Prospecting borehole drilling method

A technology for exploration engineering and drilling rigs, applied in the field of exploration hole drilling, can solve the problems of inability to remove dust, affecting normal use, failure of dust removal equipment, etc., and achieve the effects of improving clamping and separation efficiency, increasing area, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

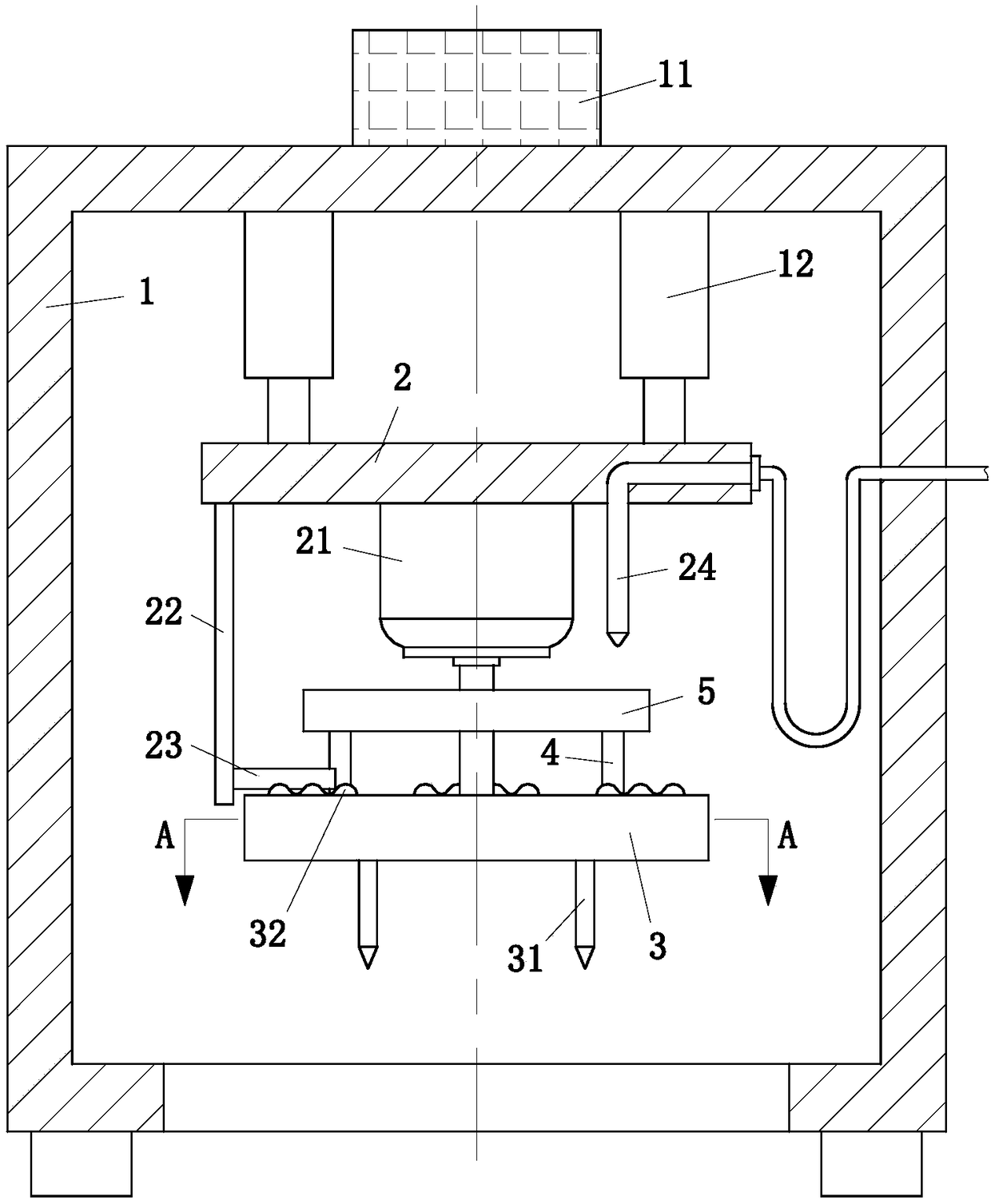

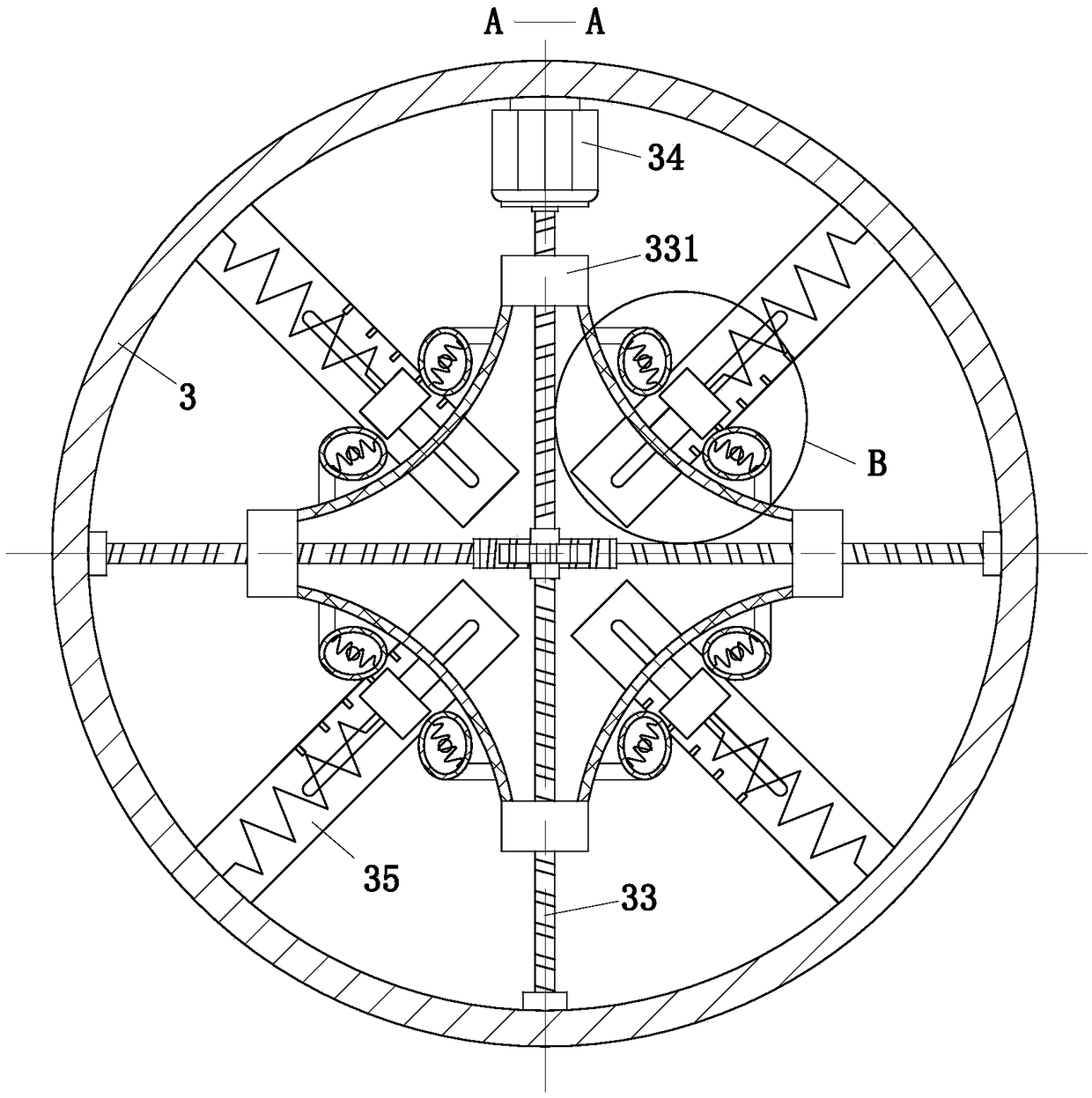

[0026] use Figure 1 to Figure 5 An exploratory hole drilling method of the present invention is described as follows.

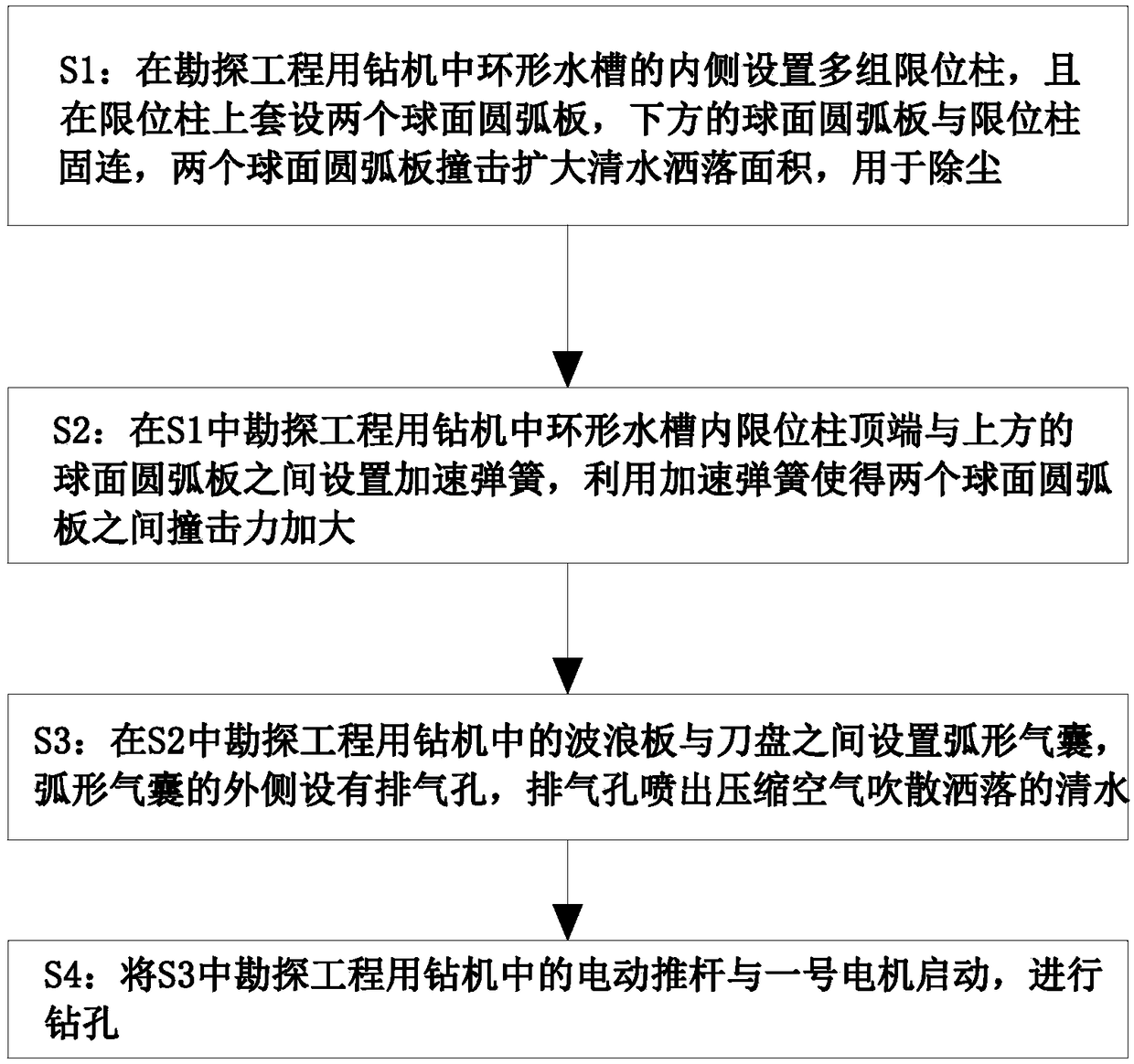

[0027] like Figure 1 to Figure 5 Shown, a kind of exploratory hole drilling method described in the present invention, this method comprises the steps:

[0028] S1: Set multiple sets of limit columns on the inner side of the annular water tank in the drilling rig for exploration engineering, and set two spherical arc plates on the limit columns, and the lower spherical arc plate is fixedly connected with the limit columns. The impact of the circular arc plate expands the spraying area of clean water for dust removal; by setting two spherical arc plates on the limit column, and the spherical arc plate below is fixedly connected with the limit column, when the annular water tank follows the knife When the plate vibrates up and down, the clear water on the upper spherical arc plate and the inner side of the annular water tank will move up a certain distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com