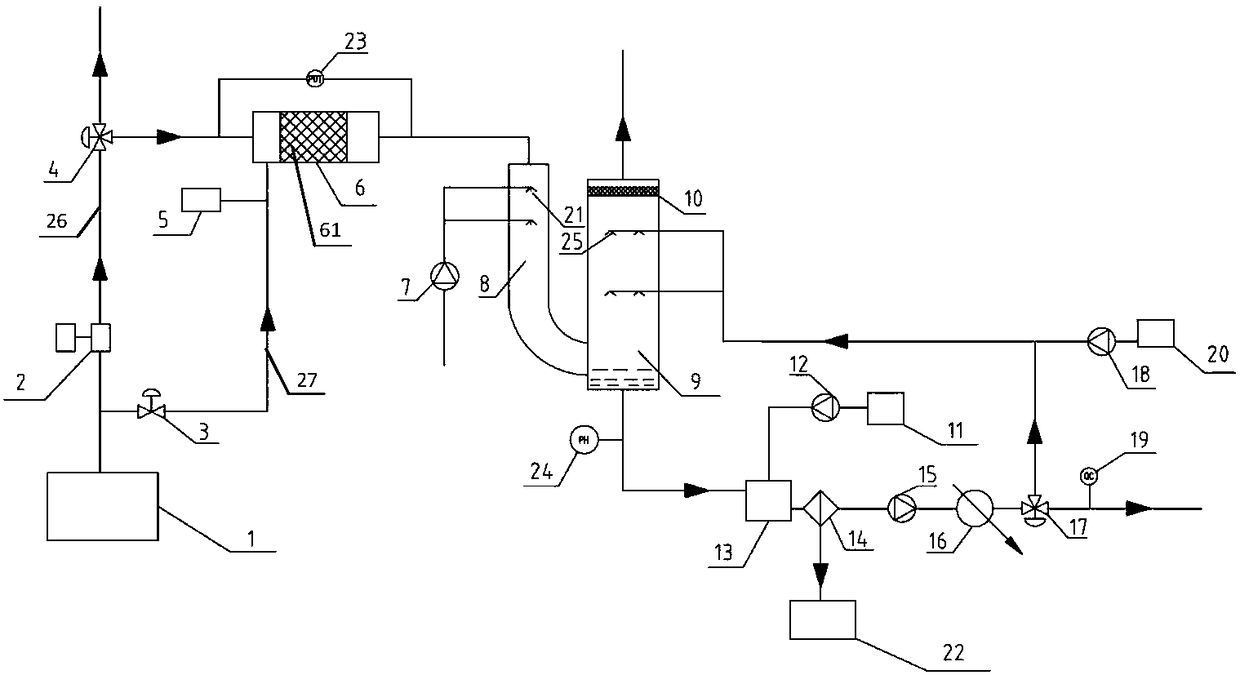

Ship waste gas desulfurization system

A technology for desulfurization of waste gas and ships, which is applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc. It can solve the problems of complex washing water treatment system, large volume and high cost, and achieve the goal of simplifying wastewater treatment process and reducing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A 72000DWT bulk carrier, the main engine power is 8000kw, the exhaust gas flow rate is 60000kg / h, using 3.5% high-sulfur oil as fuel, and the concentration of sulfur oxides in the exhaust gas is 650ppm. Using the ship exhaust gas desulfurization system of the present invention, the treated SO in exhaust gas 2 (ppm) / CO 2 The (%v / v) ratio is less than 4.5, which can meet the requirements of IMO. At the same time, the removal rate of particulate matter in the exhaust gas is above 80%. The liquid-gas ratio of the washing tower is less than 3, the consumption of fresh water is less, and the washing wastewater discharged meets the requirements of MEPC259 (68).

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com