Cement firing device and cement kiln exhaust gas denitrification method

A cement kiln and denitrification technology, applied in chemical instruments and methods, separation methods, cement production, etc., can solve the problems of high operating costs, high urea prices, low denitration efficiency, etc., to reduce NOx concentration, improve collision probability, reduce Effects of small NOx concentrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

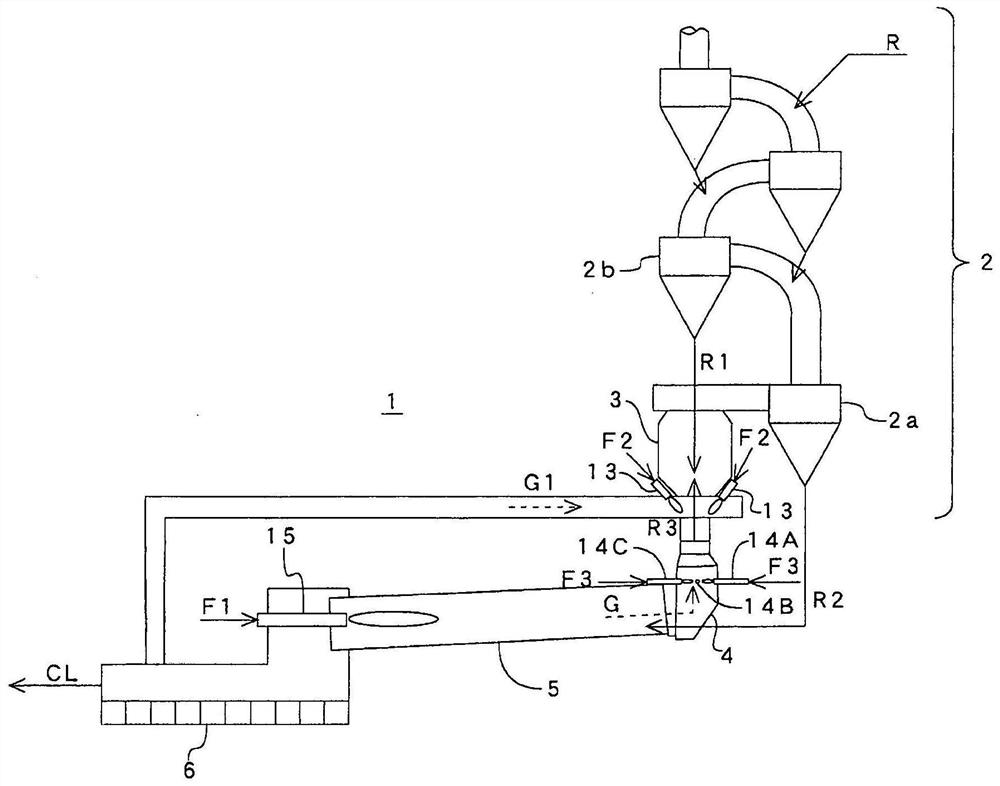

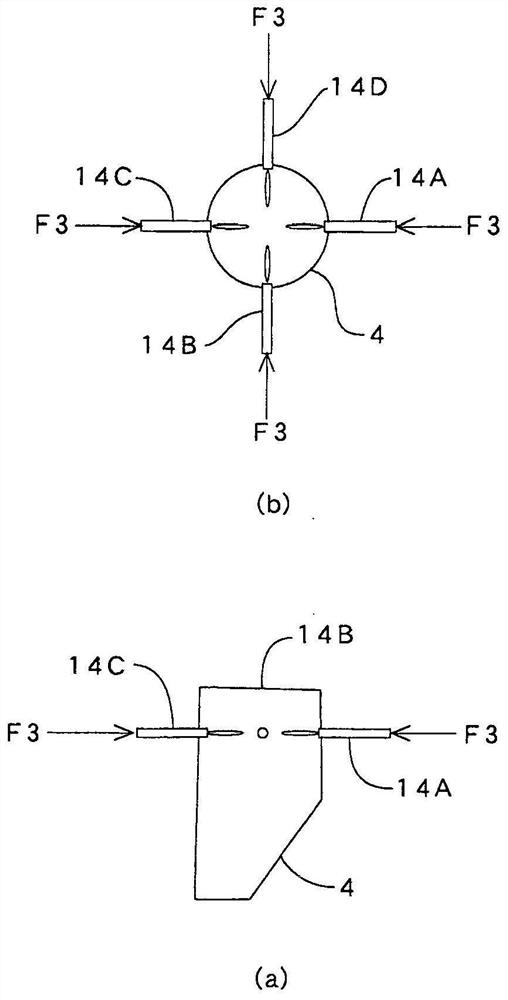

[0020] figure 1 with figure 2 One embodiment of the cement burning device according to the present invention is shown. The cement burning device 1 is composed of a preheater 2 for preheating cement raw material (hereinafter referred to as "raw material") R, and blown from a burner 13 of a calciner. The incoming fuel F2 will come from the pre-burning furnace 3 of the raw material R1 of the cyclone 2b of the third stage from the top of the pre-heater 2, and the fuel F1 blown from the main burner 15 will be used to use the fuel F1 blown in from the pre-heater 2 The cement kiln 5 for firing the raw material R2 of the lower cyclone 2a, the clinker cooler 6 for cooling the cement clinker fired in the cement kiln 5, and the four combustion chambers for denitrification installed at the kiln tail 4 of the cement kiln 5 devices 14 (14A to 14D) and the like. In addition, except the denitrification burner 14, the structure of the preheater 2, the calciner 3, the cement kiln 5, the clin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com