Method for efficient treatment of waste sulfuric acid produced in gasoline alkylation

A treatment method and alkylation technology, applied in sulfur trioxide/sulfuric acid, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high energy consumption, high cost, equipment corrosion, etc., and achieve high separation efficiency, Effect of reducing acid consumption and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

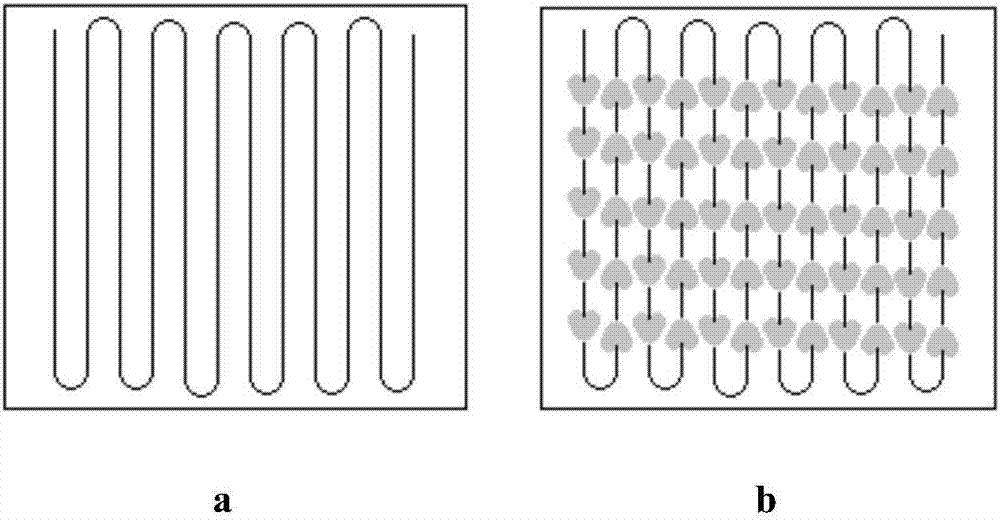

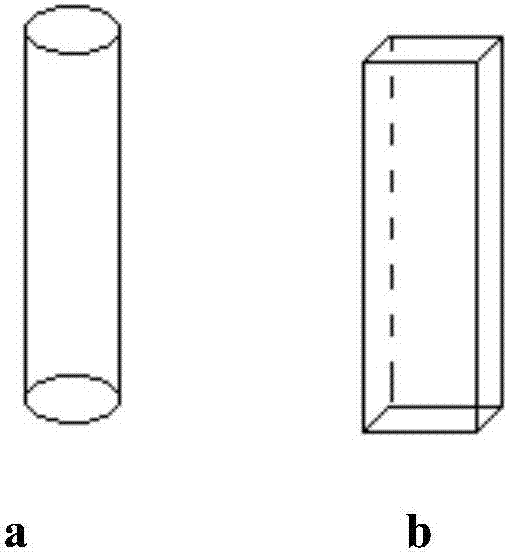

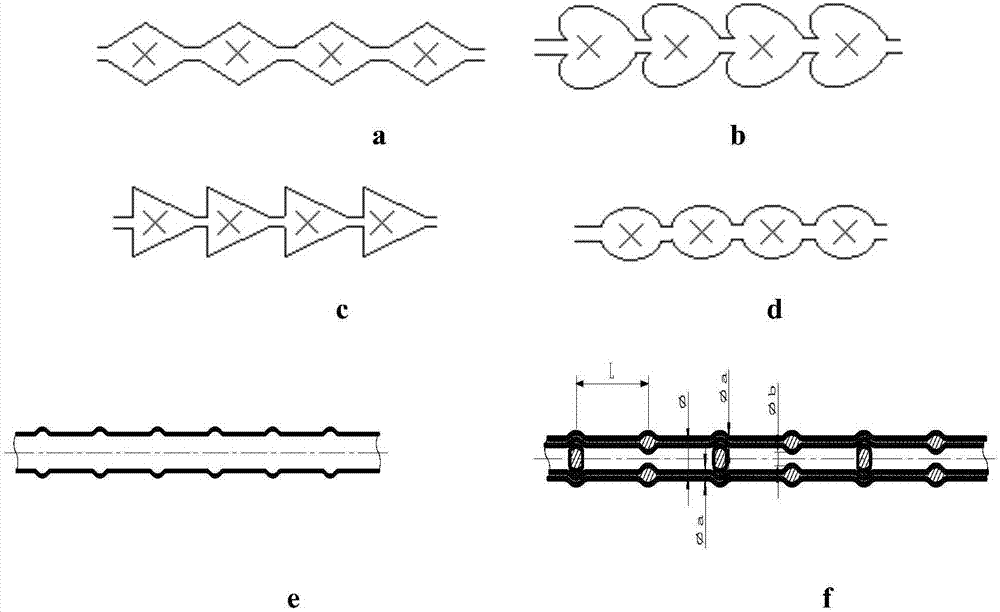

[0023] (1) The device used: millimeter channel reactor (circular structure of direct current channel module + diamond-shaped mixed structure of enhanced mass transfer channel module), the hydraulic diameter of the channel is 0.5mm, and the number of mixed reaction modules is determined according to the flow rate and reaction residence time. The heat medium is heat conduction oil.

[0024] (2) After the alkylation reaction of the continuous flow reactor is completed, the outlet end of the reactor is connected to a gas-liquid separator to effectively separate the gas-phase alkanes from the acid liquid and alkylated oil, and 80% of the acid hydrocarbons after separation The mass concentration of sulfuric acid is passed into the millimeter channel reactor, the thermal decomposition temperature is controlled between 180°C, and the pressure is controlled at 1.5MPa. The mass concentration of sulfuric acid collected after recovery and concentration can reach 95%, which is used for the ...

Embodiment 2

[0026] (1) Device used: millimeter channel reactor (rectangular structure of direct current channel module + heart-shaped mixed structure of enhanced mass transfer channel module), the hydraulic diameter of the channel is 1mm, the number of mixed reaction modules is determined according to the flow rate and reaction residence time, heat exchange The medium is heat transfer oil.

[0027] (2) After the alkylation reaction in the continuous flow reactor is completed, the outlet end of the reactor is connected to the gas-liquid separator to effectively separate the gas phase alkanes from the acid liquid and alkylate oil, and 82% of the acid hydrocarbons after separation The mass concentration of sulfuric acid is passed into the millimeter channel reactor, the thermal decomposition temperature is controlled between 190 ° C, and the pressure is controlled at 1.8 MPa. The mass concentration of sulfuric acid collected after recovery and concentration can reach 96%, which is used for th...

Embodiment 3

[0029] (1) Equipment used: millimeter channel reactor (circular structure of direct current channel module + triangular mixed structure of enhanced mass transfer channel module), the hydraulic diameter of the channel is 2mm, the number of mixed reaction modules is determined according to the flow rate and reaction residence time, heat exchange The medium is heat transfer oil.

[0030] (2) After the alkylation reaction in the continuous flow reactor is completed, the outlet end of the reactor is connected to the gas-liquid separator to effectively separate the gas phase alkanes from the acid liquid and alkylated oil, and 85% of the acid hydrocarbons after separation The mass concentration of sulfuric acid is passed into the millimeter channel reactor, the thermal decomposition temperature is controlled between 200 ° C, and the pressure is controlled at 2.0 MPa. The mass concentration of sulfuric acid collected after recovery and concentration can reach 96%, which is used for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com