Pulverized coal fired boiler with ultralow nitric oxide emission

A nitrogen oxide, pulverized coal boiler technology, applied in the field of pulverized coal boilers, can solve the problems of high operating cost, large energy consumption, environmental pollution, etc., and achieve the effects of efficiently utilizing furnace space, reducing NOx concentration, and reducing catalyst costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

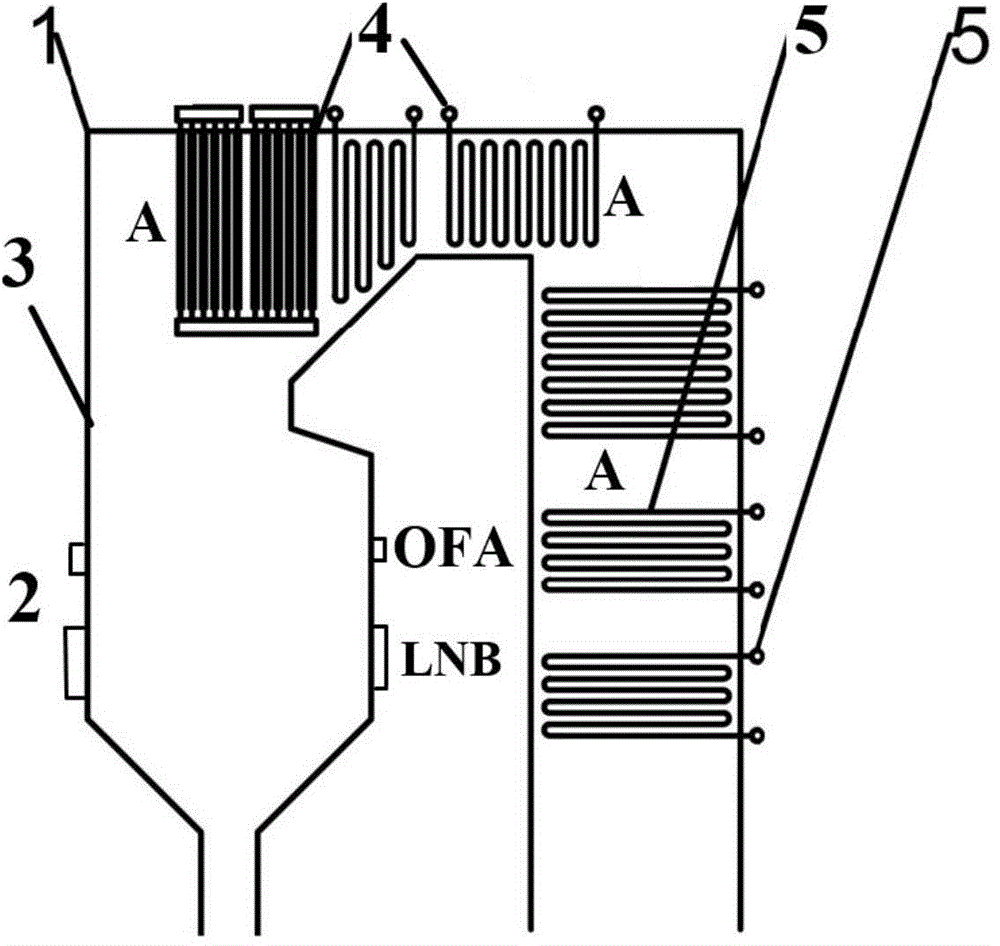

[0037] Such as figure 1 The pulverized coal boiler with ultra-low NOx emissions shown includes a furnace 1, a boiler burner 2 with a reducing agent generator, and a water-cooled wall heating surface 3, a panel heating surface 4, and convection heating installed in the furnace 1. Surface 5. During the operation of the boiler, the low-nitrogen burner LNB deep air classification is used, the excess air coefficient of combustion is 0.6, the original production of NO is 120ppm, the molar ratio of CO and NO is adjusted to 2.5 by using the overfired air OFA, and the concentration of CO production is 300ppm. The regional temperature is 1100°C. In order to improve the denitrification reaction efficiency, a 1mm-thick attached catalyst layer A is welded and attached to the screen-type heating surface 4. The surface temperature of the screen-type heating surface 4 is 750°C, and the main component of the attached catalyst layer is Fe 2 o 3 and CuO. After the denitration reaction, the N...

Embodiment 2

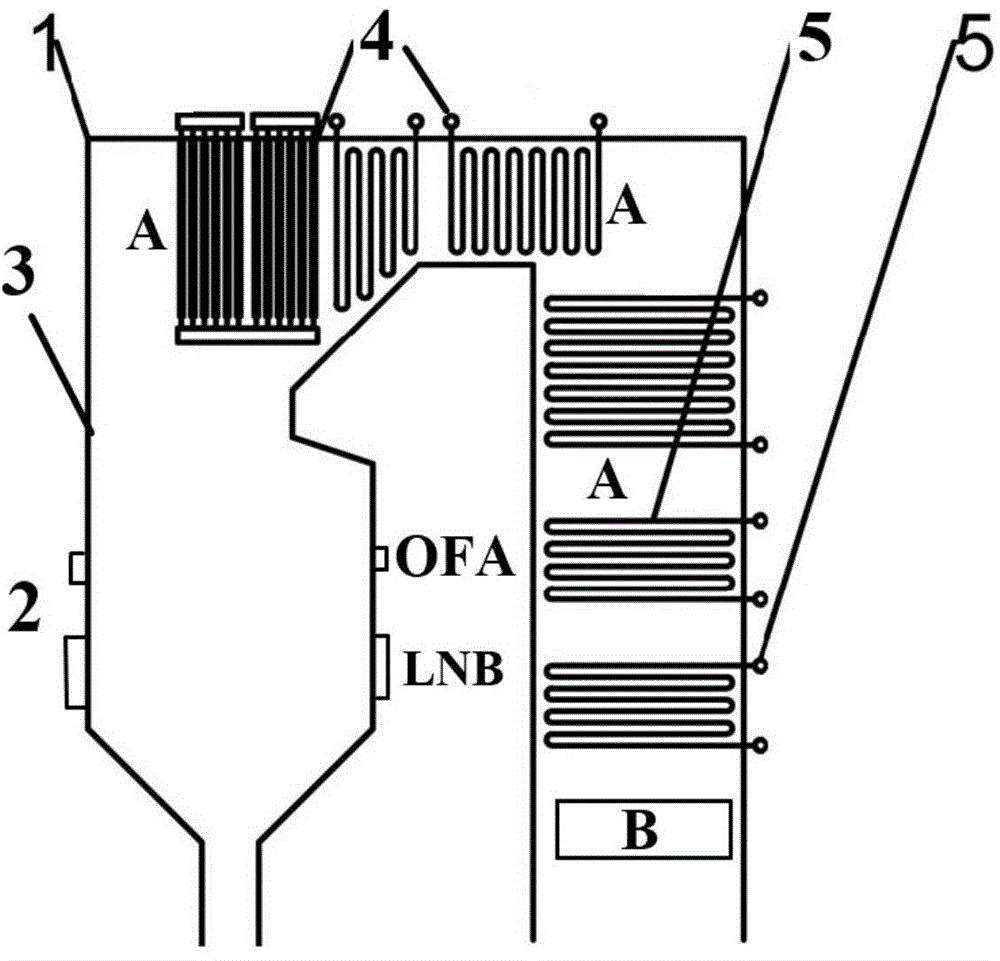

[0039] Such as figure 2 The pulverized coal boiler with ultra-low nitrogen oxide emissions shown in the figure sets an independent independent catalyst layer B to improve the denitrification efficiency. The independent catalyst layer B adopts a honeycomb catalyst and is arranged in one layer. The main component of the attached catalyst layer is Fe 2 o 3 and oxides of rare earth elements. After the denitration reaction, the NO emission concentration is reduced to 10ppm, and the denitration efficiency is increased to 92%.

Embodiment 3

[0041] In the pulverized coal boiler with ultra-low nitrogen oxide emissions in this embodiment, the excess air coefficient of the low-nitrogen burner LNB combustion is 0.8, the original production amount of NO is 200ppm, and the molar ratio of CO and NO is adjusted to 3 by using the overfired air OFA, corresponding to The CO generation concentration is 600ppm, and the combustion zone temperature is 1200°C. On the panel heating surface 4 and the convection heating surface 5, a catalyst layer A with a thickness of 1.5mm is welded and attached. The surface temperature of the panel heating surface 4 is 800°C, and the surface temperature of the convection heating surface 5 is 600°C. The main component of the catalyst layer is Fe 2 o 3 and CuO. After the denitration reaction, the NO emission concentration is reduced to 50ppm, and the denitration efficiency is 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com