Patents

Literature

33results about How to "Decrease the gas-liquid ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

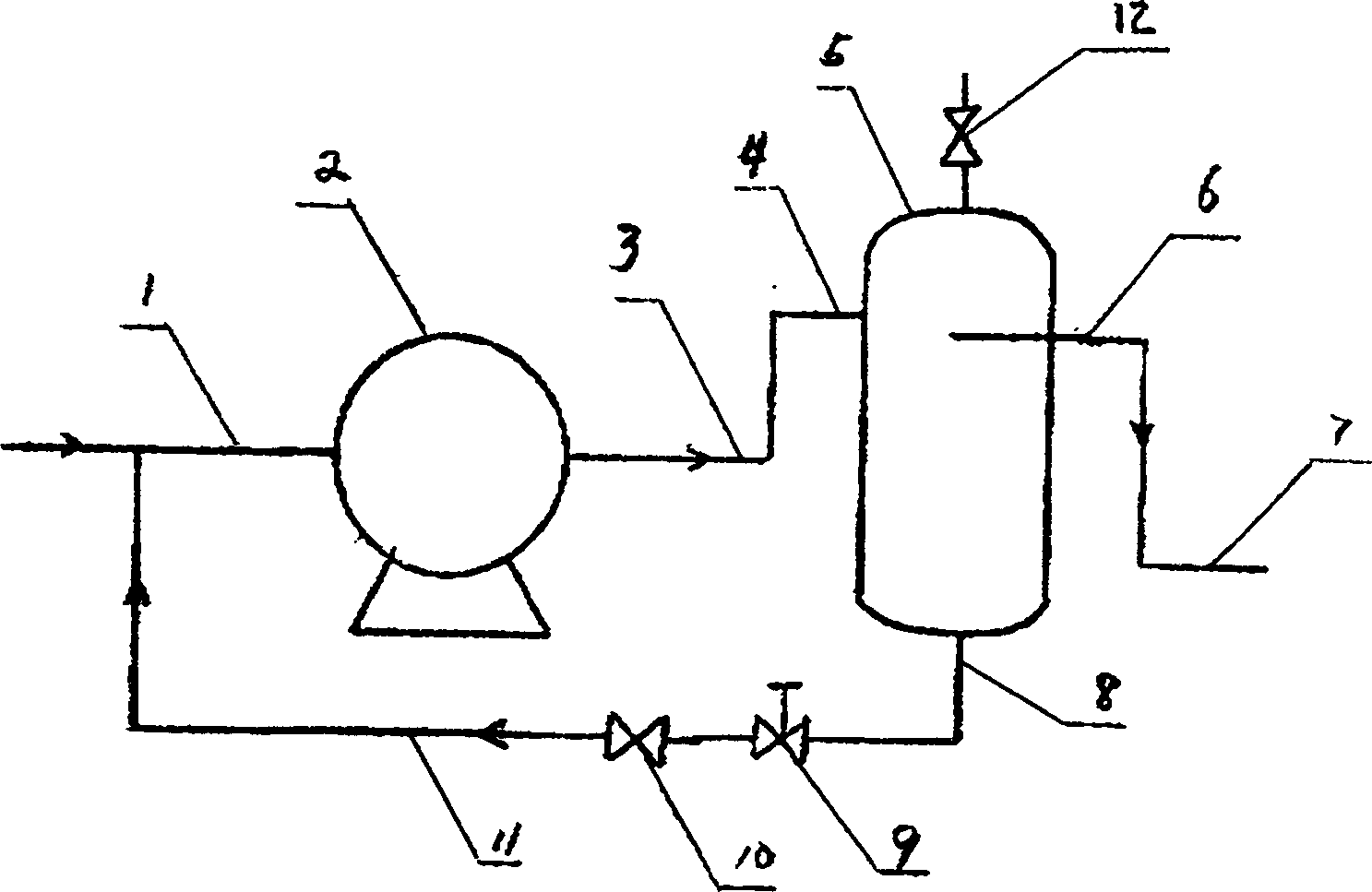

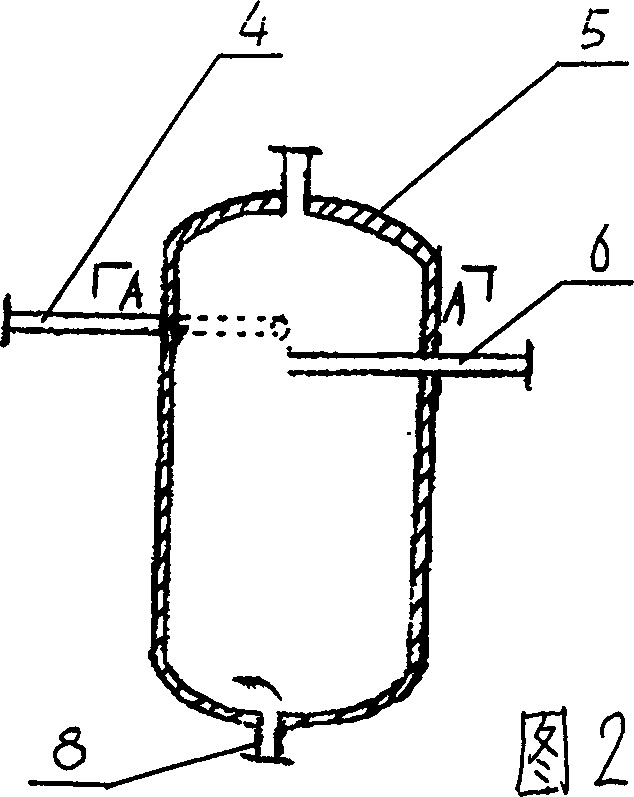

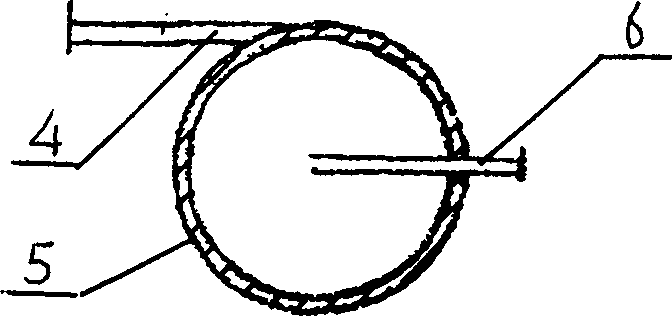

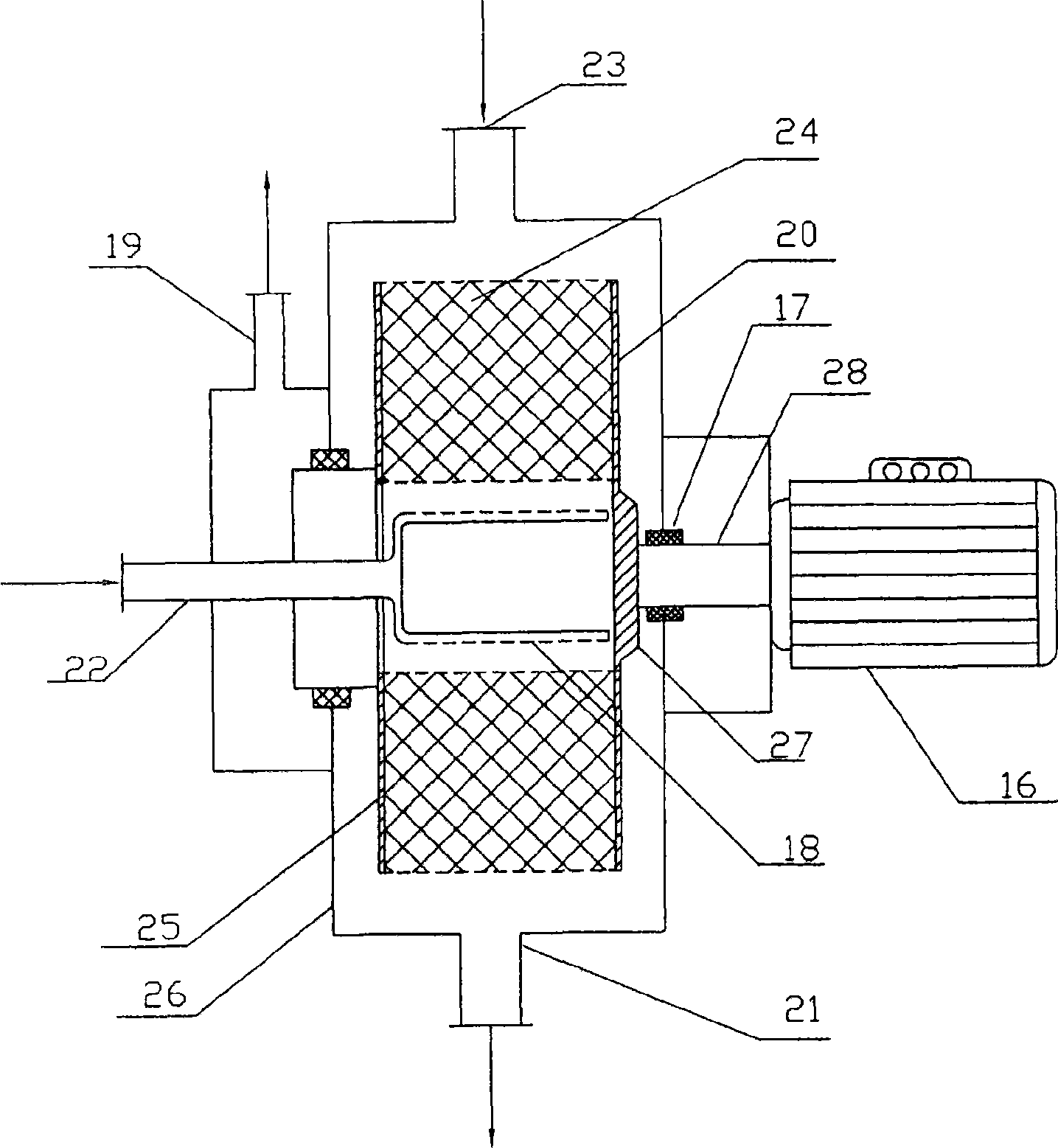

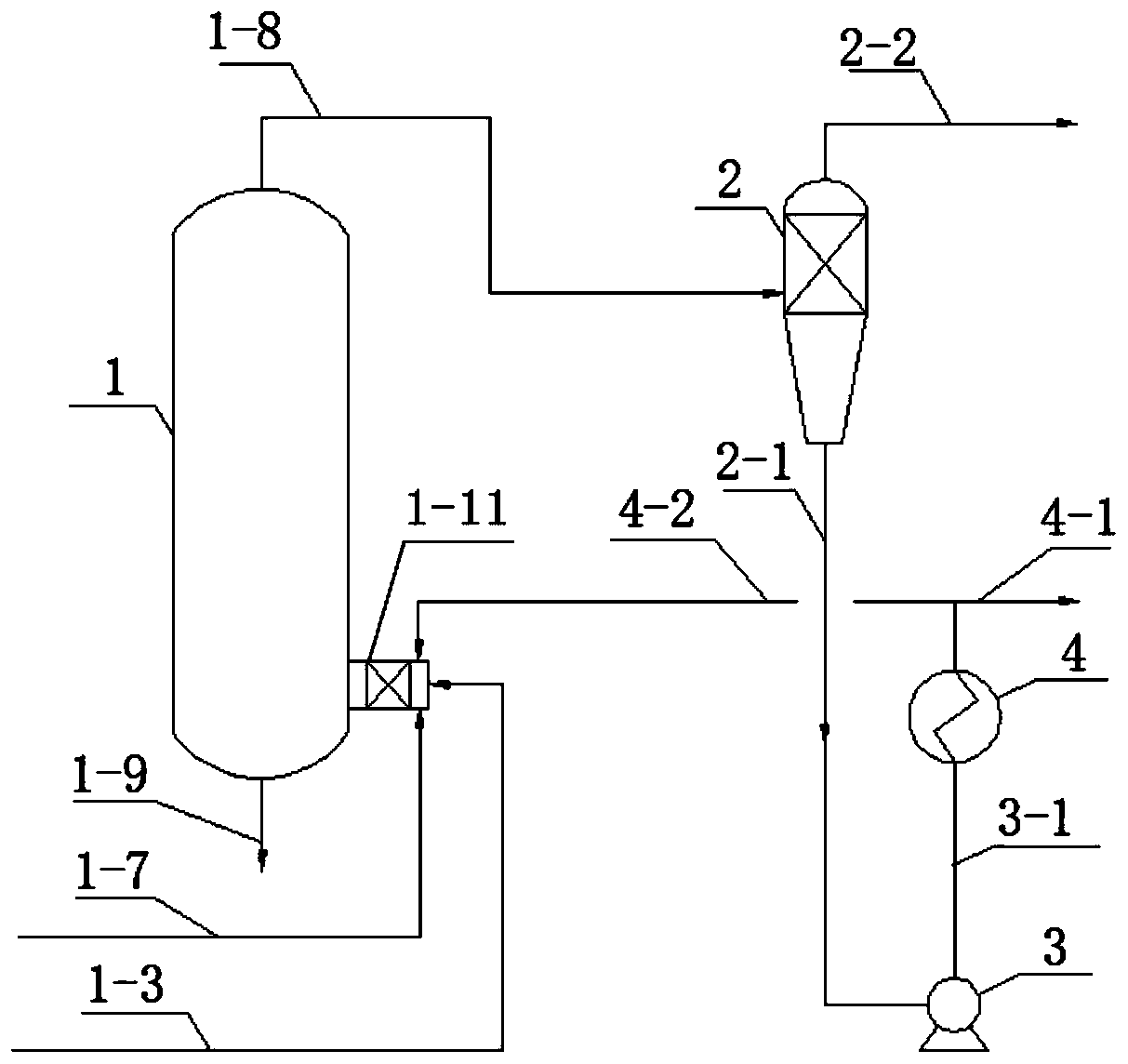

Oil Well gas-liquid mixed conveyor

InactiveCN1417515ADecrease the gas-liquid ratioGuaranteed to workPipeline systemsVapor–liquid separatorLiquid ratio

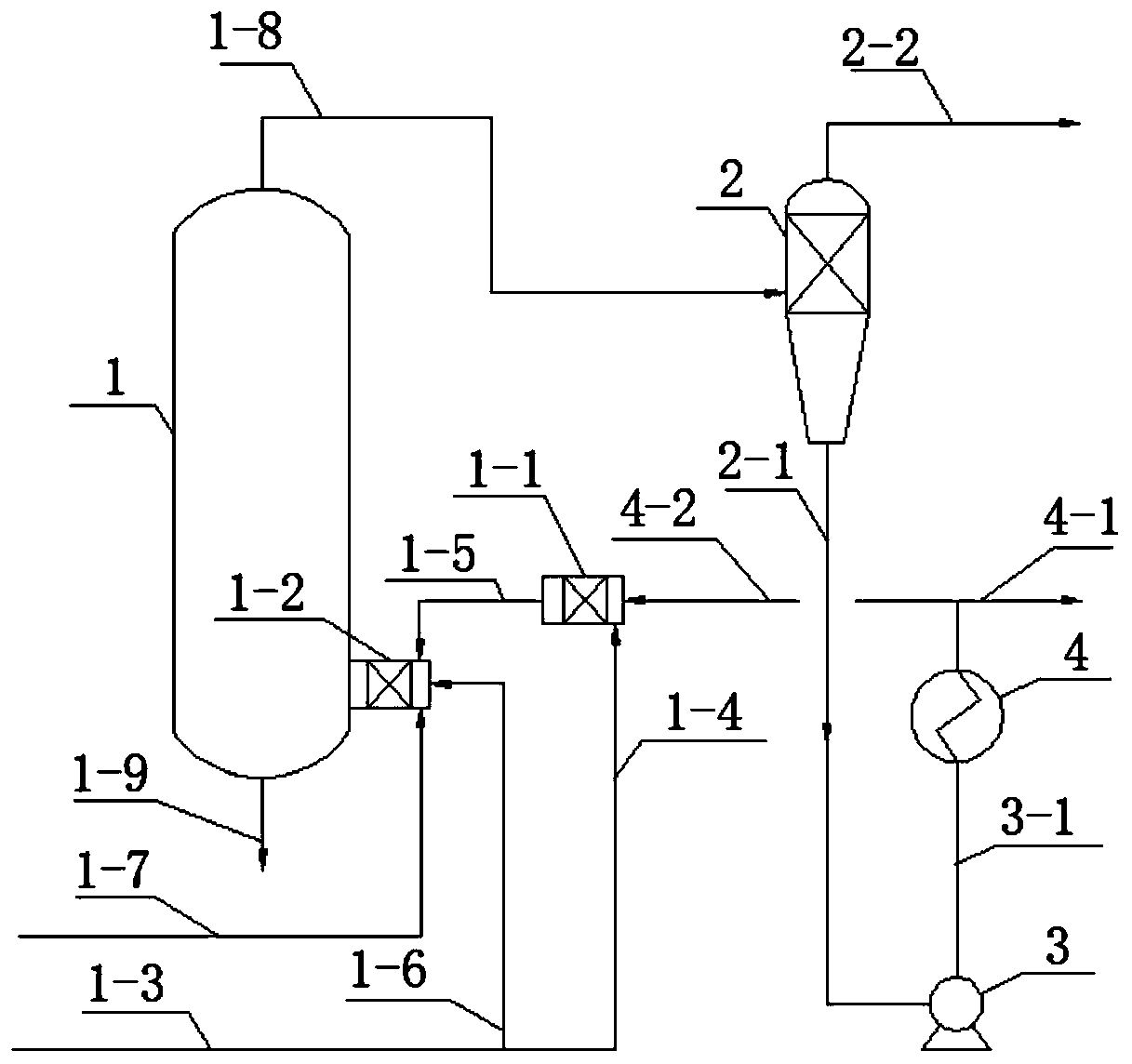

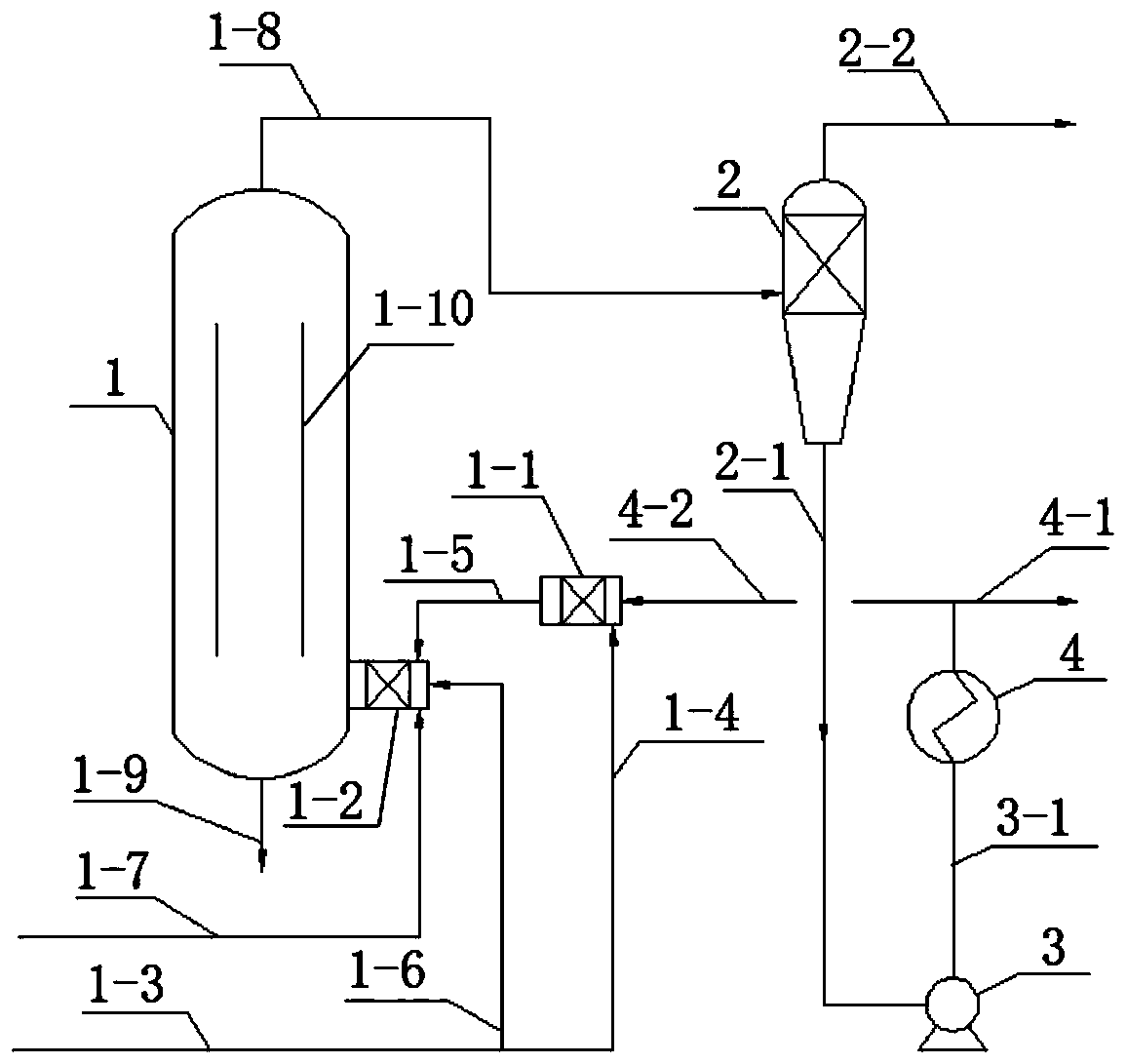

The oil well gas-liquid mixture conveyer consists of gas-liquid mixture conveying pump and gas-liquid separator connected via pipes. Oil well gas-liquid mixture entered by the inlet pipe is pressure raised in the pump before entering the gas-liquid separator by the outlet pipe. Partial liquid from the gas-liquid separator is returned via the lower outlet and reflux pipe to the inlet of the gas-liquid mixture conveying pump, and the separated gas and the other part of the liquid are output via the upper outlet and outer pipe. The reflux liquid flow rate is adjusted by the adjusting valve. The present invention has lowered gas / liquid ratio into the pump to avoid gas lock and to ensure the normal operation of the pump.

Owner:姚瑞忠

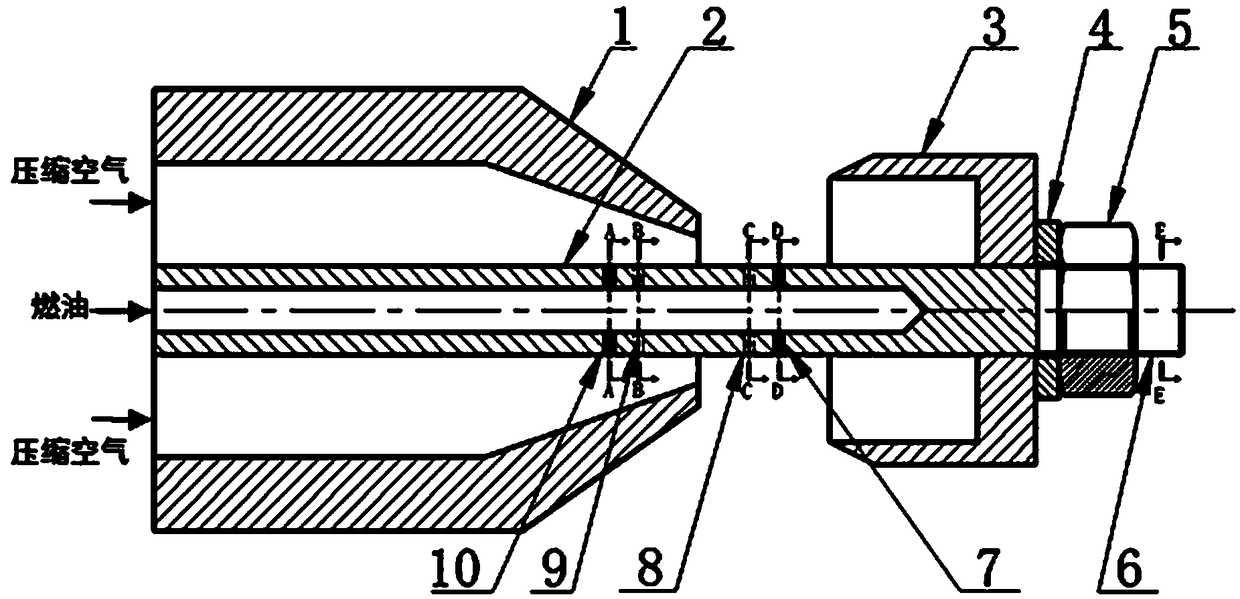

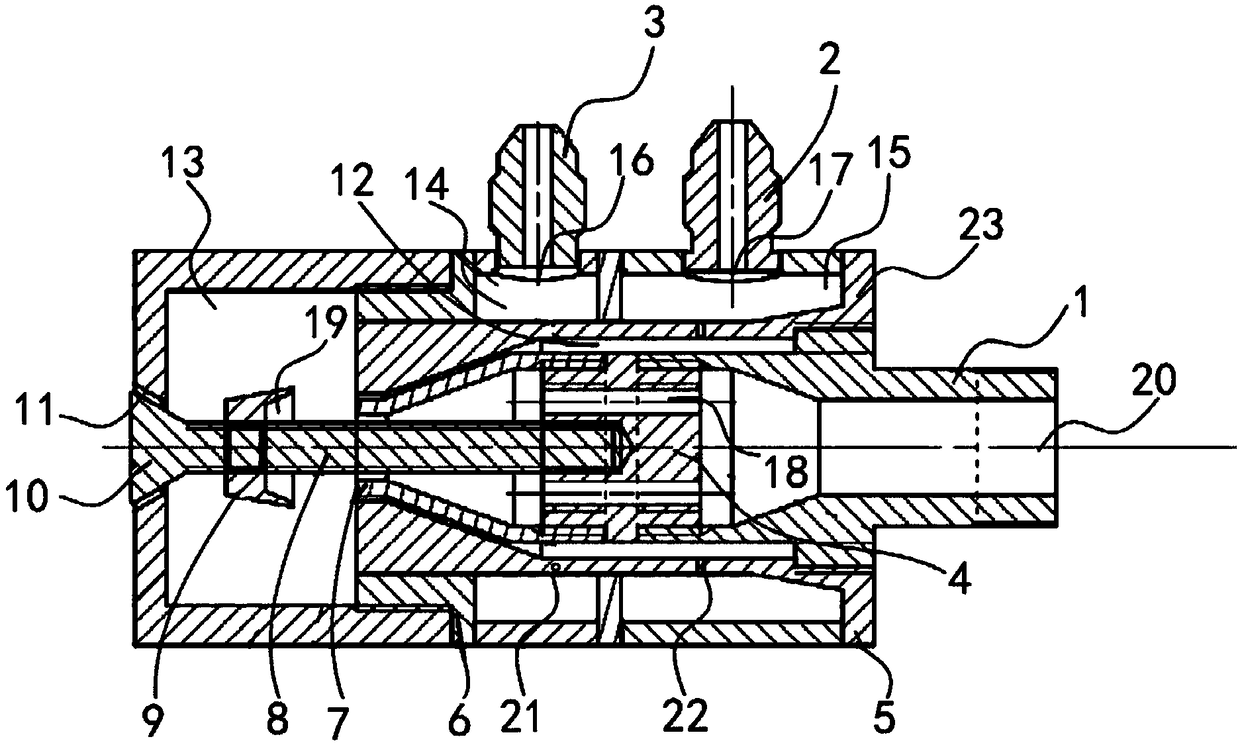

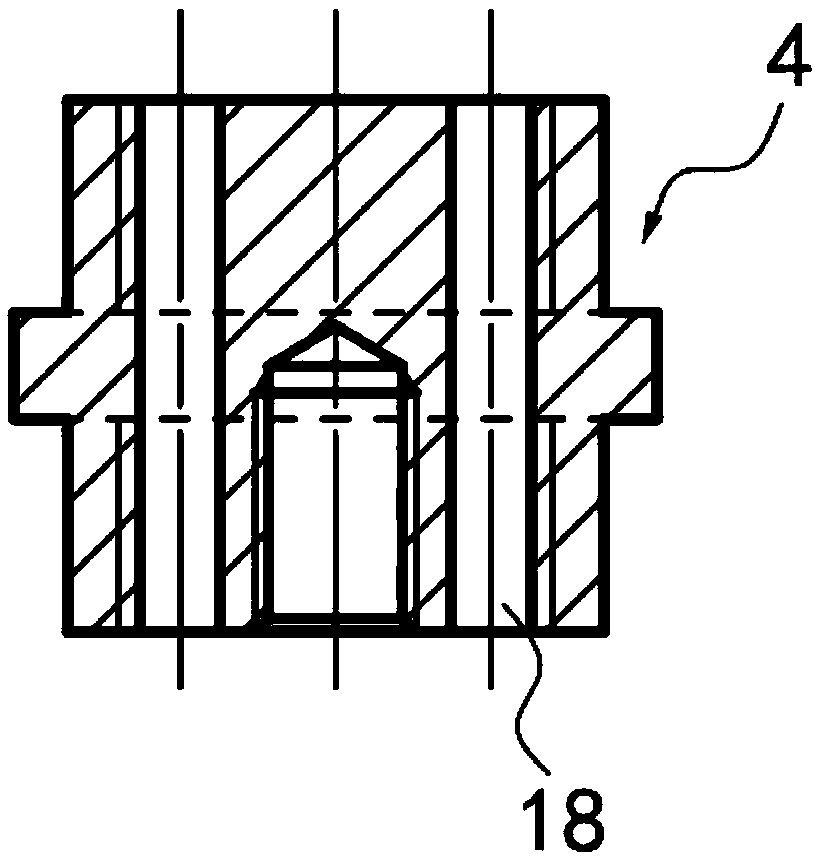

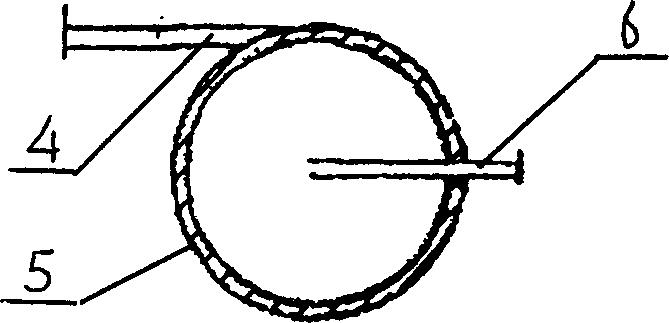

Double-pre-film type ultrasonic spray nozzle

PendingCN108644810AImprove atomization qualityIncrease contact areaContinuous combustion chamberResonant cavityCombustor

The invention discloses a double-pre-film type ultrasonic spray nozzle, specially an ultrasonic atomizing spray nozzle suitable for a combustor, which belongs to the field of industrial combustion. The double-pre-film type ultrasonic spray nozzle comprises a spray tube, a central rod, a resonant cavity, a flat gasket and a hexagonal nut, wherein the outlet section of the spray tube is equipped with a convergent spray tube; the inner part at the left end of the central rod is hollow; the right end of the central rod is equipped with a solid rod; the outer surface of the solid rod is tapped withthreads; and the resonant cavity, the flat gasket and the hexagonal nut are connected by the central rod. Double-pre-film type oil spray and convergent spray tube type design are adopted, so that thespray nozzle can realize secondary atomizing; fuel oil flow and air flow can be met according to the dimension of a to-be-regulated structure; and meanwhile, a distance from the resonant cavity to anoutlet of the spray tube can be regulated to obtain different spray angles. The double-pre-film type ultrasonic spray nozzle is simple in structure, is small in gas-liquid ratio, is good in atomizingeffect, is great in atomizing angle variable range, sufficiently utilizes structure characteristics, flow field characteristics and sound pressure characteristics of an ultrasonic generator, greatlyimproves atomizing quality of fuel oil from structure and principle, and improves combustion efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

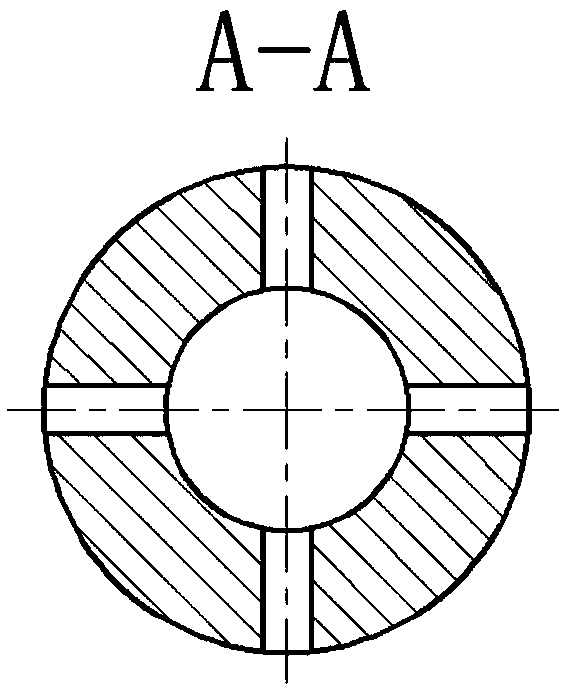

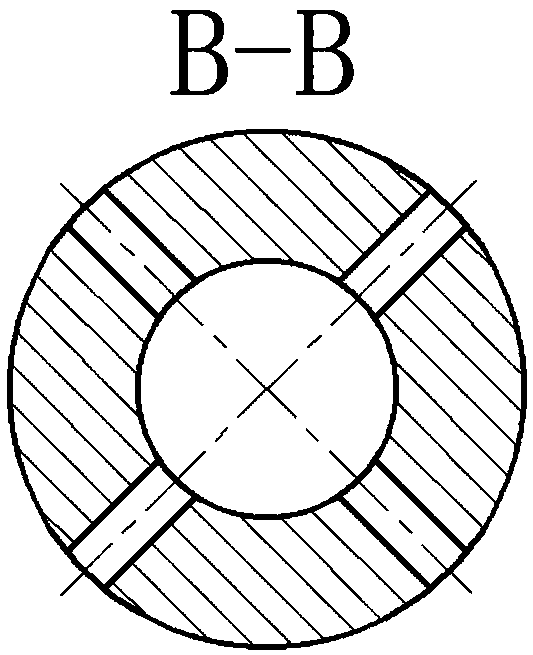

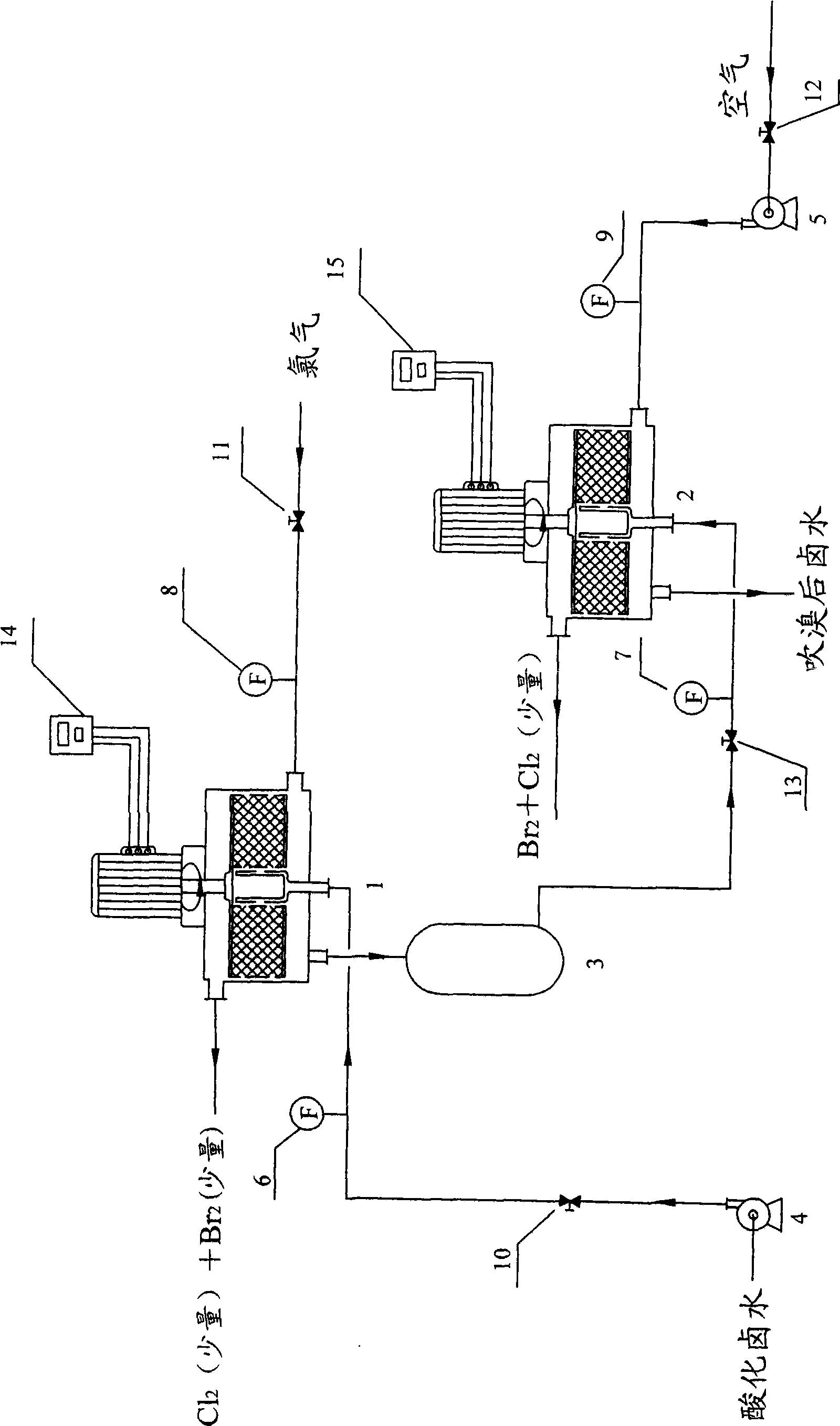

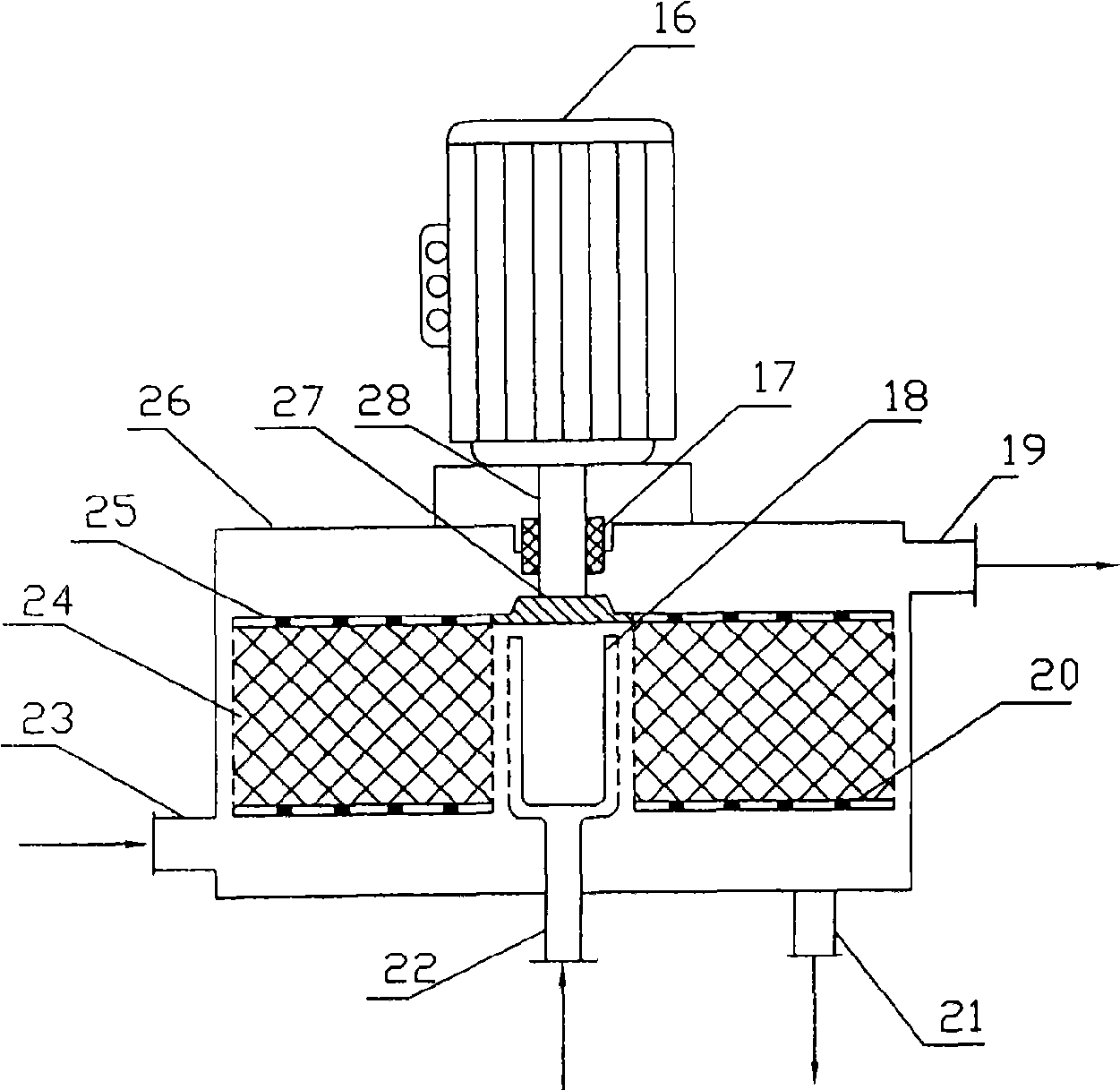

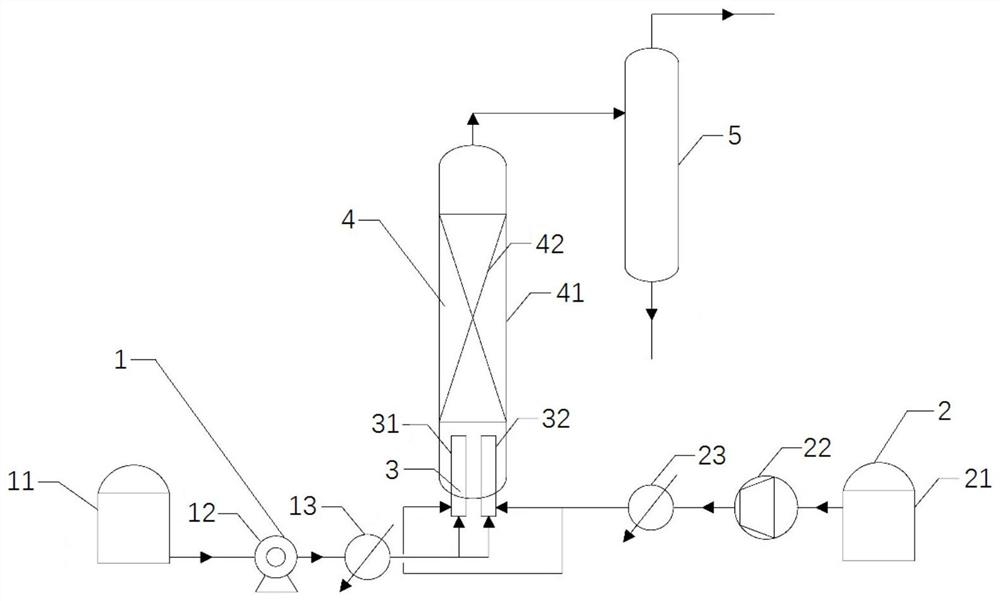

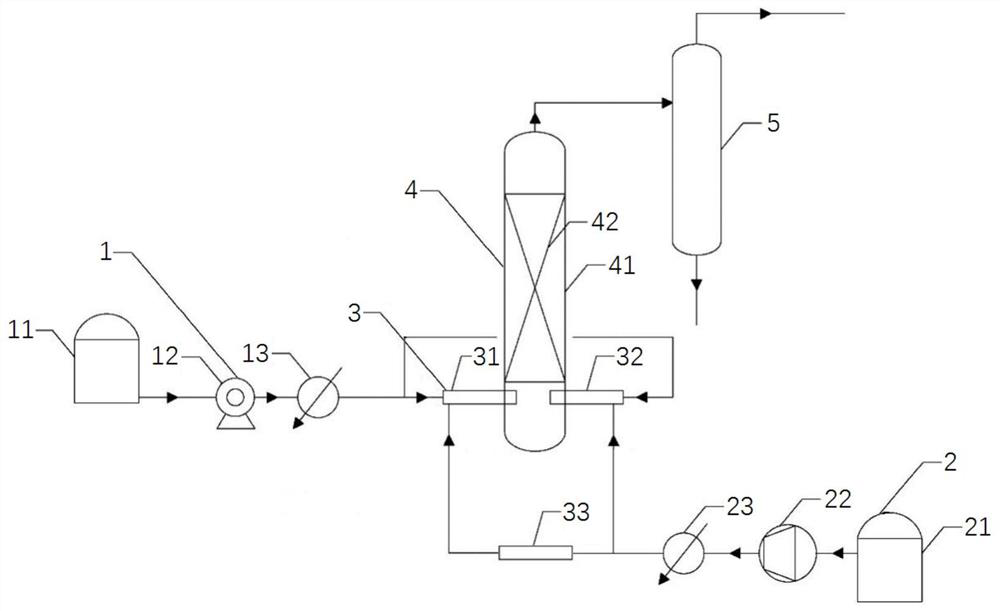

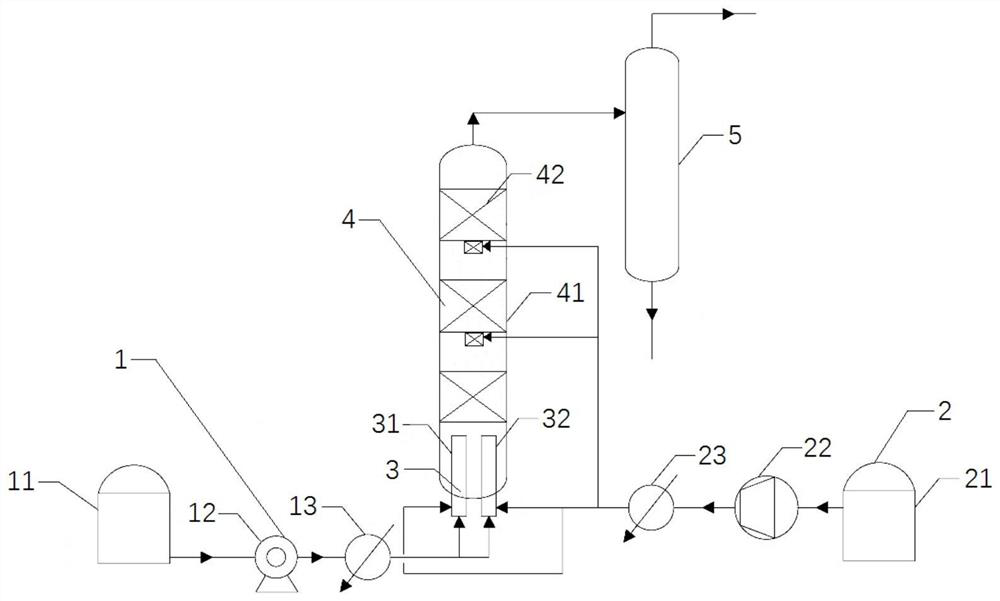

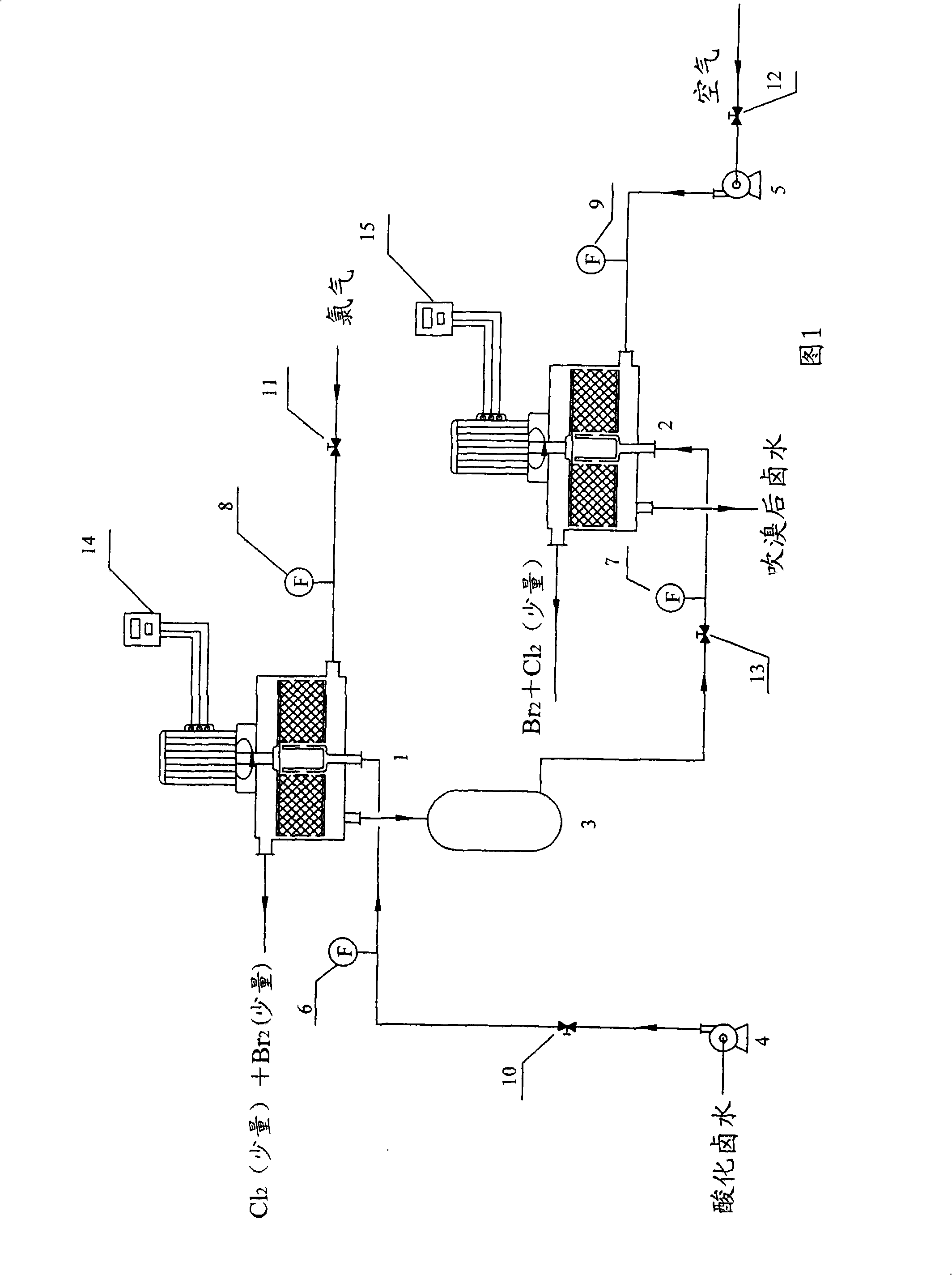

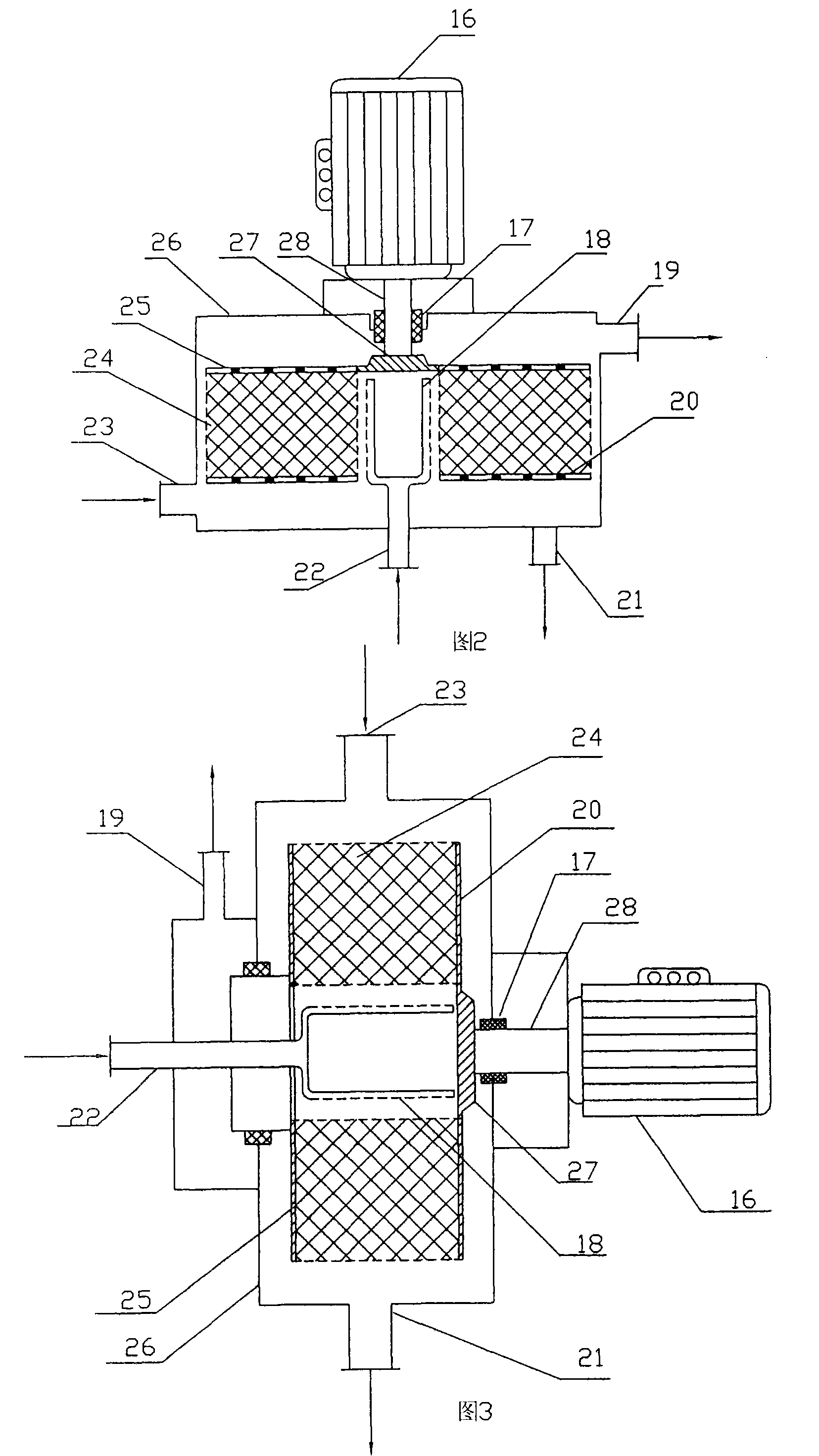

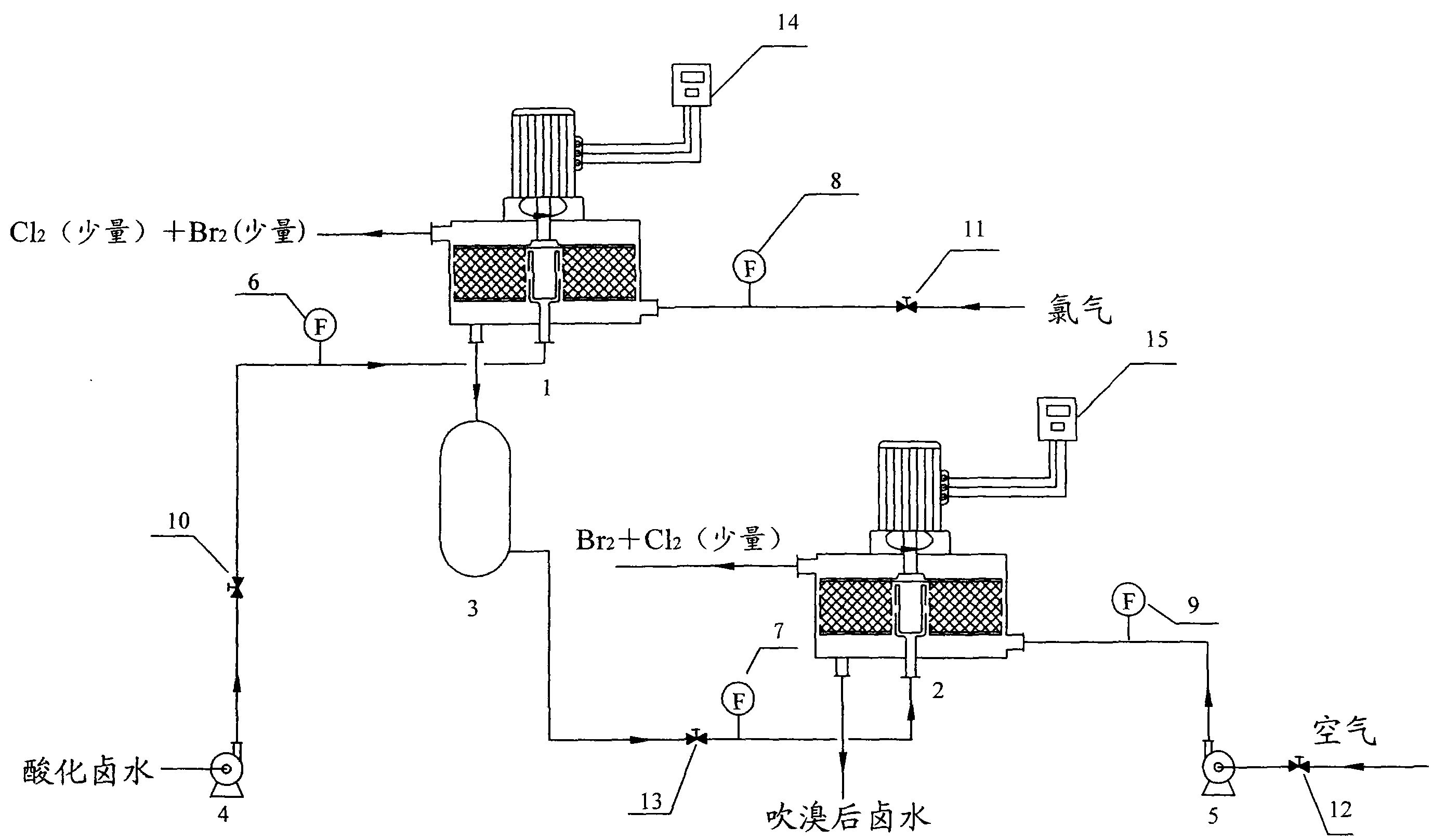

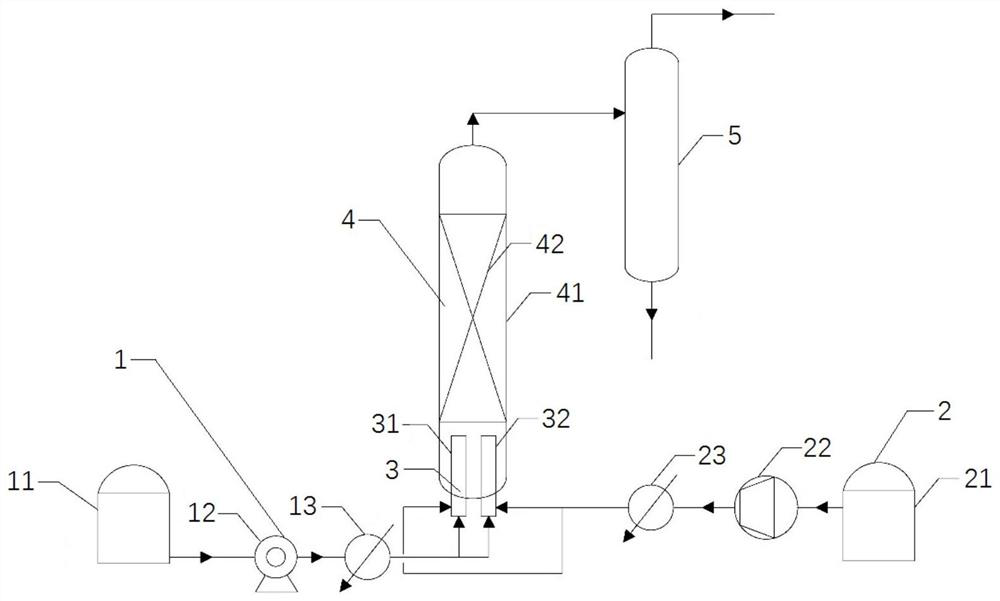

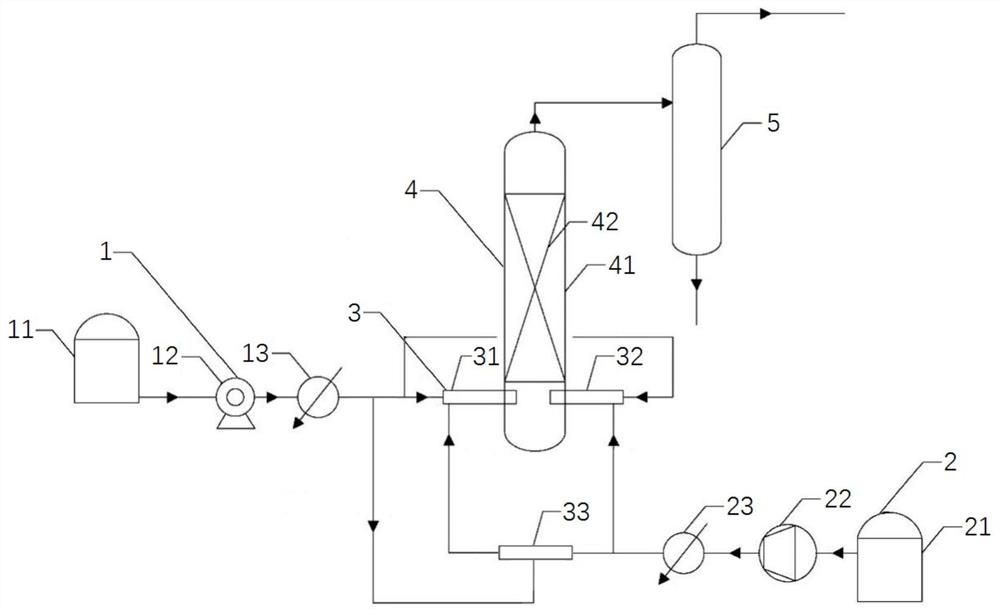

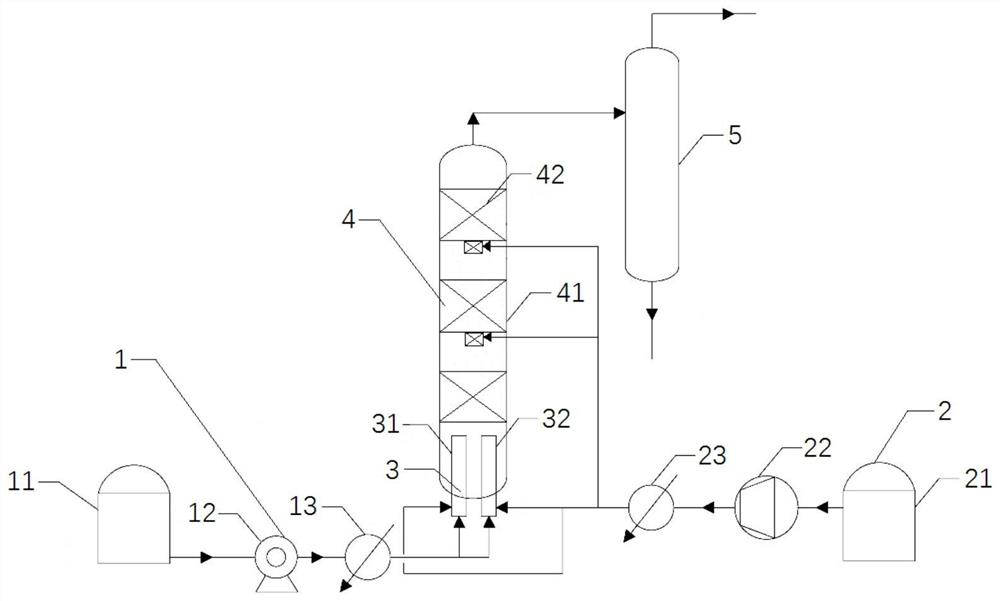

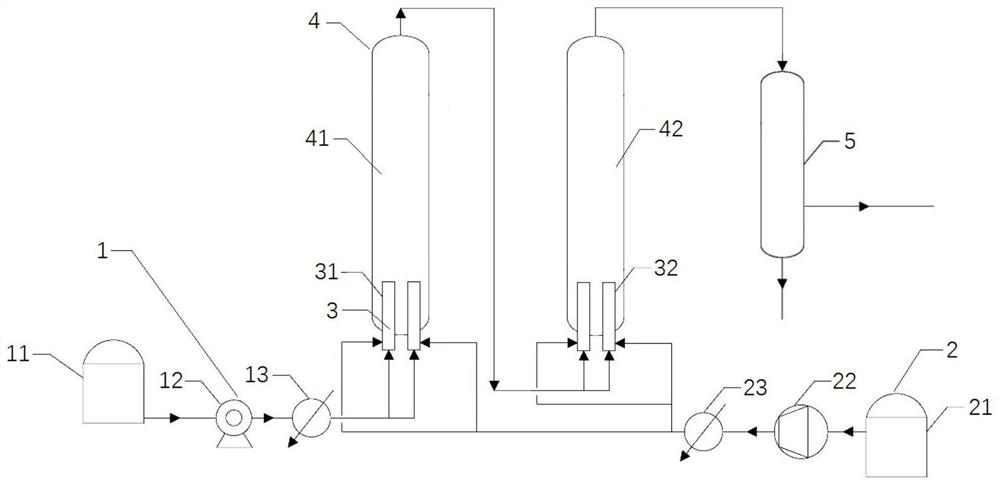

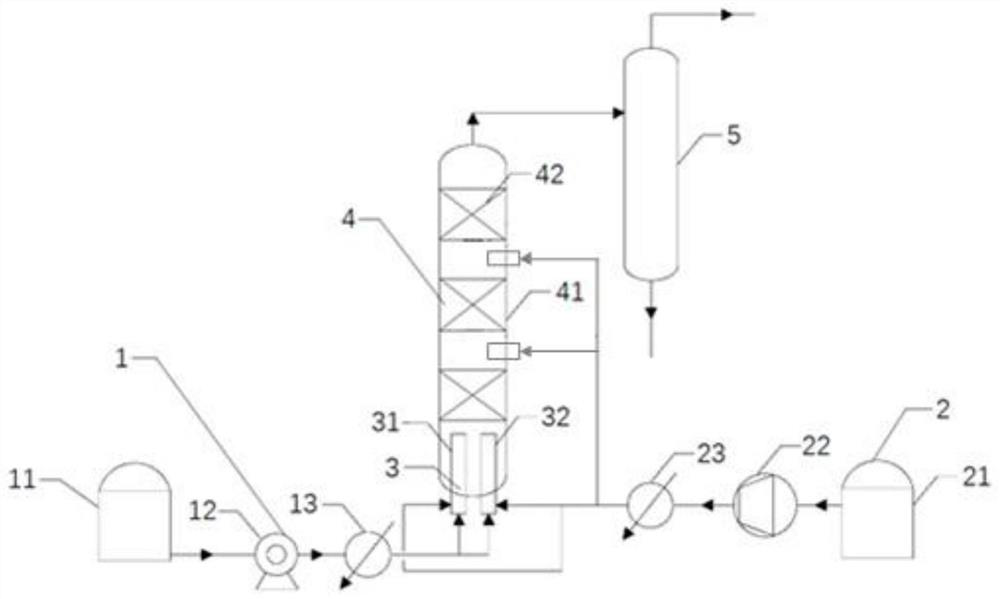

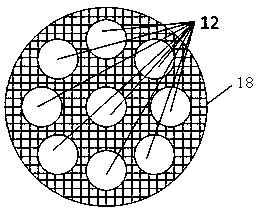

Oxidation and blowout technological process and apparatus for bittern bromine process

ActiveCN101486445AIncrease the specific surface area of contactEnhanced mass transferBromine/hydrogen-bromideLiquid ratioBromine

The invention pertains to the technical field of extraction of bromine from brine, more particularly relates to the technique of oxidation and blow-out during the process of extraction of bromine from brine, and a device thereof, which improve the oxidation rate and blow-out rate of bromine during the extraction process and reduce energy consumption. The method is as follows: acid brine and chlorine are introduced into a rotating packed bed I, and the formed oxidation solution and air enter a rotating packed bed II to blow out free bromine. The device comprises two rotating packed beds, the liquid inlet of the rotating packed bed I is connected with a pump and the gas inlet thereof is connected with a chlorine pipe; the rotating packed bed I and the rotating packed bed II are connected by a storage tank; and the gas inlet of the rotating packed bed II is connected with a fan. The method has the advantages of improving the oxidation rate of bromonium ions, the utilization ratio of chlorine and the blow-out rate of free bromine, and reducing chlorine adding ratio, chlorine consumption amount, the causticity of the device during the process after the extraction of bromine and the process of salt extraction, gas-liquid ratio and operation cost; and the device occupies less land and is easy to be start and shut off and maintained.

Owner:ZHONGBEI UNIV

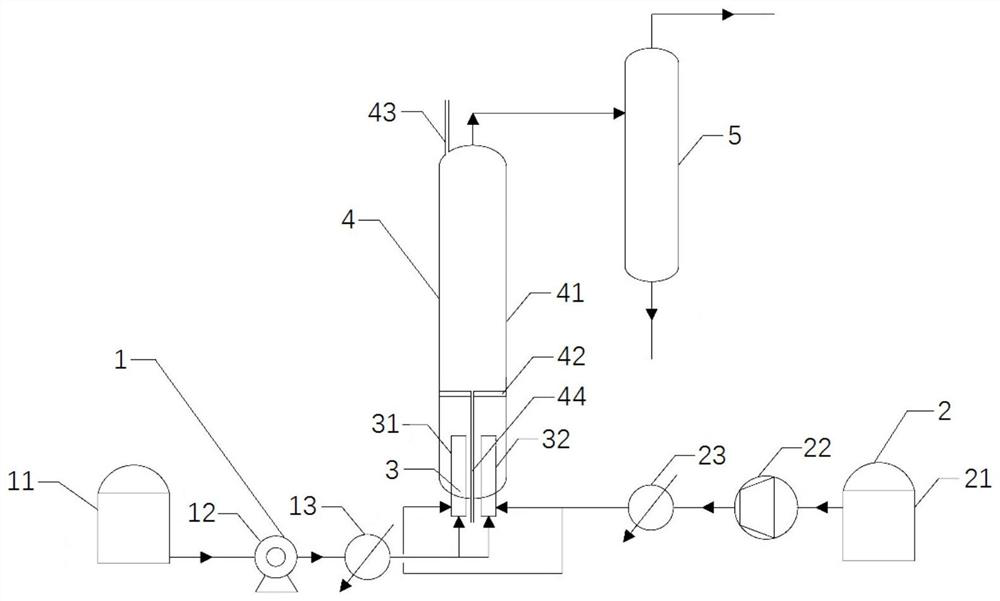

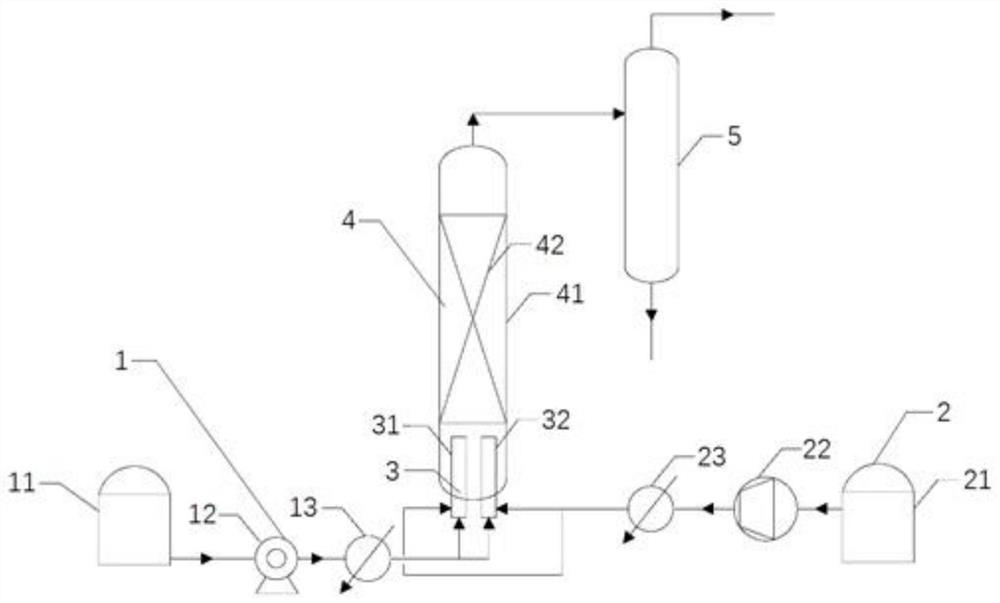

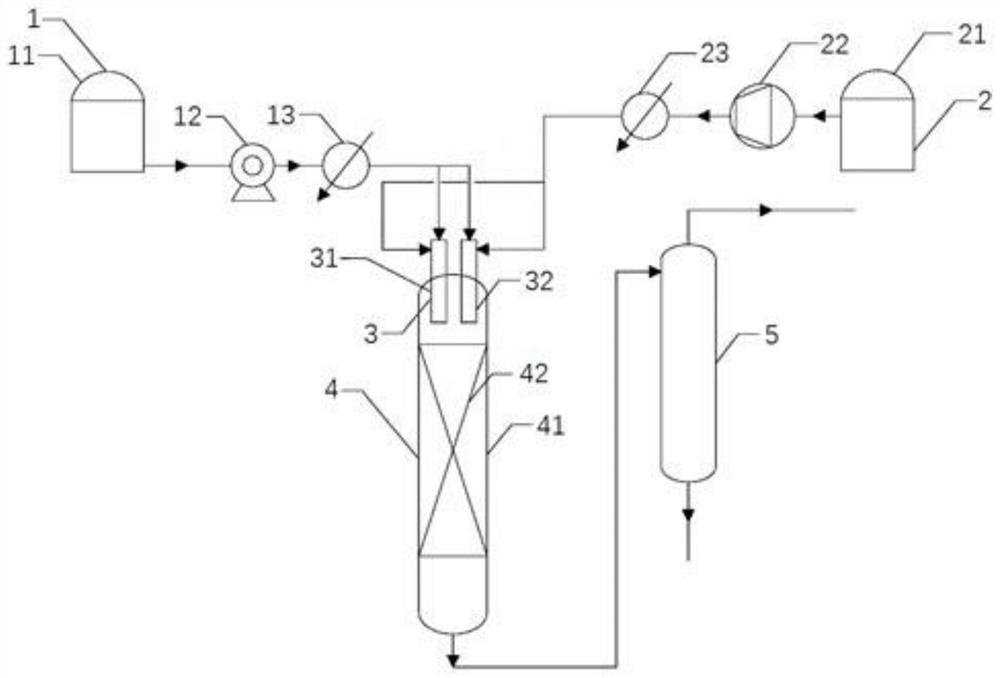

Gasoline hydrodesulfurization modification micro-interface enhanced reaction system and method

PendingCN111686646AReduce energy consumptionIncrease the interphase areaChemical/physical processesHydrocarbon oils treatmentEmulsionFluid phase

The invention relates to gasoline hydrodesulfurization modification micro-interface enhanced reaction system and method. The system comprises a liquid phase feeding unit, a gas phase feeding unit, a micro-interface generator, a fixed bed reactor and a separation tank. Compared with a traditional fixed bed reactor, according to the invention, gas is crushed to form micron-scale micro-bubbles, and the micro-bubbles and gasoline are mixed to form an emulsion, so that the gas-liquid two-phase interphase area is increased, the effect of enhancing mass transfer within a relatively low preset range is achieved, and the pressure in the reaction process can be reduced by 10-80% while the reaction efficiency is ensured; meanwhile, mass transfer is greatly enhanced, so that the gas-liquid ratio can be greatly reduced, the material consumption of gas is reduced; the energy consumption of subsequent gas circulating compression is also reduced; therefore, the method is low in process severity, highin production safety, low in ton product cost and high in market competitiveness.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Liquid nitrogen pump equipment loading test and testing device and test and testing method thereof

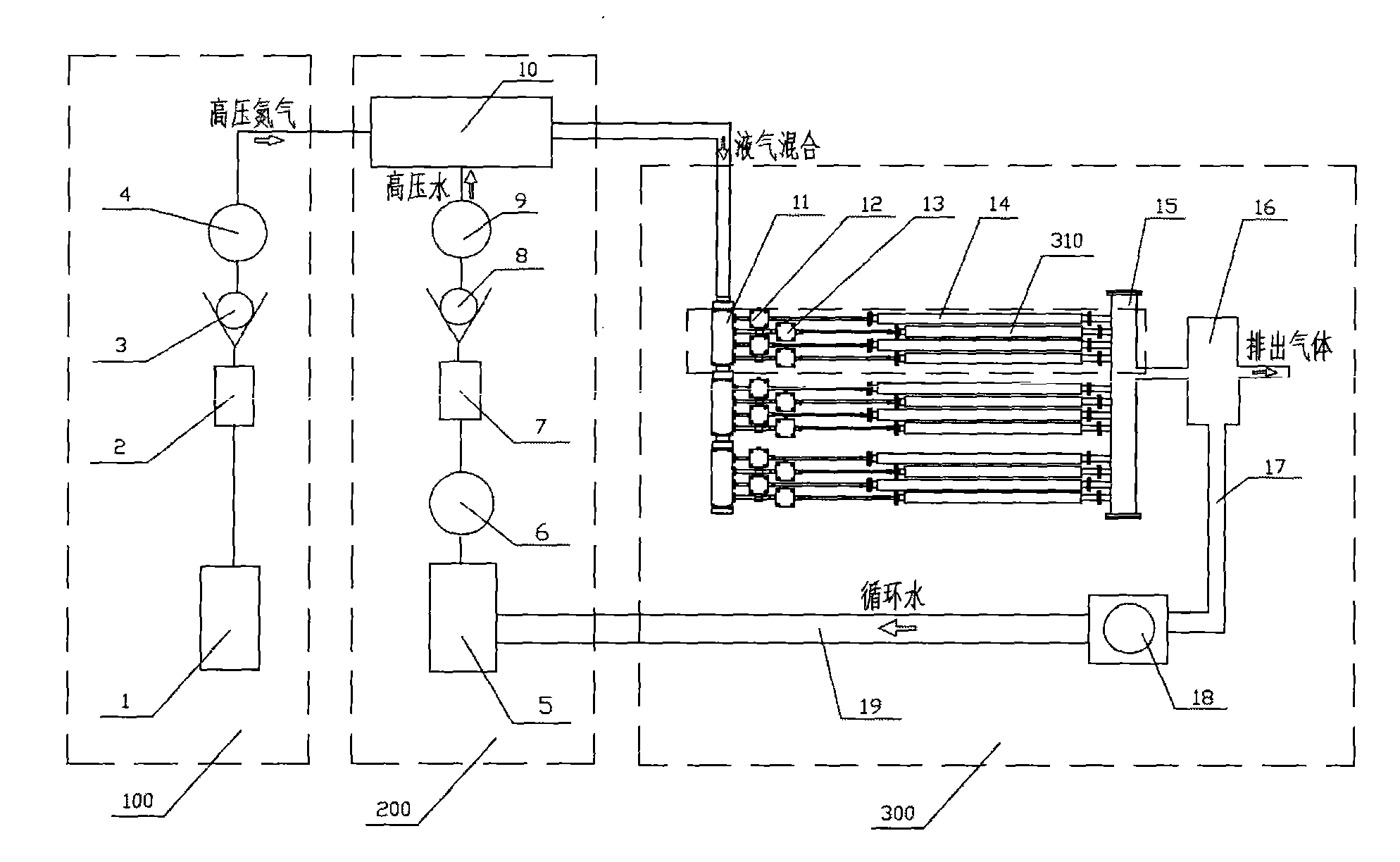

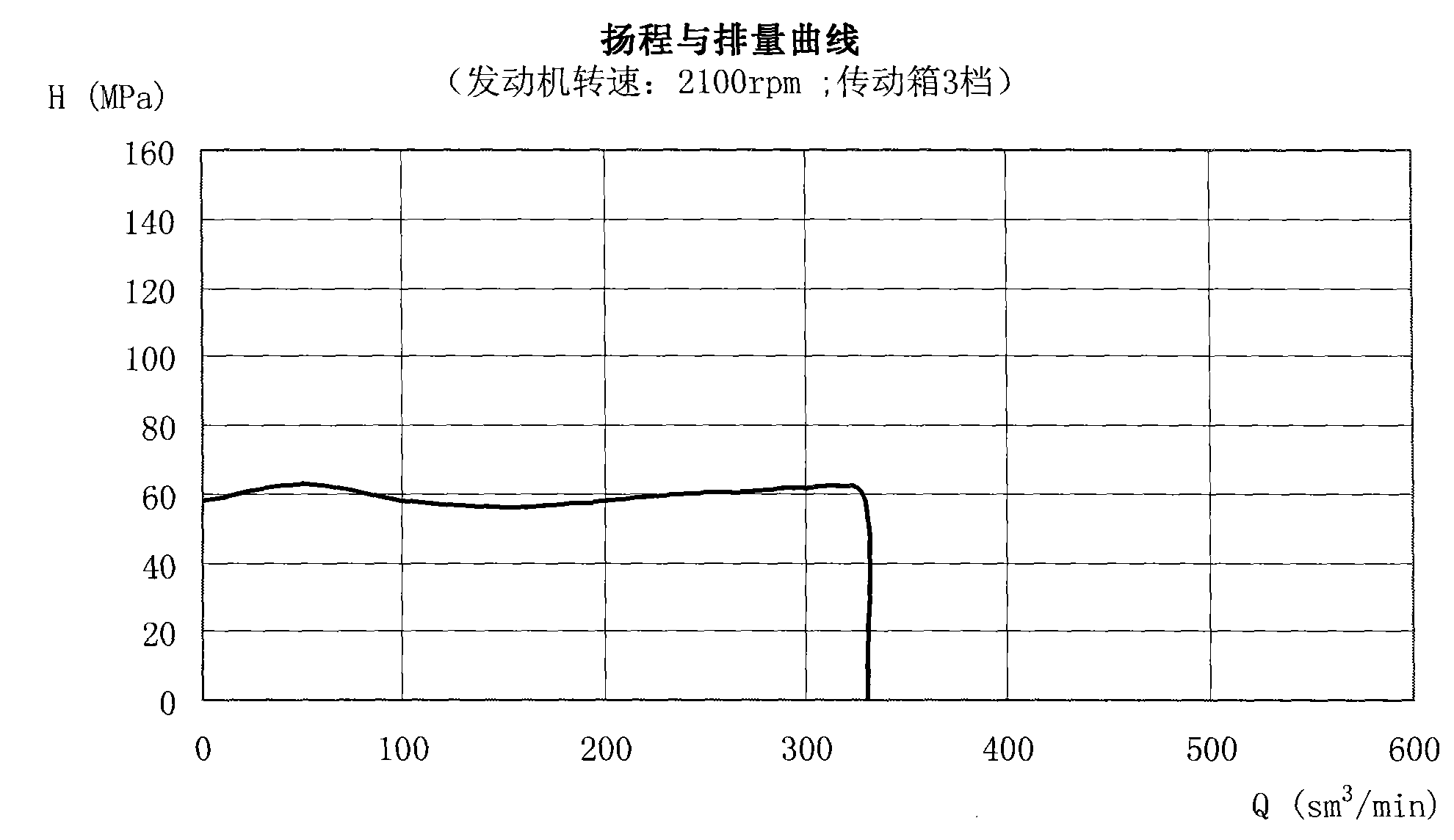

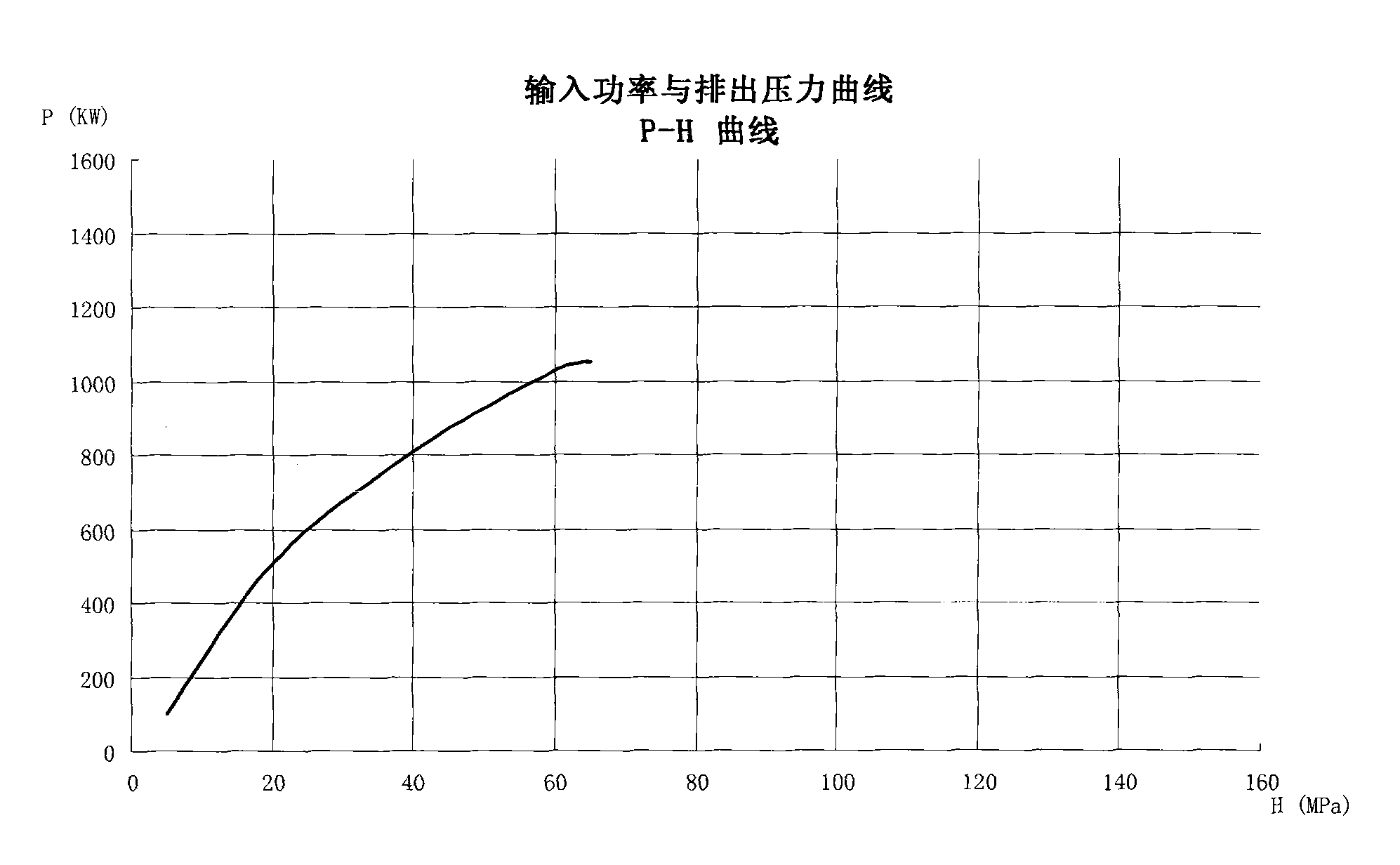

InactiveCN101968051ADecrease the gas-liquid ratioReduce testingPump testingPiston pumpsWater dischargeDrivetrain

The invention discloses a liquid nitrogen pump equipment loading test and testing device and a test and testing method thereof, which are used for oil-gas field or coal bed gas nitrogen foam fracturing equipment tests. A waterpower damping device unit and a pressure regulation unit are specially arranged, wherein the waterpower damping device unit comprises a water tank, pump unit equipment and a pipe manifold system connected in turn; the pipe manifold system mixes normal-temperature high-pressure gaseous nitrogen from liquid nitrogen pump equipment and high-pressure water from the pump unit equipment to form a high-pressure liquid and gaseous mixture; and the pressure regulation unit pressurizes water discharged from the waterpower damping device unit by adjusting the flow of the high-pressure liquid and gaseous mixture. By loading through a waterpower loading device, the invention avoids technical difficulty and security risk brought by pressure loading of gas; the pressure regulation system is easy, convenient and accurate to operate; the nitrogen discharge of the liquid nitrogen equipment is controlled by a power transmission system and a fluid distribution system of the equipment per se without additional power; and the equipment cost and energy are saved.

Owner:CHINA NAT PETROLEUM CORP +1

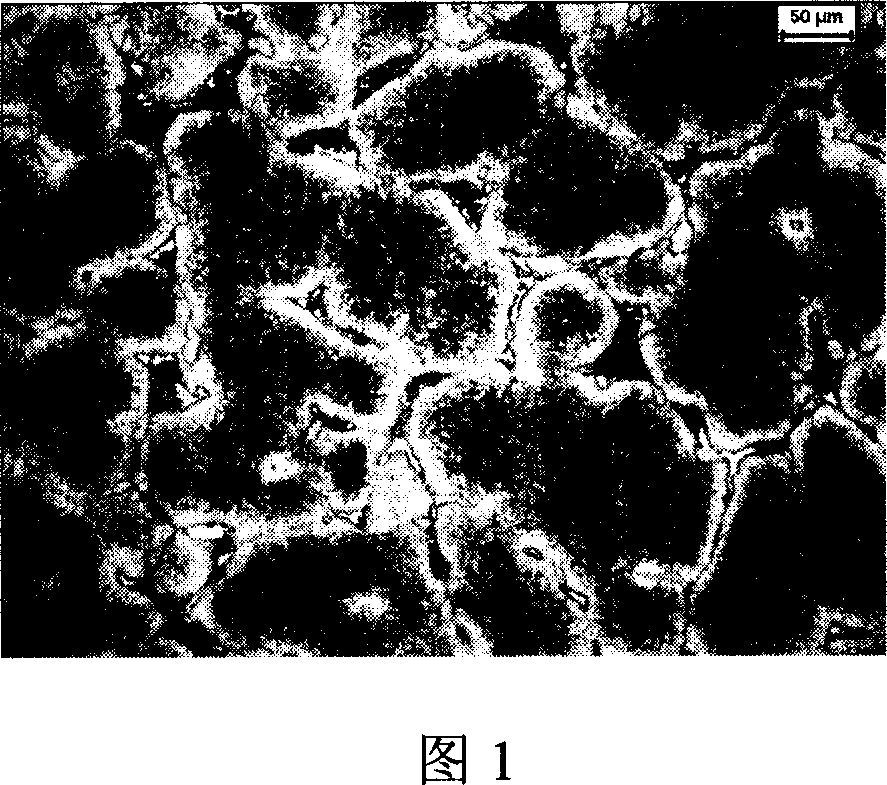

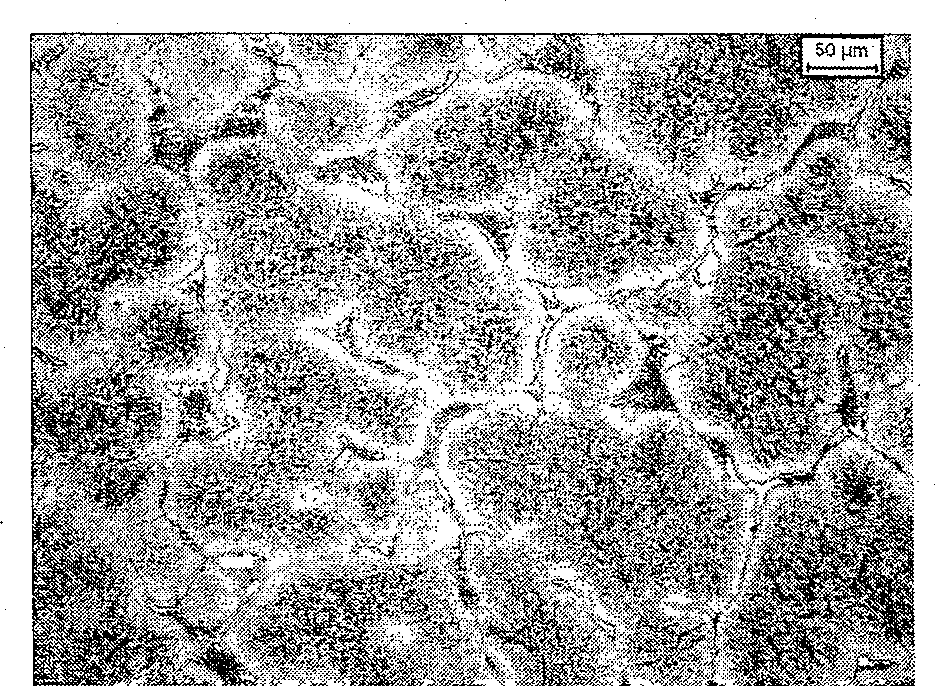

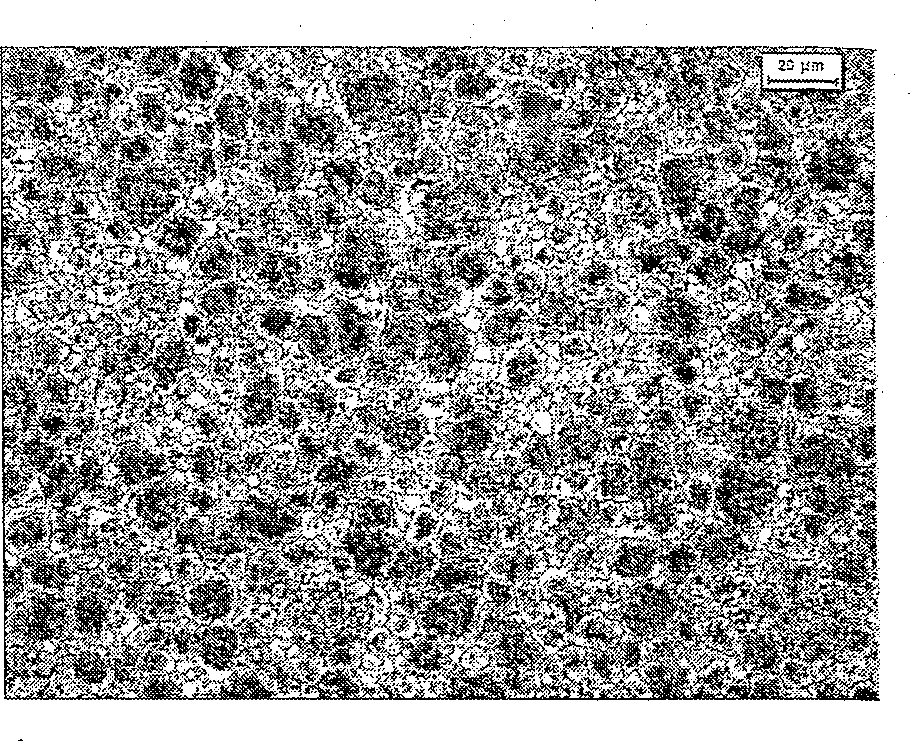

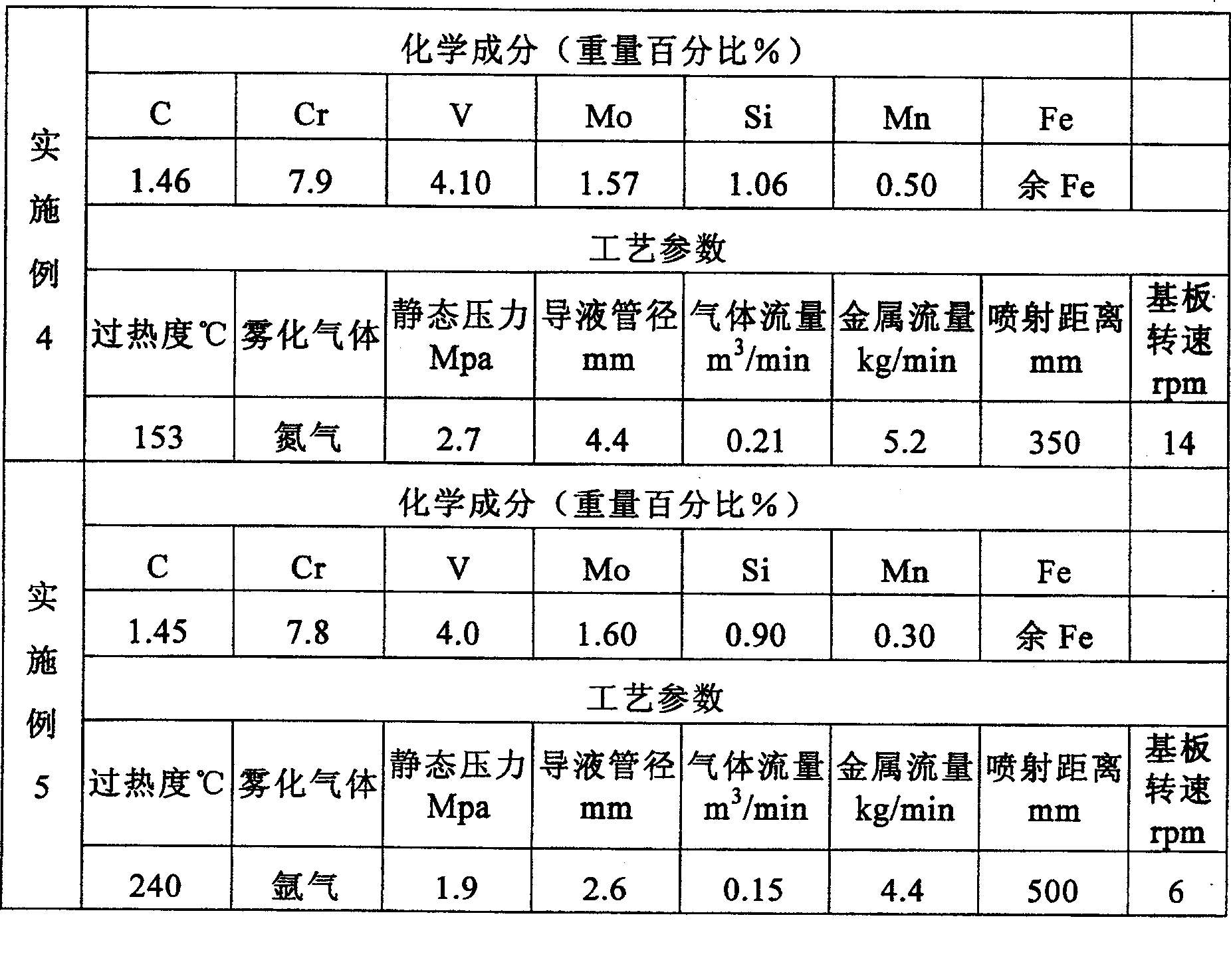

Technical method for preparing cold work die steel in high alloy through jetting deposition

ActiveCN1958833AImprove microstructureEasy to produceMolten spray coatingCrystallitePowder metallurgy

This invention discloses a method for preparing high-alloy cold-working die steel by injection deposition. The method comprises: (1) preparing molten high-alloy cold-working die steel; (2) preparing high-alloy cold-working die steel green body by atomization deposition in inert gas when the temperature reaches required overheating degree. The components of molten high-alloy cold-working die steel are: C 1.45-1.55 wt.%, Cr 7.8-8.2 wt.%, V 3.9-4.1 wt.%, Mo 1.4-1.6 wt.%, Si 0.9-1.1 wt.%, Mn 0.3-0.5 wt.%, and Fe. Since atomization deposition is utilized, the obtained green body has tiny and uniform microstructure without macroscopic precipitation. The grain sizes of the green body are 2-10 mums, and the green body can be directly hot-rolled without forging. The method can avoid the occurrence of eutectic ledeburite, and has such advantages as simple process, low cost and low energy consumption.

Owner:BAOSHAN IRON & STEEL CO LTD

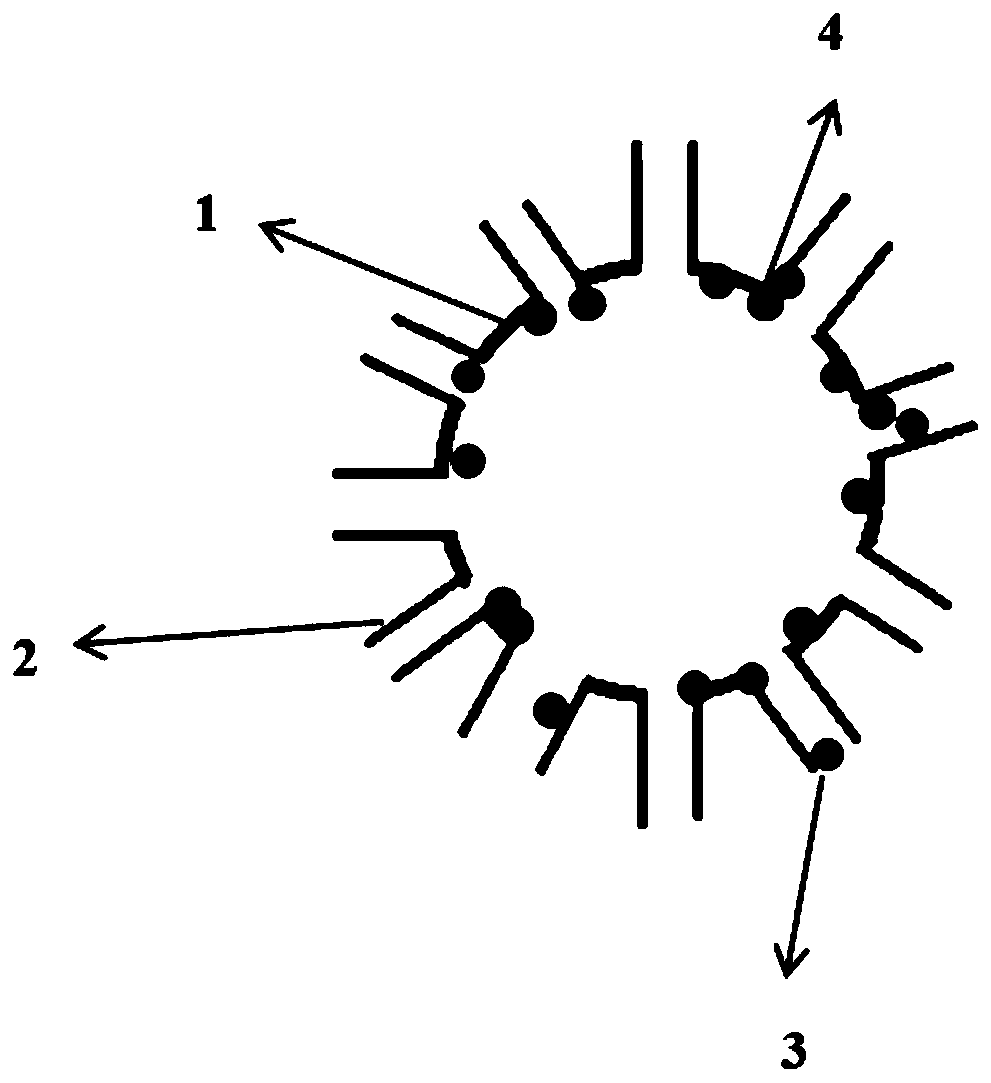

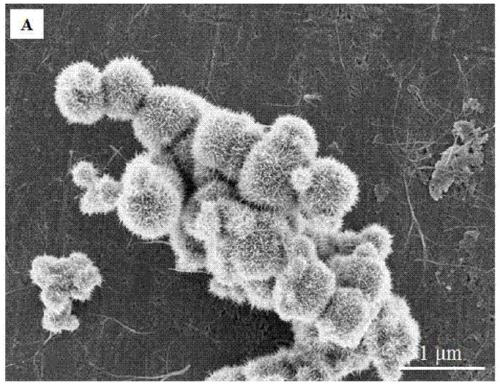

Catalyst and method for preparing beta-phenylethanol by using same

ActiveCN109847754ARealize continuous productionHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsPreparation by hydrolysisStyrene oxideNanoreactor

The invention discloses a catalyst and a method for preparing beta-phenylethanol by the catalyst. The catalyst is a nickel-copper silicate composite echinus-shaped reactor type nanocatalyst. Accordingto the catalyst, the problem that the content of a byproduct, i.e., ethylbenzene is high due to the fact that a hydrogenation reaction speed of styrene oxide is too high and the supply of hydrogen isinsufficient is solved, the beta-phenylethanol can be prepared from the styrene oxide under mild conditions through high-selectivity and high-yield hydrogenation, the conversion ratio of the styreneoxide is higher than 99%, the selectivity of the beta-phenylethanol is not lower than 99.5%; and due to sufficient hydrogen supply, the high selectivity of the product can also be guaranteed under thecondition that hydrogenation of the styrene oxide is carried out in the absence of auxiliaries, the procedure of removing the auxiliaries is avoided, and product separating flows are simplified. Themethod for preparing the beta-phenylethanol can achieve continuous production of the beta-phenylethanol, and the production efficiency is increased greatly.

Owner:WANHUA CHEM GRP CO LTD

Oil-coal co-hydrogenation micro-interface enhanced fluidized bed reaction system

InactiveCN111686657AReduce material consumptionReduce energy consumptionChemical/physical processesHydrocarbon oils treatmentEmulsionFluid phase

The invention relates to an oil-coal co-hydrogenation micro-interface enhanced fluidized bed reaction system. The system comprises a liquid phase feeding unit, a gas phase feeding unit, a micro-interface generator, a fluidized bed reactor and a separation tank. Compared with a traditional fluidized bed reactor, according to the invention, gas is crushed to form micron-scale micro-bubbles, and themicro-bubbles are mixed with a mixed oil product to form an emulsion, so that the gas-liquid two-phase interphase area is increased, the effect of enhancing mass transfer within a relatively low preset range is achieved, and the pressure in the reaction process can be reduced by 10-80% while the reaction efficiency is ensured; meanwhile, mass transfer is greatly enhanced, so that the gas-liquid ratio can be greatly reduced, the material consumption of gas is reduced, and meanwhile, the energy consumption of subsequent gas circulating compression is also reduced; the method is low in process severity, high in production safety, low in ton product cost and high in market competitiveness.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Micro-interface enhanced suspended bed hydrogenation reaction system and method

PendingCN111686651AReduce material consumptionReduce energy consumptionTransportation and packagingMixing methodsMicron scaleFluid phase

The invention relates to a micro-interface enhanced suspended bed hydrogenation reaction system, which enables micro-bubbles in a reactor to be in a micron scale by using a micro-interface generator so as to increase the mass transfer area between a reaction medium and hydrogen, and comprises a liquid phase feeding unit, a gas phase feeding unit, a micro-interface generator, a suspended bed reactor and a separation tank. Compared with a traditional suspended bed reactor, the suspended bed reactor has the advantages that gas is crushed and mixed with a reaction medium to form emulsified liquid,so that the interphase area of gas and liquid phases is increased and the effect of enhancing mass transfer within a lower preset range is achieved; the pressure in the reaction process can be reduced by 10-80% while the reaction efficiency is guaranteed; meanwhile, mass transfer is greatly enhanced, so that the gas-liquid ratio can be greatly reduced, the material consumption of gas is reduced;in addition, the energy consumption of subsequent gas circulating compression is also reduced; the method is low in process severity, high in production safety, low in ton product cost and high in market competitiveness.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

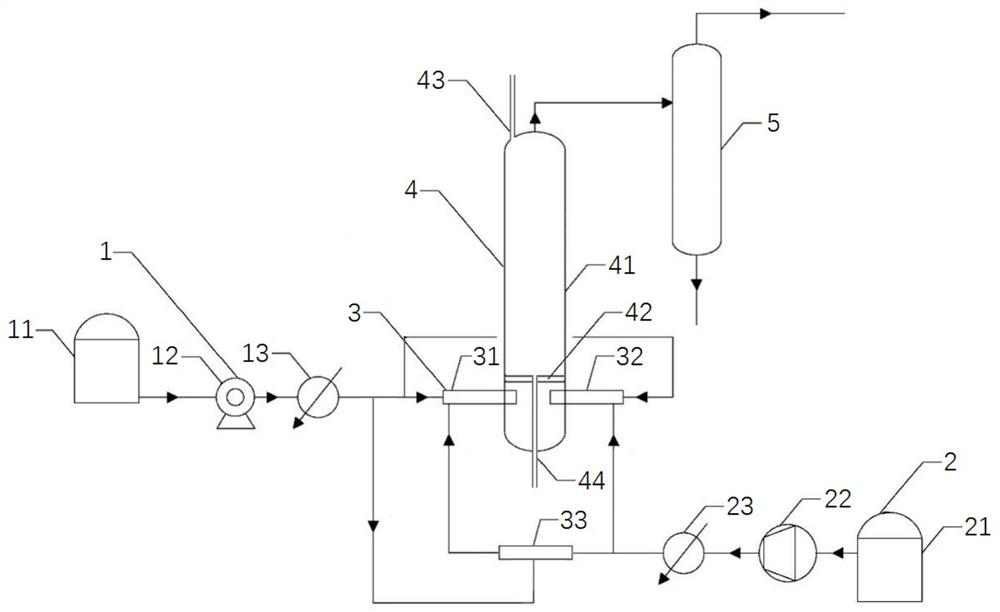

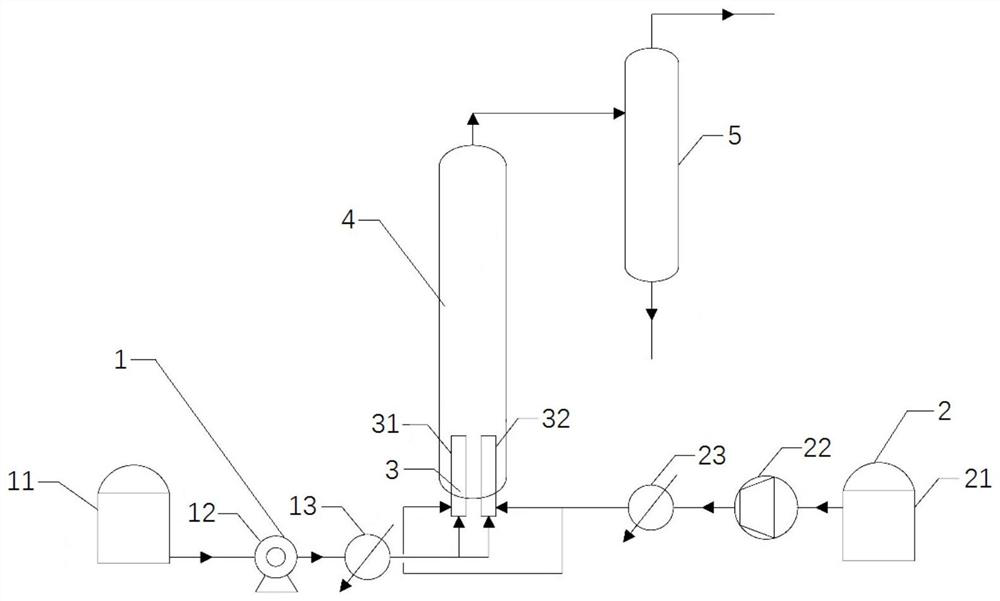

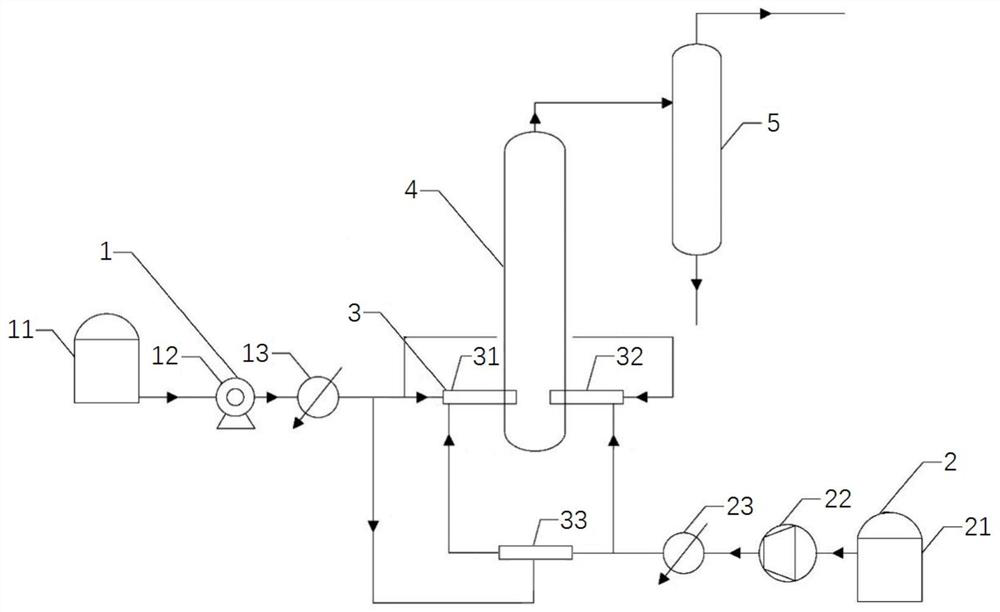

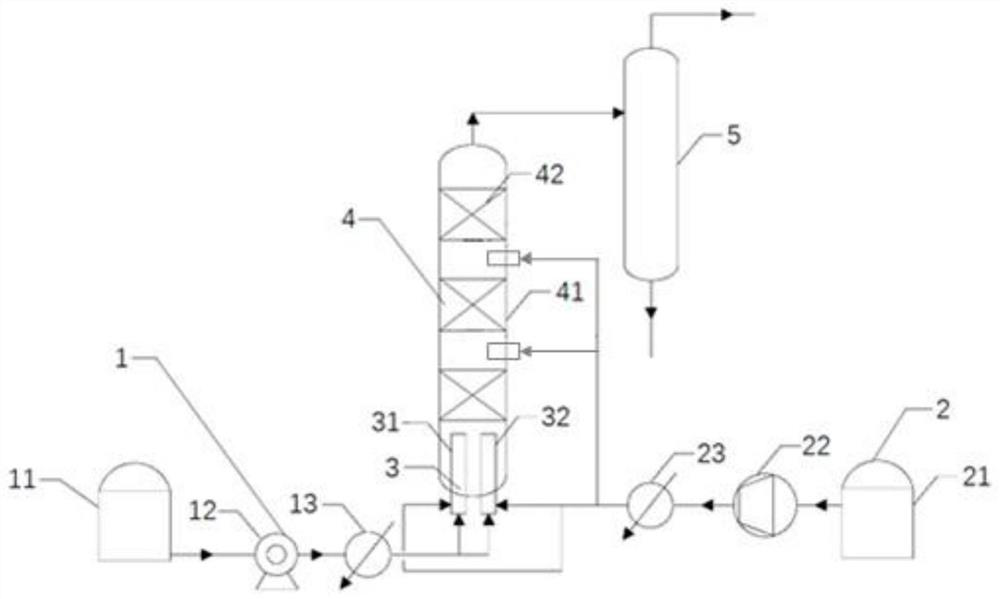

Top-mounted gas-liquid enhanced emulsification fixed bed reaction device and method

InactiveCN111482136AImprove solubilityIncreased phase boundary areaMixing methodsTransportation and packagingPtru catalystVapor–liquid separator

The invention discloses a top-mounted gas-liquid enhanced emulsification fixed bed reaction device and method. The top-mounted gas-liquid enhanced emulsification fixed bed reaction device comprises afixed bed reactor, at least one bubble breaker, a gas-liquid separator, a feeding pump, a gas inlet device and a liquid inlet device. A gas raw material and a liquid raw material are preheated and then respectively enter the bubble breakers from a gas phase inlet and a liquid phase inlet, gas is broken into micron-sized bubbles, the micron-sized bubbles are mixed with liquid to form a gas-liquid emulsion, and the gas-liquid emulsion then enters the fixed bed reactor from top to bottom; the micron-sized bubbles have the characteristics of low speed and difficulty in coalescence and keep the original form when penetrating through a catalyst bed layer, so that a stable gas-liquid enhanced emulsification fixed bed reaction system is formed; and a product obtained after the reaction enters a gas-liquid separator from a second discharge port, gas-liquid two-phase separation is carried out, and gas and liquid are collected separately for subsequent treatment. The device and the method have the advantages of low operation pressure, large gas-liquid mass transfer phase interface area, high apparent reaction speed, high gas utilization rate, low investment, low energy consumption, flexible process and the like.

Owner:NANJING UNIV +1

Mixed oil hydrogenation micro-interface enhanced reaction system and method

InactiveCN112175667AReduce material consumptionReduce energy consumptionHydrocarbon oil crackingChemical/physical processesFluid phaseEmulsion

The invention relates to a mixed oil hydrogenation micro-interface enhanced reaction system and method. The mixed oil hydrogenation micro-interface enhanced reaction system comprises a liquid phase feeding unit, a gas phase feeding unit, a micro-interface generator, a fixed bed reactor and a separation tank. Compared with a traditional fixed bed reactor, the micro-interface generator is arranged on the fixed bed reactor, and before reaction raw materials enter the reactor for reaction, pressure energy of gas and / or kinetic energy of liquid in the reaction process are / is converted into surfaceenergy of hydrogen bubbles, hydrogen bubbles are crushed into micro-bubbles with a diameter of more than or equal to 1 [mu] m and less than 1 mm, so the phase contact area between mixed oil and hydrogen in the hydrogenation reaction process is effectively increased, the mass transfer efficiency between the mixed oil and hydrogen is improved, and the mixed oil and the hydrogen micro-bubbles are mixed to form a gas-liquid emulsion after crushing, and furthermore, the reaction efficiency between the mixed oil and the hydrogen is enhanced within a relatively low preset pressure range.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Oxidation and blowout technological process and apparatus for bittern bromine process

The invention pertains to the technical field of extraction of bromine from brine, more particularly relates to the technique of oxidation and blow-out during the process of extraction of bromine from brine, and a device thereof, which improve the oxidation rate and blow-out rate of bromine during the extraction process and reduce energy consumption. The method is as follows: acid brine and chlorine are introduced into a rotating packed bed I, and the formed oxidation solution and air enter a rotating packed bed II to blow out free bromine. The device comprises two rotating packed beds, the liquid inlet of the rotating packed bed I is connected with a pump and the gas inlet thereof is connected with a chlorine pipe; the rotating packed bed I and the rotating packed bed II are connected bya storage tank; and the gas inlet of the rotating packed bed II is connected with a fan. The method has the advantages of improving the oxidation rate of bromonium ions, the utilization ratio of chlorine and the blow-out rate of free bromine, and reducing chlorine adding ratio, chlorine consumption amount, the causticity of the device during the process after the extraction of bromine and the process of salt extraction, gas-liquid ratio and operation cost; and the device occupies less land and is easy to be start and shut off and maintained.

Owner:ZHONGBEI UNIV

fuel atomizing nozzle

The invention discloses a fuel oil atomization nozzle. The fuel oil atomization nozzle comprises a nozzle shell, an auxiliary gas way and oil way base, a main gas inlet nozzle, a nozzle core and a resonant tube. The fuel oil atomization nozzle is applied to a combustion heater, an ultrasonic atomization mechanism and a bubble atomization mechanism are combined, the resonant type inner ultrasonic wave-bubble combined atomization nozzle is designed, and the atomization nozzle which is low in gas-liquid ratio and good in atomization effect, has the self-cleaning function and can have good atomization capacity on light oil (such as kerosene) and heavy oil is obtained by combining the two advantages. Furthermore, according to the fuel oil atomization nozzle, the atomization process is simplified, and the length of the nozzle is reduced. Furthermore, according to the fuel oil atomization nozzle, the oil-gas ratio of bubble atomization can be adjusted by changing the number of gas inlet holes, the number of oil inlet holes, the opening size and the pressure of an auxiliary gas inlet pipe and a fuel oil guide pipe, and therefore fluctuation of the main gas way gas quantity and the influence of the gas quantity on the atomization performance are reduced.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

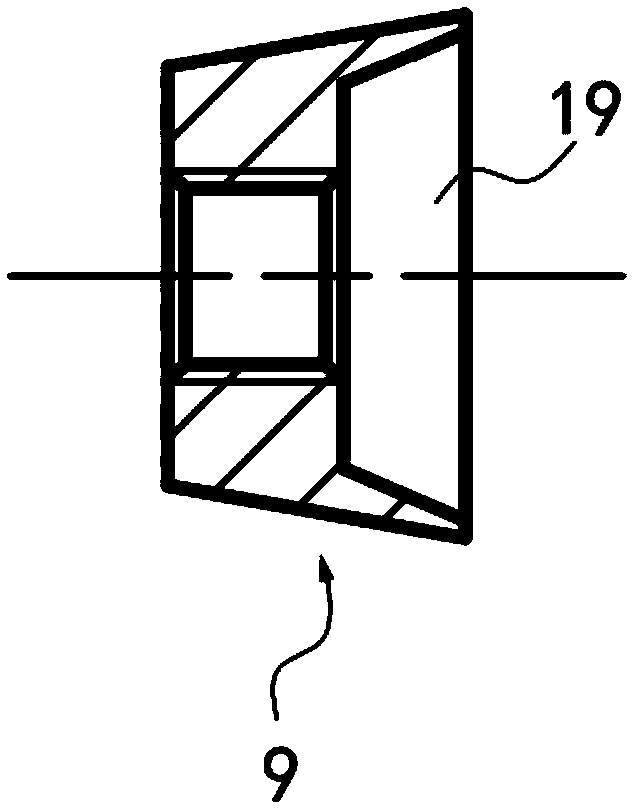

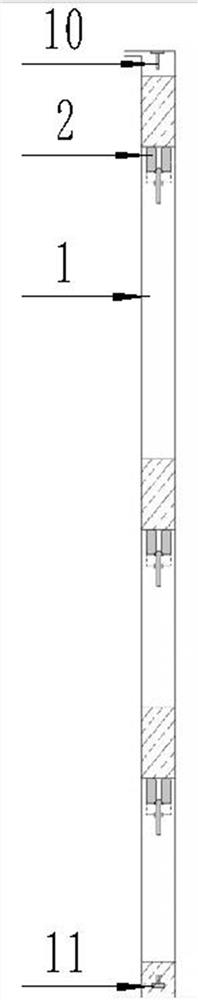

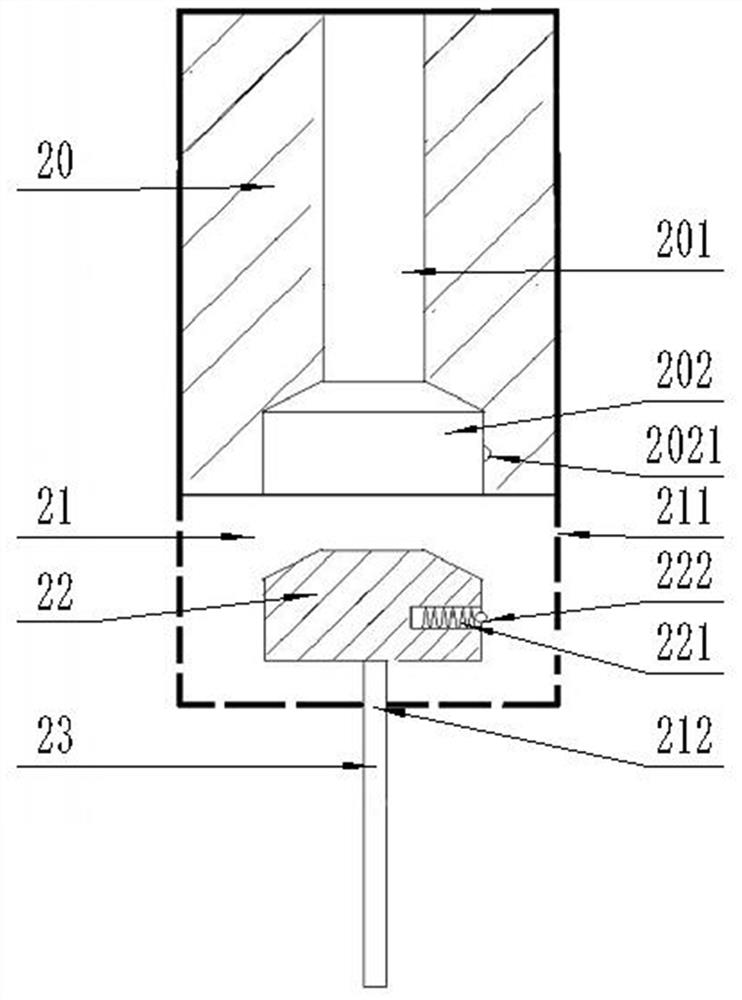

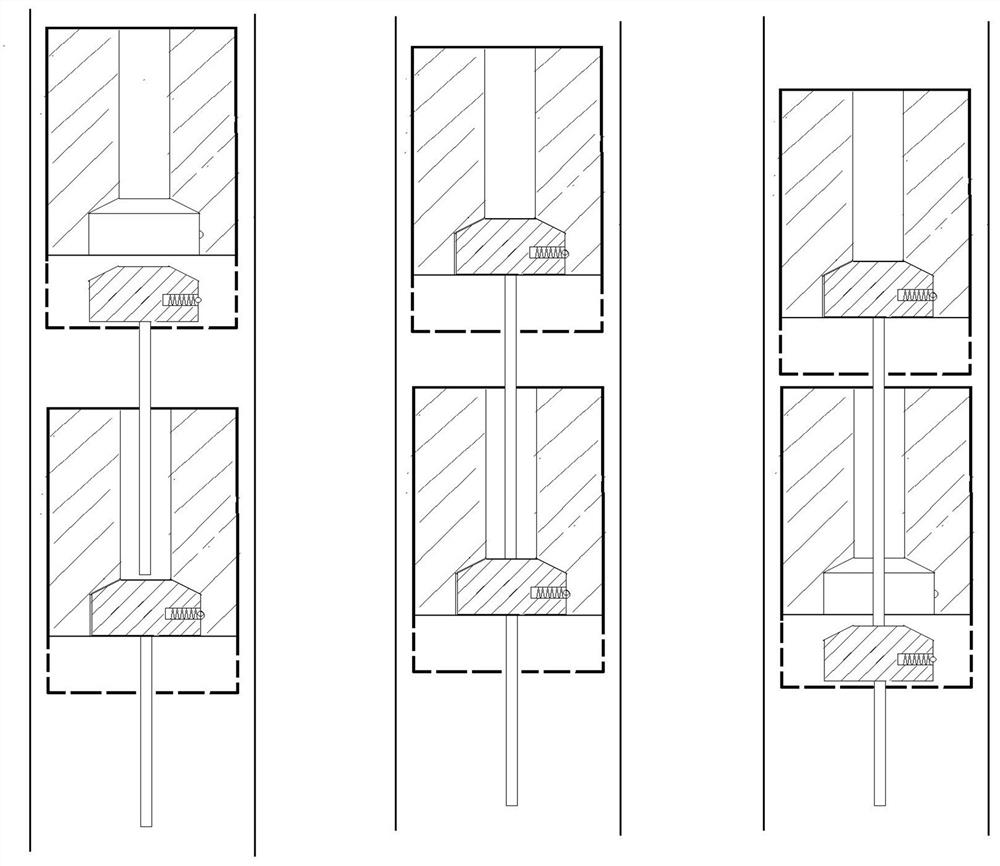

Multi-plunger cooperative gas-lift liquid drainage technology

ActiveCN111997571ADecrease the gas-liquid ratioLarge amount of liquidPositive displacement pump componentsFlexible member pumpsGas liftMechanical engineering

The invention relates to a multi-plunger cooperative gas-lift liquid drainage technology. The technology is applied to a multi-plunger cooperative gas-lift liquid drainage system, the liquid drainagesystem operates circularly in a reciprocating mode, a plurality of plungers divide a large-section liquid column and a gas column in an oil pipe into multiple sections of liquid columns, the plungersand the gas columns are connected in series, and the plungers are connected in the oil pipe vertically and mutually to achieve liquid load cooperative work. Liquid is drained from a shaft step by step, pressure formed by a small section of liquid column disappears when each small section of liquid column is drained, the pressure of each stage of gas column below the small section of liquid columnis reduced, the volume is expanded, the gas columns are expanded step by step, and meanwhile, gas expansion can be fully utilized to accelerate the plungers and the liquid columns above the plungers to ascend, the needed gas-liquid ratio is reduced, and liquid drainage mount is increased. Under the condition of the same gas amount, more liquid can be drained, or under the condition of the same liquid drainage amount, the gas amount required by the liquid drainage system is greatly reduced.

Owner:贺信

Micro-interface enhanced lubricating oil hydrofining reaction system and method

PendingCN111686647AReduce material consumptionReduce energy consumptionTransportation and packagingMixing gases/vapours with liquidsEmulsionFluid phase

The invention relates to micro-interface enhanced lubricating oil hydrofining reaction system and method. The system comprises a liquid phase feeding unit, a gas phase feeding unit, a micro-interfacegenerator, a fixed bed reactor and a separation tank. Compared with a traditional fixed bed reactor, according to the invention, gas is crushed to form micron-scale microbubbles, wherein the microbubbles and lubricating oil are mixed to form an emulsion, so that the interphase area of gas and liquid phases is increased, the effect of enhancing mass transfer within a lower preset range is achieved,and the pressure in the reaction process can be reduced by 10-80% while the reaction efficiency is ensured; meanwhile, mass transfer is greatly enhanced, so that the gas-liquid ratio can be greatly reduced, the material consumption of gas is reduced; in addition, the energy consumption of subsequent gas circulating compression is also reduced; therefore, the method is low in process severity, high in production safety, low in ton product cost and high in market competitiveness.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

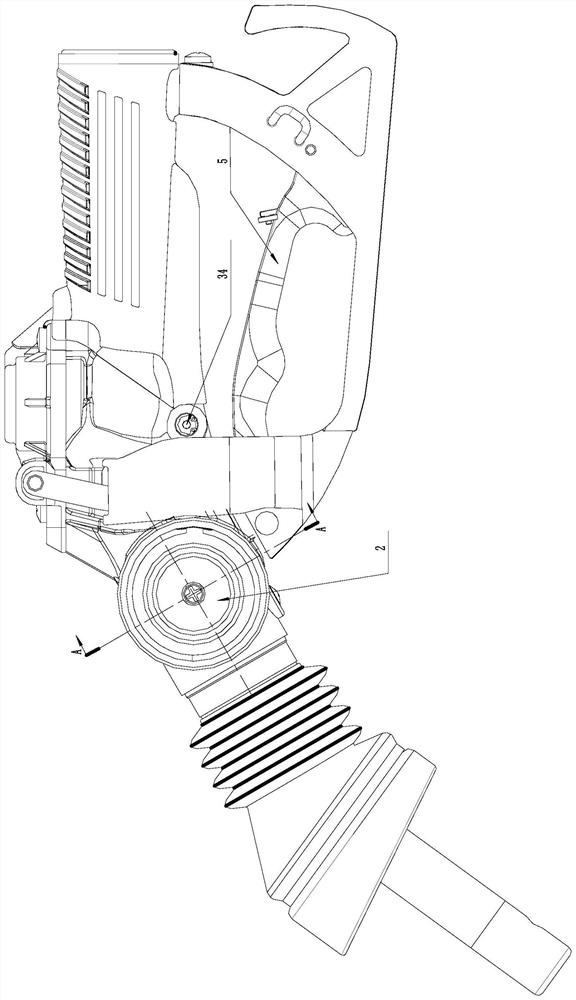

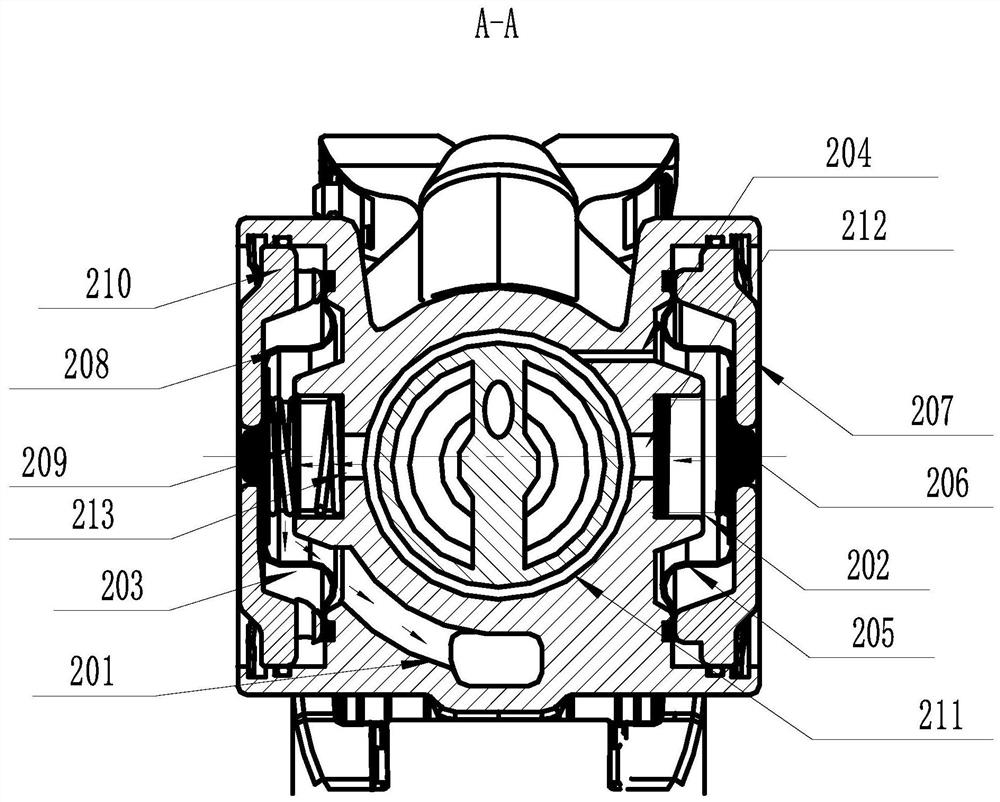

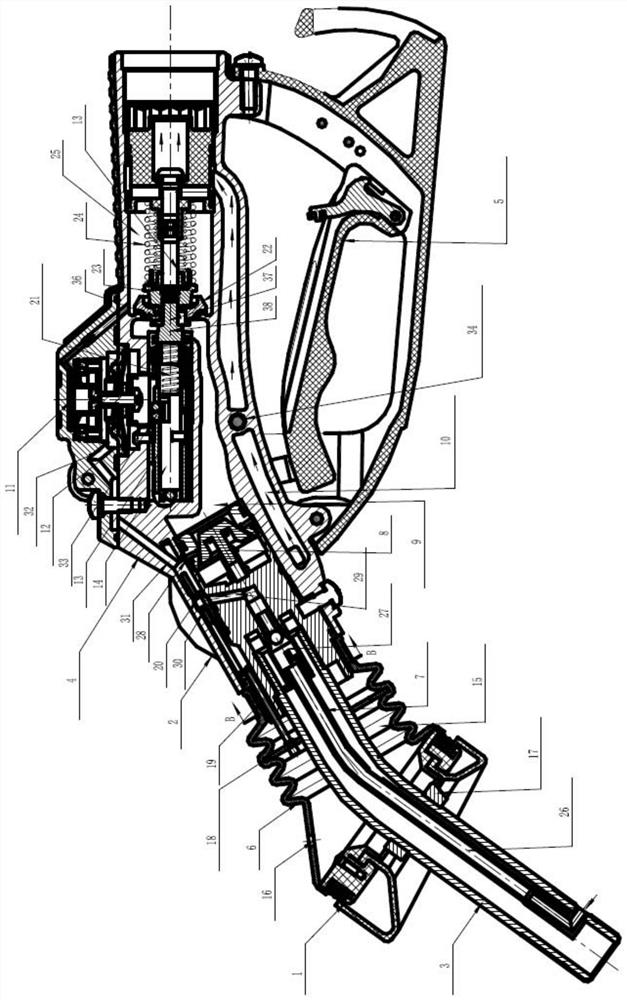

Oil gun integrating vehicle-mounted oil gas recovery system and gas station secondary oil gas recovery system and oiling machine

PendingCN113816328AAvoid influenceDecrease the gas-liquid ratioLiquid transferring devicesIn vehicleControl theory

The invention relates to the technical field of oil guns, and discloses an oil gun integrating a vehicle-mounted oil gas recovery system and a gas station secondary oil gas recovery system and an oiling machine. The oil gun comprises a vehicle-mounted oil gas recovery sensing valve, and a first valve part and a second valve part are located on the two radial opposite sides of a valve seat. A first valve cavity is defined by the first valve part, and the first valve part comprises a first diaphragm and a first valve part spring connected to the first diaphragm and the valve seat. A second valve cavity, a second diaphragm and a second valve part spring connected to the second diaphragm and the valve seat are defined by the second valve part. The valve seat is provided with a first valve seat through hole, a throttling through hole and a second valve seat through hole, a valve seat gas circuit is arranged in the valve seat, the first valve seat through hole and the throttling through hole communicated with the valve seat gas circuit and the first valve cavity correspondingly, the second valve seat through hole communicates with the valve seat gas circuit and the second valve cavity, and the first valve seat through hole and the second valve seat through hole are plugged by the first diaphragm and the second diaphragm correspondingly. A front gas path and a rear gas path are formed in the oil gun, the front end of the first valve cavity communicates with the front gas path, and the rear end of the second valve cavity communicates with the rear gas path.

Owner:CHINA PETROLEUM & CHEM CORP +1

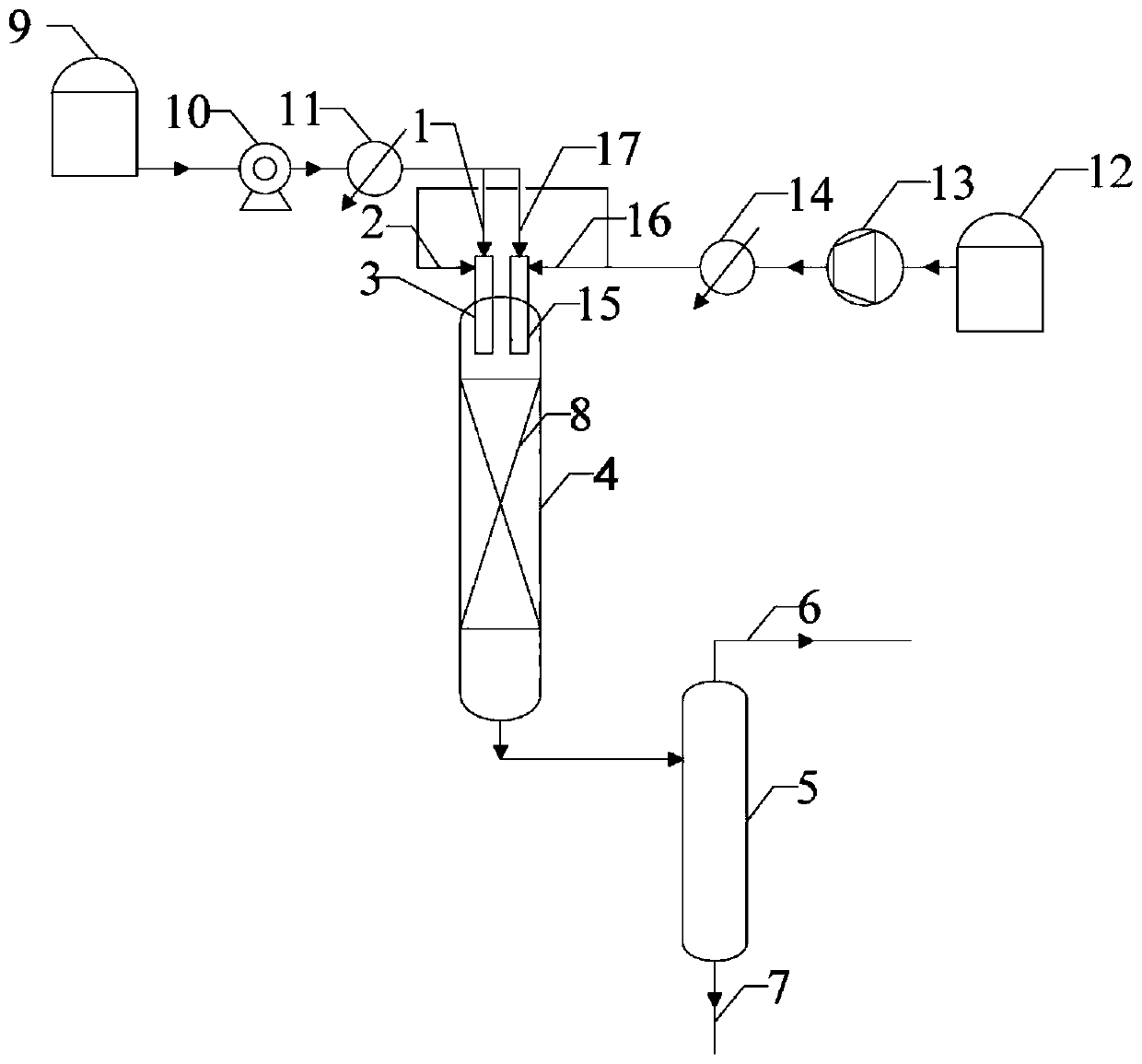

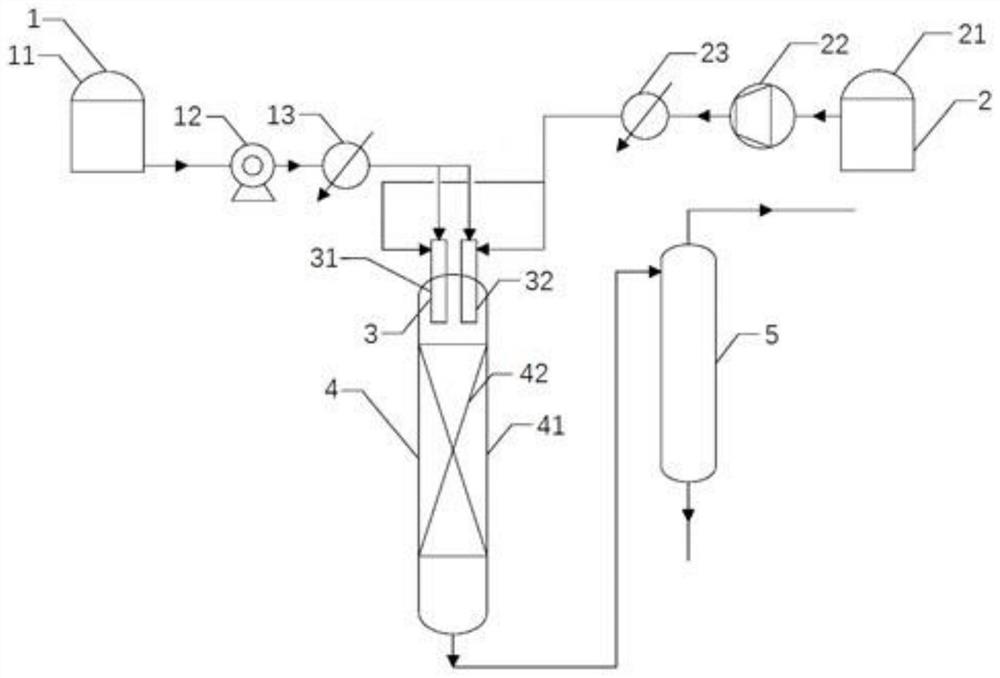

Side-mounted residual oil hydrogenation emulsification bed micro-interface enhanced reaction device and method

InactiveCN111482140AIncrease profitIncrease gas holdupTransportation and packagingHydrocarbon oil crackingVapor–liquid separatorEmulsion

The invention discloses a side-mounted residual oil hydrogenation emulsification bed micro-interface enhanced reaction device and method. The device comprises a reactor body, at least one bubble breaker laterally arranged on the reactor body, a gas-liquid separator, a circulating pump and a heat exchanger. A gas material and a liquid material are firstly fed into the breakers, the gas is crushed into small micron-sized bubbles, the micron-sized bubbles are violently mixed with the liquid to form a gas-liquid emulsion, and the gas-liquid emulsion enters the reactor body. Due to the characteristics of low speed and difficult coalescence of the micro-bubbles, a gas-liquid emulsification bed reaction system is formed in the reactor body. After the reaction is completed, reaction materials enter the gas-liquid separator to separate gas and liquid, the material liquid is conveyed by the circulating pump and passes through the heat exchanger, one part of the material liquid is extracted, andthe other part of the material liquid enters the corresponding breaker to be used for bubble breaking. The device and the method disclosed by the invention have the advantages of low operation pressure, large gas-liquid mass transfer phase interface area, high apparent reaction speed, high gas utilization rate, low investment, low energy consumption, flexible process and the like.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Rotating packing type decarbonizing device and method used for recycling CO2

PendingCN110054246AWell mixedFully contactedWater/sewage treatment by degassingWater/sewage treatment apparatusPipe fittingAtmospheric air

The invention relates to a water processing device and technology, and specifically relates to a rotating packing type decarbonizing device and a method used for recycling CO2. The rotating packing type decarbonizing device at least comprises a decarbonizing device and a blower fan, and also comprises a water tank, an air purifying device, and a CO2 recycling device; the decarbonizing device is connected with a water inlet pipe, a water outlet, a gas inlet, and a gas outlet pipe; the water inlet pipe is provided with a valve; the water outlet is connected with a water tank; at least the blowerfan and the air purifying device are arranged between the gas inlet and the external air successively; the gas inlet, the blower fan, and the air purifying device are connected through pipe fitting valves; the gas outlet pipe is connected with the CO2 recycling device; a gas exhaust port of the CO2 recycling device is communicated with the atmosphere through a pipe fitting valve. The rotating packing type decarbonizing device is simple in structure; processing manufacturing is convenient; the process is excellent; pollution on water and recycled CO2 caused by blown air can be prevented; and decarbonizing efficiency is high.

Owner:XIAN HUAJIANG ENVIRONMENTAL TECH

Technical method for preparing cold work die steel in high alloy through jetting deposition

This invention discloses a method for preparing high-alloy cold-working die steel by injection deposition. The method comprises: (1) preparing molten high-alloy cold-working die steel; (2) preparing high-alloy cold-working die steel green body by atomization deposition in inert gas when the temperature reaches required overheating degree. The components of molten high-alloy cold-working die steel are: C 1.45-1.55 wt.%, Cr 7.8-8.2 wt.%, V 3.9-4.1 wt.%, Mo 1.4-1.6 wt.%, Si 0.9-1.1 wt.%, Mn 0.3-0.5 wt.%, and Fe. Since atomization deposition is utilized, the obtained green body has tiny and uniform microstructure without macroscopic precipitation. The grain sizes of the green body are 2-10 mums, and the green body can be directly hot-rolled without forging. The method can avoid the occurrence of eutectic ledeburite, and has such advantages as simple process, low cost and low energy consumption.

Owner:BAOSHAN IRON & STEEL CO LTD

Multi-stage liquefaction system and process for coal and biomass

PendingCN112175649AIncreased phase boundary areaReduce thicknessHydrocarbon distillationLiquid hydrocarbon mixture productionEmulsionFluid phase

The invention relates to a multistage liquefaction system and process for coal and biomass. The multistage liquefaction system comprises a liquid-phase feeding unit, a gas-phase feeding unit, a micro-interface generator, at least two reactors and a separation tank. According to the invention, gas is crushed to form micron-sized bubbles, and the micron-sized bubbles are mixed with biomass keroseneslurry to form a gas-liquid emulsion, so that the phase contact area of a gas phase and a liquid phase is increased, the effect of enhancing mass transfer within a lower preset range is achieved, andthe reaction efficiency of the system is improved while the energy consumption is reduced; meanwhile, mass transfer is greatly enhanced, so that the gas-liquid ratio can be greatly reduced, and the energy consumption of subsequent gas circulating compression is reduced while the gas material consumption is reduced; and the method is low in process severity, high in production safety, low in ton product cost and high in market competitiveness.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

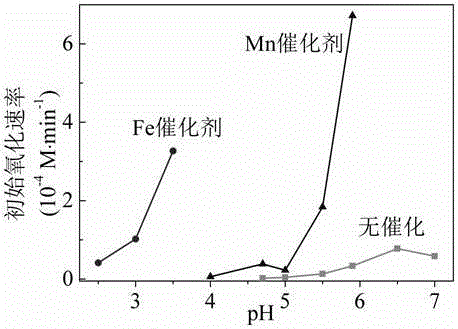

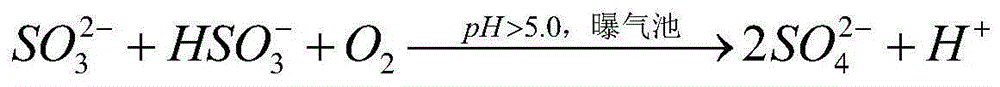

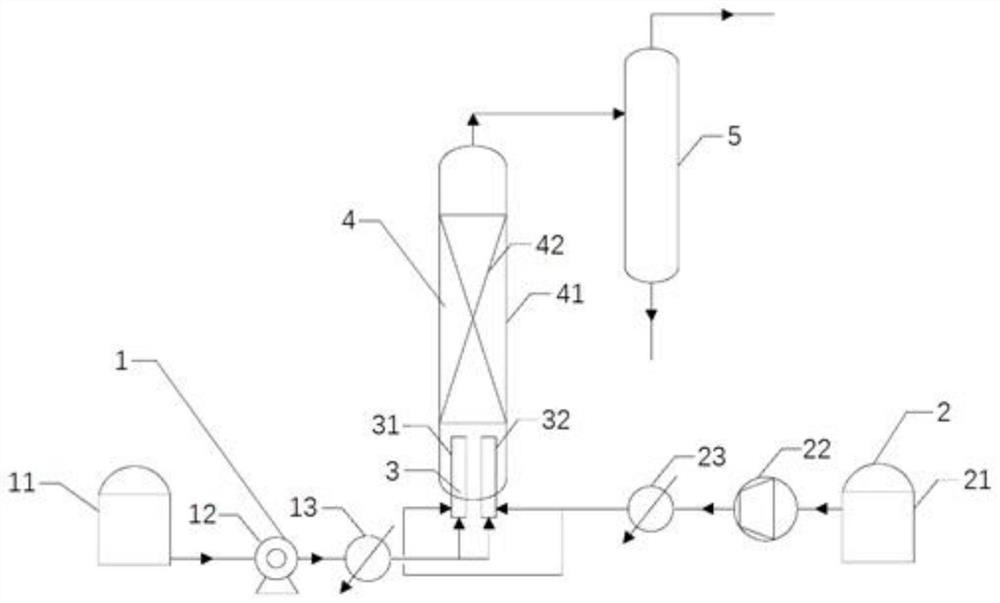

A desulfurization tower packing for seawater desulfurization and preparation method thereof

ActiveCN103191638BReduce dosageSave design volumeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMass ratioHigh energy

The invention discloses a novel desulfurizer packing material for seawater desulfurization and a preparation method thereof. The novel desulfurizer packing material for seawater desulfurization is prepared through the following steps of: adding a steeping liquor and porous Raschig ring washed by sulfuric acid into a stainless steel reaction kettle, wherein mass ratio of the steeping liquor to the Raschig ring is at 1:(10-1):1; stirring, regulating pH value to 3.0-5.0 through sulfuric acid, heating to 25-60 DEG C, stirring for 12-36 hours at constant temperature, heating to 85-100 DEG C, stirring, depositing and steeping at constant temperature for 24-48 hours, washing by water until discharged water is colorless, and calcining for 3-5 hours at 400-800 DEG C to obtain the novel desulfurizer packing material for seawater desulfurization. The method is simple and materials are cheap and easily available, and the defects of the conventional seawater desulfurization process which is incomplete in sulfite radicle oxidization of seawater absorbing liquid, large occupied room of aerator, high energy consumption and the like are overcome; and the novel desulfurizer packing material realizes coupling of absorption and oxidization in a desulfurization packing tower, and is environmental-friendly and economical.

Owner:ZHEJIANG UNIV

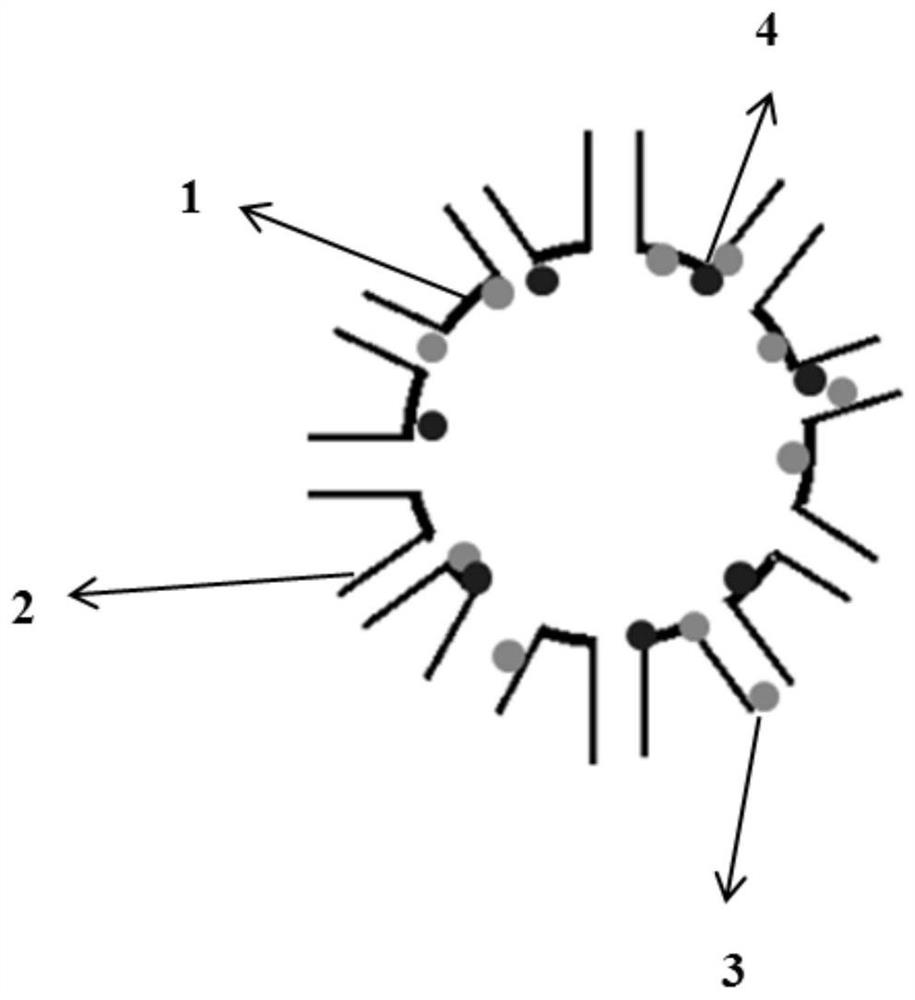

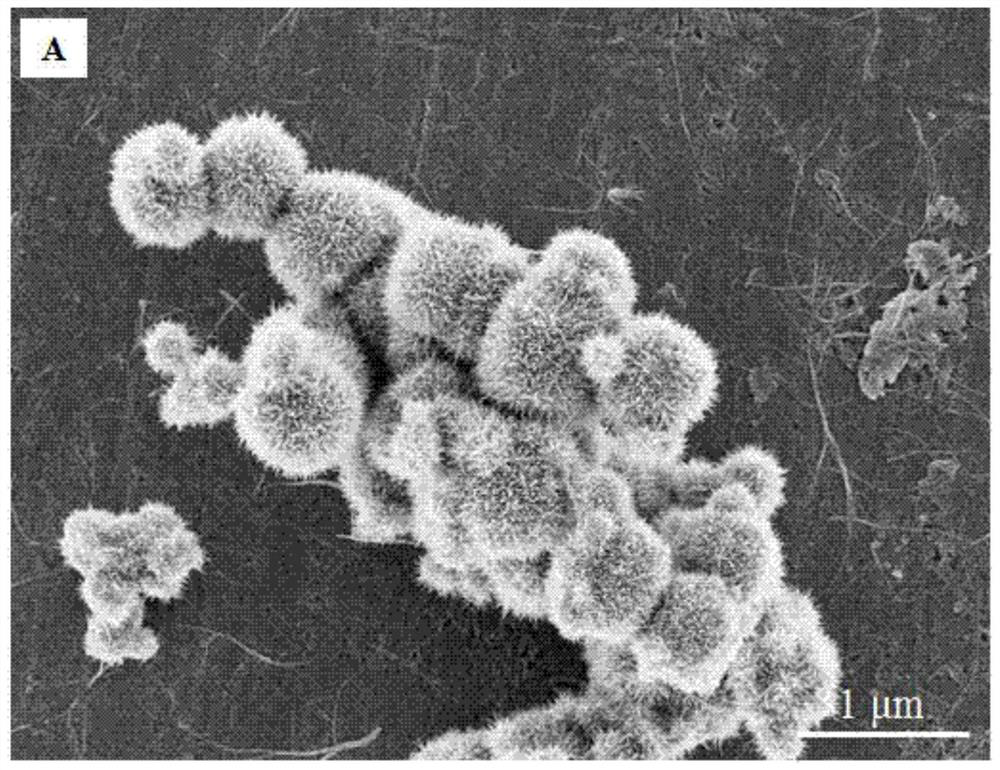

A kind of catalyst and the method for using the catalyst to prepare β-phenylethanol

ActiveCN109847754BRealize continuous productionHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsPreparation by hydrolysisPtru catalystNanoreactor

The invention discloses a catalyst and a method for preparing β-phenethyl alcohol with the catalyst. The catalyst is nickel silicate-copper composite sea urchin-shaped nano-reactor type catalyst. The catalyst solves the problem that the hydrogenation reaction of styrene oxide is too fast and the hydrogen supply is insufficient, resulting in a high content of by-product ethylbenzene, and can make styrene oxide hydrogenate under mild conditions with high selectivity and high yield to produce β-benzene Ethanol, styrene oxide conversion rate > 99%, β-phenylethanol selectivity ≥ 99.5%, sufficient hydrogen supply, so that the hydrogenation of styrene oxide can also ensure high selectivity of the product under the condition of no additives, reducing desorption The auxiliary process simplifies the product separation process. The preparation method of β-phenylethanol can realize the continuous production of β-phenylethanol and greatly improve the production efficiency.

Owner:WANHUA CHEM GRP CO LTD

Naphtha hydrogenation micro-interface enhanced reaction system and method

InactiveCN112175665AReduce material consumptionReduce energy consumptionMixing methodsTransportation and packagingNaphthaFluid phase

The invention relates to a naphtha hydrogenation micro-interface enhanced reaction system and method. The naphtha hydrogenation micro-interface enhanced reaction system comprises a liquid phase feeding unit, a gas phase feeding unit, a micro-interface generator, a fixed bed reactor and a separation tank. Compared with a traditional fixed bed reactor, the micro-interface generator is arranged on the fixed bed reactor, before reaction raw materials enter the reactor for reaction, pressure energy of gas and / or kinetic energy of liquid in the reaction process are / is converted into surface energy of hydrogen bubbles, hydrogen bubbles are crushed into micro-bubbles with a diameter of 1 [mu] m or more and less than 1 mm, such that the phase contact area of naphtha and hydrogen during a hydrogenation reaction process is effectively increased, the mass transfer efficiency between naphtha and hydrogen is improved, naphtha and hydrogen micro-bubbles are mixed after crushing so as to form a gas-liquid emulsion, and furthermore, the reaction efficiency between naphtha and hydrogen is enhanced within a relatively low preset pressure range.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

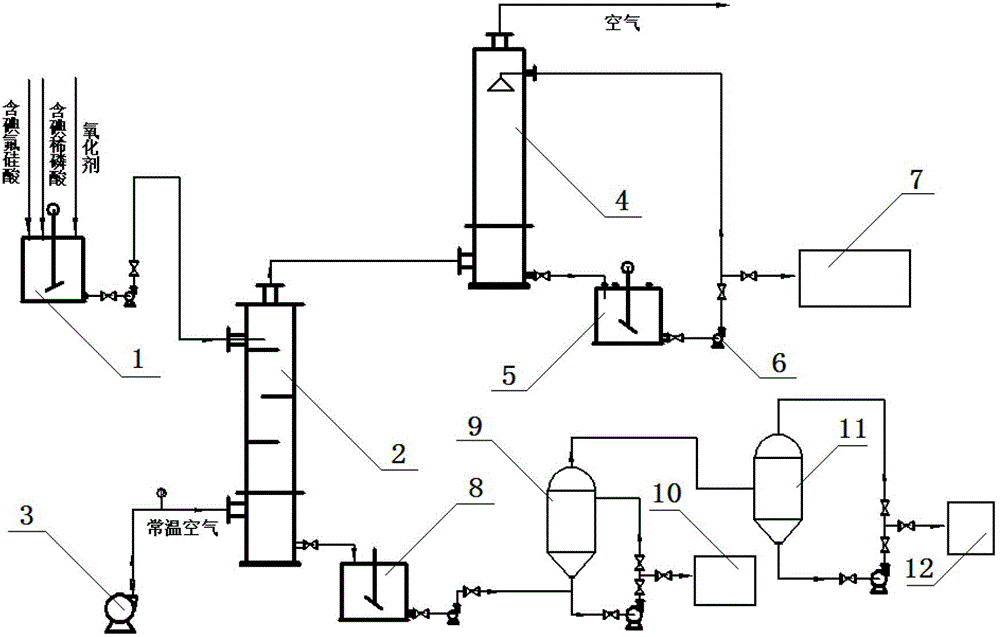

Recovery method for iodine from wet-process phosphoric acid at low gas-liquid ratio

Owner:贵州开磷碘业有限责任公司

Method for simultaneously recovering iodine in iodine-containing fluosilicic acid and iodine-containing dilute phosphoric acid

InactiveCN103395747BEasy to produceSmall form factorSilicon halogen compoundsIodineLiquid ratioPhosphoric acid

The method discloses a method for simultaneously recovering iodine in iodine-containing fluosilicic acid and iodine-containing dilute phosphoric acid. The method utilizes an air blow-out method to realize iodine recovery. The method is characterized in that iodine-containing fluosilicic acid and iodine-containing dilute phosphoric acid are mixed into an iodine-containing mixed acid; in the same recovery device, the iodine-containing mixed acid and an oxidizing agent undergo a reaction; iodine molecules are blown out by normal-temperature air, wherein an air-liquid ratio which is a volume ratio of blown air to the iodine-containing mixed acid is low; and phosphoric acid and fluosilicic acid in the iodine-containing mixed acid can be separated by condensation. The method saves a construction investment and a space resource, reduces an equipment cost and energy consumption, reduces an operation cost, has good economic benefits, and saves manpower resources; before entering into an extraction tower, air is not heated and has a normal temperature so that energy consumption, equipment configuration and an equipment cost are reduced; through the low air-liquid ratio, the size of the extraction tower is effectively reduced and an equipment construction and maintenance cost is greatly reduced; and after iodine extraction, phosphoric acid and fluosilicic acid can be separated so that phosphoric acid production is promoted.

Owner:贵州开磷碘业有限责任公司

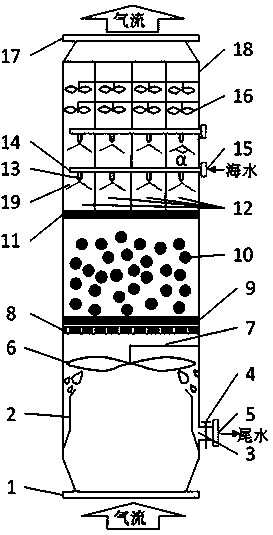

Seawater desulfurization device for tail gas of marine diesel engine

ActiveCN103007694BReduce the overall heightSmall pressure lossCombination devicesLiquid ratioDistributor

The invention relates to a seawater desulfurization device for tail gas of a marine diesel engine. The seawater desulfurization device comprises a shell, an air flow inlet flange, a tail liquid collecting tank, a tail liquid separator, a uniform air flow distributor, a turbulent flow ball layer, a parallel independent straight-pipe cross flow spraying device, a dehumidification device and an air flow outlet flange, wherein the air flow inlet flange is mounted at the bottom of the shell; the tail liquid collecting tank is mounted inside the shell and is located above the air flow inlet flange; the tail liquid separator is mounted inside the shell and is located above the tail liquid collecting tank; the uniform air flow distributor is mounted inside the shell and is located above the tail liquid separator; the turbulent flow ball layer is mounted inside the shell and is located above the uniform air flow distributor; the parallel independent straight-pipe cross flow spraying device is mounted inside the shell and is located above the turbulent flow ball layer; the dehumidification device is mounted in the shell and is located above the parallel independent straight-pipe cross flow spraying device; and the air flow outlet flange is mounted above the dehumidification device and is located at the top of the shell. According to the seawater desulfurization device, independent straight-pipe-type optimization is carried out on a spraying manner, the height, pressure loss and gas-liquid ratio of the desulfurization device are reduced on the premise of not increasing equipment and operation, and the desulfurization efficiency is effectively improved.

Owner:SHANGHAI MARITIME UNIVERSITY

Enhanced reaction system and method for alkane oxidation

InactiveCN112169721AReduce material consumptionIncreased phase boundary areaChemical/physical/physico-chemical microreactorsCatalystsAlkaneMass transfer resistance

The invention relates to an enhanced reaction system and method for alkane oxidation. The enhanced reaction system comprises a liquid-phase feeding unit used for storing and conveying liquid alkane ofC4 or above, a gas-phase feeding unit, a micro-interface generator, a reactor and a separation tank. Gas is crushed to form micron-sized bubbles, the micron-sized bubbles and alkane are mixed to forma gas-liquid emulsion, the phase contact area of a gas phase and a liquid phase is increased, meanwhile, the thickness of a liquid film is reduced, the mass transfer resistance is reduced, the effectof enhancing mass transfer within a low preset operation condition range is achieved, and the energy consumption can be greatly reduced while the reaction efficiency is guaranteed; and meanwhile, mass transfer is greatly enhanced, so that the gas-liquid ratio can be greatly reduced, and the energy consumption of subsequent gas circulation compression is reduced while the gas material consumptionis reduced.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

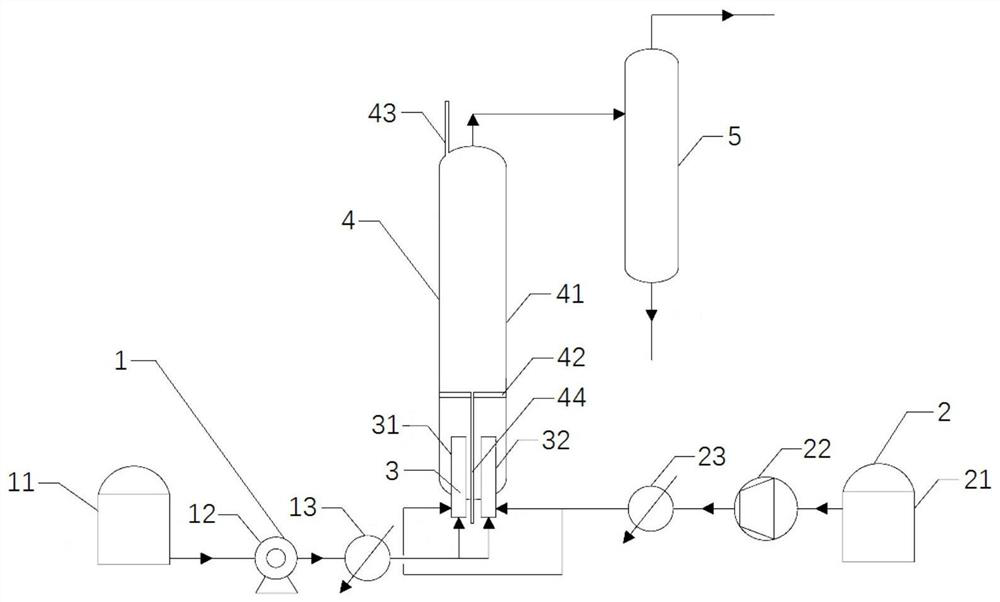

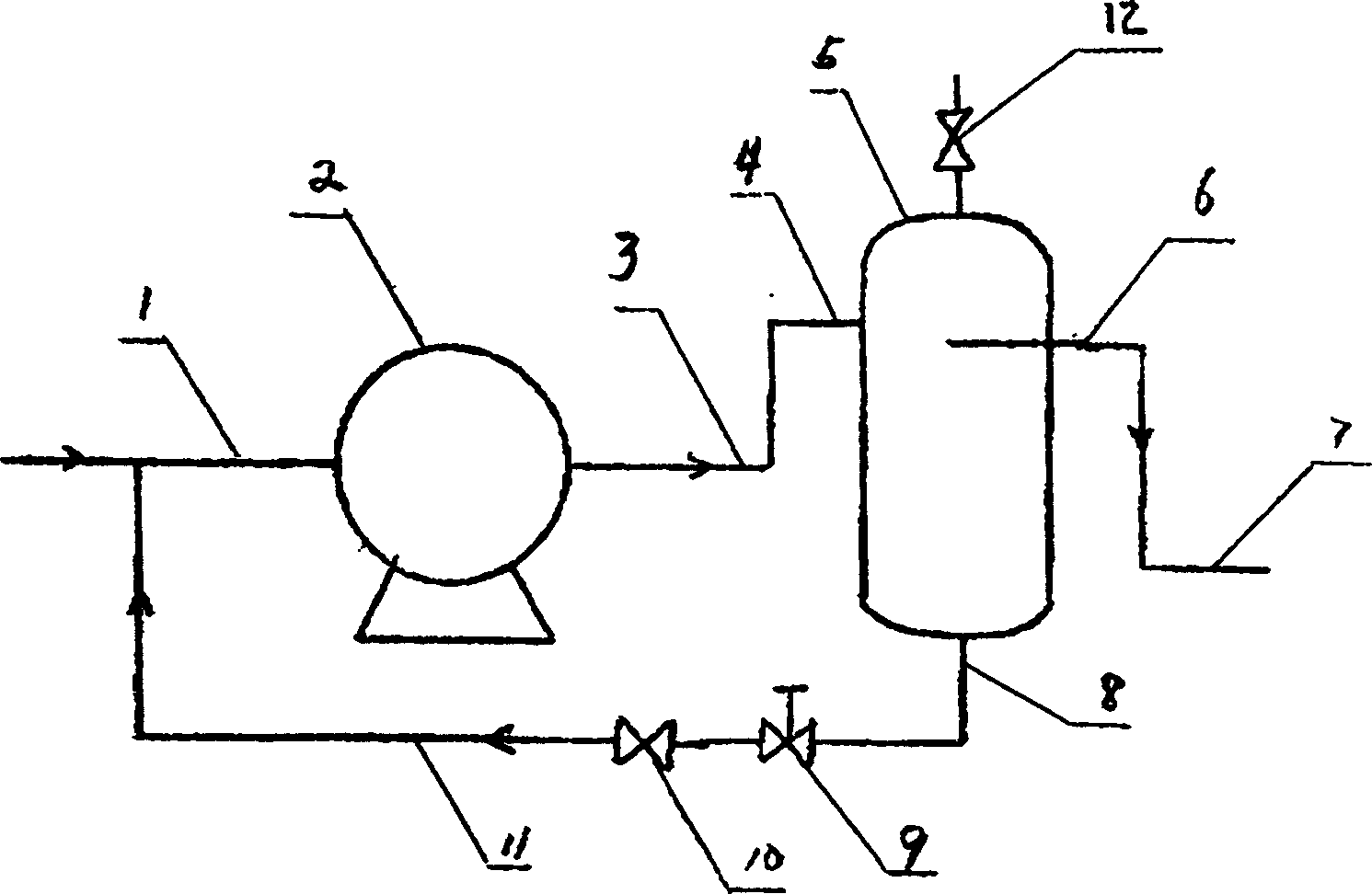

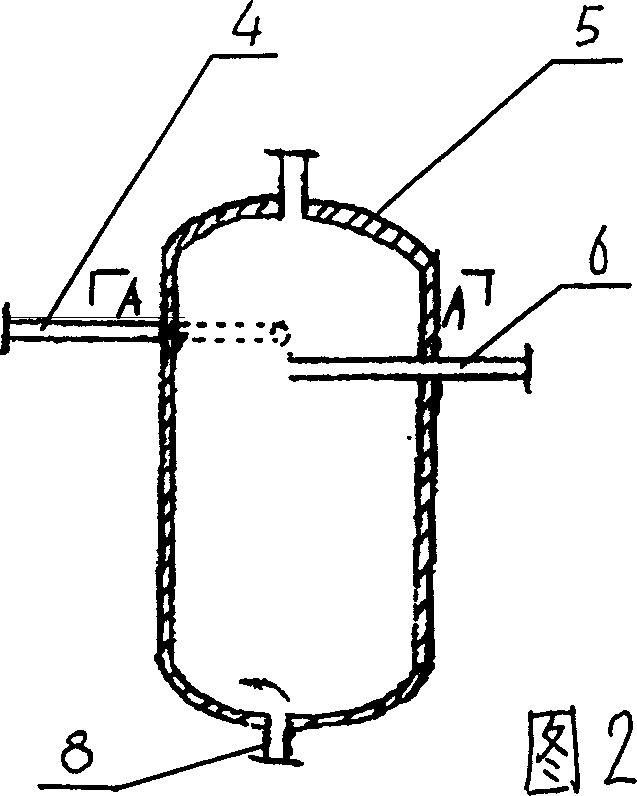

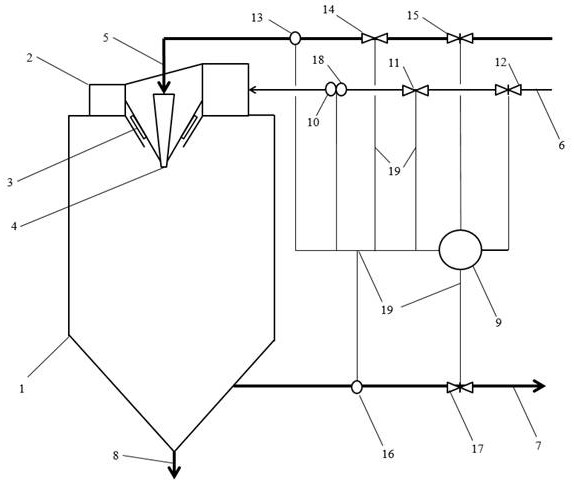

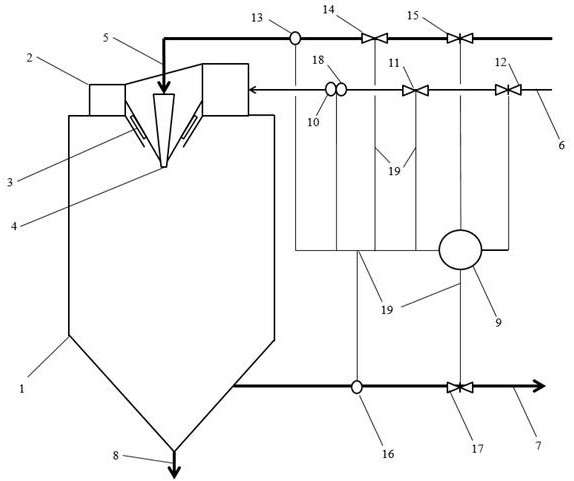

Oil well gas-liquid mixed conveyor

InactiveCN1161553CDecrease the gas-liquid ratioGuaranteed to workPipeline systemsVapor–liquid separatorLiquid ratio

The oil well gas-liquid mixture conveyer consists of gas-liquid mixture conveying pump and gas-liquid separator connected via pipes. Oil well gas-liquid mixture entered by the inlet pipe is pressure raised in the pump before entering the gas-liquid separator by the outlet pipe. Partial liquid from the gas-liquid separator is returned via the lower outlet and reflux pipe to the inlet of the gas-liquid mixture conveying pump, and the separated gas and the other part of the liquid are output via the upper outlet and outer pipe. The reflux liquid flow rate is adjusted by the adjusting valve. The present invention has lowered gas / liquid ratio into the pump to avoid gas lock and to ensure the normal operation of the pump.

Owner:姚瑞忠

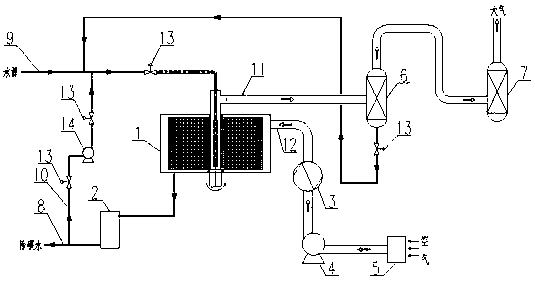

An intelligently adjustable wastewater zero discharge system and method

ActiveCN113620363BReduce trafficHigh trafficWater treatment parameter controlTreatment control/steeringFlue gasProcess engineering

The invention relates to the technical field of waste water treatment for thermal power generation, in particular to an intelligently adjustable waste water zero discharge system and method. The system includes evaporation tower, intelligent adjustment center, inlet flue, waste water pipe and outlet flue; the inlet flue is connected with the flue gas inlet of the evaporation tower, the waste water pipe is connected with the waste water inlet of the evaporation tower, and the outlet flue is connected with the The flue gas outlet is connected; the flue gas parameter monitoring device and the flue gas parameter adjustment device are installed on the inlet flue; the wastewater parameter monitoring device and the wastewater parameter adjustment device are installed on the waste water pipe; the outlet flue gas parameter monitoring device and the outlet The flue switch baffle; the flue gas parameter monitoring device, the wastewater parameter monitoring device, the outlet flue gas parameter monitoring device, the outlet flue switch baffle, the flue gas parameter adjustment device and the wastewater parameter adjustment device are all connected to the intelligent adjustment center. The system can solve the problems of endless evaporation of waste water or waste of heat when the operating conditions of the unit change.

Owner:DATANG ENVIRONMENT IND GRP

Intelligently adjustable wastewater zero discharge system and method

ActiveCN113620363AReduce trafficHigh trafficWater treatment parameter controlTreatment control/steeringThermodynamicsFlue gas

The invention relates to the technical field of thermal power generation wastewater treatment, in particular to an intelligently adjustable wastewater zero discharge system and a method. The system comprises an evaporation tower, an intelligent adjusting center, an inlet flue, a wastewater pipeline and an outlet flue, the inlet flue is communicated with a flue gas inlet of the evaporation tower, the wastewater pipeline is communicated with a wastewater inlet of the evaporation tower, and the outlet flue is communicated with a flue gas outlet of the evaporation tower; a flue gas parameter monitoring device and a flue gas parameter adjusting device are arranged on the inlet flue; a wastewater parameter monitoring device and a wastewater parameter adjusting device are arranged on the wastewater pipeline; an outlet flue gas parameter monitoring device and an outlet flue switch baffle are arranged on the outlet flue; the flue gas parameter monitoring device, the wastewater parameter monitoring device, the outlet flue gas parameter monitoring device, the outlet flue switch baffle, the flue gas parameter adjusting device and the wastewater parameter adjusting device are all connected with the intelligent adjusting center. The system can solve the problem that waste water cannot be evaporated completely or heat is wasted when the unit operation condition changes.

Owner:DATANG ENVIRONMENT IND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com