Emission reduction method of nitrogen oxide of cement enterprises

A nitrogen oxide and enterprise technology, applied in the cement field, can solve the problems of unoptimistic emission reduction and high pressure, and achieve the effect of decreasing NOx concentration and stable and controlled working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

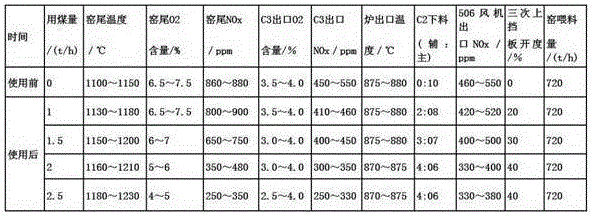

Examples

Embodiment Construction

[0007] The present invention will be described in detail below in conjunction with specific embodiments. The description in this section is only exemplary and explanatory, and should not have any limitation on the protection scope of the present invention.

[0008] The control of the denitrification burner in the cement kiln is as follows:

[0009] (1) After the kiln tail denitrification burner is put into use, the given coal feed rate lt / h will increase by 0.5 tons every 24 hours, and the maximum coal feed rate will not exceed 10% of the kiln head coal consumption. Pay close attention to the crust of the kiln tail during use;

[0010] (2) During the control period, the upper third air damper is gradually opened, and the lower third air damper is gradually closed according to the operation of the rotary kiln;

[0011] (3) Gradually adjust the material distribution of the main and auxiliary slide pipes according to the analysis data of the kiln tail and C3 outlet gas and the material d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com