Burner and combustion device using same

A combustion device and combustion chamber technology, applied in the direction of burners, combustion methods, combustion types, etc., can solve the problems of difficult ignition of gas pipes, ignition deflagration, and affecting the maximum combustion effect of burners, so as to improve combustion effect and reduce NOx concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

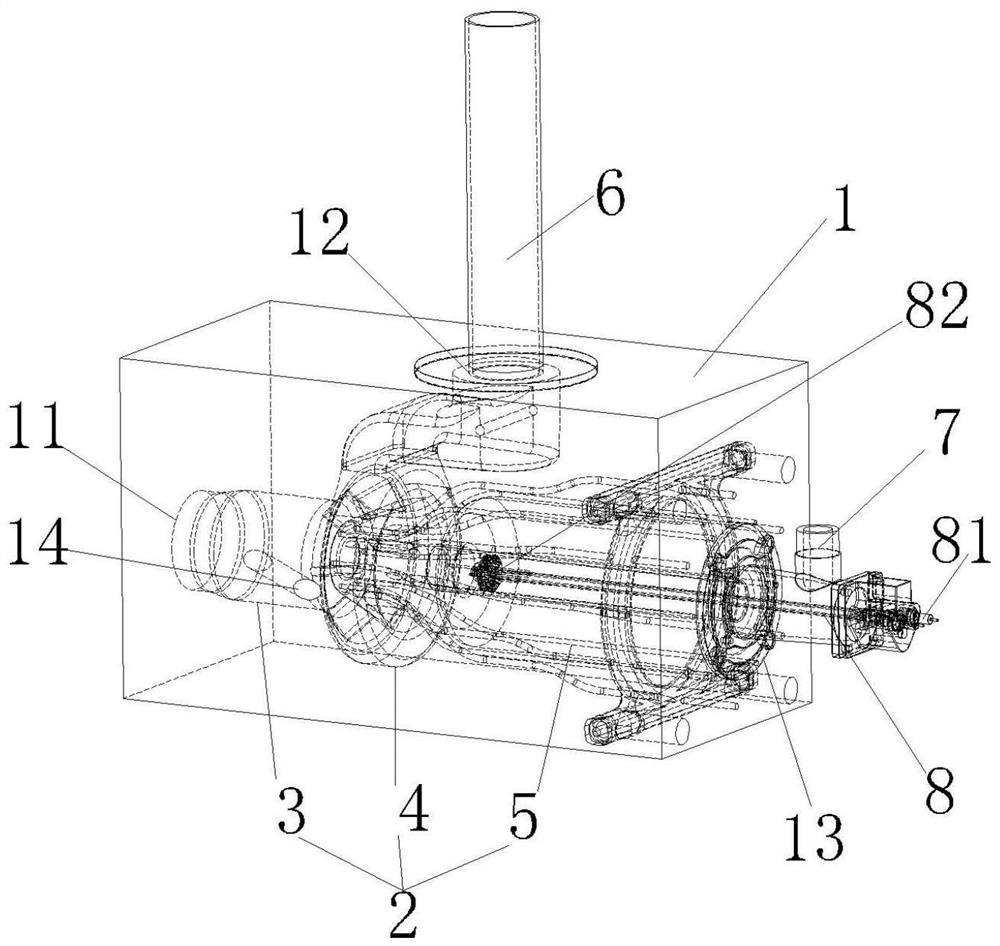

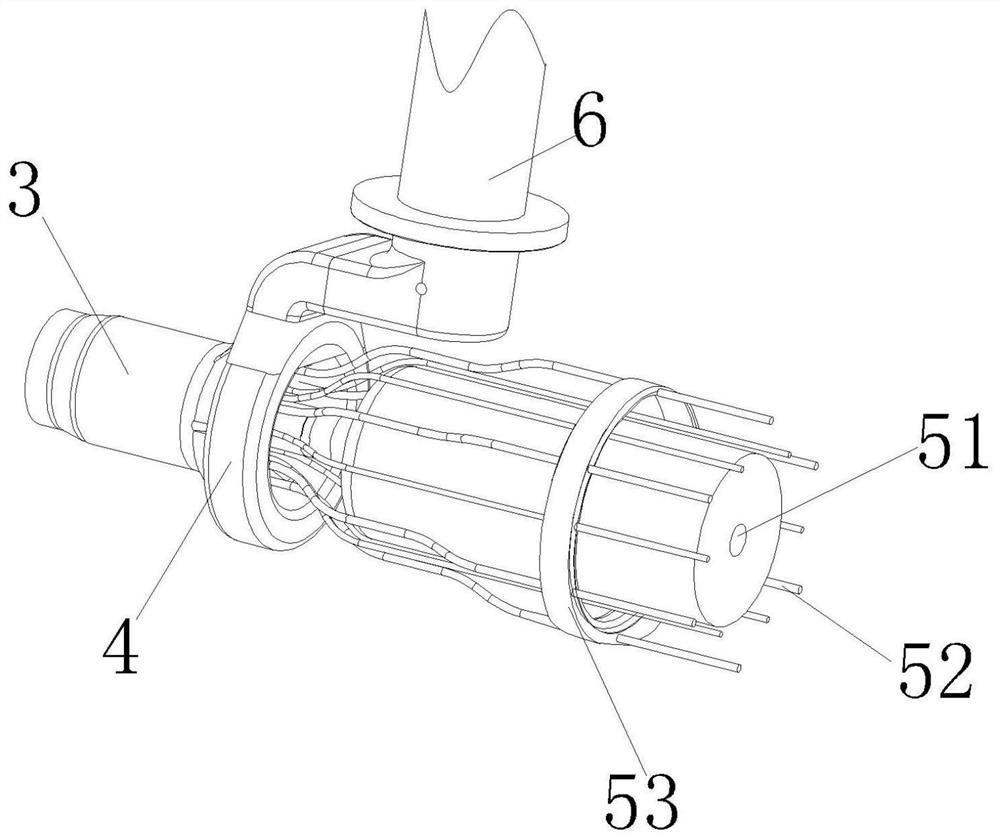

[0026] Such as figure 1 As shown, a burner is disclosed in this embodiment, which includes a body 1, and the surface of the body 1 is provided with a flame outlet 11, a gas-supporting gas inlet port 12 for communicating with the gas-supporting gas conduit 6, and several The gas inlet port 13 communicated with the gas conduit 7. The main body 1 is provided with an inner chamber main body 2. The inner chamber main body 2 includes a combustion chamber 3, an air-fuel guide chamber 4 and a gas inlet channel 5. The combustion chamber 3 communicates with the flame outlet 11, and the gas inlet channel 5 communicates with the gas The air inlet port 13 is connected, the air-fuel guiding body chamber 4 and the gas inlet channel 5 are connected to the combustion chamber 3 , and the gas-supporting gas inlet port 12 is connected to the air-fuel guiding body chamber 4 . combine figure 2 As shown, the gas inlet passage 5 includes a primary gas passage 51, an annular passage 53 and several ...

Embodiment 2

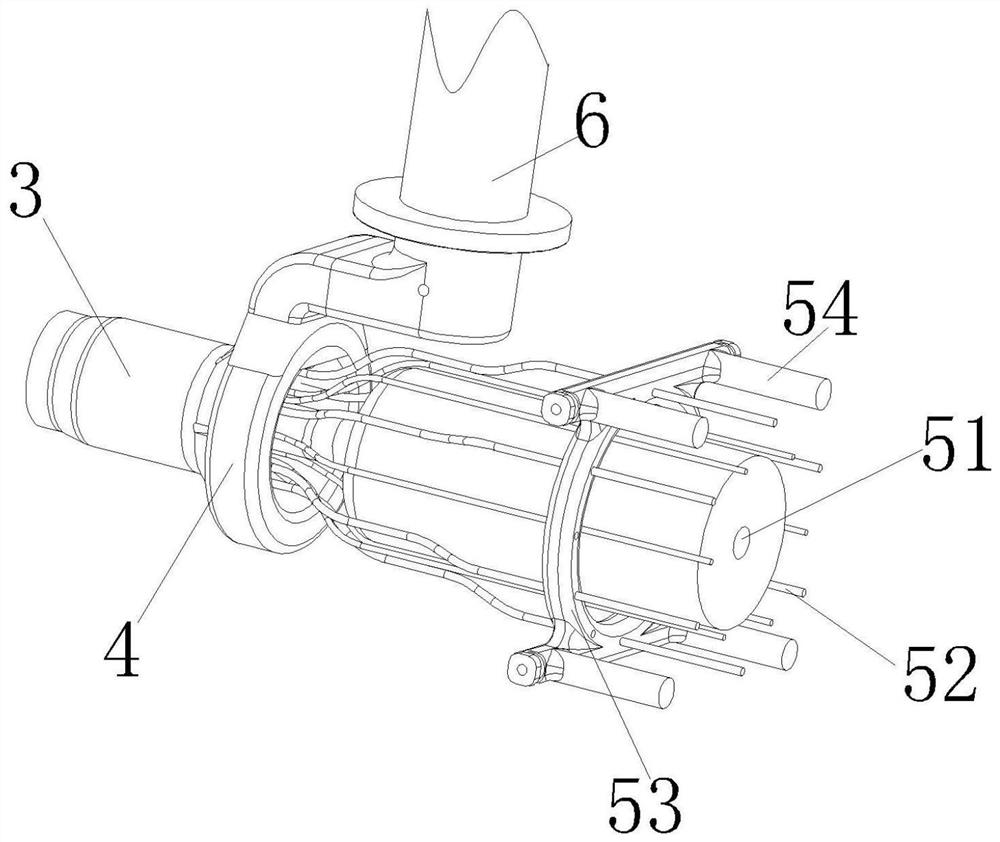

[0031] This embodiment is different from Embodiment 1 in that the gas inlet passage 5 also includes a plurality of three-stage gas passages 54, and the three-stage gas passages 54 communicate with the annular passage 53. Correspondingly, the number of gas inlet ports 13 is one The sum of the number of first-level gas passages 51, second-level gas passages 52 and third-level gas passages 54. The sum of the sectional areas of the air inlets of the four tertiary gas passages 54 is greater than the sum of the sectional areas of the air inlets of the secondary gas passages 52 .

[0032] In this embodiment, the number of three-level gas passages 54 is four, and it can also be replaced by three, five or six-level gas passages. Correspondingly, the number of gas inlet ports 13 communicating with the gas conduit 7 changes accordingly.

Embodiment 3

[0034] combine Figure 4-6 As shown, a combustion device is disclosed in this embodiment, which uses any burner in Embodiment 1 or Embodiment 2. The heat storage body 10 is provided with a space for storing exhaust gas, and the body 1 is provided with a flame outlet. One end of the air outlet 11 extends into the heat storage body 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com