Double-pre-film type ultrasonic spray nozzle

A double pre-film type, ultrasonic technology, applied in the combustion method, combustion chamber, combustion equipment and other directions, can solve the problems of high gas-liquid ratio and insufficient atomization effect, achieve low gas-liquid ratio, improve atomization quality, The effect of low atomization particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

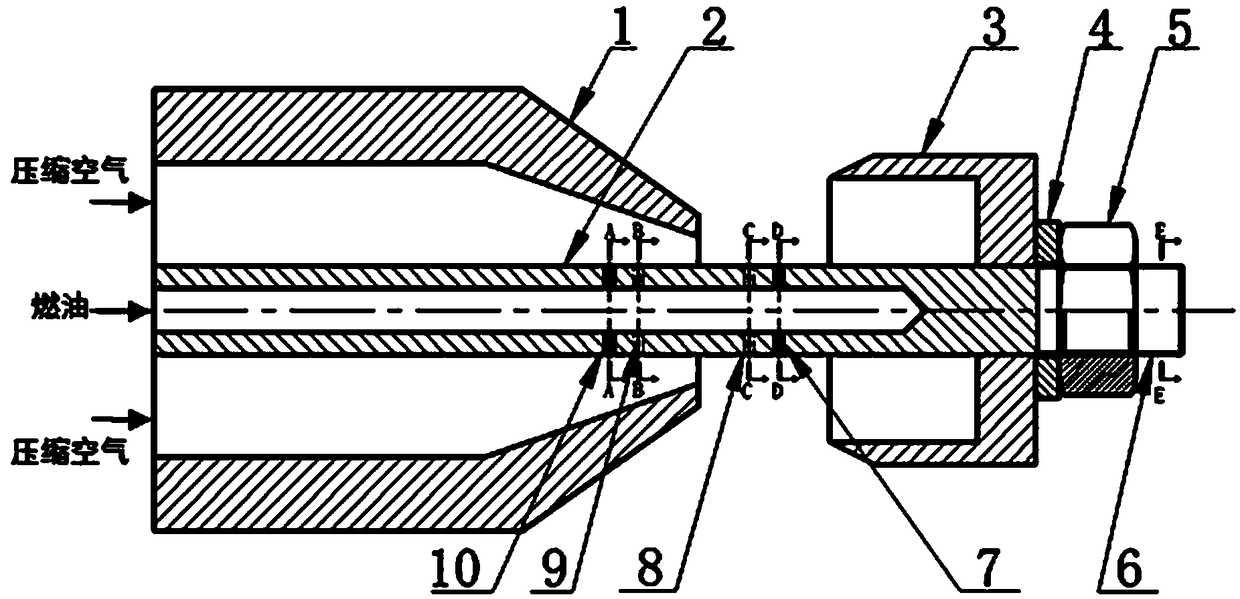

[0027] Such as figure 1 Shown is a double pre-membrane ultrasonic nozzle, including a nozzle 1, a central rod 2, and a resonance cavity 3;

[0028] Wherein, the nozzle pipe 1 is coaxially socketed and fixed on the left end of the center rod 2, and the resonant cavity 3 is socketed and fixed on the right end of the center rod 2; out, and form a supersonic airflow behind the nozzle, and the airflow moves to the downstream resonant cavity 3 to reflect and generate an unstable shock wave that periodically oscillates;

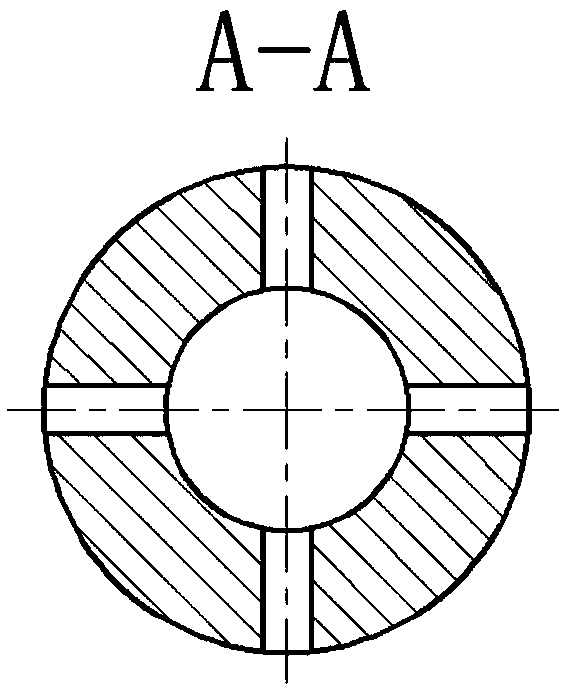

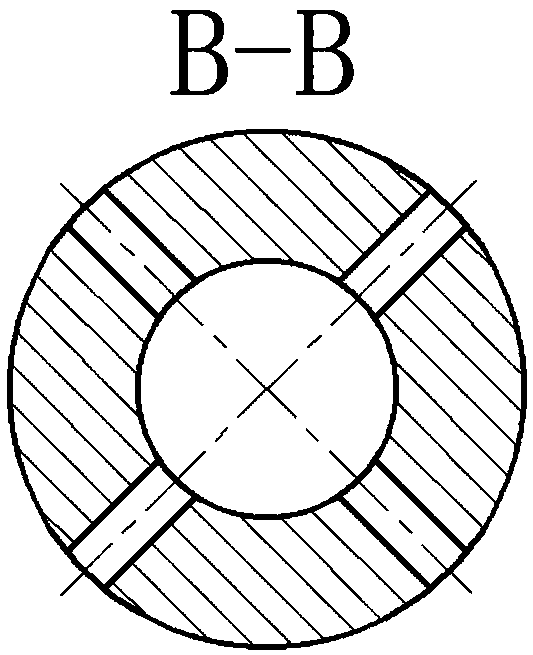

[0029] The central rod 2 is a round rod, the left end of which is hollow to form a fuel passage, and two oil passages are provided on the hollow section, the fuel sprayed from the first oil passage forms the first oil film on the inner wall of the converging section of the nozzle pipe 1, and the second The fuel sprayed from the two oil circuits forms a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com