Boiler fume particulate matter purification device and method

A boiler flue gas and purification device technology, which is applied to chemical instruments and methods, separation methods, combined devices, etc., can solve the problems of large particle content and small particle content, and achieve the effect of small size, good adaptability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

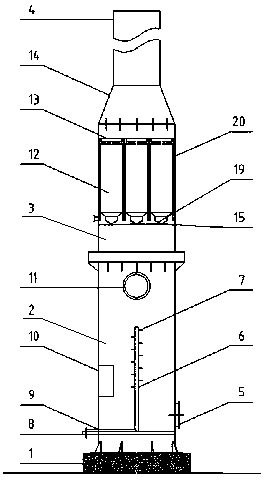

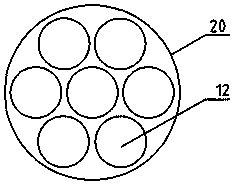

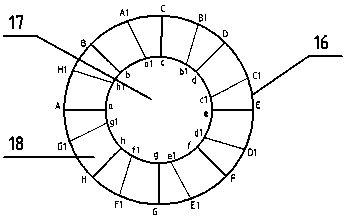

[0024] The boiler flue gas particle purification device of the present invention is composed of a base 1 , a lower tower body 2 , an upper tower body 3 and a chimney 4 .

[0025] figure 1 It shows that the lower tower body 2 is connected with the base 1 , the upper tower body 3 is connected above the lower tower body 2 , and the upper end of the upper tower body 3 is connected with the chimney 4 .

[0026] figure 1 It shows that there is an air inlet 5 at the lower end of the lower tower body 2, and the boiler flue gas enters the lower tower body 2 through the air inlet 5. A vertical center pipe 6 is installed in the lower tower body 2 , the bottom of the center pipe 6 is connected with the water delivery pipeline, and the circumference of the center pipe 6 is evenly distributed with spray holes 7 . The water is sprayed from the spray hole 7 through the central pipe 6 to remove the smoke particles.

[0027] figure 1 Shown, the lower end of the central pipe 6 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com