A biomass briquette fuel hot water boiler system

A molding fuel and hot water boiler technology, applied in the direction of fuel supply, solid fuel combustion, combustion air/fuel supply, etc., can solve the problem of low level of boiler automatic adjustment control, reduction of air pollutant emission concentration, strong oxidizing atmosphere, etc. problems, to achieve the effect of improving the utilization rate and comprehensive heating energy efficiency, enhancing the radiation heat transfer intensity in the furnace, and reducing the NOx concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

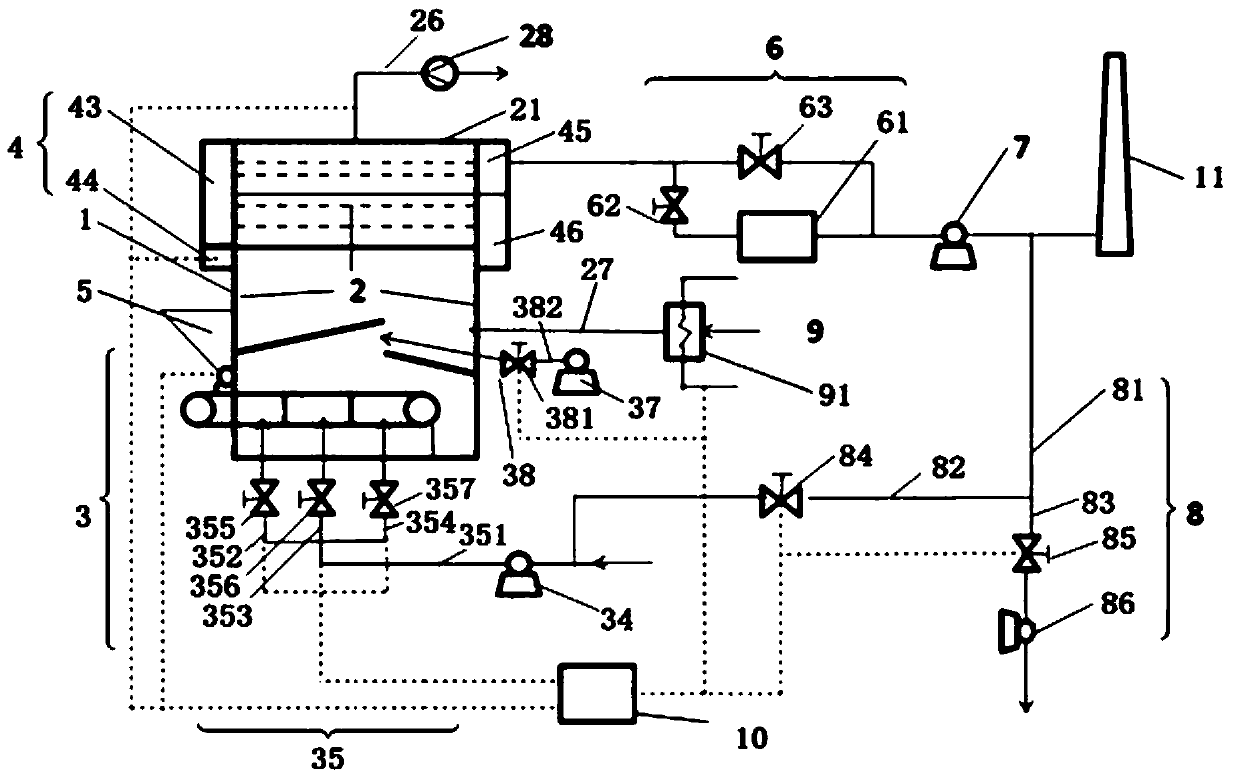

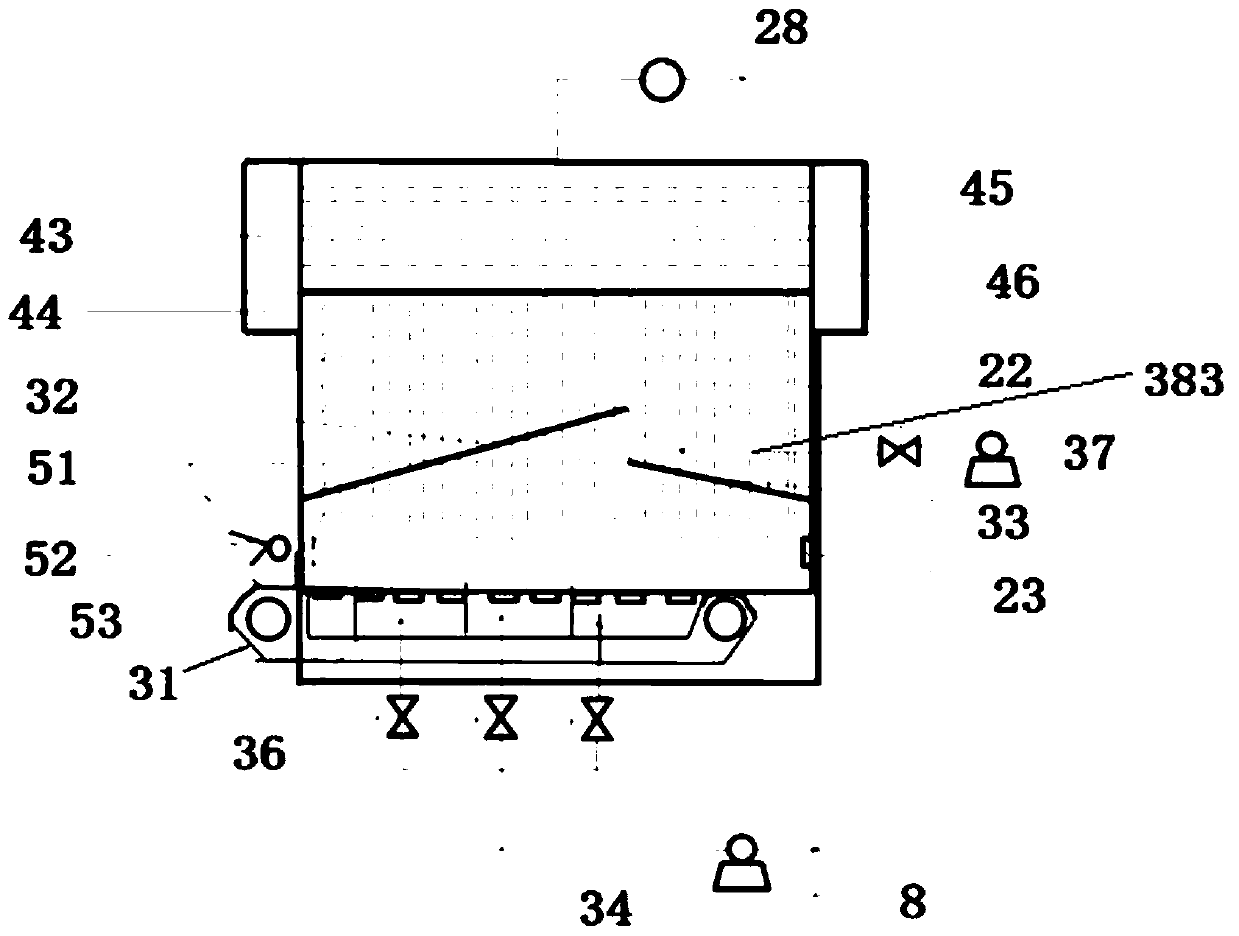

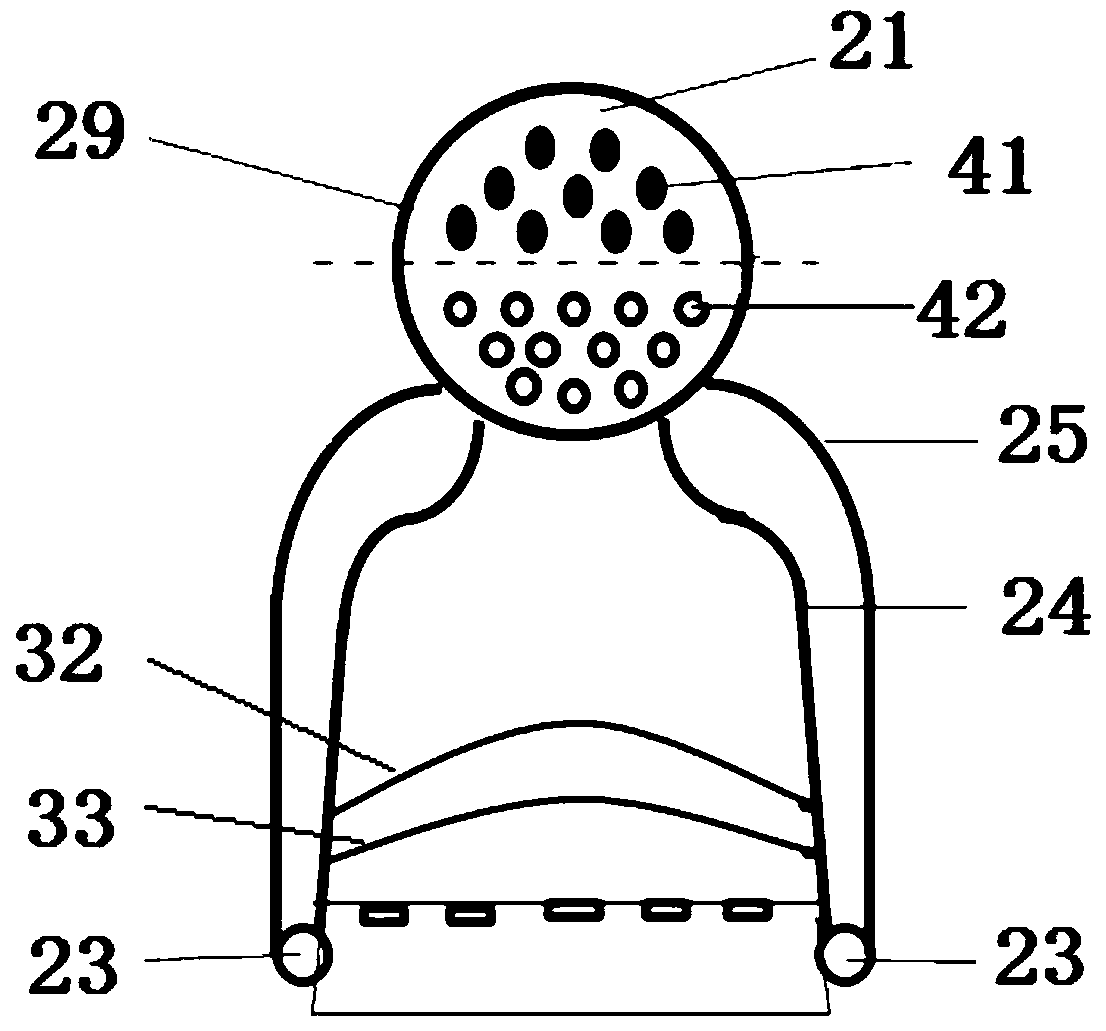

[0026] Such as Figure 1 ~ Figure 3 As shown, a biomass molding fuel hot water boiler system provided by the present invention includes a boiler 1, a water circulation system 2, a grate and combustion system 3, a heat transfer system 4, a molding fuel feeding system 5, a dust removal system 6, an induction Wind system 7, flue gas recirculation system 8, solar photovoltaic power system 9 for supplementary heating of boiler return water, and control system 10 for controlling the above-mentioned systems. The fuel in the molding fuel feeding system 5 enters the grate and the combustion system 3 from the feed port at the lower end of the boiler 1 for combustion, and the high-temperature flue gas generated by the combustion heats the low-temperature water in the water circulation system 2 through the heat transfer system 4, and the heated The high-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com