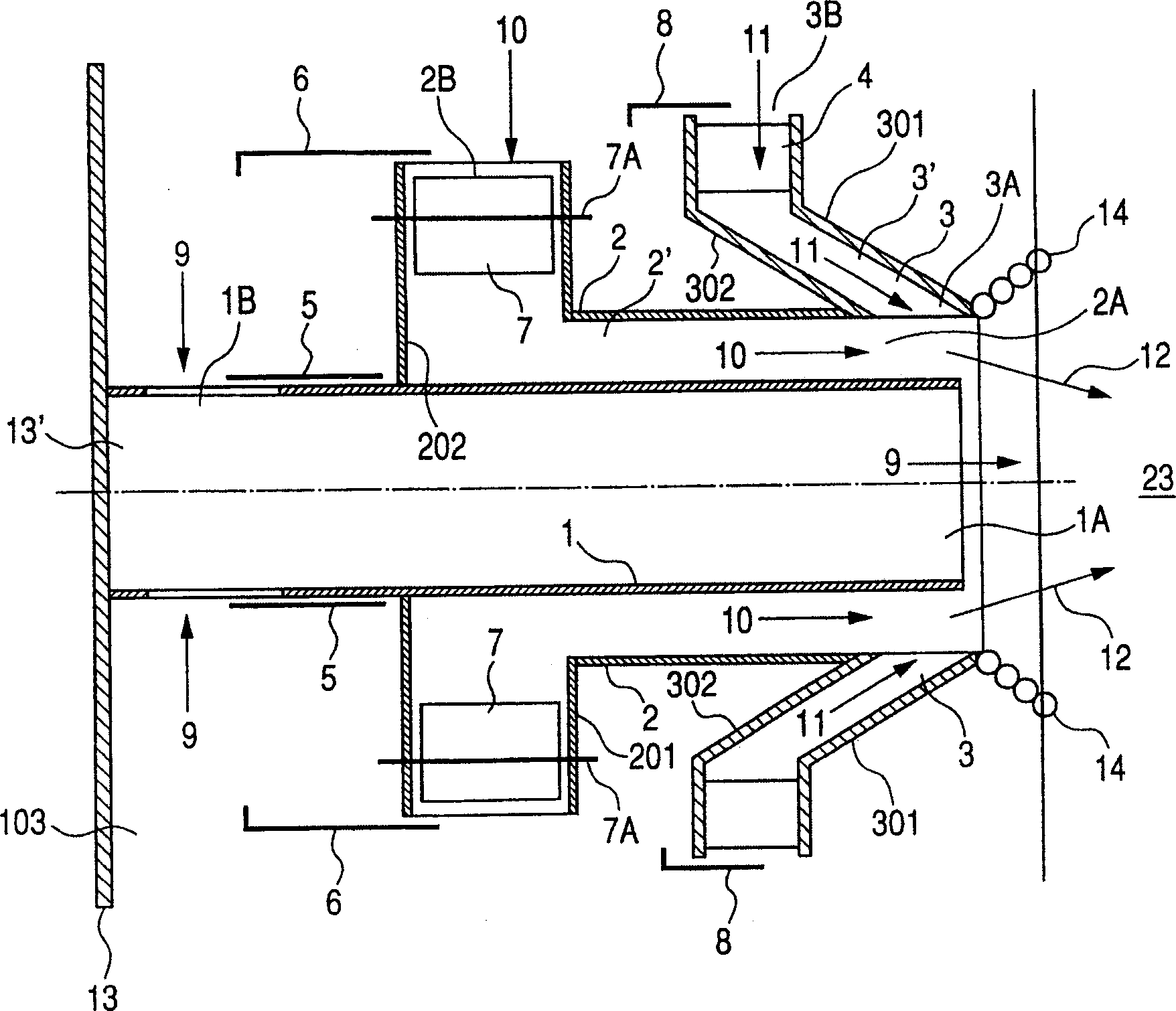

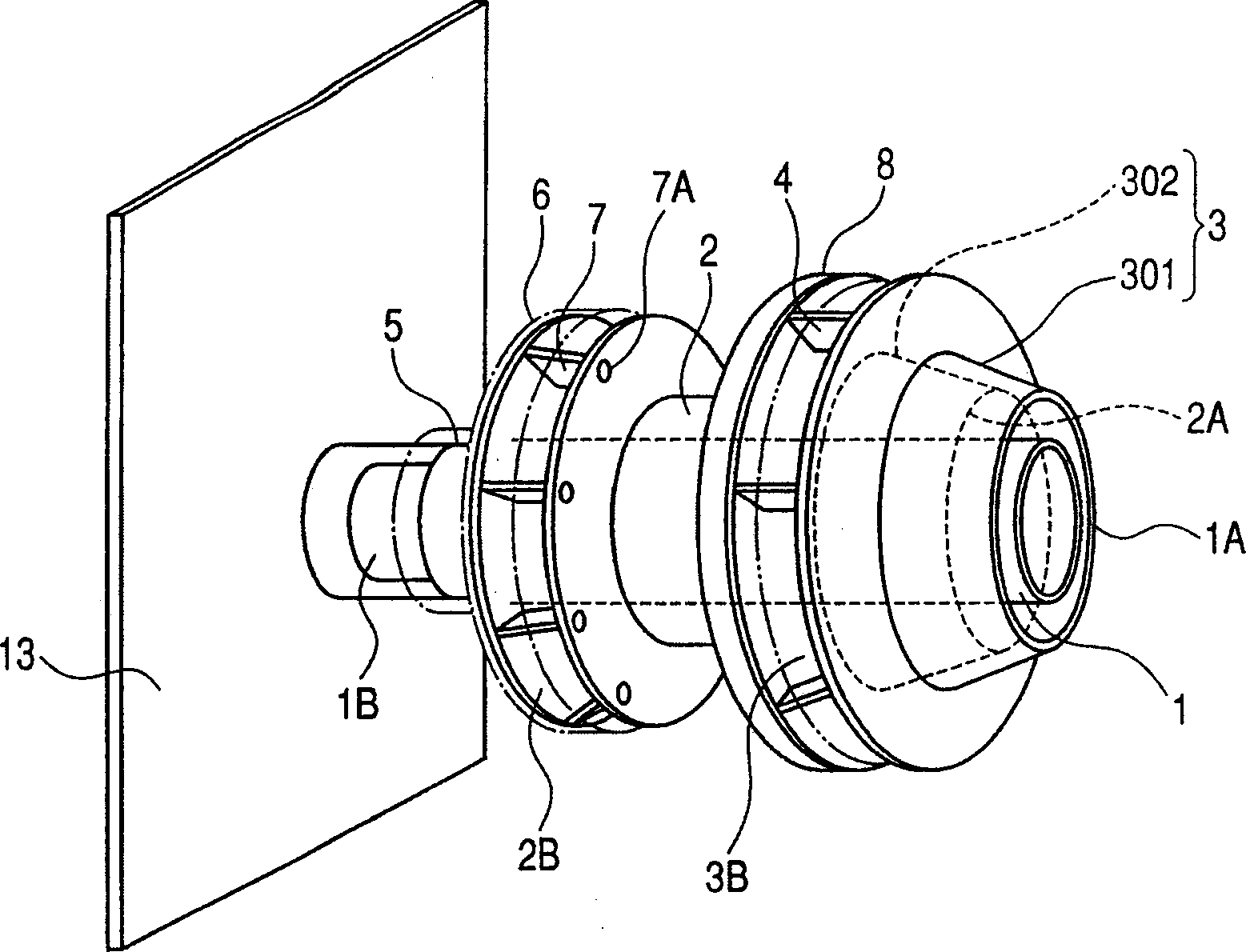

InactiveCN1807985AReduce NOx concentrationReduce unburned fractionNon-combustible gases/liquids supplyCombustorNozzle

The boiler is provided with a burner (101) and an air port (100). The air port (100) is an air port for supplying an amount of air necessary for complete combustion to the incomplete combustion region below the theoretical air ratio formed by the burner (101) in the furnace (23). The air port (100) includes a nozzle mechanism for ejecting combustion air including an axial velocity component and a velocity component toward the center of the air flow, and a mechanism for changing the velocity component ratio. The nozzle mechanism consists of a primary nozzle (1) that ejects primary air that advances linearly in the axial direction of the air port, a secondary nozzle (2) that ejects secondary air accompanied by a swirling flow, and a secondary nozzle (2) that ejects the air from the outside of the primary nozzle. The flowing air is constituted as a tertiary nozzle (3) for ejecting tertiary air.

Owner:BABCOCK HITACHI KK

Biodiesel with higher water content rate and its use

InactiveCN1891793AReduce manufacturing costFull use of oxygen enrichmentBiofuelsLiquid carbonaceous fuelsManufacturing cost reductionBiodiesel

The invention relates to biological diesel oil with high water content and its application. It belongs to liquid fuel technical field. The constituent weight percentages of the biological diesel oil are follows: fatty acid monoester 75-98%, water 1-20%, and emulsifier 0.1-5% whose hydrophilic oleophilic equilibrium value HLB is 1.0-8.0. And its features at room temperature are that its density is 0.80-0.96g / cm3; viscosity is 1.0-10.0 mm2 / s; heat value is 32.00-42.00MJ / Kg; solution surface tension is 1.0*10-2-8.0*10-2N / m; and dripping diameter is 0.001-10.00um. The invention offers the emulsifying biological diesel oil with high water content which has storage stability. And it can simplify removing water technology, reduce manufacturing cost, and improve the burning performance of the biological diesel oil.

Owner:NANCHANG UNIV

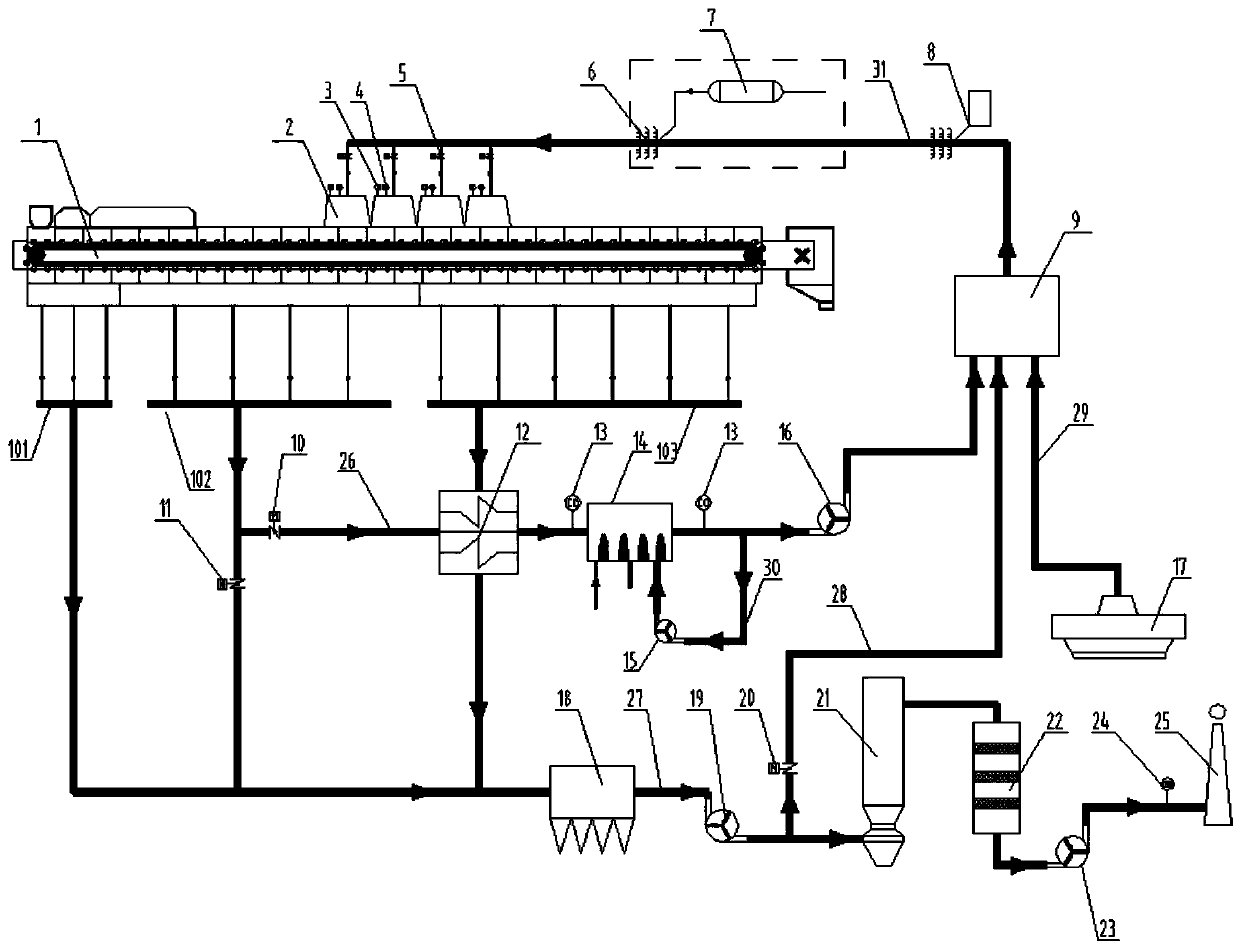

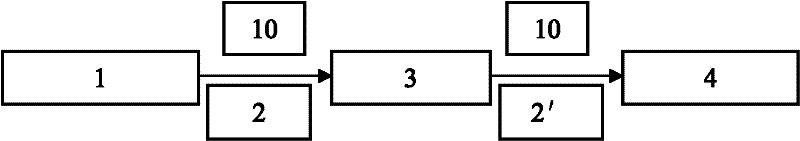

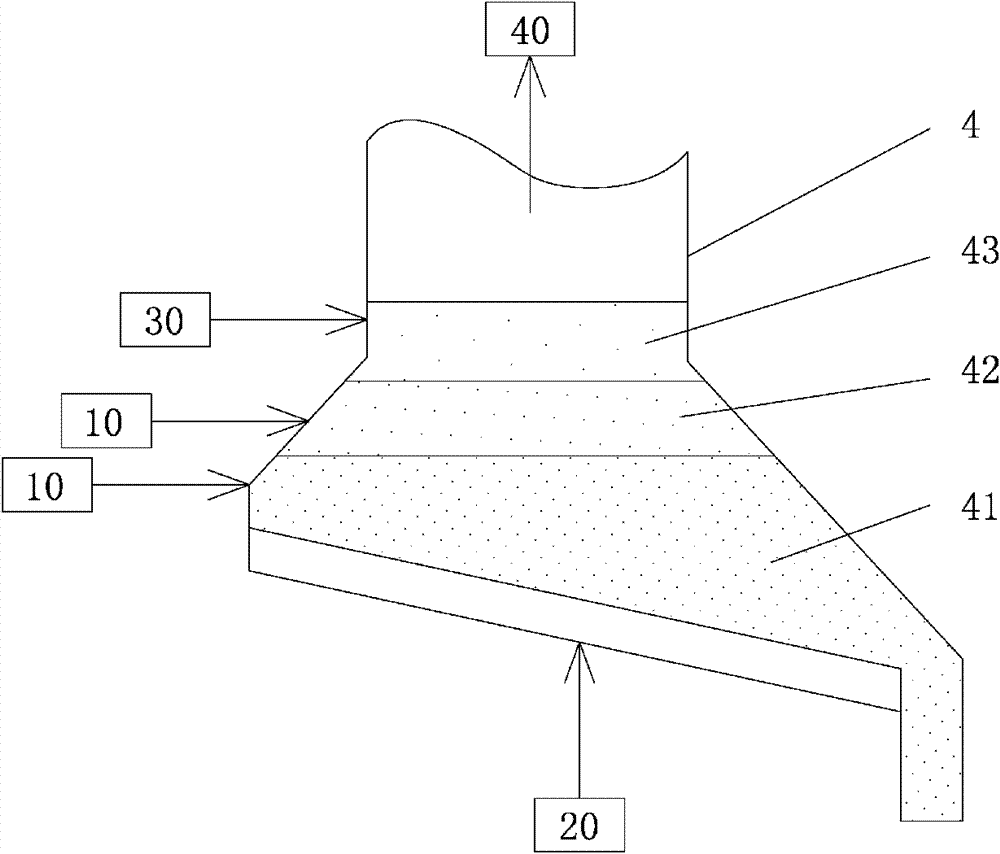

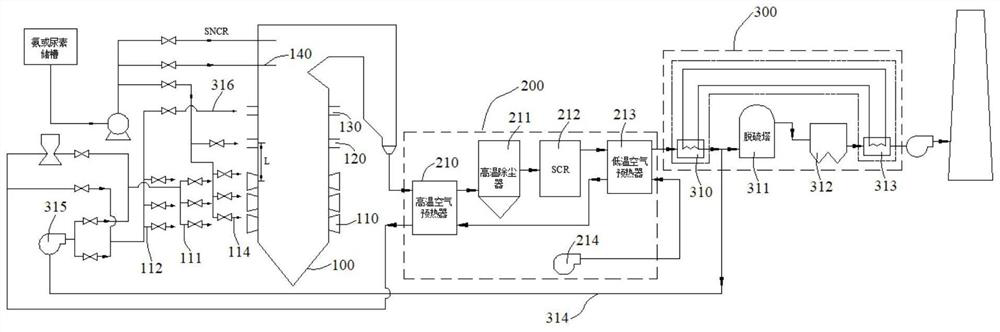

Internal-external circulation system and method for sintering flue gas

PendingCN111569623AGood effectIncreased sintering flue gas circulation rateDispersed particle separationIncinerator apparatusThermodynamicsFlue gas

The invention provides an internal-external circulation system for sintering flue gas. The internal-external circulation system comprises an internal circulation device, an external circulation deviceand a desulfurization and denitrification device, wherein the internal circulation device is connected with a middle-front section flue of a main flue of a sintering machine, and first purified fluegas is obtained and is then circulated into the sintering machine; the outer circulation device is connected with a machine head flue and a middle-rear section flue of the main flue of the sintering machine, second purified flue gas is obtained, one part of the second purified flue gas is circulated into the sintering machine, and the other part of the second purified flue gas enters the desulfurization and denitrification device; and flue gas from the middle-rear section flue exchanges heat with flue gas from the middle-front section flue and then enters the outer circulation device. The invention further provides an internal-external circulation system for sintering flue gas. According to the invention, the circulation rate of the sintering flue gas is increased from 20% to 60% or above,the utilization rate of waste heat is increased, the concentration of NOx in the flue gas is reduced, a two-stage CO removal reaction is achieved, and a large amount of investment and operation costis saved.

Owner:BEIJING ZHTD ENVIRONMENTAL PROTECTION TECH CO LTD

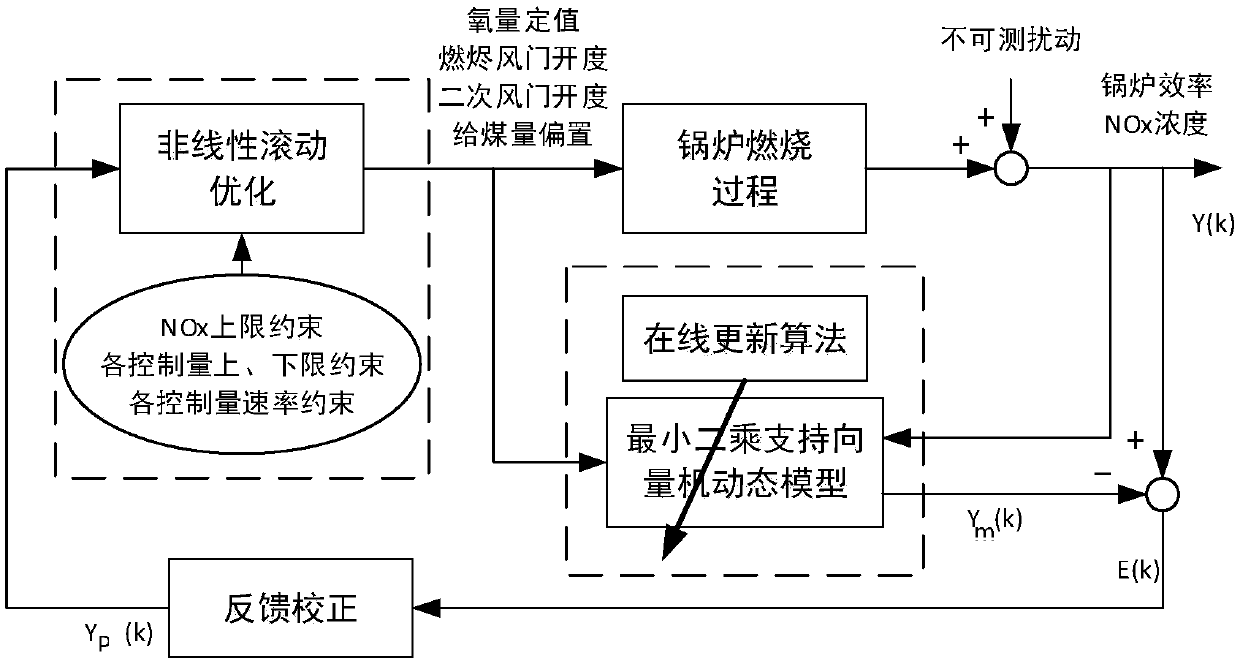

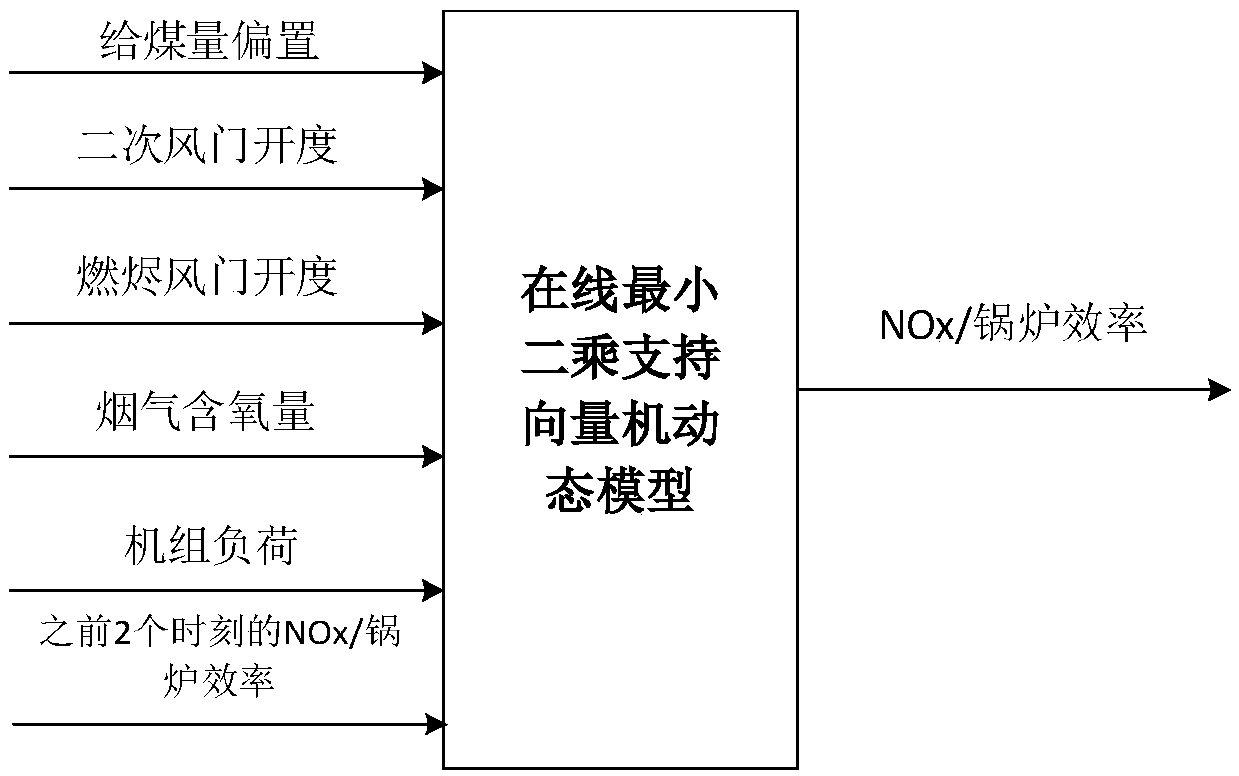

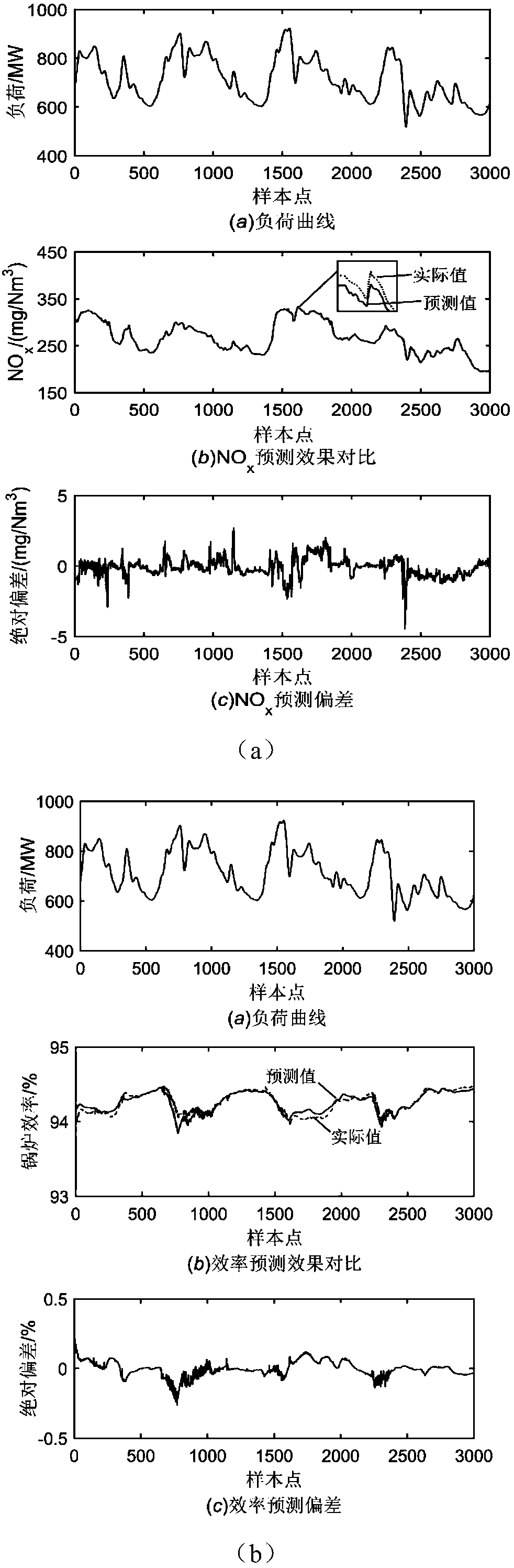

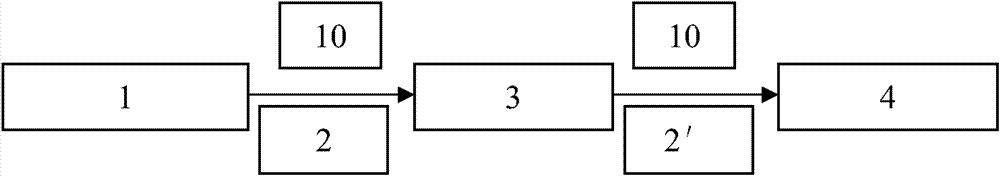

Ultra-supercritical boiler closed-loop combustion optimal control method

ActiveCN109519957AImprove adaptabilityGood forecastFuel supply regulationSupercritical steam generatorCombustion system

The invention discloses an ultra-supercritical boiler closed-loop combustion optimal control method; based on a combustion system dynamic model built by an untracked Kalman filtering least squares support vector machine, the boiler efficiency and the dynamic characteristics of NOx emission changed along with loads can be accurately reflected; and meanwhile, through introduction of updating mechanisms, the excellent self-adaption capacity and prediction capacity of the dynamic model under different working conditions are also guaranteed. When the load of a 1000 MW fired coal boiler is variableor stable, and the adjusting quantity, the controlled index and related parameters are all located in a reasonable range and stably changed, the boiler efficiency can be kept stable; and meanwhile, after SCR inlet conversion, the NOx concentration is obviously reduced after application.

Owner:SOUTHEAST UNIV

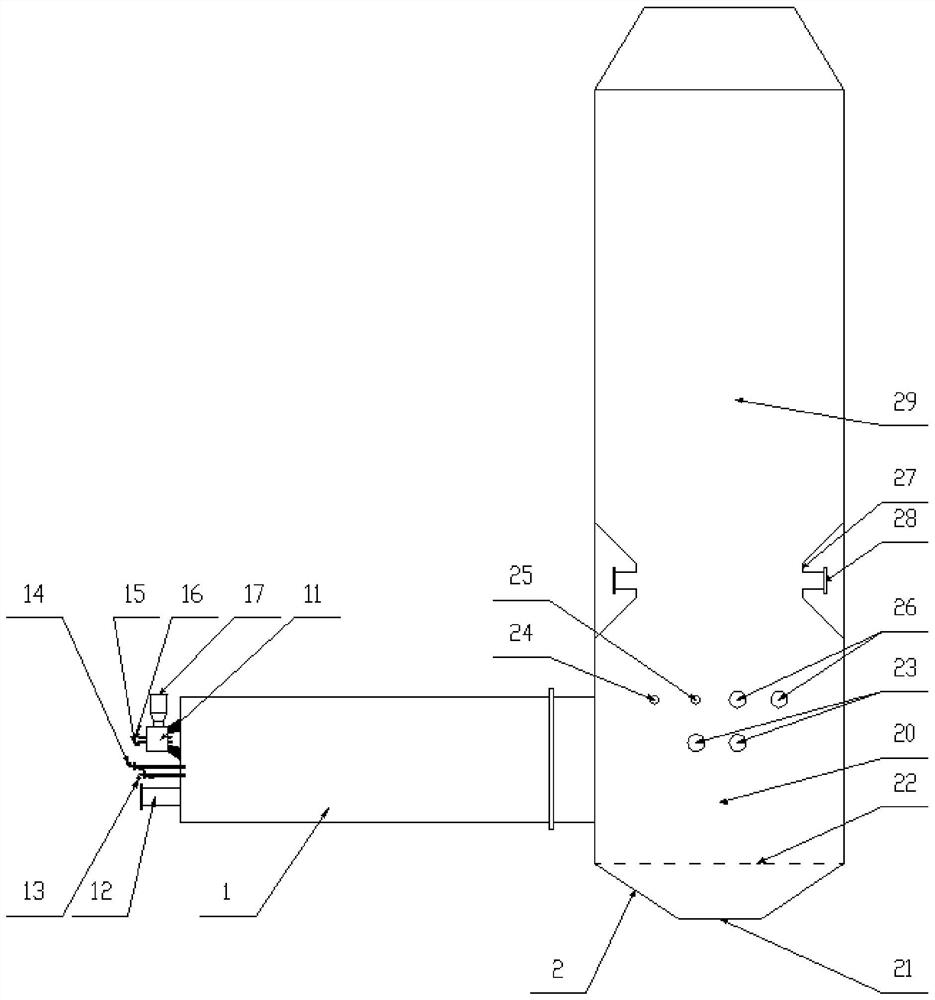

Flue structure for SNCR (selective non-catalytic reduction) denitration of flue gas of pulverized coal boiler and heating of sludge drying heat-conducting oil

PendingCN111425874ASimplify the heating systemWell mixedSludge treatment by de-watering/drying/thickeningGas treatmentSludgeFlue gas

The invention provides a flue structure for SNCR (selective non-catalytic reduction) denitration of flue gas of a pulverized coal boiler and heating of sludge drying heat-conducting oil. An SNCR denitration device is arranged in a proper area in a flue of the pulverized coal boiler, so that the flue gas carrying a reducing agent can be fully mixed when flowing through the SNCR denitration device,and ideal denitration efficiency is achieved. A heat-conducting oil heater pipeline is embedded in a basic mechanism unit, so that a heat-conducting oil heating system is simplified, and part of heatenergy in high-temperature flue gas is obtained for drying of municipal sludge. The whole design structure is simple, the concentration of NOx in the flue gas in front of an SCR device is greatly reduced, energy in the flue gas is obtained with the simple structure for drying of the municipal sludge, and better economic benefits and social benefits can be obtained in two aspects of pollutant emission reduction and municipal waste utilization.

Owner:HUANENG POWER INT INC +2

Heat-storage-type burning device

ActiveCN104848220AExtended service lifeReduce oxidation burnIndirect carbon-dioxide mitigationGaseous fuel burnerFurnace temperatureSurface oxidation

The invention discloses a heat-storage-type burning device which comprises a furnace body, a burner block part, a furnace wall connecting member, a heat storage chamber, a combustible gas incoming pipe, an air-gas connecting body and an igniter. The burner block part comprises a burner block pouring material and a metal plate, an air nozzle and multiple combustible gas nozzles are arranged on the burner block pouring material, the combustible gas nozzles are arranged in a manner of surrounding the air nozzle, and the metal plate sleeves the burner block pouring material and is connected with the same through an anchoring hook. By the heat-storage-type burning device, reductive in-furnace atmosphere can be generated, and an in-furnace temperature field is more uniform, so that oxidation burning loss of the surface of a workpiece is reduced; uniformity of the in-furnace temperature field ensures integral balance uniformity in heating of the workpiece, so that quality of a heated workpiece is improved, and service life of the burner block part is prolonged. Due to porous and hierarchic burning, high-temperature oxygen-deficient burning can be realized, NOx concentration in the process of burning is lowered remarkably, oxidation burning loss of melting products is reduced, and energy conservation and environment protection are realized.

Owner:SHENWU TECH GRP CO LTD

Method and treatment system for reducing nitrogen oxides by using incineration of refuse landfill gas

InactiveCN102252333AEfficient collectionNo pollution in the processIncinerator apparatusPower stationNitrogen oxides

The invention relates to a refuse landfill gas burning and re-burning technology, and in particular relates to a method and a treatment system for reducing nitrogen oxides by using incineration of refuse landfill gas. The treatment system mainly consists of a refuse landfill, an air pipe, a fan, the other air pipe and an incinerator connected sequentially; during working, the landfill gas of the refuse landfill is led out by the fan through the air pipe, delivered to the incinerator through the other air pipe, and burnt and re-burnt by the incinerator; and the landfill gas is used for reducing NOx in the incinerator, so that the NOx content of the flue gas exhausted by the incinerator is effectively reduced. The method and the system solve the problem of air pollution caused by stench of the refuse landfill and the problem of NOx concentration in the flue gas exhausted by the refuse incinerator, and are particularly suitable for a newly built refuse power plant, particularly a refuse burning power plant which is built nearby the refuse landfill and can provide the landfill gas more conveniently and effectively.

Owner:福建省丰泉环保控股有限公司

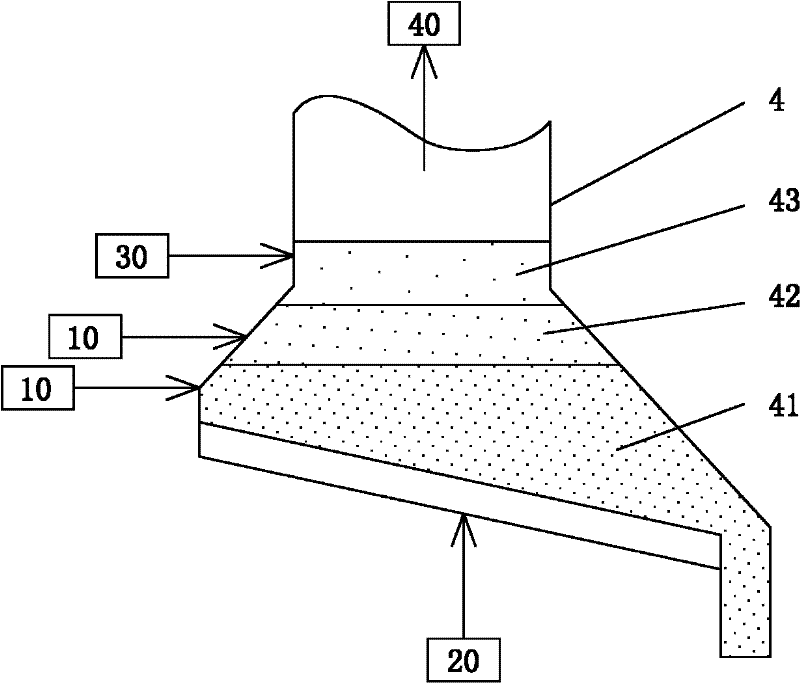

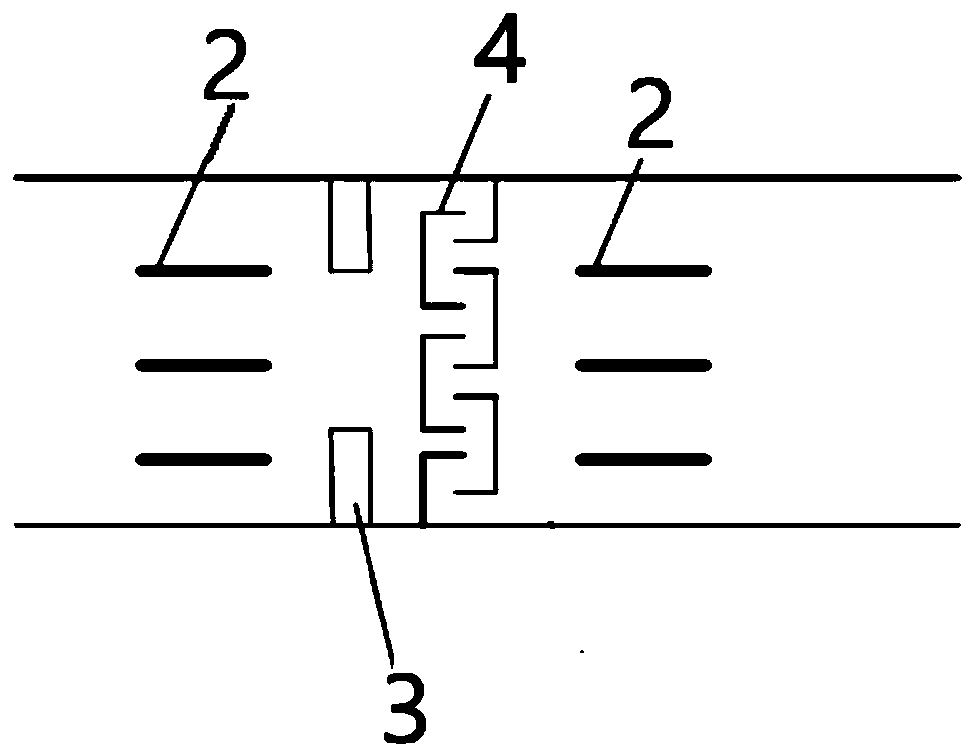

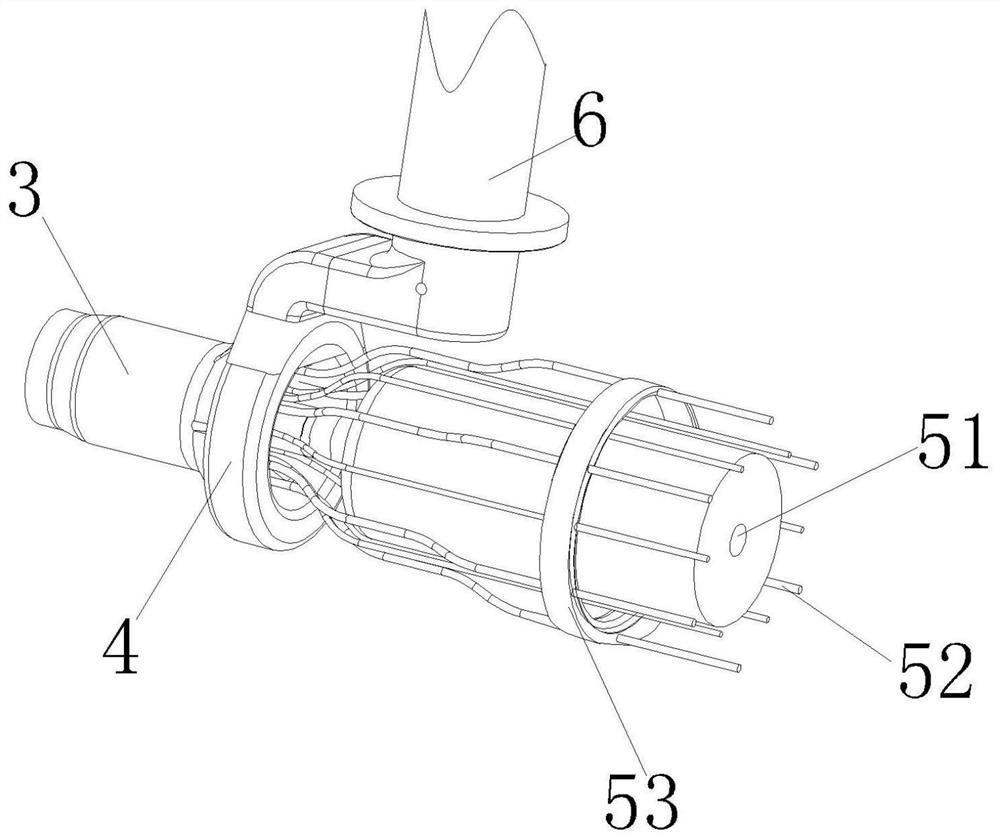

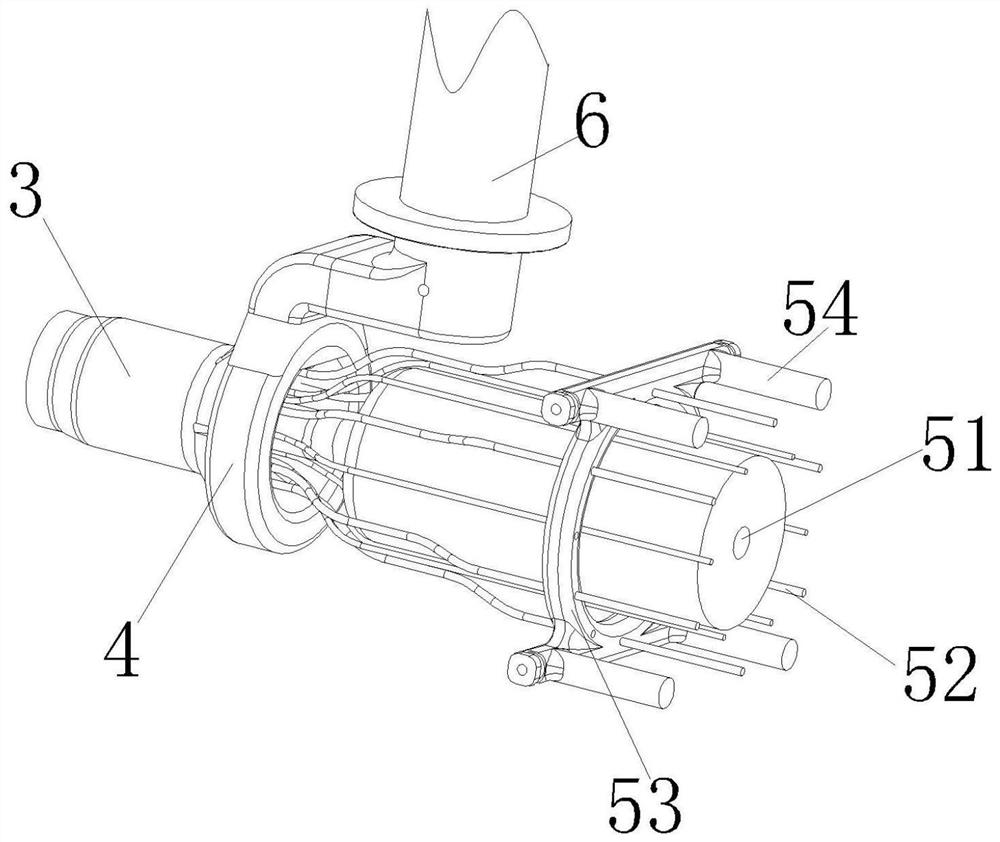

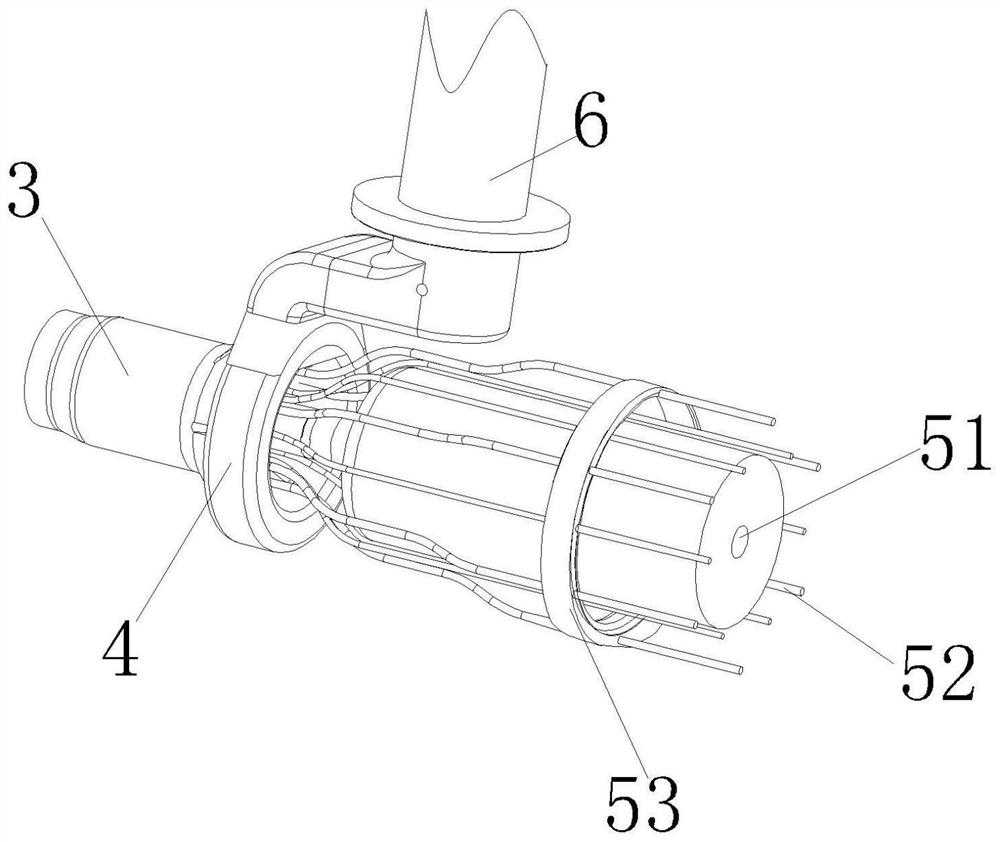

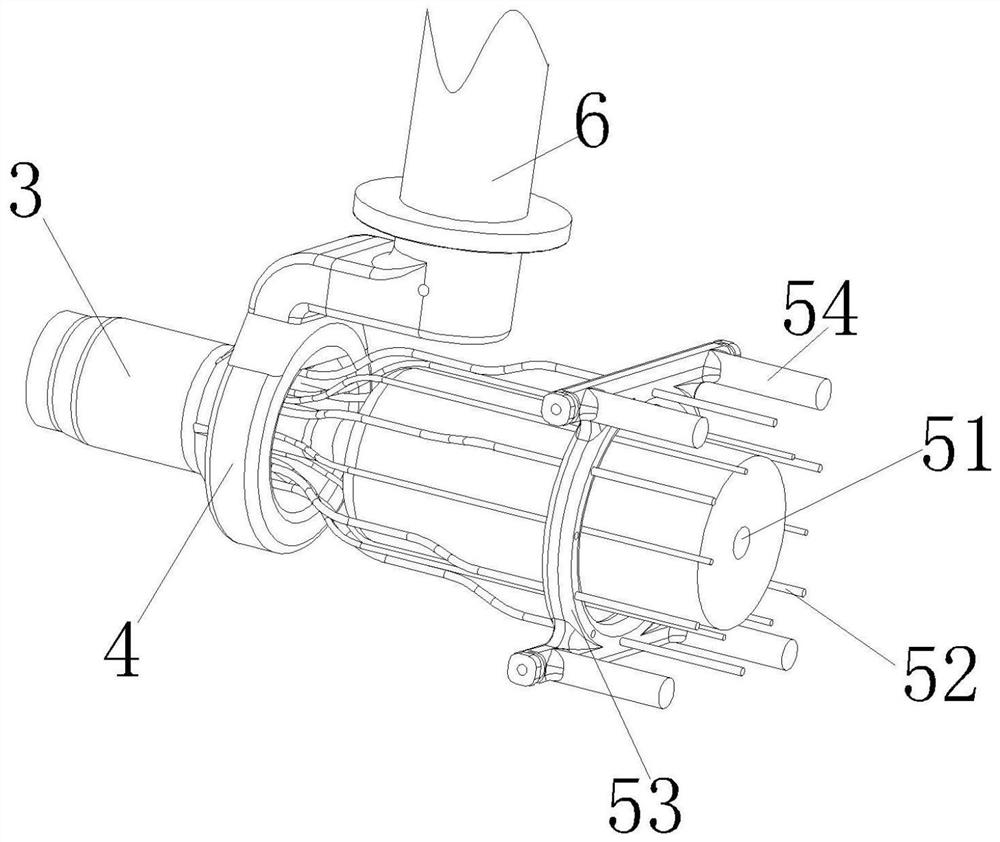

A channel type mixer device for efficient SNCR denitration of flue gas of a pulverized coal boiler

PendingCN109966899AAdd depthEnhanced interactionGas treatmentDispersed particle separationFlue gasEconomic benefits

A channel type mixer device for efficient SNCR denitration of flue gas of a pulverized coal boiler is provided. The device includes channel type mixers arranged between a hearth outlet flue and a downstream flue. The channel type mixers comprise at least two layers of channel type mixer main bodies each of which includes a plurality of pieces of equally spaced channel steel. The device achieves ahigh SNCR denitration efficiency, thus greatly reducing the NOx concentration before pulverized coal boiler SCR equipment, facilitating reduction in dosage of an SCR catalyst, prolonging service lifetime of the catalyst, reducing the cost of catalyst replacement and treatment, and producing good economic benefit.

Owner:HUANENG POWER INTERNATIONAL +1

Method and treatment system for reducing nitrogen oxides by using incineration of refuse landfill gas

InactiveCN102252333BEfficient collectionWill not affect lifeIncinerator apparatusPower stationNitrogen oxides

Owner:福建省丰泉环保控股有限公司

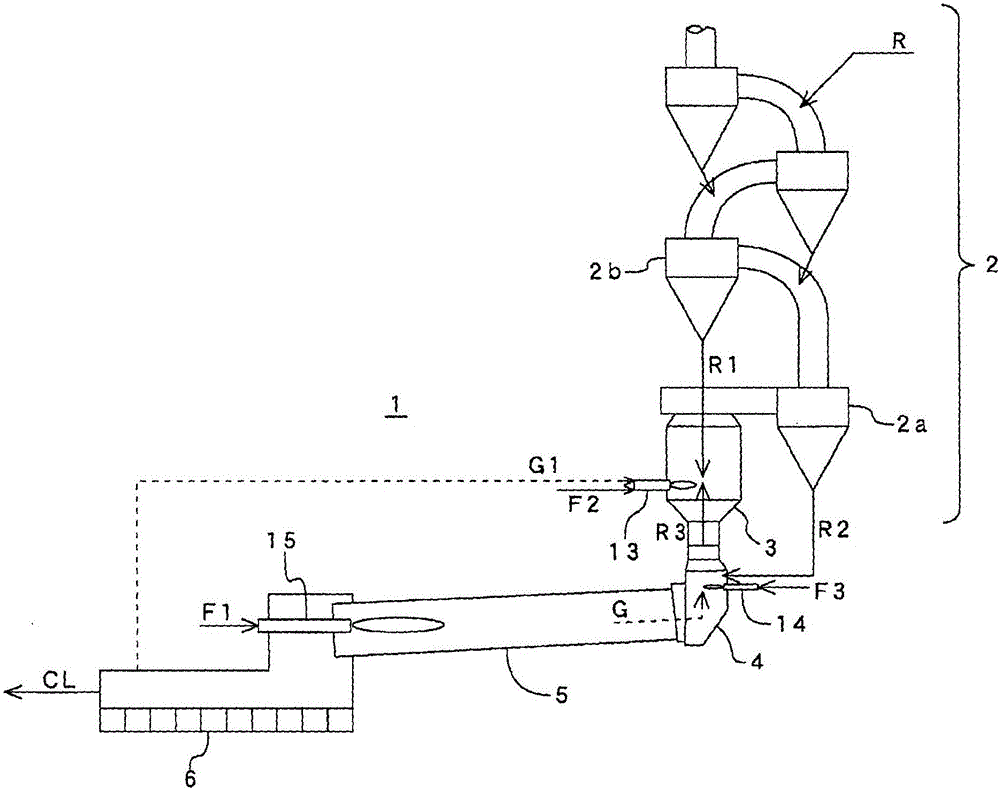

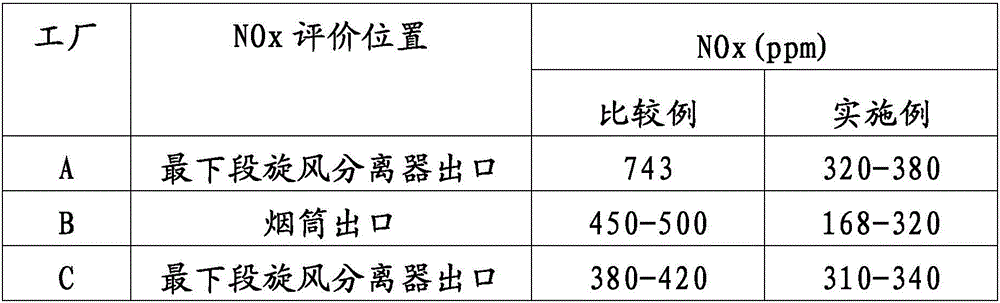

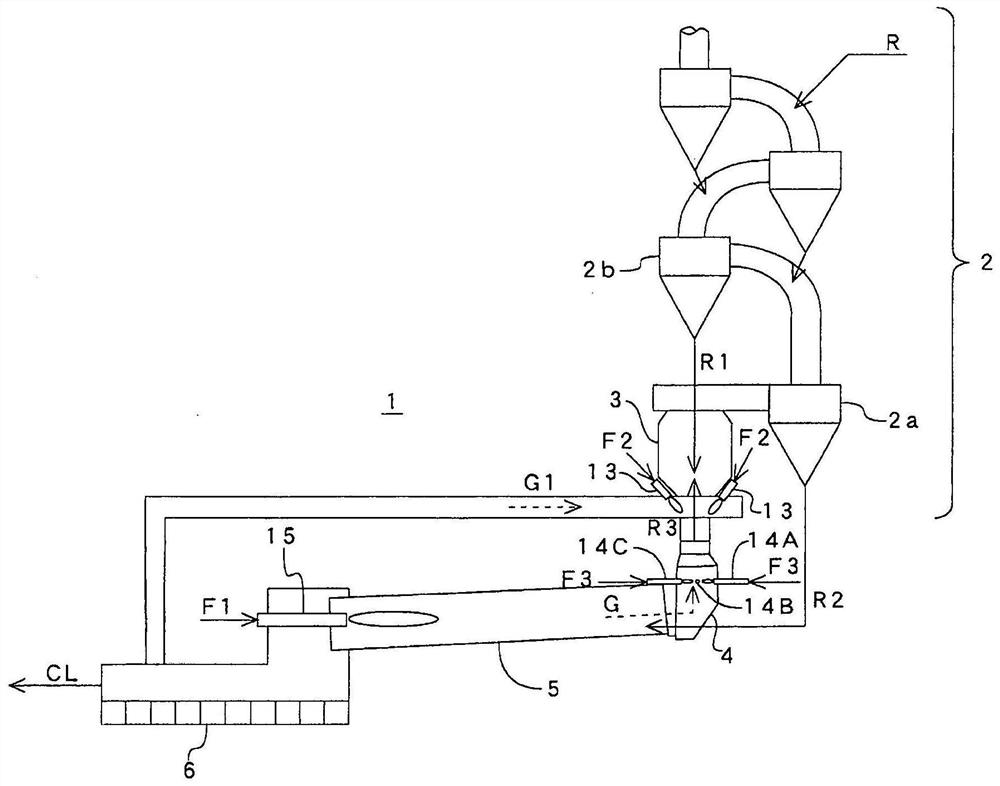

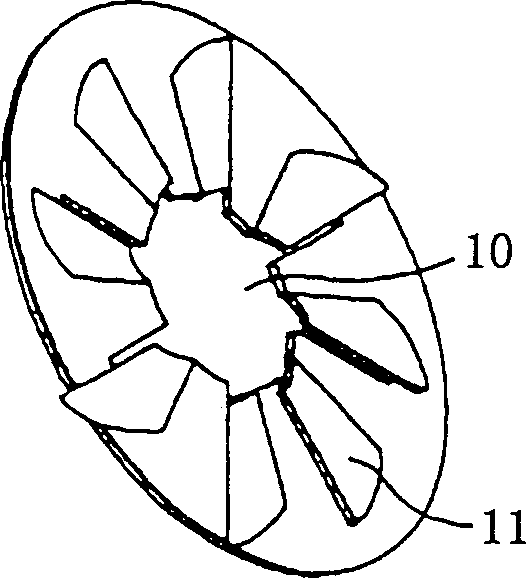

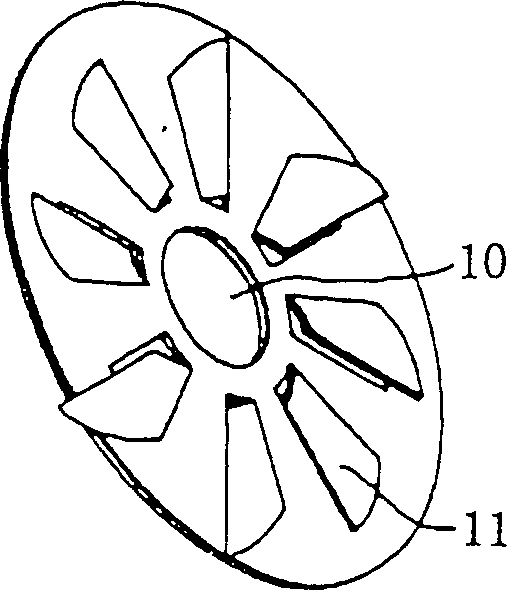

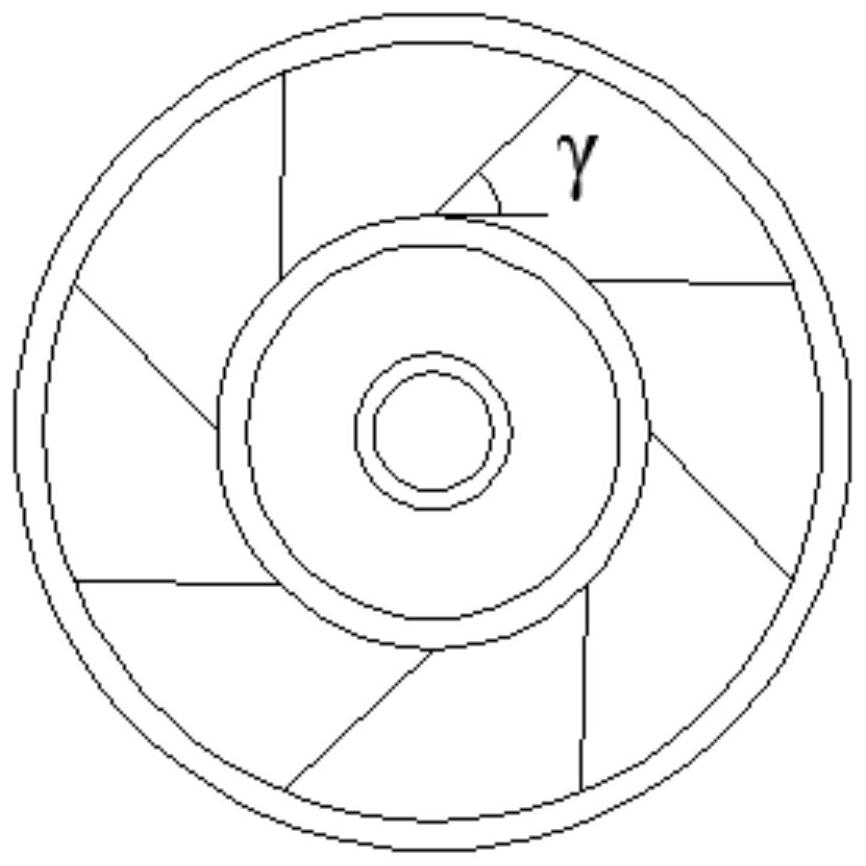

Cement burning apparatus, and method for denitrating exhaust gas from cement kiln

InactiveCN106029599AImprove decarbonization efficiencyReduce NOx concentrationFurnace componentsDispersed particle separationExhaust gasCoal

[Problem] To efficiently reduce the concentration of NOx in an exhaust gas from a cement kiln while keeping the burned state at a good level regardless of the type of a calcining furnace to be used. [Solution] A cement burning apparatus (1) equipped with a burner (14) for blowing a fuel (F3) and combustion air into a kiln tail part (4) of a cement kiln (5) to burn the fuel. It becomes possible to reduce NOx, which is contained in an exhaust gas from the cement kiln, in a low-oxygen zone in the kiln tail part, and it also becomes possible to improve the decarbocxylation efficiency of a cement raw material due to the burning of the fuel. The burner may be equipped with a swirl vane (a swirl means) (14b) for swirling a mixed flow of the fuel and the combustion air. It is preferred that the amount of the fuel to be supplied into the kiln tail part of the cement kiln is 20% or more and less than 50% of the amount of the fuel to be supplied into a calcining furnace (3) that is provided in the cement kiln. The fuel to be supplied into the kiln tail part of the cement kiln may comprise at least one of pulverized coal, a heavy oil and a burnable waste material.

Owner:TAIHEIYO ENG

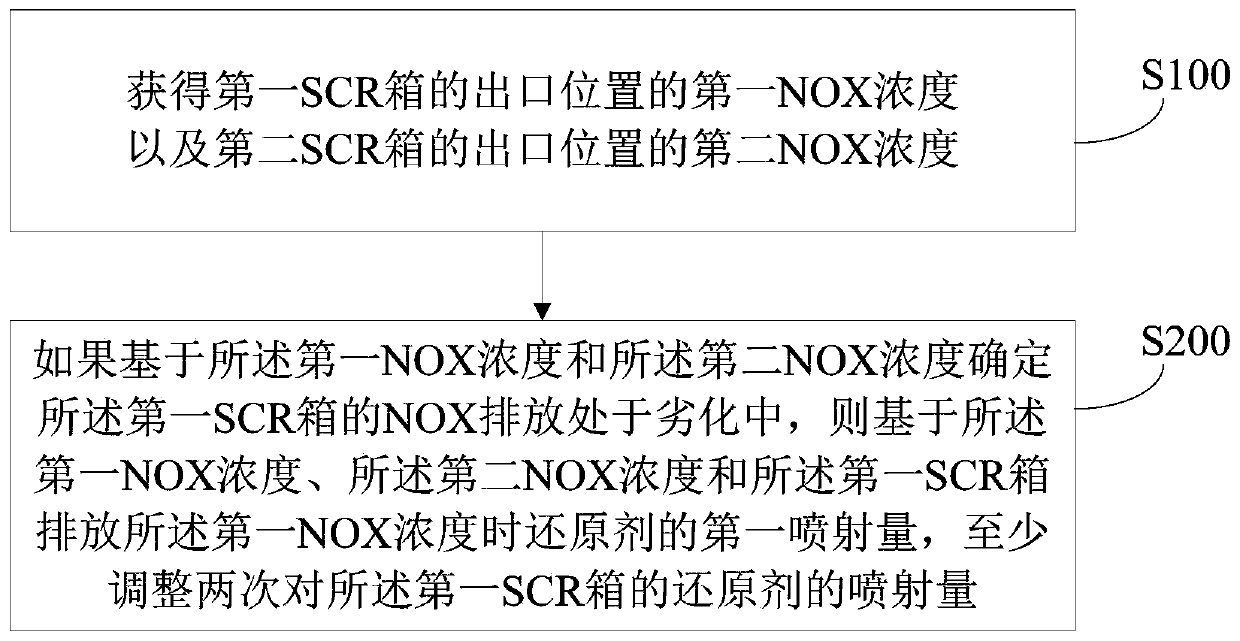

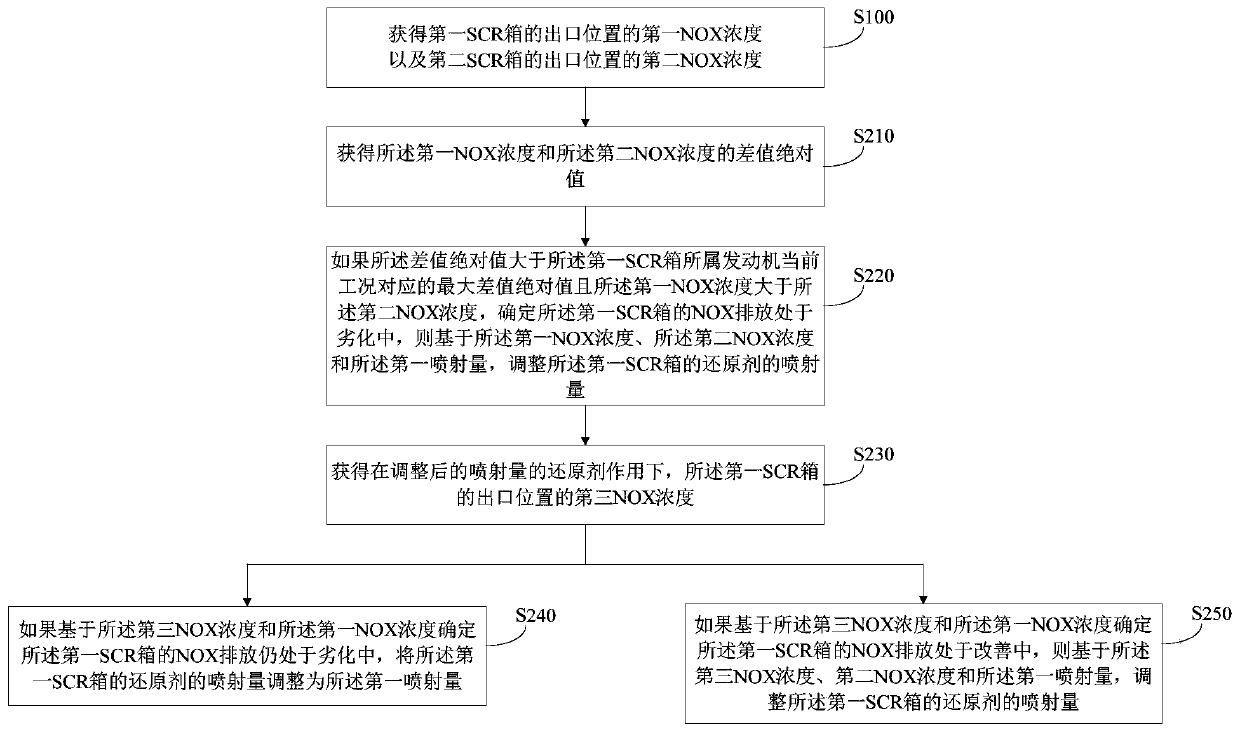

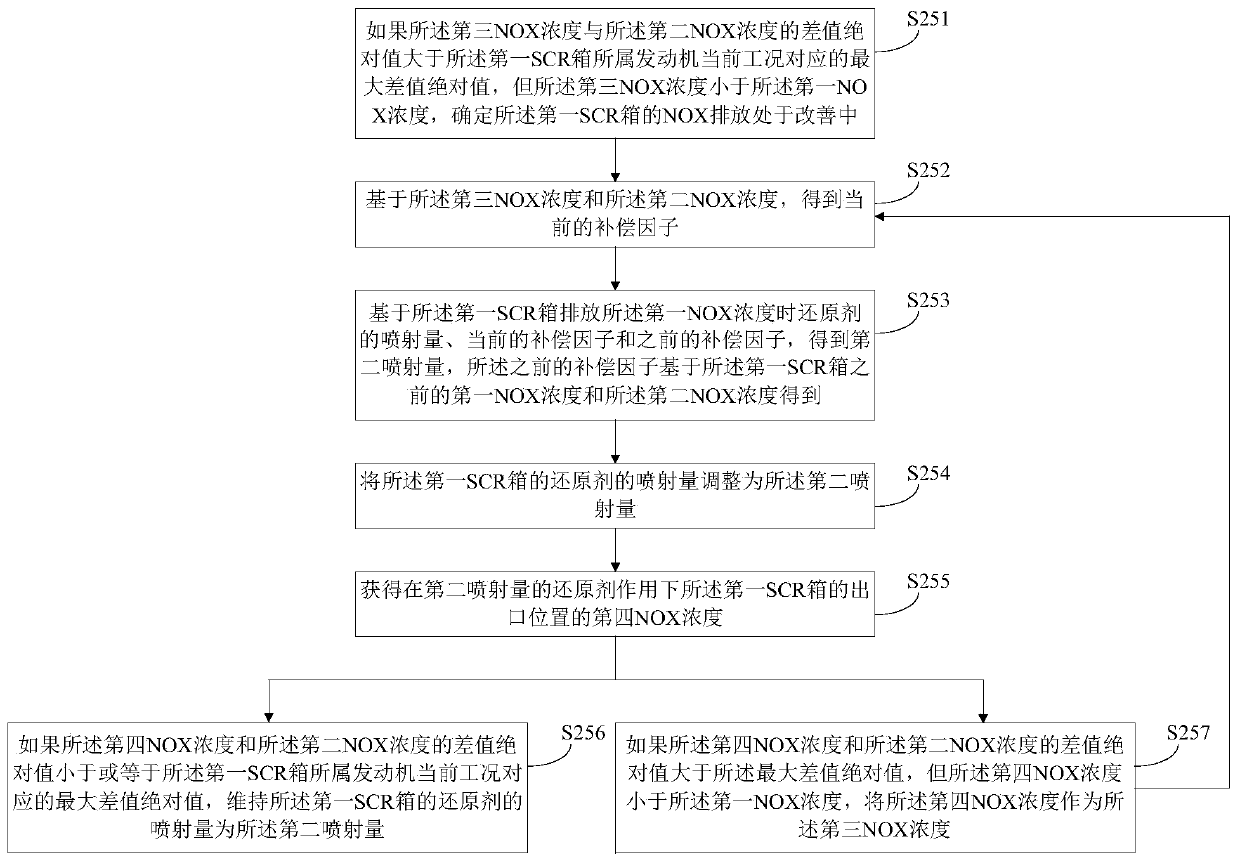

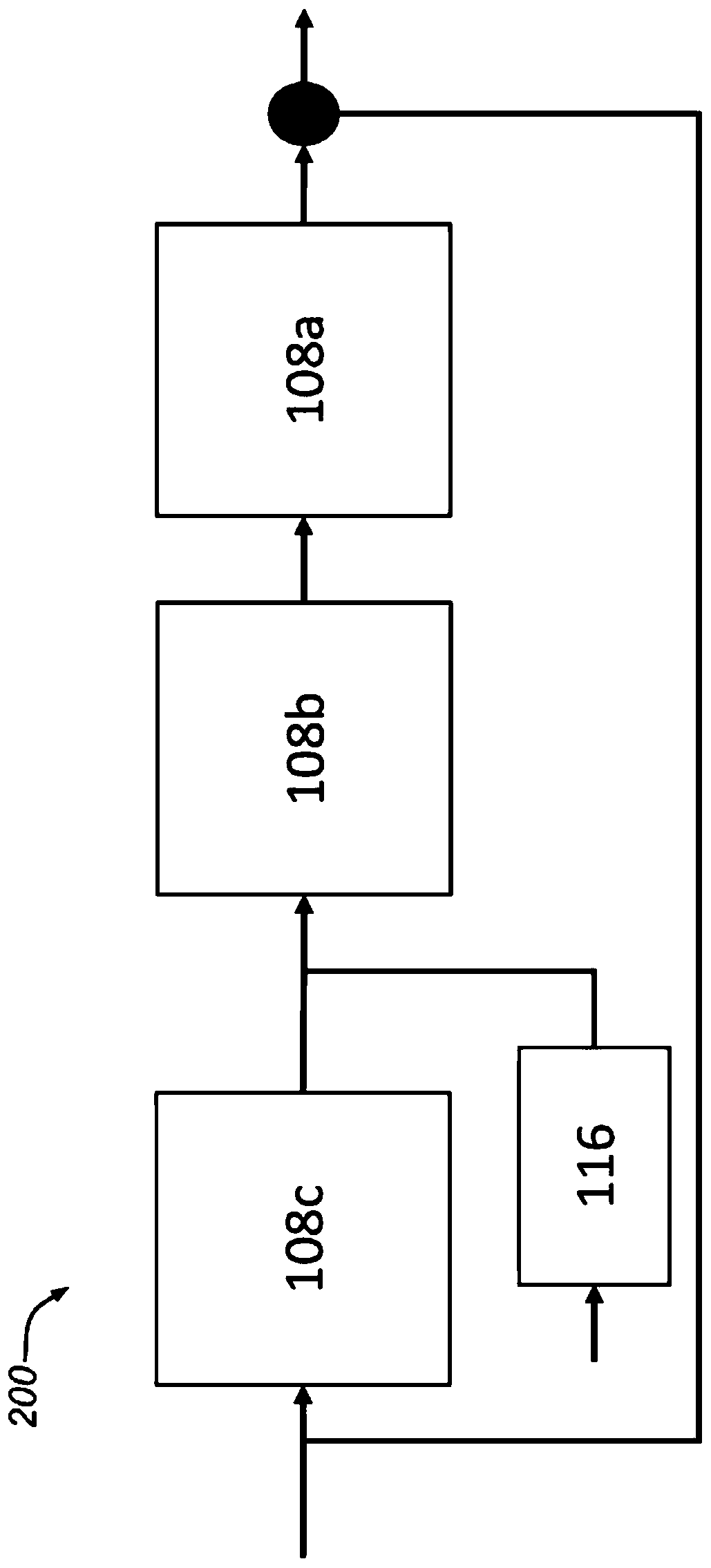

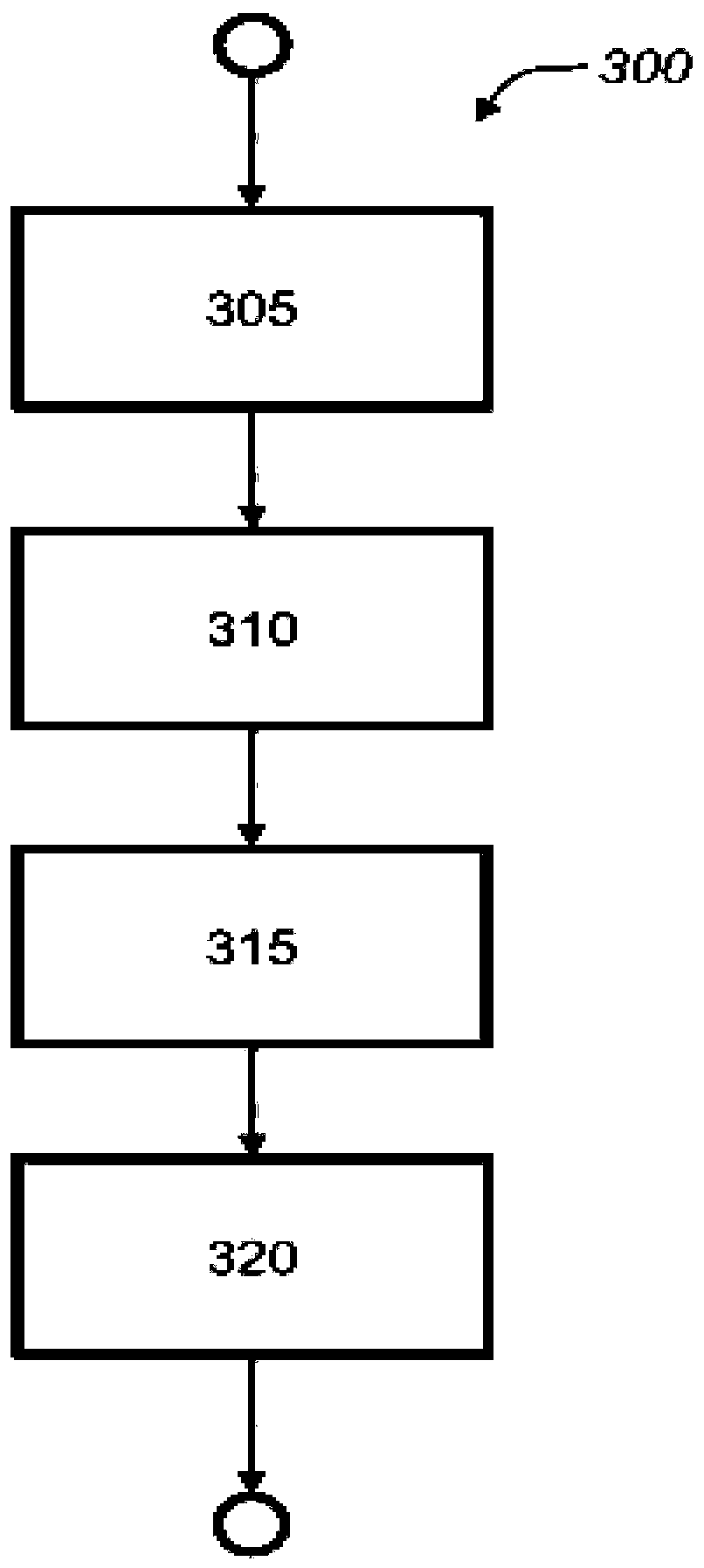

Reducing agent injection control method and device

ActiveCN110295979APrecise positioningEasy dischargeInternal combustion piston enginesExhaust apparatusExhaust fumesEngineering

The invention provides a reducing agent injection control method and device. The reducing agent injection control method comprises the following steps of: obtaining a first NOX concentration of an outlet position of a first SCR (selective catalytic reduction) tank and a second NOX concentration of an outlet position of a second SCR tank; if the degradation of the NOX discharge of the first SCR tank is determined based on the first NOX concentration and the second NOX concentration, adjusting the injection amount of a reducing agent of the first SCR tank at least two times based on the first NOX concentration, the second NOX concentration and the first injection amount of the reducing agent when the first SCR tank discharges the first NOX concentration. The reducing agent injection controlmethod and device can accurately locate the degraded SCR tanks, and reduce the NOX emission by adjusting the injection amount of the reducing agent of the degraded SCR tanks, and thus, when a nozzle is blocked, the emission degradation problem can be effectively solved by an injection amount adjustment manner, and further the NOX concentration in waste gases can be effectively reduced.

Owner:WEICHAI POWER CO LTD

Construction machine

ActiveCN101680209BDegree of inhibition reductionImprove reliabilityInternal combustion piston enginesExhaust apparatusHydraulic motorHydraulic cylinder

[PROBLEM] To provide a construction machine capable of performing necessary operation or operations without a difficulty even when a remaining amount of a reducing agent becomes small. [SOLUTION] In a hydraulic excavator having an engine, a hydraulic cylinder (18), plural actuators including a hydraulic motor (29), and an exhaust gas treatment system for subjecting, to purification treatment, nitrogen oxides in exhaust gas from the engine, the hydraulic excavator is provided with an actuator operation control means for performing, when the remaining amount of the reducing agent in a reducing agent storage tank (30) is detected by a remaining reducing-agent amount detector (33) to have become equal to or smaller than a predetermined remaining amount, limiting control to limit an operation of the hydraulic cylinder (18) such that a front working implement driven by the hydraulic cylinder (18) becomes difficult to exhibit its function, and at a same time, holding control for holding the hydraulic motor (20) operable such that a function of a travel base (1) or swing upperstructure (3) driven by the hydraulic motor (20) can be exhibited.

Owner:NIHON KENKI CO LTD

Regenerative combustion device

ActiveCN104848220BExtended service lifeReduce oxidation burnIndirect carbon-dioxide mitigationGaseous fuel burnerFurnace temperatureCombustible gas

Owner:SHENWU TECH GRP CO LTD

Burner and combustion device applying same

InactiveCN112610952ADoes not affect the maximum combustion effectIncreased maximum burning effectHeat storage plantsGaseous fuel burnerThermodynamicsCombustion chamber

The invention discloses a burner. The burner comprises a body, and the surface of the body is provided with a flame and gas outlet, a combustion-supporting gas inlet connector and gas inlet connectors. An inner cavity body is arranged in the body and comprises a combustion chamber, an air-fuel flow guide body cavity and a gas inlet channel. The combustion chamber communicates with the flame and gas outlet, the gas inlet channel communicates with the gas inlet connectors, the air-fuel flow guide body cavity and the gas inlet channel both communicate with the combustion chamber, and the combustion-supporting gas inlet connector communicates with the air-fuel flow guide body cavity. The gas inlet channel comprises a first-stage gas channel and multiple second-stage gas channels annularly arranged on the periphery of the first-stage gas channel, and the second-stage gas channels communicate with one another through an annular channel which is arranged on the periphery of the first-stage gas channel in a sleeving manner. The burner is provided, and the burner is respectively provided with the multiple flow levels of gas channels, minimum flow ignition is adopted, the supply amount of gas is gradually increased, and the situation of difficult ignition or ignition deflagration can be effectively avoided.

Owner:孙坤磊

Burner and combustion device using same

InactiveCN113154383ADoes not affect the maximum combustion effectIncreased maximum burning effectGaseous fuel burnerThermodynamicsCombustion chamber

The invention discloses a burner. The burner comprises a body, wherein a flame outlet, a combustion-supporting gas inlet connector and a gas inlet connector are arranged on the surface of the body, an inner cavity main body is arranged inside the body and comprises a combustion chamber, an air-fuel flow guide body cavity and a gas inlet channel, the combustion chamber communicates with the flame outlet, the gas inlet channel communicates with the gas inlet connector, the air-fuel flow guide body cavity and the gas inlet channel both communicate with the combustion chamber, the combustion-supporting gas inlet connector communicates with the air-fuel flow guide body cavity, the gas inlet channel comprises a first-stage gas channel and a plurality of second-stage gas channels annularly arranged on the periphery of the first-stage gas channel, and the second-stage gas channels communicate through an annular channel arranged on the periphery of the first-stage gas channel in a sleeve mode. The invention provides a burner which is provided with the gas channels with multiple flow levels, ignition is conducted through the minimum flow by the burner, then the supply amount of gas is gradually increased, and the situation that ignition is difficult or ignition deflagration occurs can be effectively avoided.

Owner:刘翠霞

Tea leaf steaming machine

InactiveCN102217681AImprove heating efficiencyIncrease profitPre-extraction tea treatmentCombustorForced-air

Provided is a tea leaf steaming machine, comprising a metal fiber burner, a casing, a roller, a smoke vent, etc. The metal fiber burner, the casing and the roller form an annular sealed chamber, wherein the upper part of the casing is provided with the smoke vent. The metal fiber burner can be of a natural injection type or a forced air blast type. The metal fiber burner can be made of metal fiber woven materials or metal fiber sintered materials.

Owner:广州市蓝炬能源科技有限公司

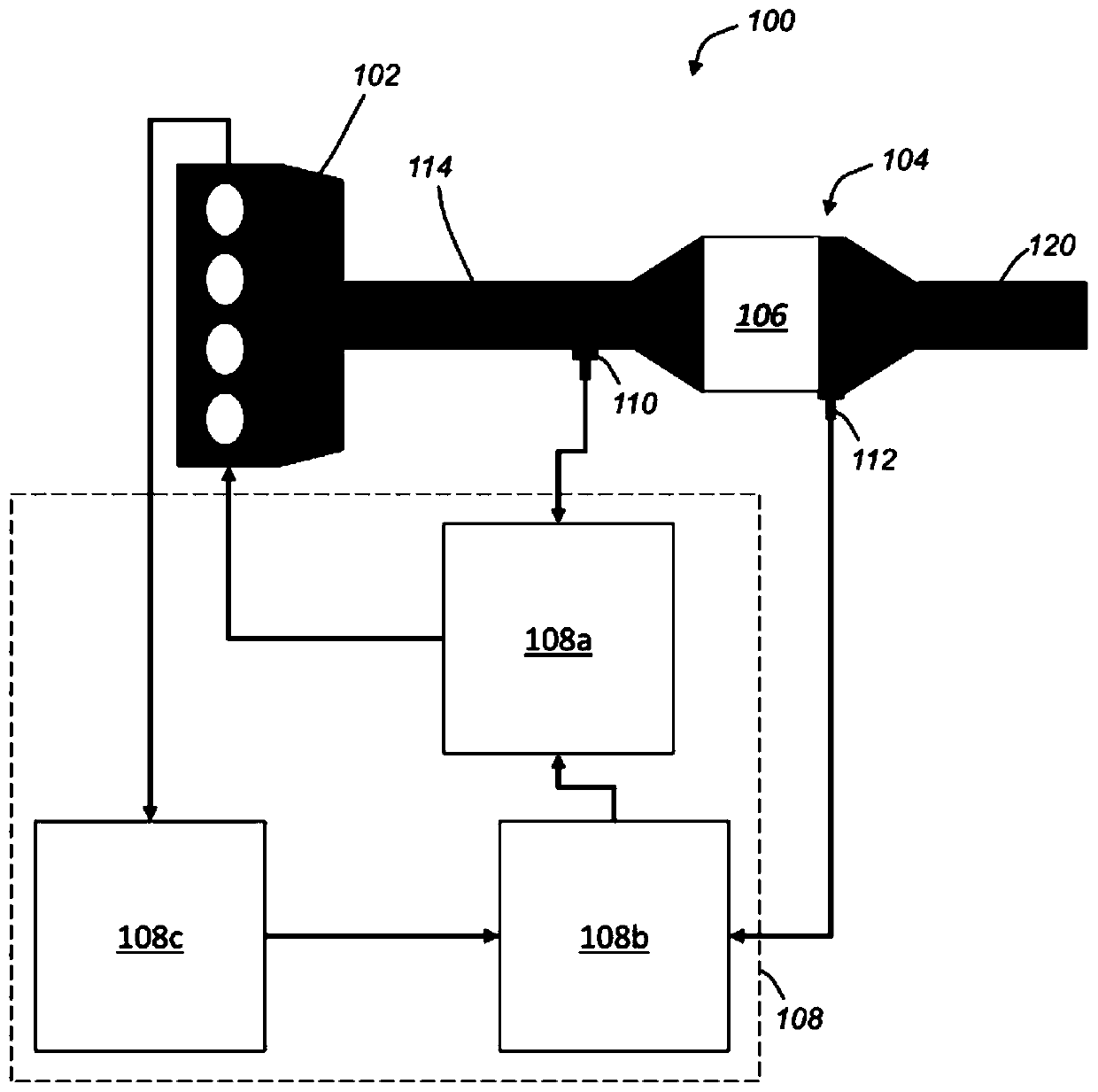

Nox formation prediction for improved catalytic converter control

InactiveCN111022158AReduce NOx concentrationGas treatmentElectrical controlCatalytic transformationNitrogen oxides

Methods of treating exhaust in a vehicle, and exhaust systems for a vehicle, are disclosed. Example methods may include providing a catalytic converter in an exhaust tailpipe and an oxygen sensor downstream of the catalytic converter. The catalytic converter may be configured to reduce a concentration of a nitrogen oxide (NOx) present in an exhaust flow through the catalytic converter. The methodfurther includes predicting an increase in an oxygen concentration within the catalytic converter based upon at least one or more real-time vehicle operating parameters, wherein the increase is predicted before a corresponding increase in oxygen concentration is measured by the downstream oxygen sensor. The method may also include adjusting an air-fuel ratio of an engine of the vehicle based uponthe predicted increase in oxygen concentration, thereby at least partially preventing the corresponding increase in the oxygen concentration.

Owner:GM GLOBAL TECH OPERATIONS LLC

Burner and combustion device using same

PendingCN114060809ADoes not affect the maximum combustion effectIncreased maximum burning effectHeat storage plantsGaseous fuel burnerThermodynamicsCombustion chamber

The invention discloses a burner which comprises a body, wherein a flame outlet, a combustion-supporting gas inlet connector and a fuel gas inlet connector are arranged on the surface of the body, an inner cavity main body is arranged in the body and comprises a combustion chamber, an air-fuel flow guide body cavity and a fuel gas inlet channel, the combustion chamber is communicated with the flame outlet, the gas inlet channel is communicated with the gas inlet connector, the air-fuel flow guide body cavity and the fuel gas inlet channel are both communicated with the combustion chamber, the combustion-supporting gas inlet connector is communicated with the air-fuel flow guide body cavity, the fuel gas inlet channel comprises a first-stage gas channel and a plurality of second-stage gas channels annularly arranged on the periphery of the first-stage gas channel, and the second-stage gas channels are communicated through an annular channel arranged on the periphery of the first-stage gas channel in a sleeving mode. The disclosed burner is provided with gas channels with multiple flow levels, ignition is conducted through the minimum flow, then the supply amount of gas is gradually increased, and the situation that ignition is difficult or ignition deflagration occurs can be effectively avoided.

Owner:孙坤磊

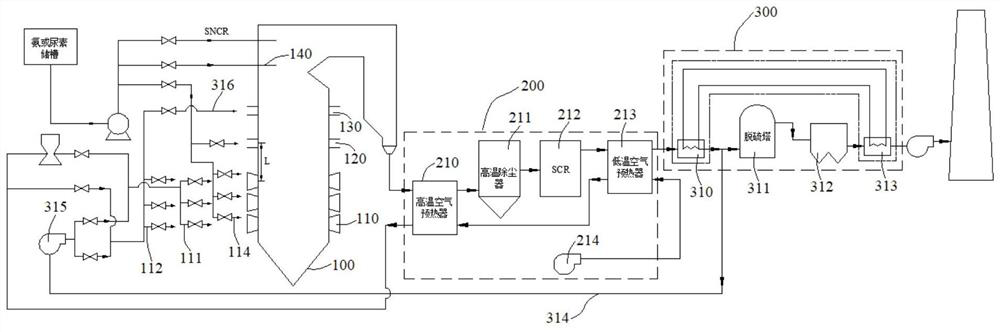

A supercritical carbon dioxide coal-fired boiler denitrification, desulfurization and dust removal integrated system

ActiveCN111450681BRealize deep denitrificationAchieve graded denitrificationGas treatmentLighting and heating apparatusCombustorFlue gas

The invention discloses a supercritical carbon dioxide coal-fired boiler denitrification, desulfurization and dust removal integrated system, which belongs to the technical field of NOx emission reduction. The boiler unit of the present invention is equipped with a multi-stage ammonia injection denitrification device to realize graded denitrification in the furnace, and the dust removal and denitrification unit can denitrify and remove dust again through selective catalytic reduction reaction; the combustion in the low-temperature flue gas recirculation mode can effectively reduce the temperature in the furnace and reduce the Thermal NOx generation reduces the concentration of NOx emitted from the furnace tail. At the same time, because the oxygen concentration of the recirculated flue gas is reduced, it is beneficial to meet the annular high-temperature and low-oxygen reduction zone formed by the ammonia injection burner, thereby realizing the deep denitrification of supercritical carbon dioxide coal-fired boilers. . The invention overcomes the insufficient denitrification degree caused by the high temperature of the supercritical carbon dioxide coal-fired boiler, can combine the three-stage ammonia injection denitrification process with the dust removal desulfurization and denitrification process, and denitrifies the flue gas cycle, realizing the integration of desulfurization, dust removal and denitrification.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Combustion treatment device and process for nitrogen-containing raw material

PendingCN111928251AInhibit transformationReduce NOx concentrationIncinerator apparatusCombustion chamberThermodynamics

The invention discloses a multi-phase combustion treatment device for nitrogen-containing raw material. The multi-phase combustion treatment device comprises a pyrolysis section and a combustion section which are connected into a whole, wherein a multi-medium combustor and a plurality of nitrogen-containing raw material inlets are arranged at one end of the pyrolysis section; the multi-medium combustor is provided with a plurality of inlets used for introducing high-calorific-value waste gas and liquid and air for combustion of the high-calorific-value waste gas and liquid; the combustion section comprises a plurality of communicated combustion chambers and is used for completely combusting pyrolysis products step by step; and the other end of the pyrolysis section is connected to one of the combustion chambers. The invention further provides a multi-phase combustion treatment process of the nitrogen-containing raw material. According to the combustion treatment device and process, integrated multi-phase combustion can be carried out especially for high-nitrogen three wastes, the NOx conversion rate of raw material nitrogen is reduced to 5% or below, the oxygen content of flue gasis controlled within 1%-5%, the flue gas amount and the flue gas purification cost are reduced, and better social and economic benefits are achieved.

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

A biomass briquette fuel hot water boiler system

ActiveCN107120824BEnhance the intensity of radiation heat transferHigh thermal efficiencySolid fuel combustionWater heatersWater circulationBiomass briquettes

The invention relates to a biomass briquette hot water boiler system. The biomass briquette hot water boiler system is characterized by comprising a boiler, a water circulation system, a fire grate and combustion system, a heat transfer system, a briquette fuel feeding system, a dust removal system, an induced draught system, a flue gas recirculation system, a solar photovoltaic power system and a control system; fuel in the briquette fuel feeding system enters the fire grate and combustion system through a feeding opening in the lower end of the boiler and is used for combustion, high-temperature flue gas generated during combustion heats low-temperature water in the water circulation system through the heat transfer system, the heated high-temperature water is conveyed to a glasshouse, the low-temperature flue gas enters the dust removal system through a smoke outlet of the heat transfer system, the flue gas obtained after dust removal is conducted through the dust removal system is extracted by the induced draught system, part of the flue gas is exhausted through a chimney, the other part of the flue gas enters the fire gate and combustion system through the flue gas recirculation system, and furthermore a small part of flue gas is extracted and used for supplementing carbon dioxide required by the photosynthesis of crops to the glasshouse. The biomass briquette hot water boiler system can be widely applied to a renewable energy source heating system.

Owner:TSINGHUA UNIV

Method for operating an exhaust gas aftertreatment system of an internal combustion engine, an exhaust gas aftertreatment system for an internal combustion engine, and an internal combustion engine comprising such an exhaust gas aftertreatment system

InactiveCN109952419AReduce the temperatureReduce NOx-concentrationInternal combustion piston enginesSilencing apparatusExhaust gasExhaust fumes

The invention relates to a method for operating an exhaust gas aftertreatment system (3) of an internal combustion engine (1), wherein at least one operating parameter is detected during the operationof the exhaust gas aftertreatment system, the operating parameter being associated with an oxidation state of an SCR catalyst material of the exhaust gas aftertreatment system (3), and at least one measure for preventing an ongoing reduction of the SCR catalyst material and / or at least one reoxidizing measure for reoxidizing the SCR catalyst material is introduced in accordance with the at leastone operating parameter.

Owner:MOTOREN & TURBINEN UNION FRIEDRICHSHAFEN GMBH

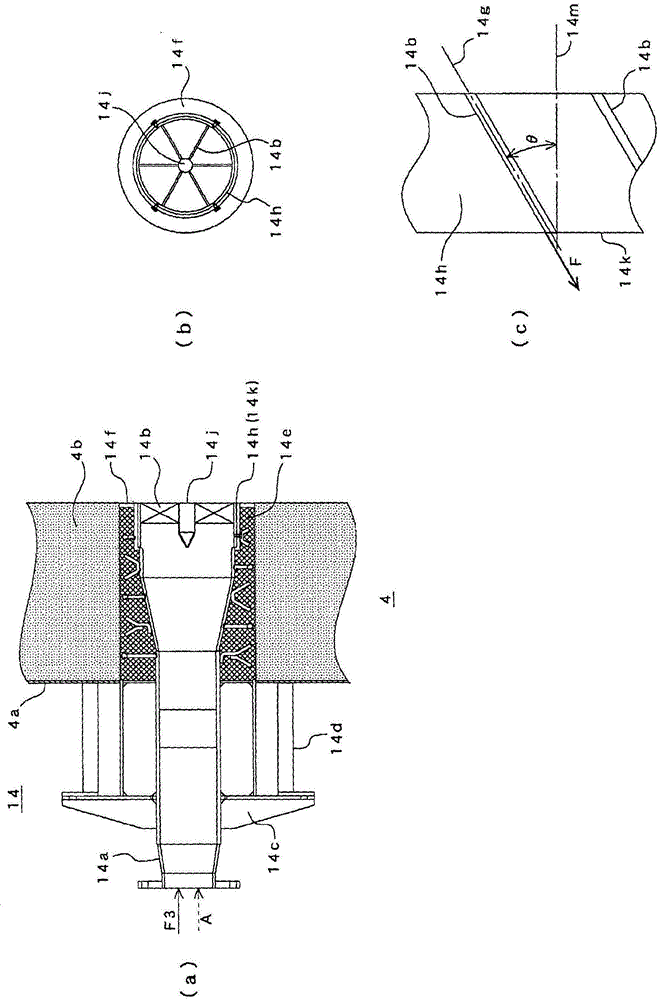

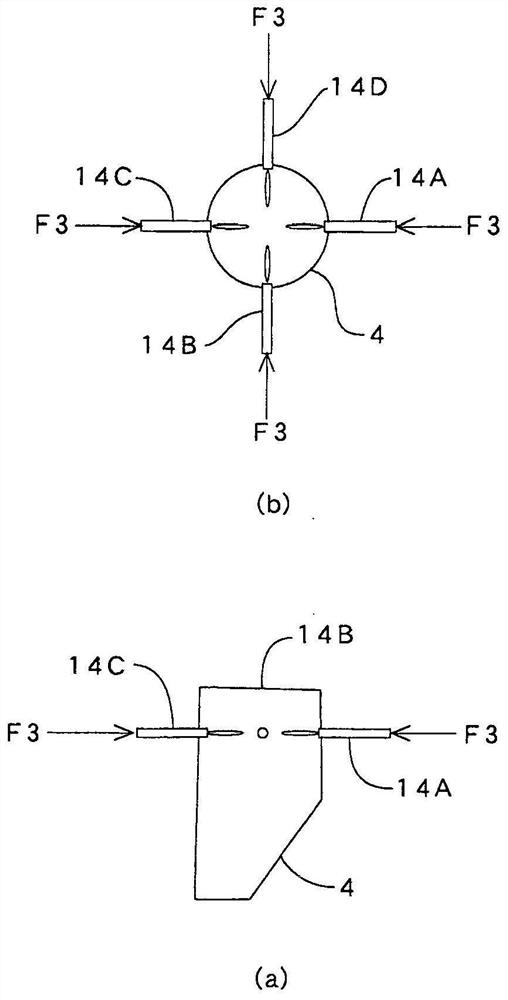

Cement firing device and cement kiln exhaust gas denitrification method

PendingCN112601725AReduce NOx concentrationDispersed particle separationClinker productionCombustorEnvironmental engineering

[Problem] To reduce the NOx concentration in cement kiln exhaust gas. [Solution] A cement firing device 1 is equipped with a plurality of denitrification burners 14 (14A to 14D) which are provided atthe kiln inlet 4 of a cement kiln 5 and inject, into the kiln inlet, combustion air and a fuel F3 in an overall amount of between 50% and 100% of the fuel F2 being burned in a precalcination oven 3 installed on the cement kiln. Increasing the fuel injected into the kiln inlet increases the amount of reducing agent, while causing the influence from the kiln inlet O2 to be mostly lost, allowing theNOx concentration in the kiln exhaust gas to be reduced further. The provision of a plurality of denitrification burners allows for a reduction in the injection amount per denitrification burner, theprevention of coating adhesion and fuel-to-fuel collision, and a higher probability of the injected fuel mixing with the kiln exhaust gas flowing in the kiln inlet and colliding with the NOx in the kiln exhaust gas. Providing the plurality of denitrification burners in the same horizontal plane further increases the probability of colliding with the NOx in the kiln exhaust gas.

Owner:TAIHEIYO ENG

Multistage for-infrared radiation machine

InactiveCN1099559CNot cut lossesHigh thermal efficiencyBurnersHot-air central heatingCombustorHeat losses

The present invention provides a nuisanceless multistage far-infrared radiation machine with less heat loss of exhaust gas. A far infrared rays radiating tube at the outlet port of combustion gas of a catalyst combustion device of a burner of the multistage far-infrared radiation machine, is connected in series to one or two heat generating units, provided with a far infrared rays radiating tube at the combustion gas outlet port of a burner combustion device.

Owner:MITSUBISHI OIL CO LTD +1

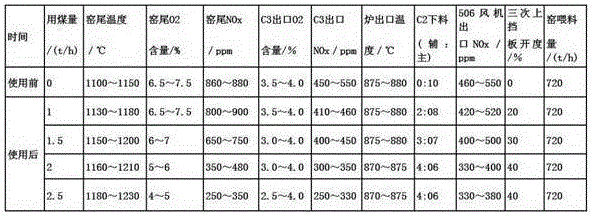

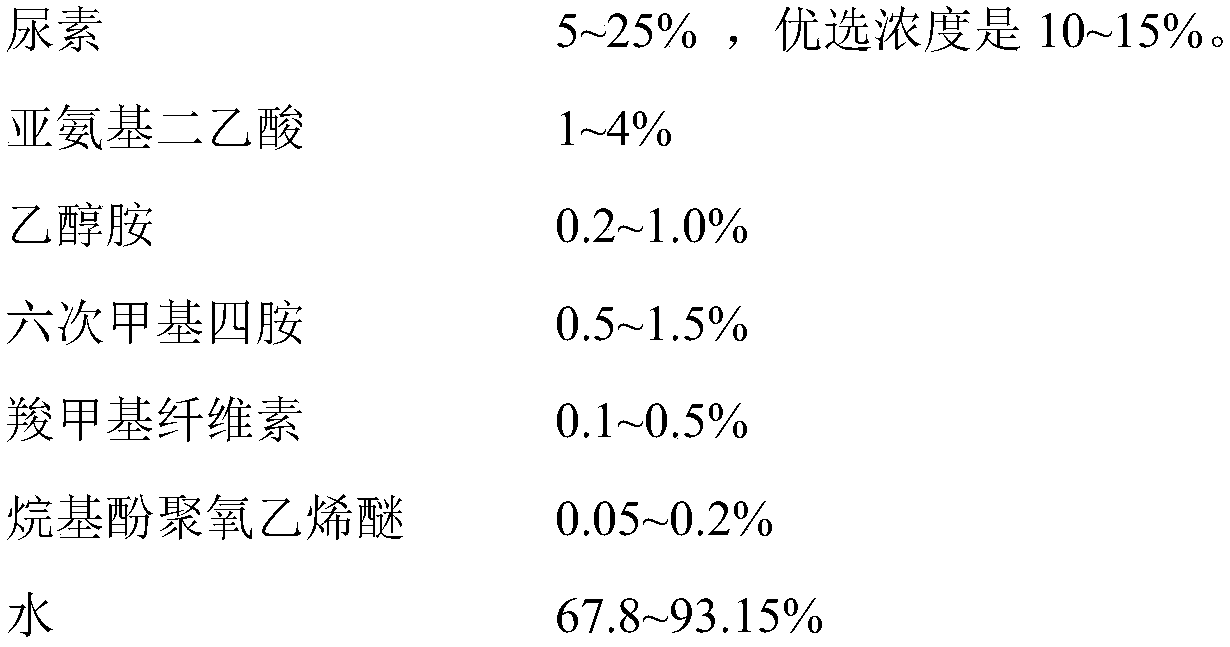

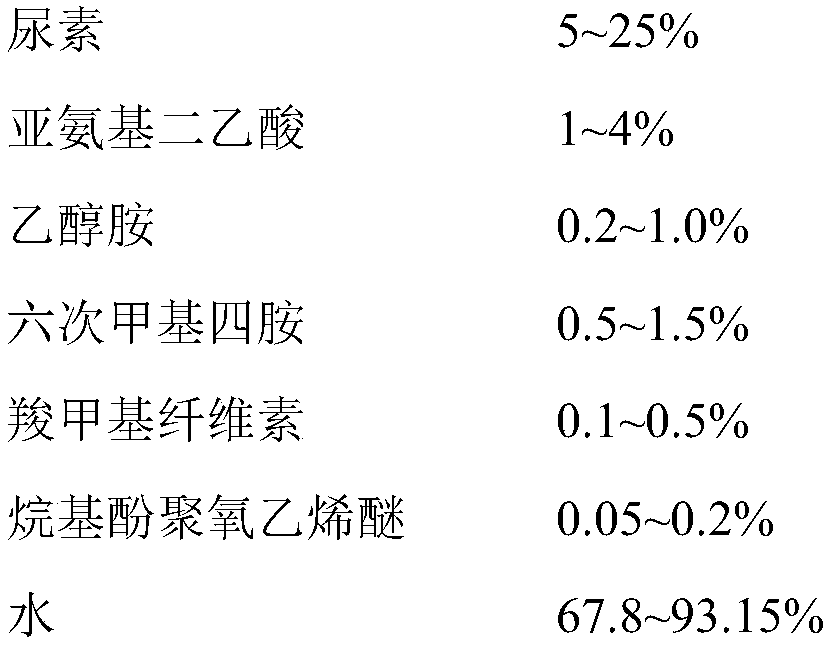

Emission reduction method of nitrogen oxide of cement enterprises

InactiveCN105805776ARegulatory successReduce NOx concentrationFuel supply regulationCombustorNitrogen oxides

The invention discloses an emission reduction method of nitrogen oxide of cement enterprises. The emission reduction method comprises the step of controlling the operation of a denitrification burner in a cement kiln: the coal feeing amount is 1 t / h, 0.5 t of coal is added every 24 hours, and the maximum coal feeing amount is not larger than 10% that of coal used by the kiln head. According to the emission reduction method, the regulation of a denitrification device is relatively successful, a desired effect is achieved, the NOx concentration of the system is obviously reduced, the working condition of the kiln is stably controlled, and related data and certain experience are accumulated for official use.

Owner:廖引家

A method for purifying tail gas containing nitrogen oxides

ActiveCN105854542BSuitable for handlingEfficient purificationGas treatmentDispersed particle separationRoom temperatureNitrogen

The invention relates to a method for purifying nitrogen-containing oxide tail gas. In a static supergravity-ultrasonic reaction absorption device, air is used as an oxidant, NOx-containing oxide tail gas and a denitration solution perform contact reaction at the room temperature. The NOx removing process can be quickly and efficiently completed, so that the NOx concentration in the tail gas is reduced to be 30 mg / m<3> or below. The method is suitable for various NOx-containing treatments.

Owner:天津市翼腾云拓科技有限公司

A supercritical carbon dioxide coal-fired boiler deep denitrification process

ActiveCN111450682BRealization of deep denitrificationReduce the temperatureGas treatmentLighting and heating apparatusThermodynamicsCombustor

The invention discloses a deep denitrification process for a supercritical carbon dioxide coal-fired boiler, which belongs to the technical field of NOx emission reduction. The present invention includes three-stage ammonia injection denitrification: the ammonia injection burner is used to inject fuel and ammonia reductant to the main combustion area of the burner in the furnace respectively to form an annular high-temperature and low-oxygen reduction area with a temperature of 850-1400°C, where the reduction reaction takes place Realize the first-level denitrification; the second-level ammonia injection device and the third-level ammonia injection device spray ammonia reductant to the main combustion zone above the high-temperature and low-oxygen reduction zone and the burnout zone after the burn-out air to realize the second-level and third-level denitrification; dust removal Desulfurization and denitrification: After the flue gas is denitrated by SCR in the dust removal and denitrification unit, it is cooled to 70-90°C and then sent to the furnace for cyclic denitrification treatment. The present invention overcomes the deficiency of insufficient denitrification degree caused by high temperature of supercritical carbon dioxide coal-fired boilers. The three-stage ammonia injection denitrification process realizes deep graded denitrification in the furnace, and the recirculation combustion of low-temperature flue gas effectively reduces the temperature in the furnace, reduces the generation of thermal NOx, and realizes Supercritical carbon dioxide coal-fired boiler deep denitrification.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Novel denitration method for concrete

InactiveCN105833681ARegulatory successAchieve the desired effectGas treatmentDispersed particle separationAqueous solutionAir temperature

The invention discloses a novel denitrification method for cement, which adopts a selective non-catalytic reduction method for denitrification, wherein the reducing agent is 20% by weight urea aqueous solution, which is sprayed at a temperature of 1000°C in the middle of the calciner. The regulation and control of the present invention is relatively successful, and the expected effect is obtained. The NOx concentration of the system is obviously reduced, and the working condition of the kiln is stable and controlled, and related data and certain experience are accumulated for formal use in the future.

Owner:廖引家

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com