Liquid nitrogen pump equipment loading test and testing device and test and testing method thereof

一种设备加载、试验装置的技术,应用在泵测试、机械设备、泵等方向,能够解决调节与监测安全风险高、技术很难实现、大压力调节阀等问题,达到降低试验与测试风险、节约设备成本及能源、确保安全测试的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

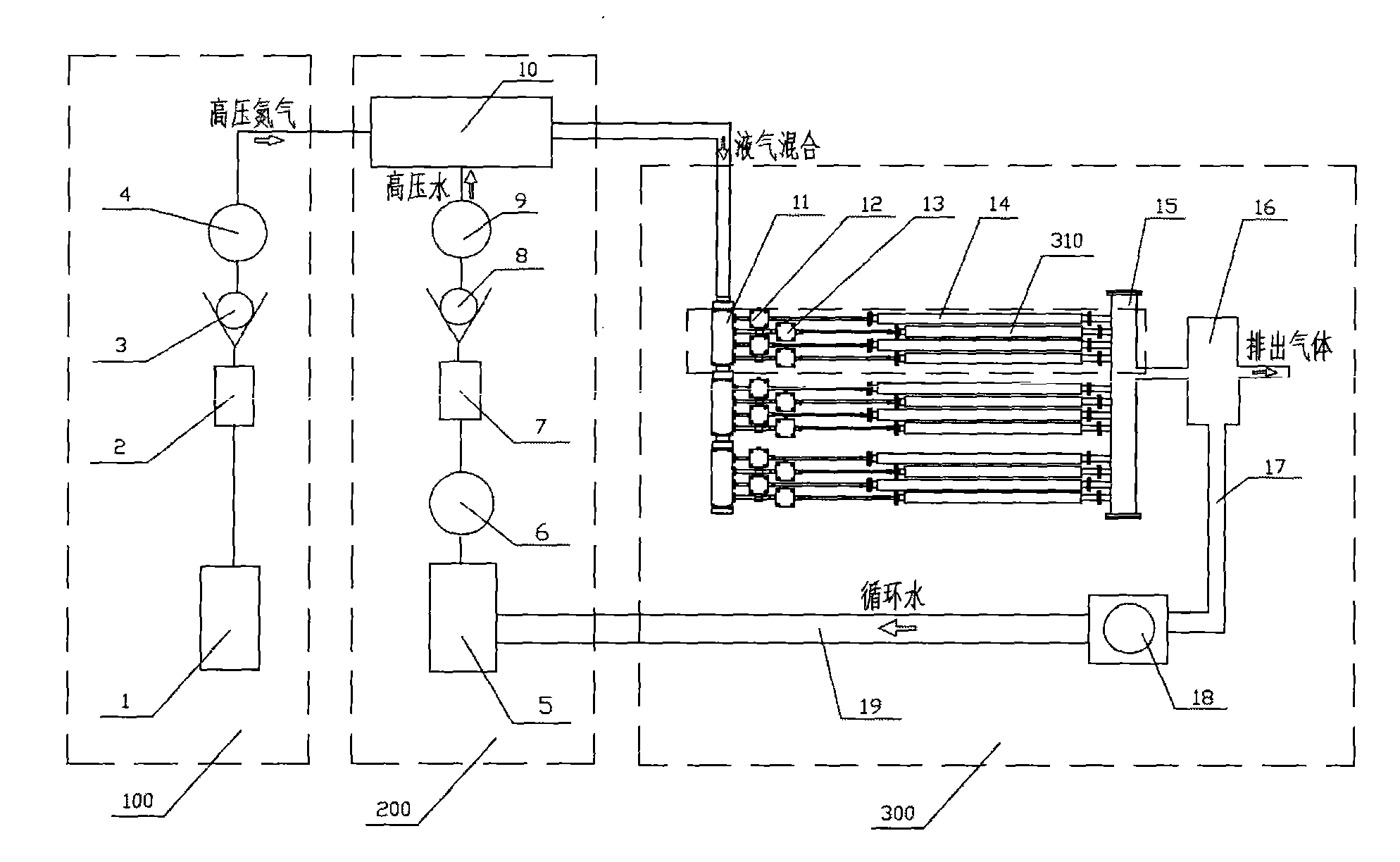

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and by taking specific implementations as examples. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

[0030] Principle of the present invention is:

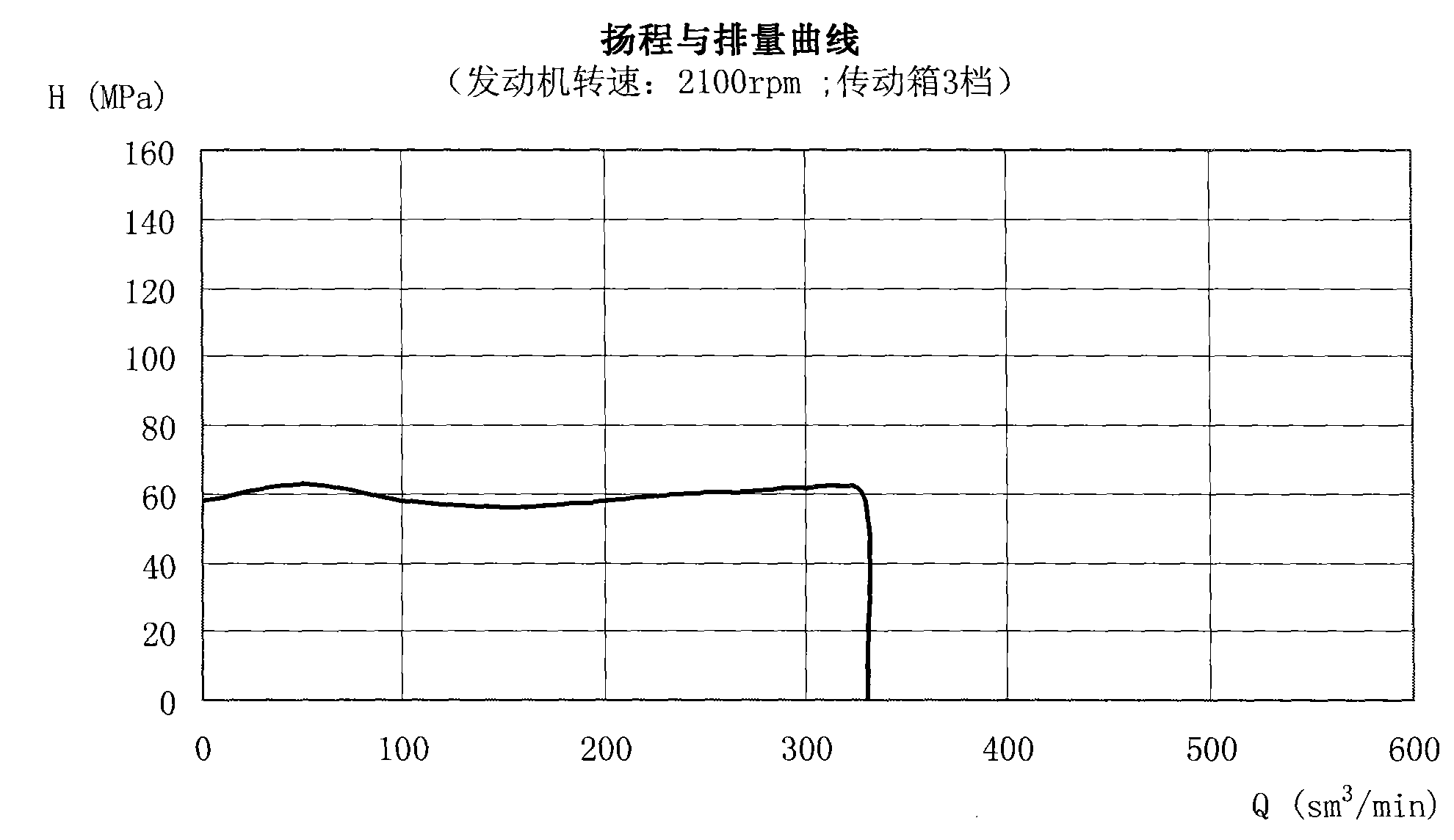

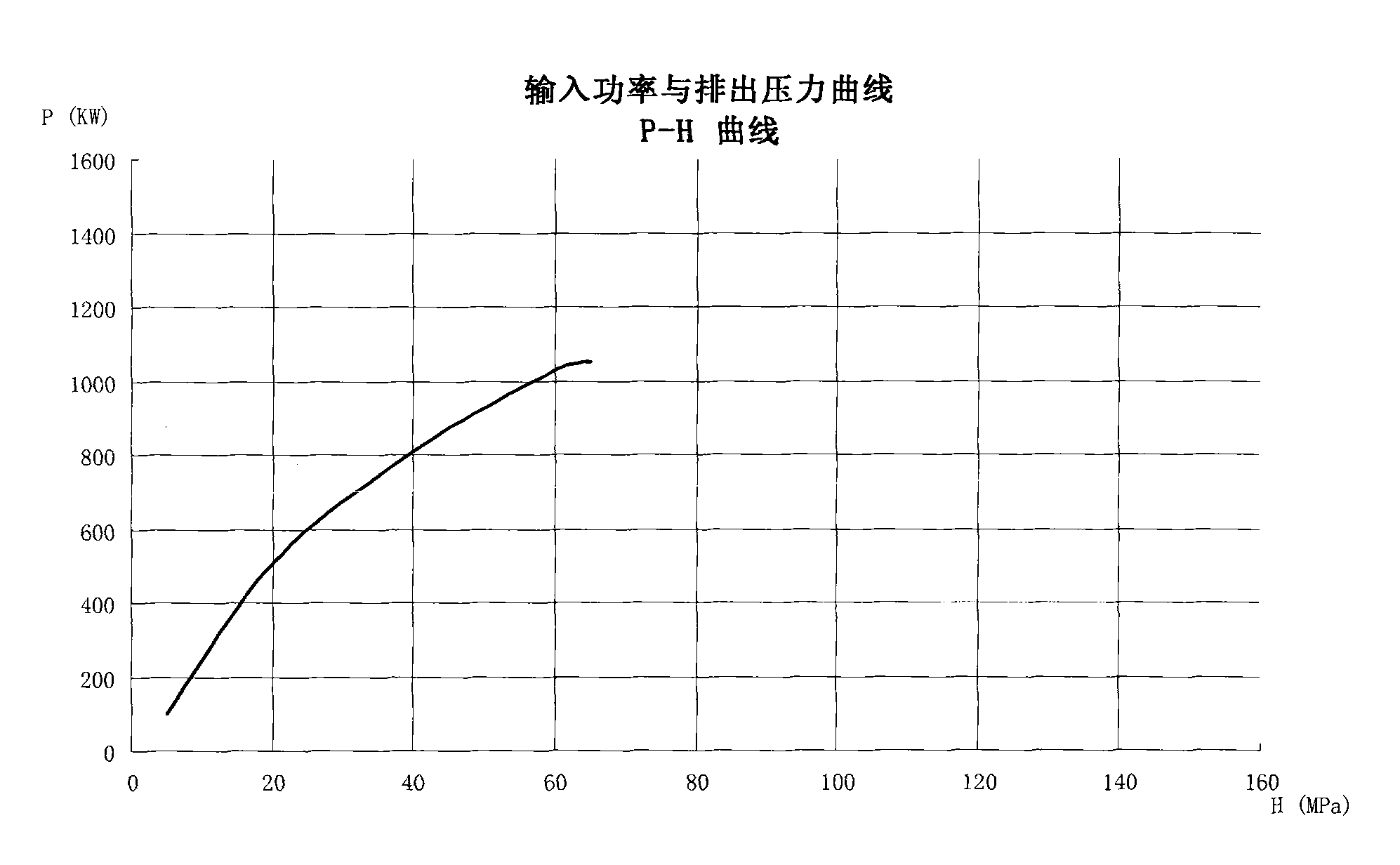

[0031] During the testing and testing process of the liquid nitrogen pump equipment used for nitrogen foam fracturing, it is necessary to test the discharge pressure and displacement of the liquid nitrogen pump equipment separately to obtain the relationship between displacement and pressure, input power and discharge pressure Relationship, loading pressure and loading time relationship, it can be seen that the discharge pressure of the liquid nitrogen pump equipment is a key parameter that needs to be controlled du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com