Fuel injection nozzle of opposite-spraying atomizing internal combustion engine

A technology of fuel injectors and internal combustion engines, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as power consumption, achieve low cost, improve energy saving and emission indicators, and simple principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

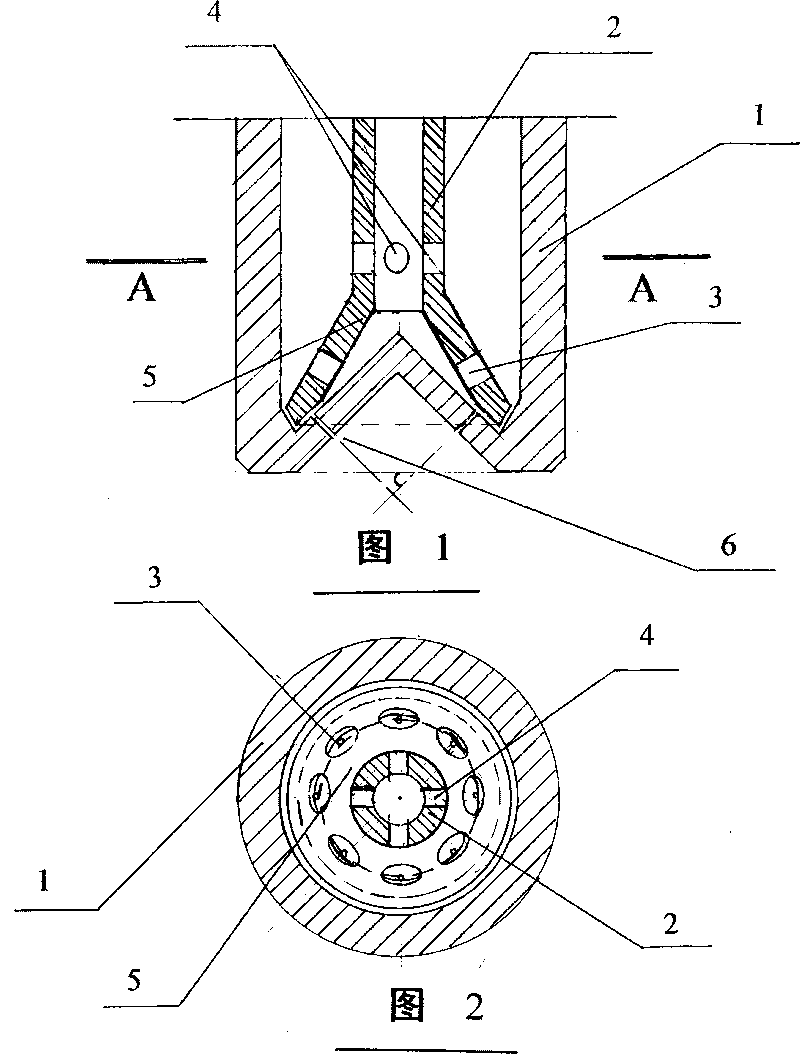

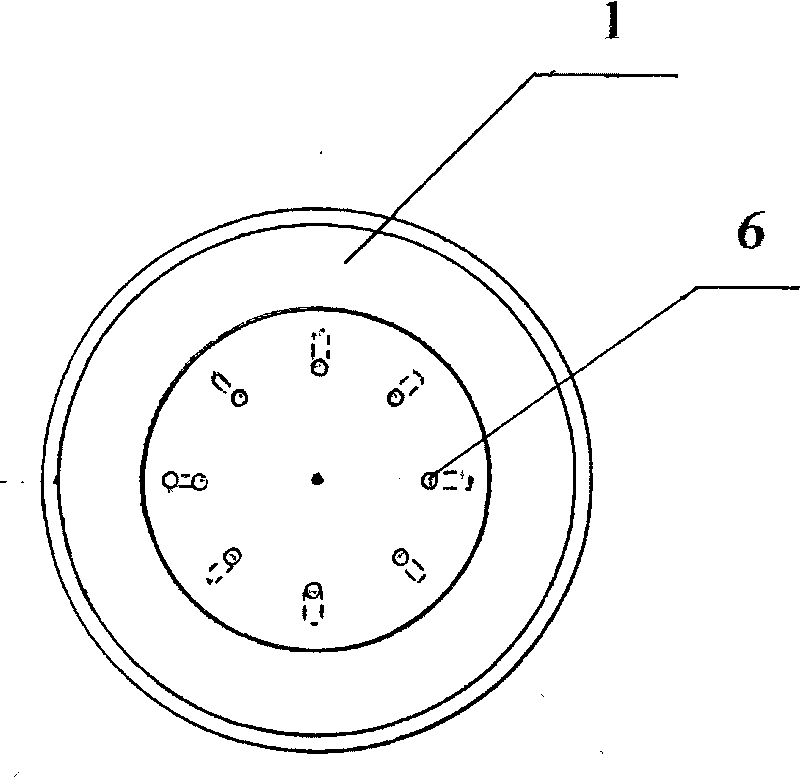

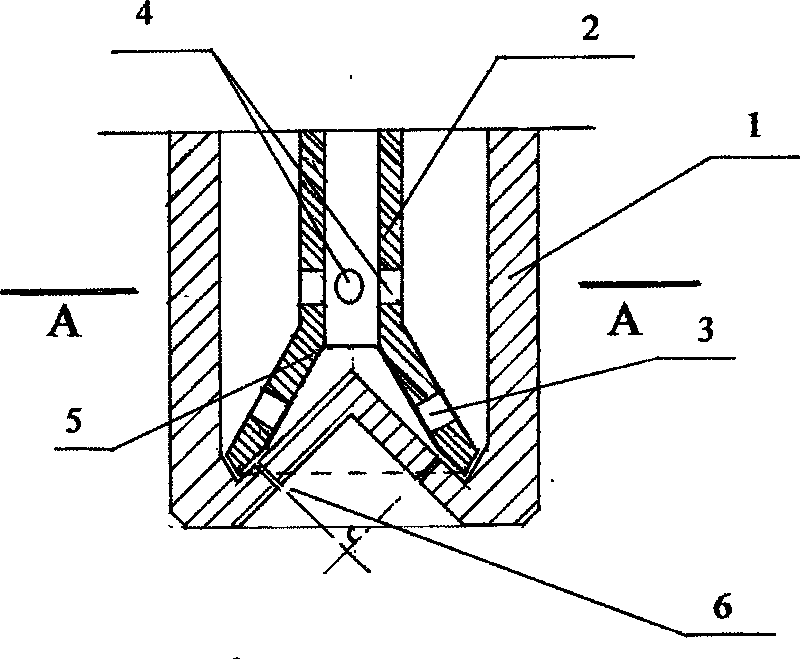

[0014] Based on the existing fuel injectors of various diesel engines and gasoline engines, it is used as a design reference. Retain its normal structure and function, change the needle valve part into a cup-shaped tubular valve, and design the number and diameter of the spray holes according to the requirements. The installation size of the newly designed fuel injector is the same as that of the original fuel injector, or approximately the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com