Process decomposition treatment device for medical waste incineration waste gas

一种医疗垃圾、分解处理的技术,应用在气体处理、分离方法、弥散粒子分离等方向,能够解决二次污染、难接触反应、滤袋阻塞等问题,达到保证可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

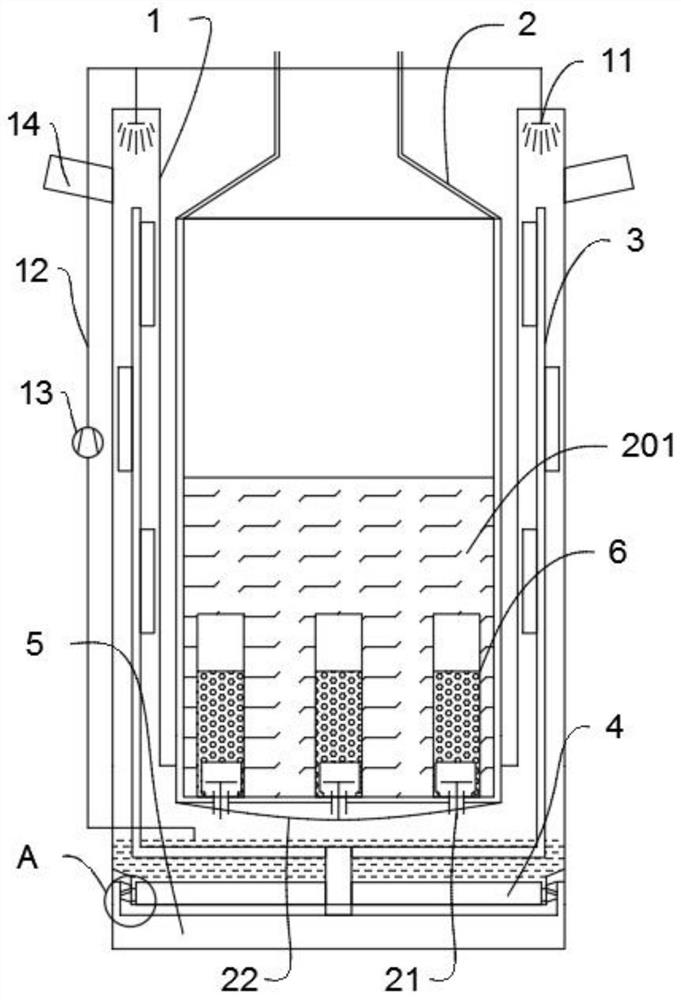

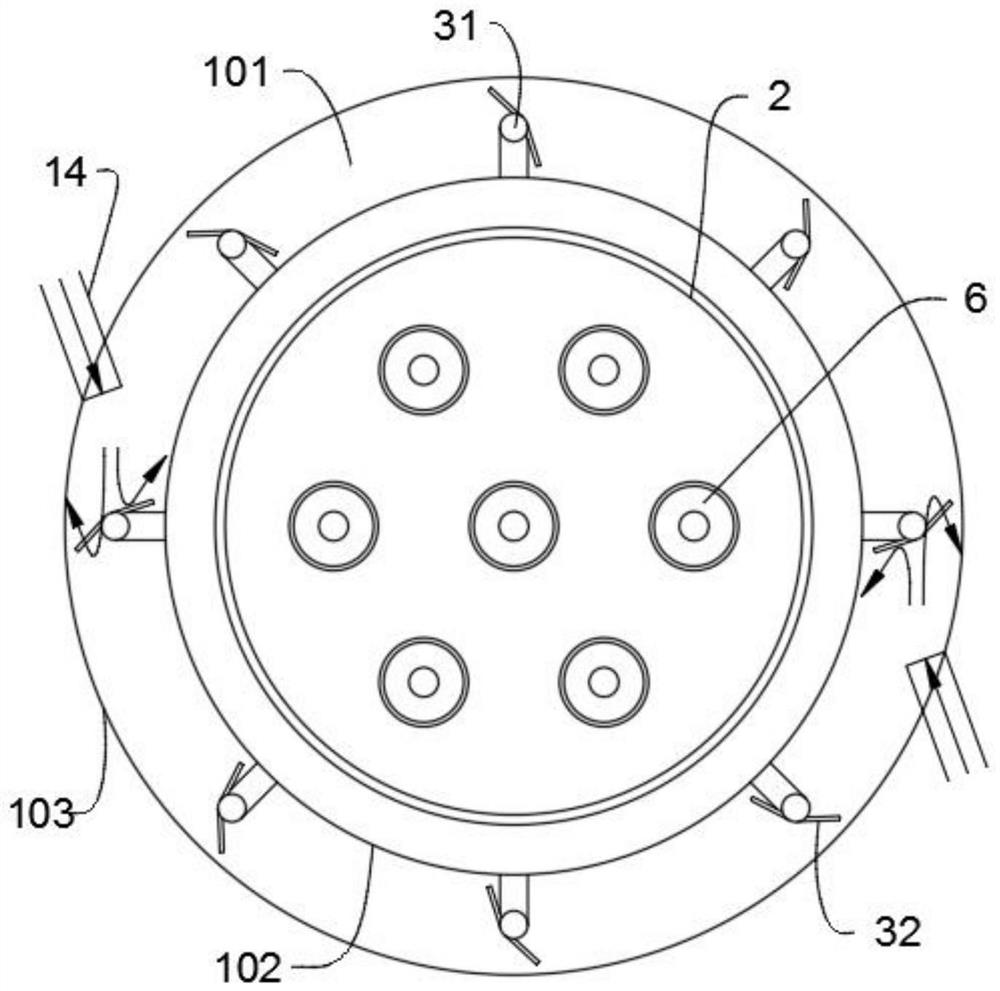

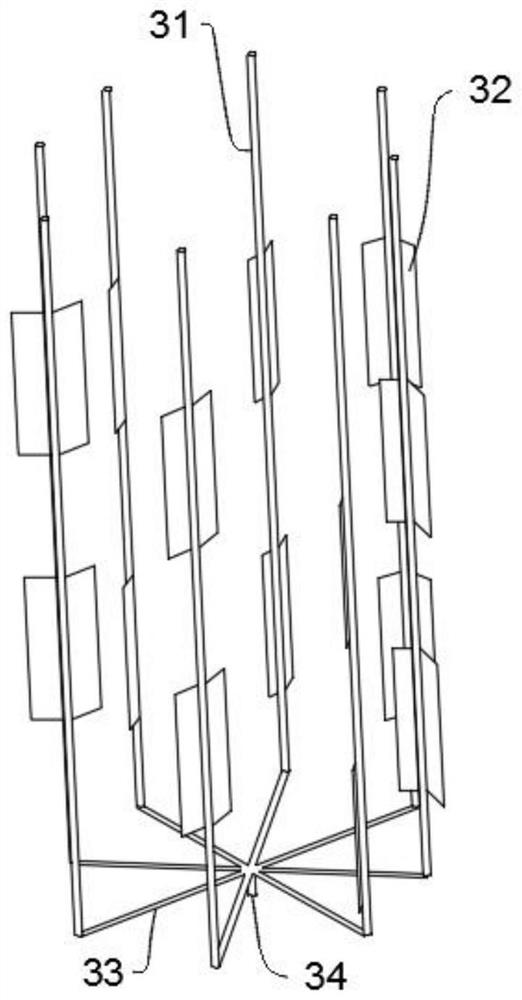

[0042] Example: such as Figure 1-7 As shown, the process-based decomposition and treatment device for medical waste incineration waste gas includes:

[0043] Dust removal interlayer 1, the upper part of the dust removal interlayer 1 has an annular dust-falling chamber 101, the lower part of the dust-removing interlayer 1 has a deposition space 104, and glycerin is provided in the deposition space 104, and the outside of the dust removal interlayer 1 is provided with glycerol from the top of the dust reduction chamber 101 downwards Spraying spray system, the upper part of the dust removal interlayer 1 is provided with an air intake pipe 14 arranged along the tangential direction of the dust reduction chamber 101, and the air intake pipe 14 has an angle of 30-45° with the horizontal direction;

[0044] Neutralization cylinder 2, neutralization cylinder 2 is located inside the dust removal interlayer 1, and connected above the deposition space 104, neutralization cylinder 2 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com