Machining ring type pre-film cyclone

A machine-added ring, swirler technology, applied in lighting and heating equipment, combustion methods, combustion chambers, etc., can solve the problems of oscillating combustion flame tubes or heads, ablation, etc., to eliminate angular vortices and save costs , the effect of improving performance and structural reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and the specific implementation process.

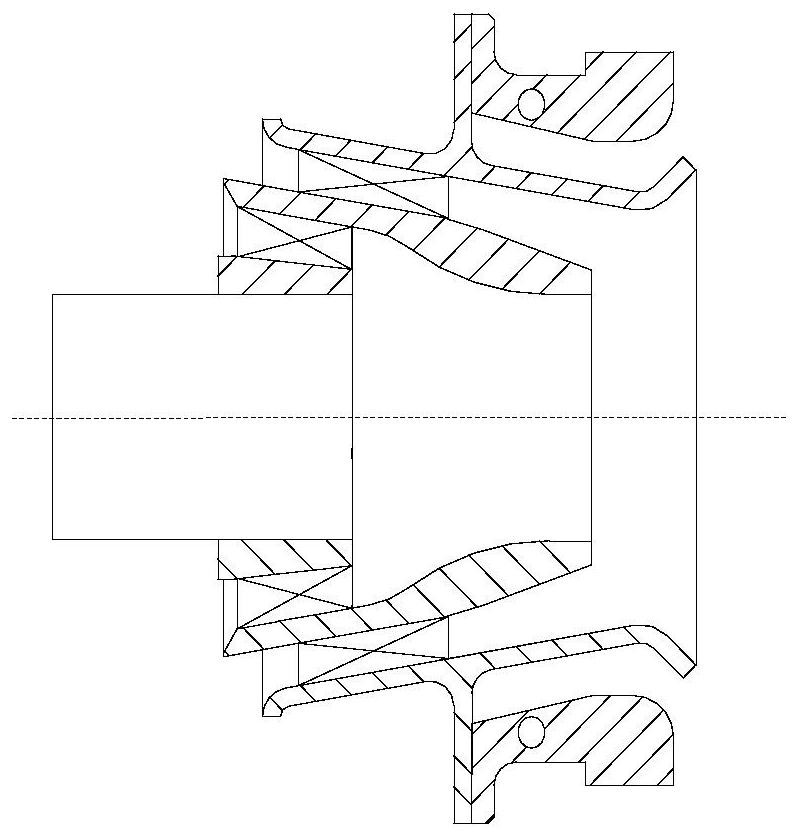

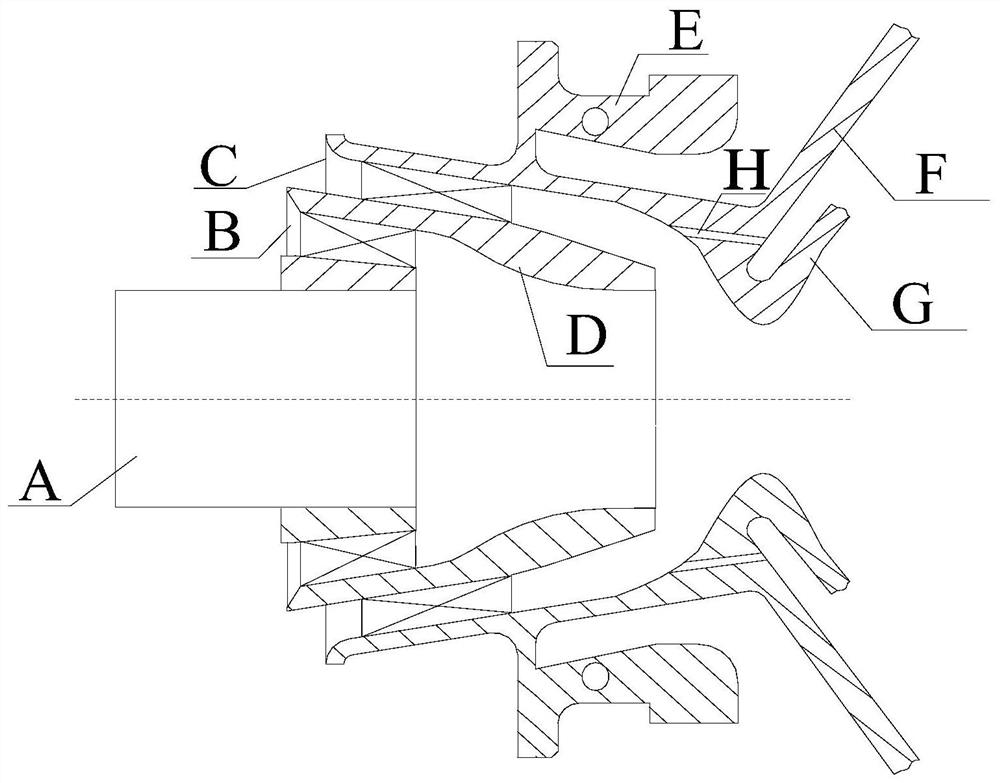

[0033] 1) The present invention is mainly composed of a central nozzle A, a primary cyclone B, a secondary cyclone C, a venturi tube D, cold air passages E and H, a machined ring straight section F, and a machined ring arc surface section G .

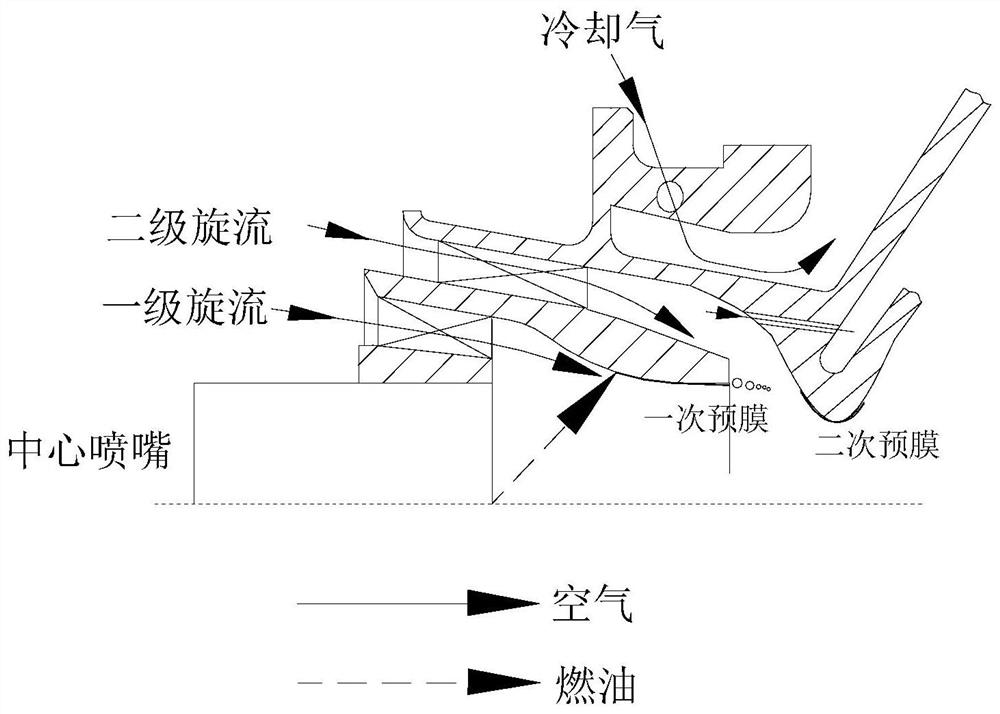

[0034] 2) working principle of the present invention sees image 3 , the impact of the fuel sprayed from the center nozzle A forms a thin liquid film on the inner wall of the venturi tube D, and is discharged at the lip or trailing edge of the venturi tube D, and flows through the primary swirler B and the secondary swirler C Oil mist is formed under the shear action. In the process of moving downstream, the oil mist passes through the machined ring arc surface section G to form a secondary pre-film to further improve the fuel atomization effect, and the oil mist and air are well mixed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com