Falling film washing system realizing ultralow emission of coal-fired power plant desulfurated tail gas and technology thereof

A coal-fired power plant, falling film technology, applied to the separation of dispersed particles, chemical instruments and methods, the use of liquid separation agents, etc., can solve the problems of low demisting efficiency, solid particle deposition, complex structure, etc., to improve separation efficiency and The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

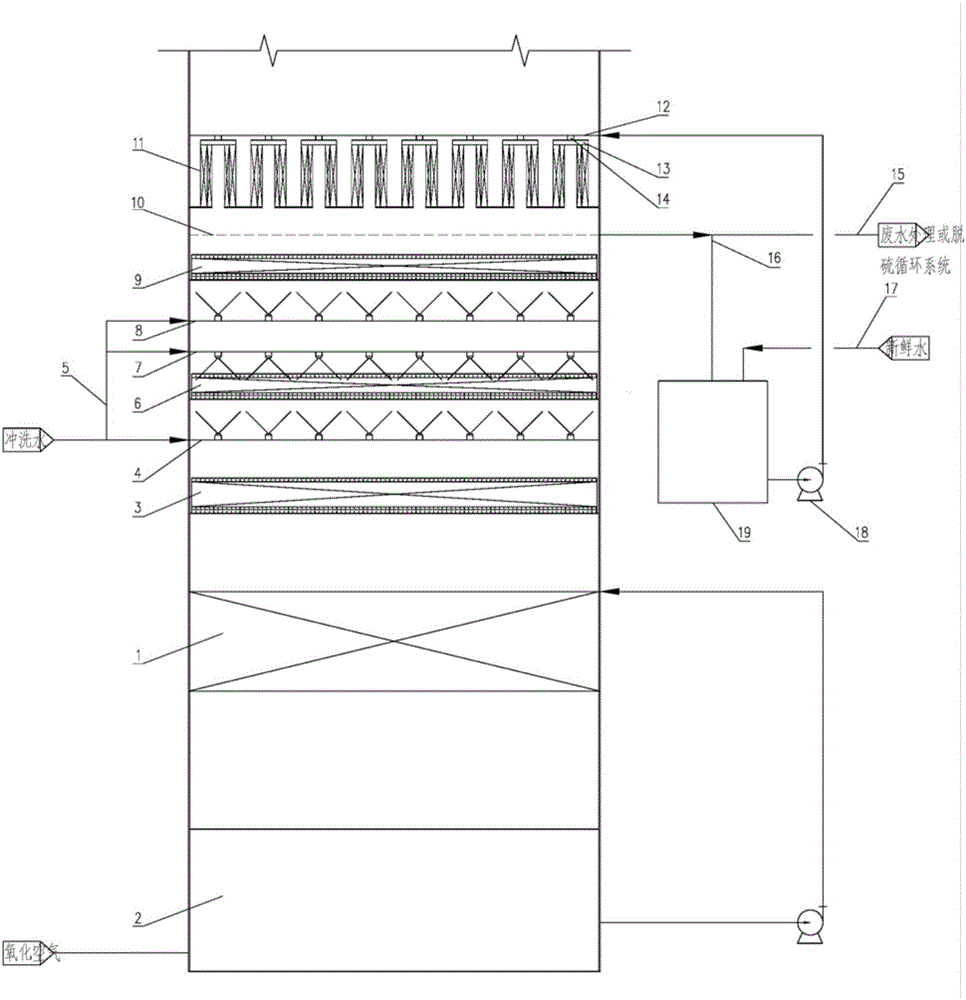

[0071] Ammonia desulfurization tower for 2X140t / h coal-fired boiler in self-owned power plant, flue gas volume 394252Nm 3 / h, the droplet content of the equipment inlet is 150~200mg / m 3 , dust content 20mg / m 3 , using liquid ammonia as desulfurizer.

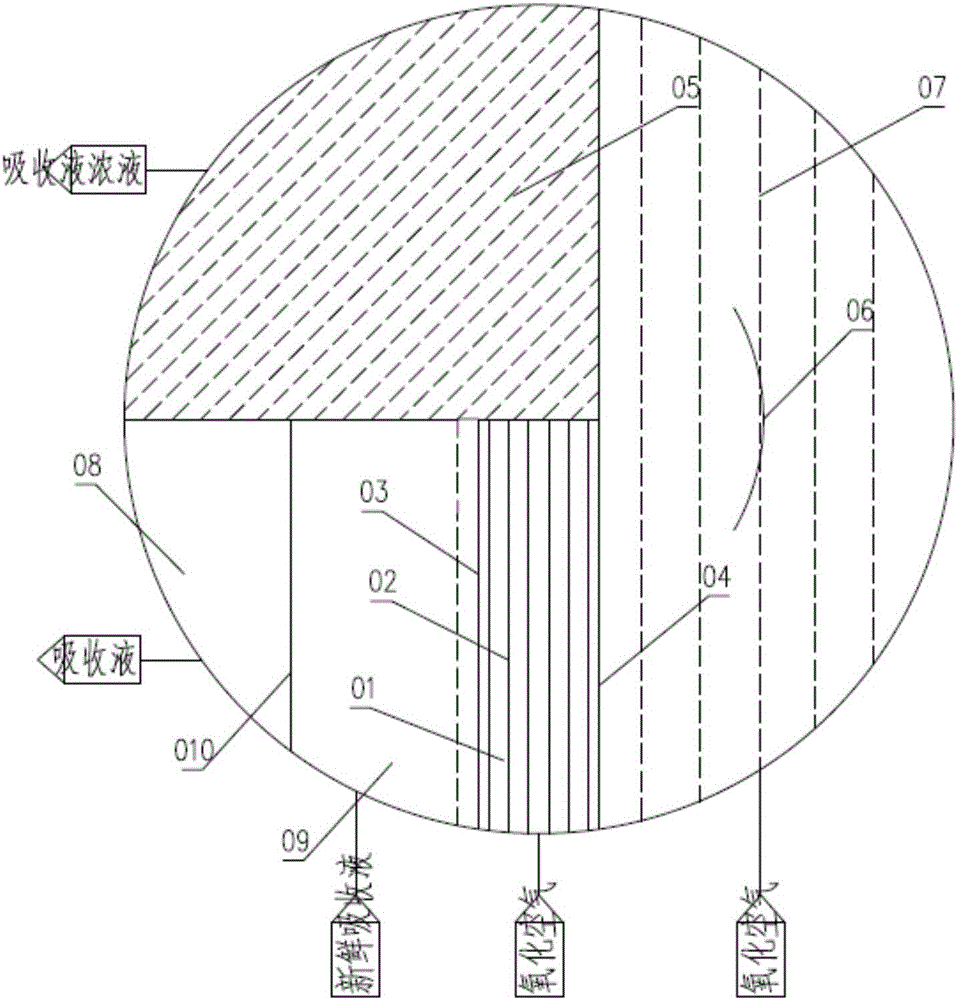

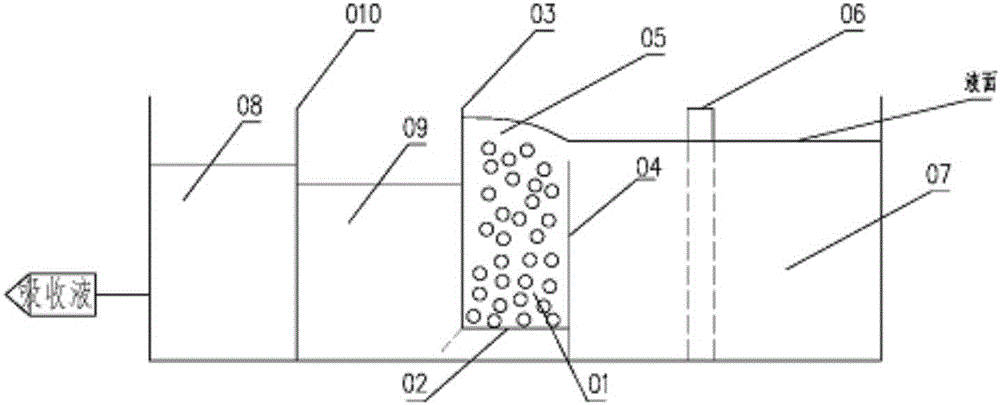

[0072] After the original flue gas passes through the absorption section 1, it realizes vapor-liquid contact with the absorbent, and the absorbent falls into the circulating absorption liquid pool 2, and the circulating absorption liquid is raised in the aeration zone 01 through the aeration pipe 02, and the air liquid level is raised. The overflow plate 04 enters the oxidation zone 07, and the oxidized absorption liquid enters the inclined plate settlement zone 05 under the action of the deflector plate 06, and the experimental solid particles are separated rapidly, the absorption liquid overflows into the clear liquid zone 08, and the slurry enters After the absorption liquid mixing area 09 is mixed with fresh slurry, it ente...

Embodiment 2

[0093] Calcium method desulfurization tower for 2X140t / h coal-fired boiler in self-owned power plant, flue gas volume 450000Nm3 / h, droplet content at equipment inlet 150~200mg / m 3 , dust content 30mg / m 3 , using lime slurry as desulfurizer.

[0094] The special plate group demister and the falling film washing section are set on the top of the desulfurization tower.

[0095] After the original flue gas passes through the absorption section 1, it realizes vapor-liquid contact with the absorbent, and the absorbent falls into the circulating absorption liquid pool 2. The flue gas will carry liquid droplets and dust and other substances to rise to the special-shaped tube demister 3, and most of them Part of the liquid droplets and particles with large particle size are captured. The special-shaped pipe has self-cleaning ability, and there is no need to set up a flushing water layer. The flue gas passes through the first-level special plate group demister 6 and the second-level sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com