A supercritical carbon dioxide coal-fired boiler denitrification, desulfurization and dust removal integrated system

A technology for carbon dioxide and coal-fired boilers, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve problems such as insufficient denitrification, achieve the effects of reducing NOx generation, good denitrification effect, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

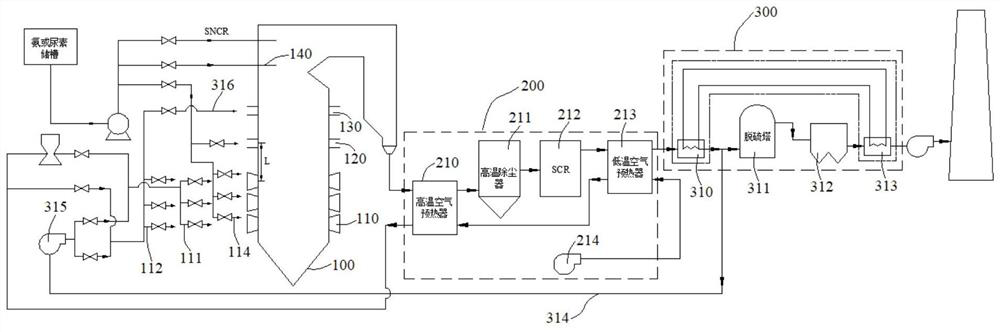

[0038] An integrated system for denitration, desulfurization and dust removal of a supercritical carbon dioxide coal-fired boiler in this embodiment. The boiler is a supercritical carbon dioxide coal-fired boiler. Compared with water vapor, supercritical carbon dioxide has a higher energy density, so the flame temperature in the high temperature region produced by the boiler is also higher. For ordinary steam boilers, the NOx content in the furnace is also higher than that of ordinary boilers. The invention combines the three-stage ammonia injection denitrification process with the dust removal, desulfurization and denitrification process to form a circulating denitration system, thereby realizing the deep denitrification of the supercritical carbon dioxide coal-fired boiler.

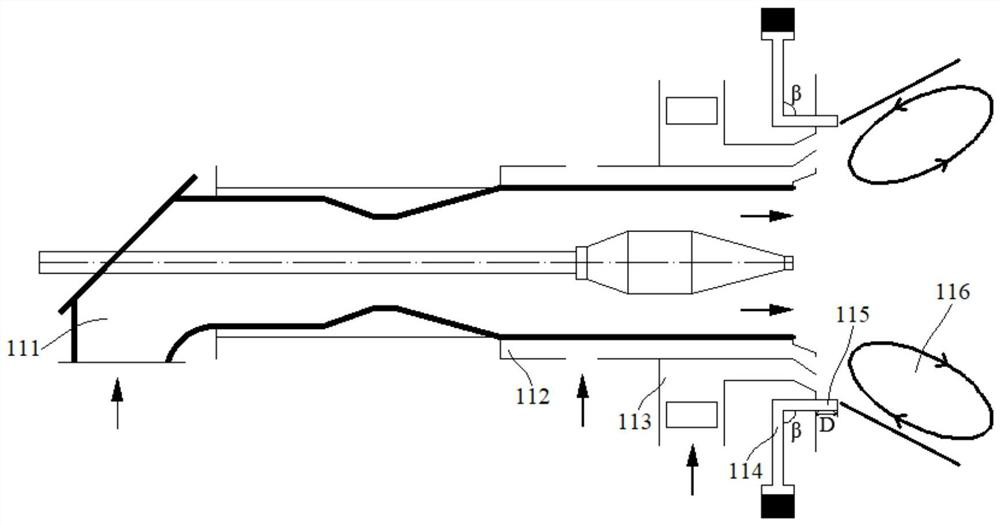

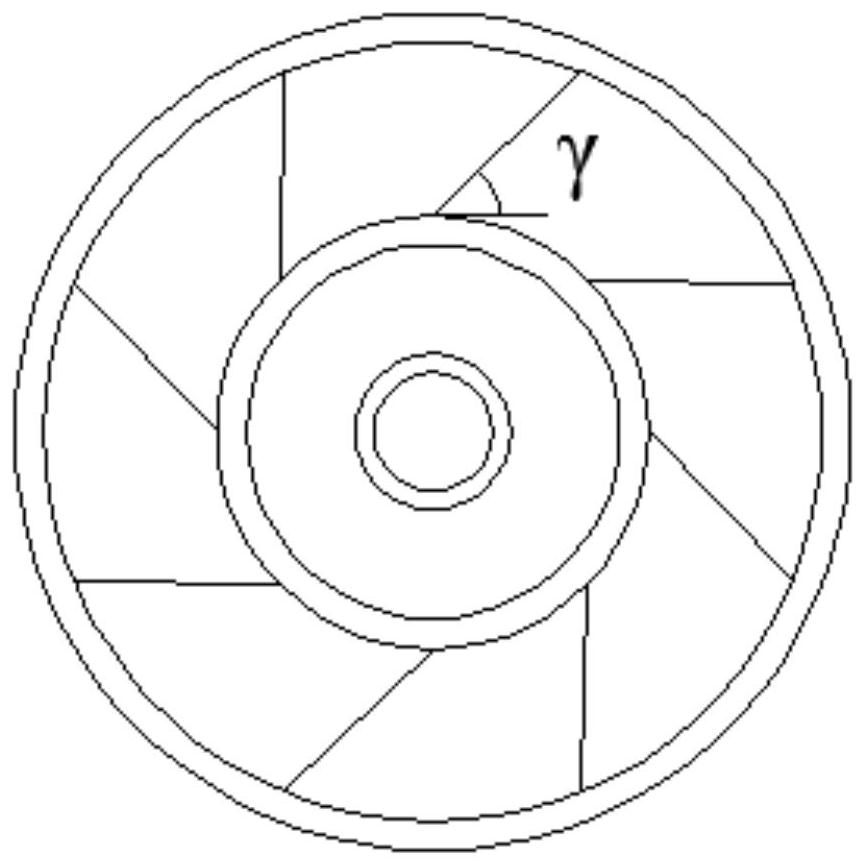

[0039] Specifically, combining figure 1 , A supercritical carbon dioxide coal-fired boiler denitrification, desulfurization and dust removal integrated system in this embodiment includes a boiler unit 1...

Embodiment 2

[0059] The structure of an integrated system for denitration, desulfurization and dust removal of a supercritical carbon dioxide coal-fired boiler in this embodiment is basically the same as that in Embodiment 1. Further, in this embodiment, a high-temperature dust collector 211 is also provided before the selective catalytic reduction device 212 , The flue gas is dedusted and filtered by the high temperature dust collector 211 and then enters the selective catalytic reduction device 212 for deep denitrification. Preferably, the high-temperature dust collector 211 adopts a high-temperature ceramic tube, and the ceramic tube can also be replaced with a metal mesh, or the ceramic tube and the metal mesh can be mixed.

[0060] In this embodiment, the dust removal and denitration unit 200 further includes a high temperature air preheater 210 and a low temperature air preheater 213. The high temperature air preheater 210 is arranged between the boiler unit 100 and the high temperatu...

Embodiment 3

[0066] The structure of an integrated system for denitrification, desulfurization and dust removal of a supercritical carbon dioxide coal-fired boiler in this embodiment is basically the same as that in Embodiment 1. Further, in this embodiment, the desulfurization unit 300 includes a heat recovery device 310, a wet desulfurization unit 310, and a wet desulfurization unit connected in sequence. The tower 311, the wet electrostatic precipitator 312 and the reheater 313, the heat recovery device 310 and the reheater 313 are also connected through the circulating working medium pipe, and the flue gas after the SCR deep denitrification is preheated by the low temperature air and enters the desulfurization unit 300. The temperature of the flue gas after the cooling treatment is 70-90° C., and then entering the wet desulfurization tower 311 for desulfurization treatment can ensure the desulfurization effect.

[0067] After the flue gas is desulfurized, it enters the wet electrostatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com