A channel type mixer device for efficient SNCR denitration of flue gas of a pulverized coal boiler

A pulverized coal boiler and mixer technology, which is applied in gas treatment, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as low out-of-stock efficiency, and achieve the effects of extending service life, good economic benefits, and promoting interaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below with reference to the accompanying drawings.

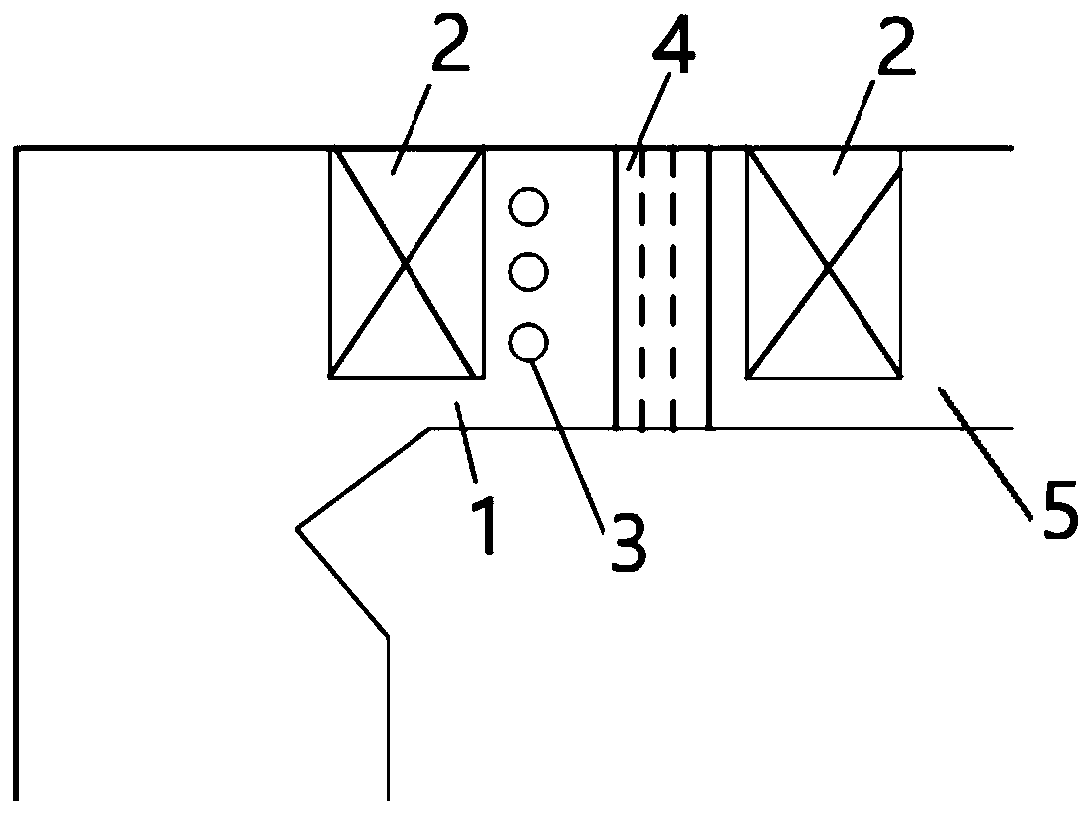

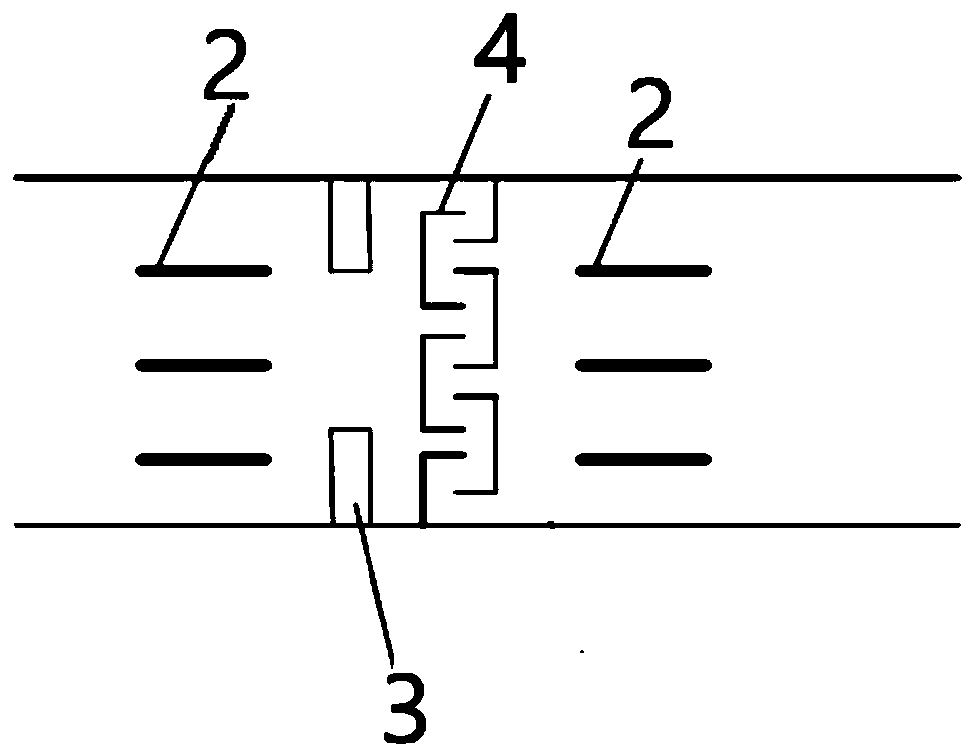

[0024] like figure 1 and figure 2 As shown, the present invention provides a trough mixer device for realizing high-efficiency SNCR denitrification of pulverized coal boiler flue gas, including furnace outlet flue 1, first screen heat exchanger 2, SNCR pneumatic spray gun 3, trough mixer 4, the second screen heat exchanger 6 and the downstream flue 5, wherein the first screen heat exchanger 2, the SNCR pneumatic spray gun 3, the trough mixer 4 and the second screen heat exchanger 6 are installed in sequence In the inner cavity of the furnace outlet flue 1 of the pulverized coal boiler.

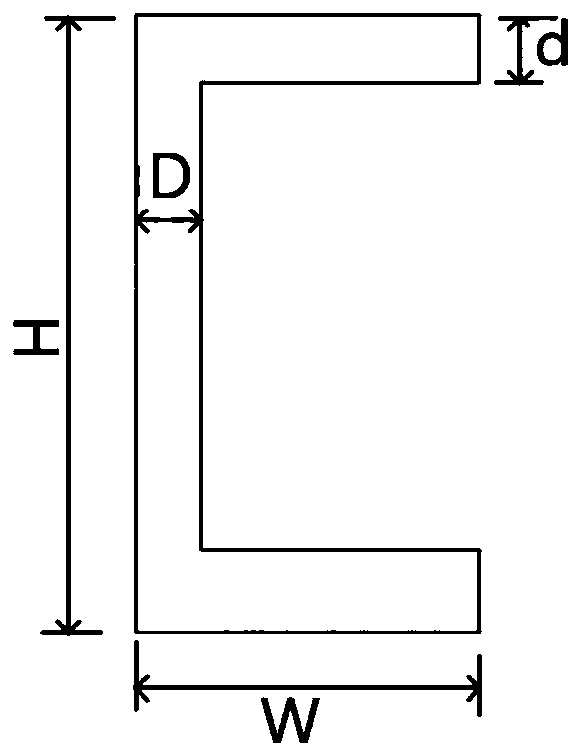

[0025] like image 3 As shown, the basic unit of the trough mixer 4 is the channel steel 6, the material of the channel steel 6 is 310S stainless steel, which can use standard channel steel parts or be customized according to the optimized simulation data, and its key dimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com