Patents

Literature

92results about How to "Increased phase boundary area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic waste gas microemulsion absorbent, and preparation method and use thereof

ActiveCN101844025AStrong solubilizing abilityLow costDispersed particle separationInorganic saltsNon toxicity

The invention discloses an organic waste gas microemulsion absorbent, and a preparation method and application thereof. The absorbent comprises the following components in percentage by mass: 99.8 to 99.4 percent of water, 0.01 to 2 percent of surfactant, 0.05 to 2 percent of aid and 0.1 to 2 percent of inorganic salt. The preparation method comprises the following steps of: dissolving the surfactant with the water to obtain solution of surfactant; dissolving the aid and the inorganic salt in the water to obtain solution of aid; and mixing the solution of surfactant and the solution of aid and continuously stirring the mixed solution at the same time to obtain the organic waste gas microemulsion absorbent. The organic waste gas microemulsion absorbent is suitable for treating organic waste gases, and has the advantages of broad raw material sources, low cost, low saturated vapor pressure, non-toxicity, stable chemical properties, less corrosion to equipment, high organic waste gas removal efficiency, no need of pre-treating the waste gases, less investment, low running cost and the like; and the saturated absorbent can be recycled so as to realize the comprehensive utilization of resources.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

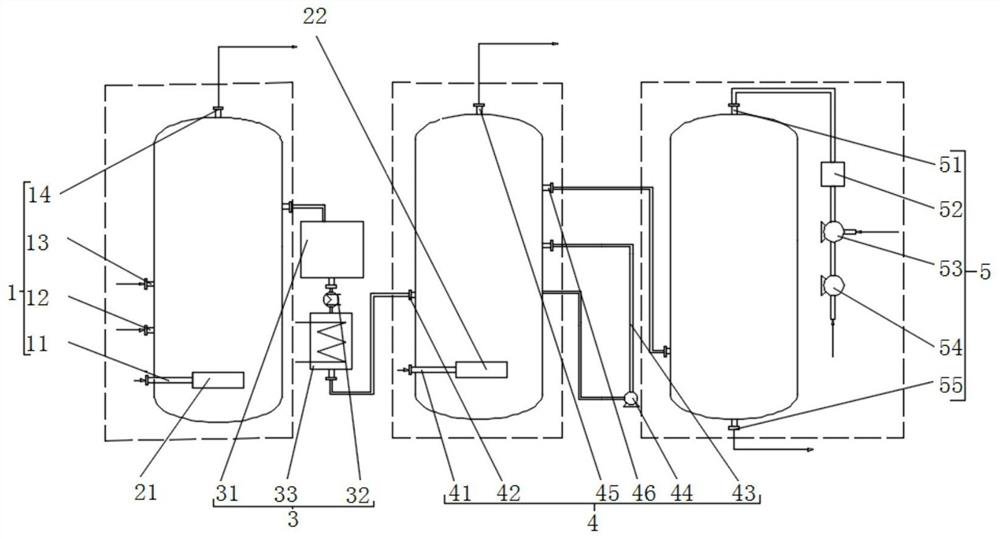

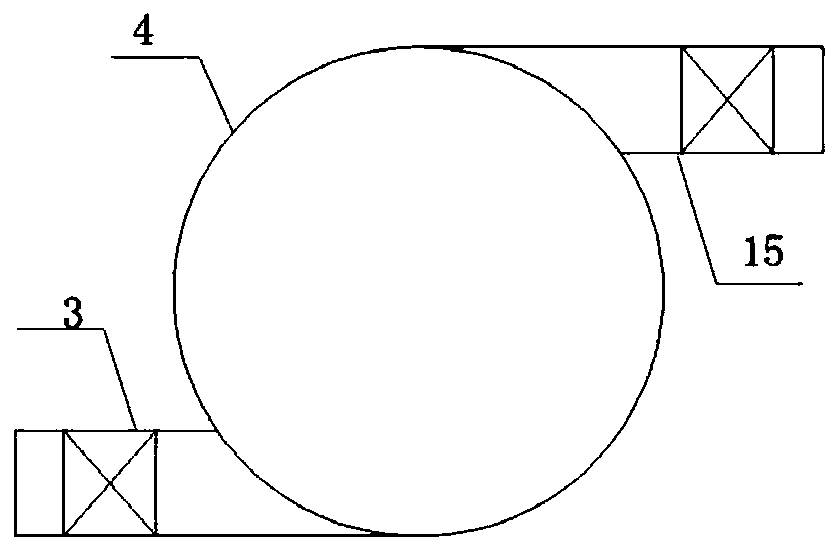

Grease epoxidation reaction device

ActiveCN105561893AIncreased phase boundary areaIncrease reaction rateOrganic chemistryChemical/physical processesCavitationEngineering

The invention provides a grease epoxidation reaction device and belongs to the technical field of epoxy grease production. The device comprises a reaction tank, an intermediate tank, a circulating pump and a hydraulic cavitation device which are sequentially connected through reaction circulating pipelines to form a circular reaction system. A material circulating outlet is formed in the upper end of a shell cover of the reaction tank, a material circulating inlet is formed in the lower end of the shell cover, and the material circulating outlet and the material circulating inlet are connected with the reaction circulating pipelines. A material inlet is formed in the input end of the circulating pump, the reaction tank is a tube nest type reactor, a tube nest and a baffle plate are arranged in the reaction tank, a first heat exchange medium inlet and outlet and a second heat exchange medium inlet and outlet are formed in the lower end and the upper end of a barrel of the reaction tank, and valves are correspondingly arranged on the pipelines. The device is simple in structure, reasonable in design, low in investment, low in energy consumption and production cost, high in product quality and beneficial for engineering enlargement.

Owner:ZHEJIANG UNIV OF TECH

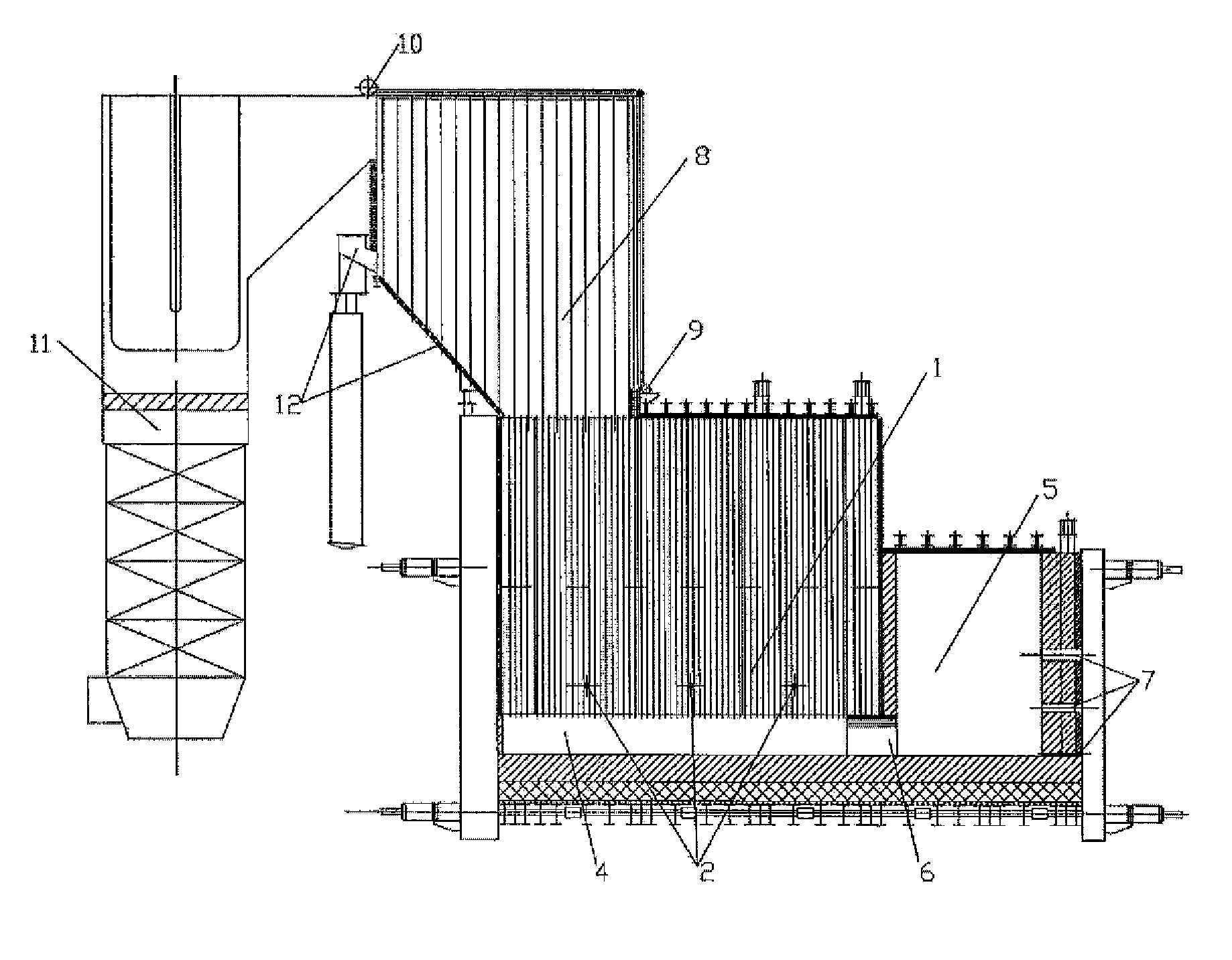

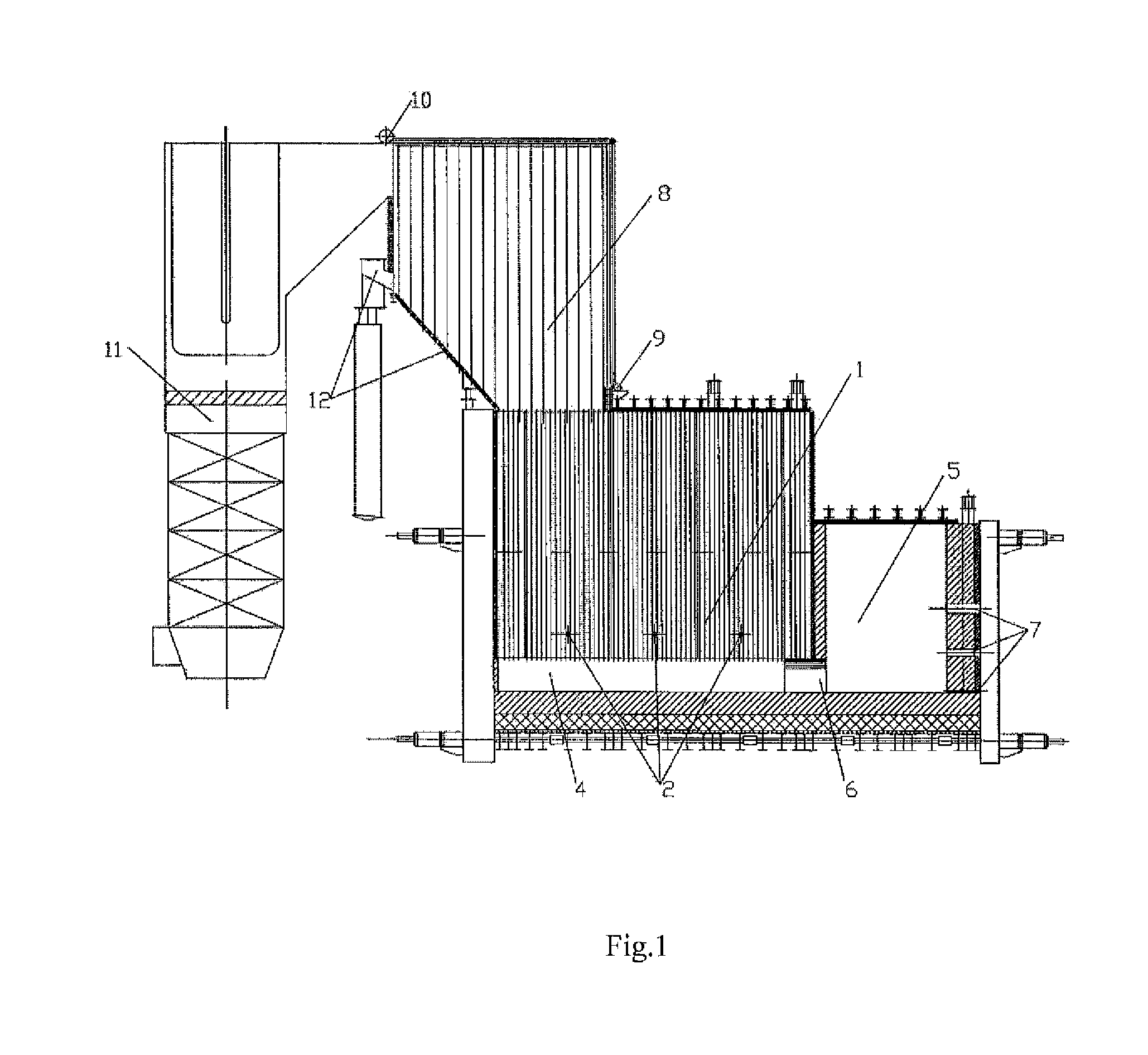

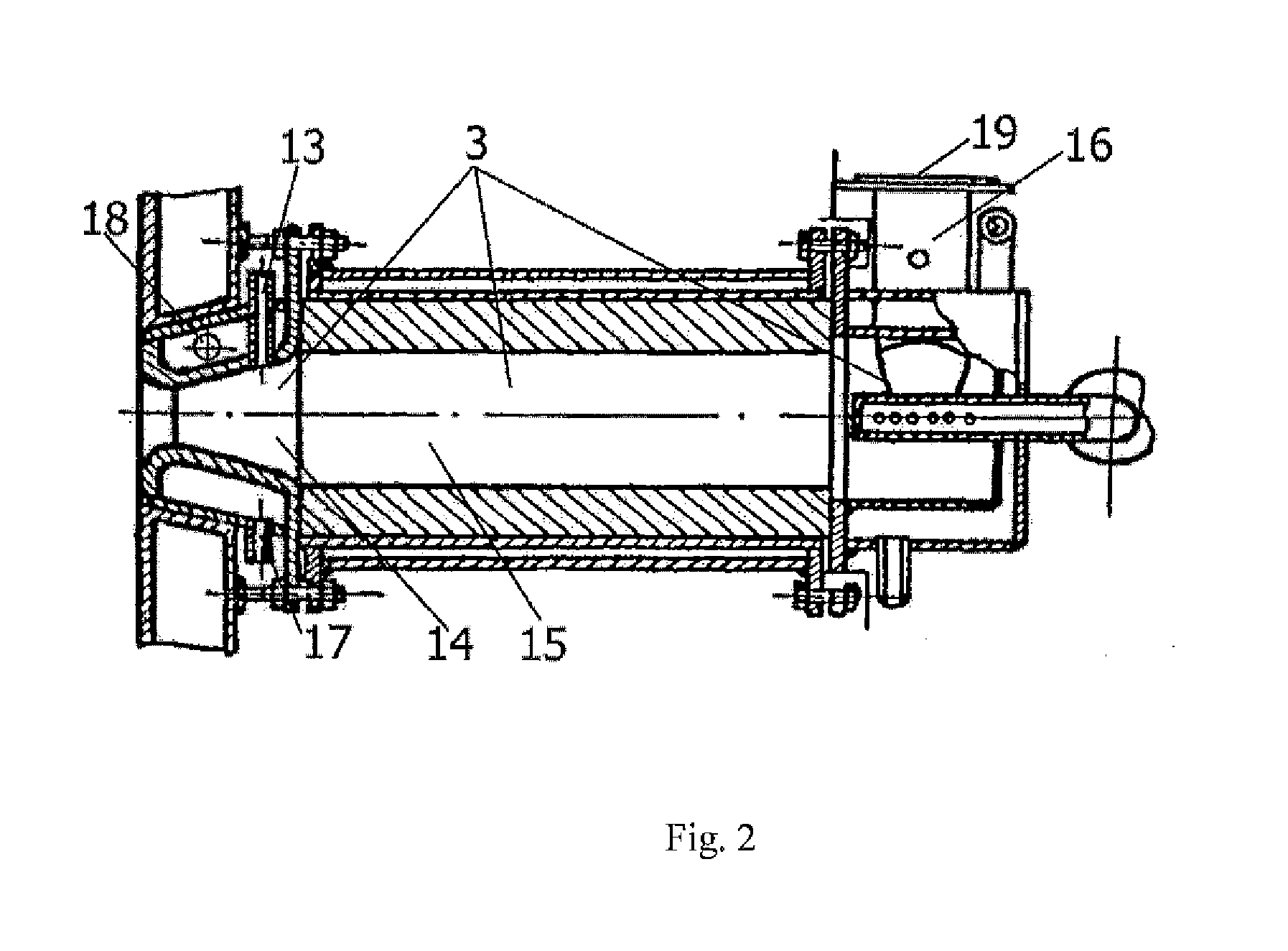

Glass melting method and molten glass layer bubbling glass melting furnace

InactiveUS20140318187A1Stable physical propertiesIncreased phase boundary areaCharging furnaceGlass furnace apparatusMelting tankGlass vessel

This invention relates to the continuous production of molten glass for further production of glassware and can be used for glass melting and obtaining glass semiproduct. The technical objective of this invention is to provide a method and a furnace for producing molten glass with stabilized physical properties due to an increased phase boundary area, higher temperature in the glass furnace bath and intensified mixing as well as due to a higher output of the glass furnace. Molten glass layer bubbling glass melting method comprising melting the glass layer in the first chamber of the furnace to the working level, further uninterrupted loading of large and small charge portions into the molten glass layer with simultaneous intense bubbling of the molten glass layer with high-temperature combustion products aiming at the formation of the maximum possible charge / molten glass phase boundary area and achieving a molten glass temperature of at least 1500° C., which conditions intensify the melting, silicate formation, vitrification and homogenizing processes, delivery of the chemically and thermally homogeneous molten glass produced by bubbling to the degassing and cooling section located under the bubbled molten glass layer, with an intense release from the molten glass layer of process gases that pass through the bubbled layer to the space above the layer where the process gases undergo primary cleaning and cooling, and the degassed molten glass is delivered to the further output section.

Owner:FEDERALNOE GOSUDARSTVENNOE AVTONOMNOE OBRAZOVATELNOE UCHREZHDENIE VYSSHEGO PROFESSIONALNOGO OBRAZOVANIJA NATSIONALNYJ ISSLEDOVATELSKIJ TEKHNOLOGICHESKIJ UNIVT MISIS

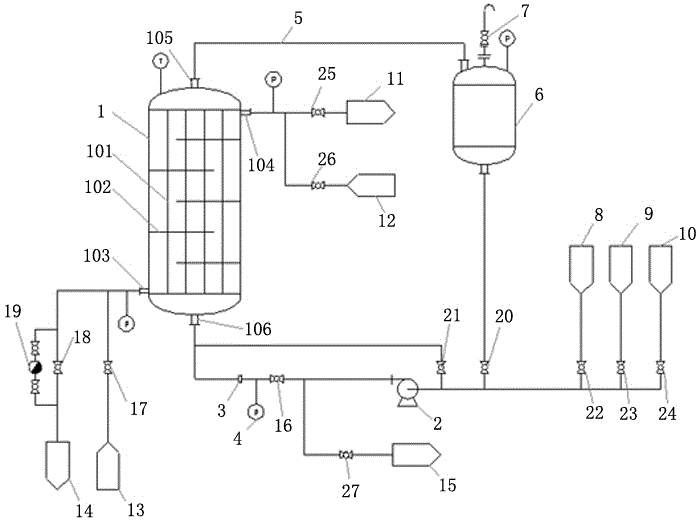

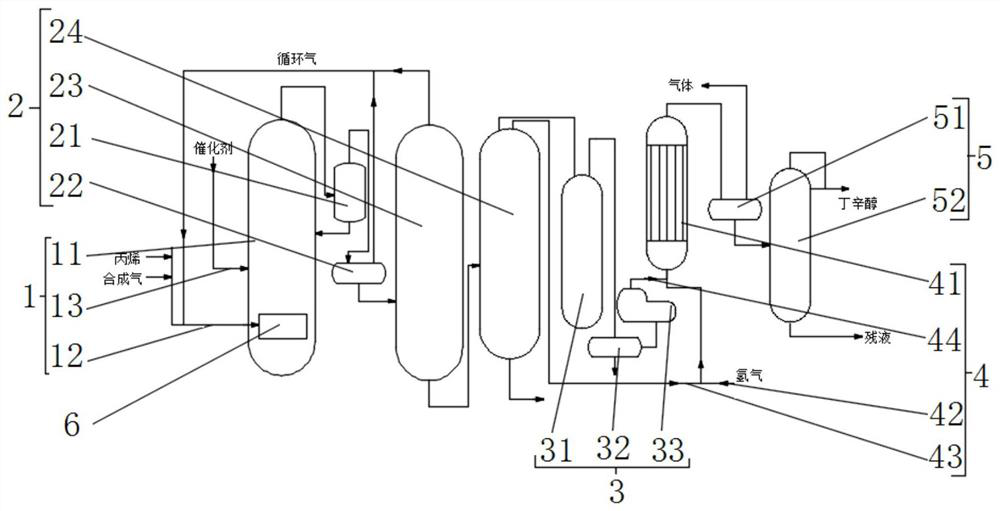

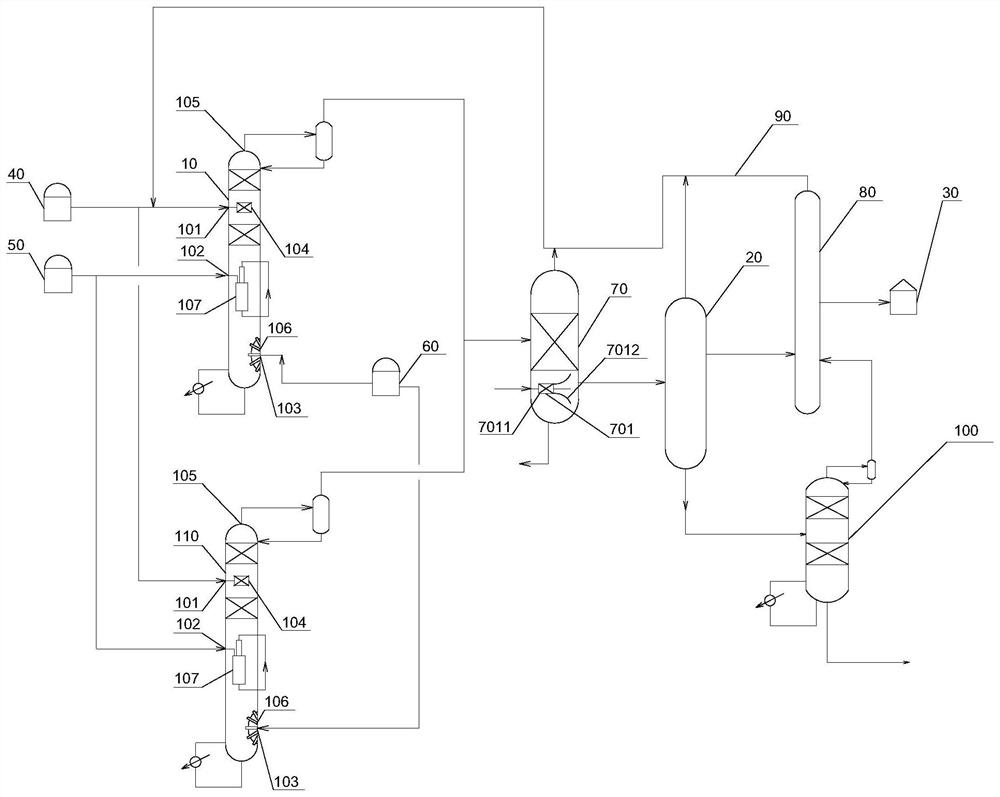

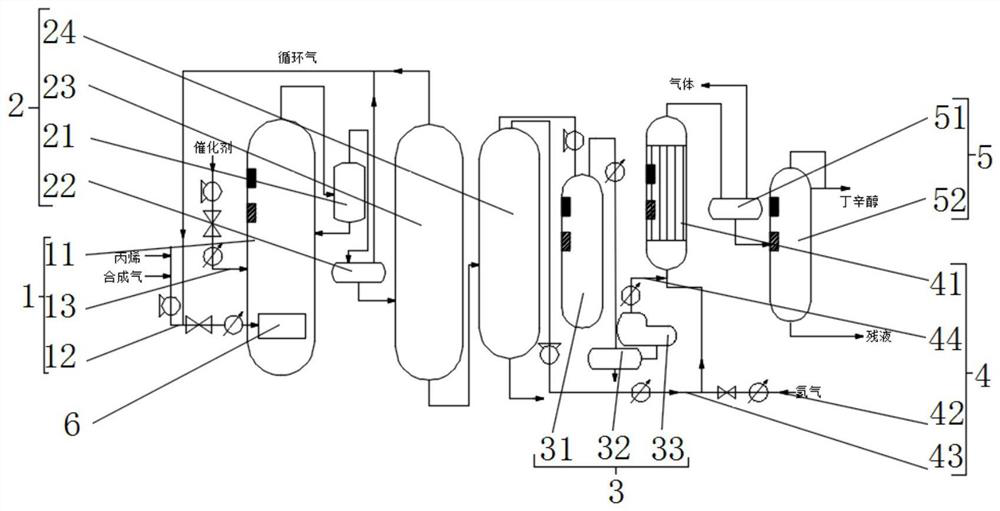

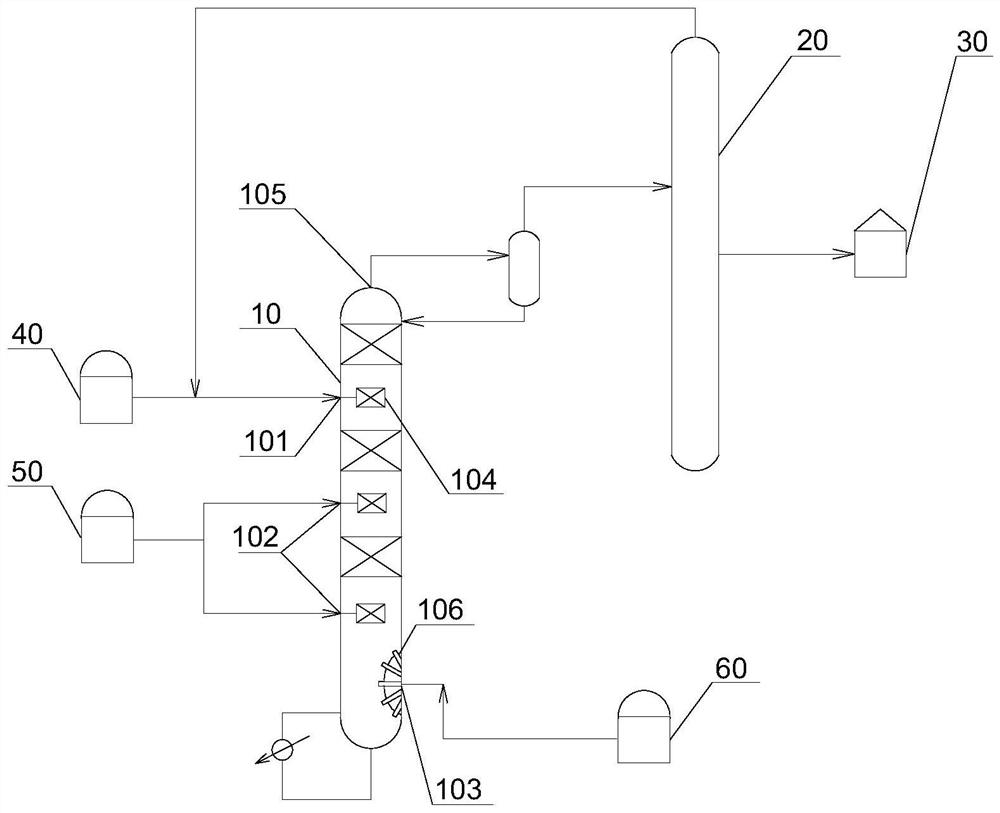

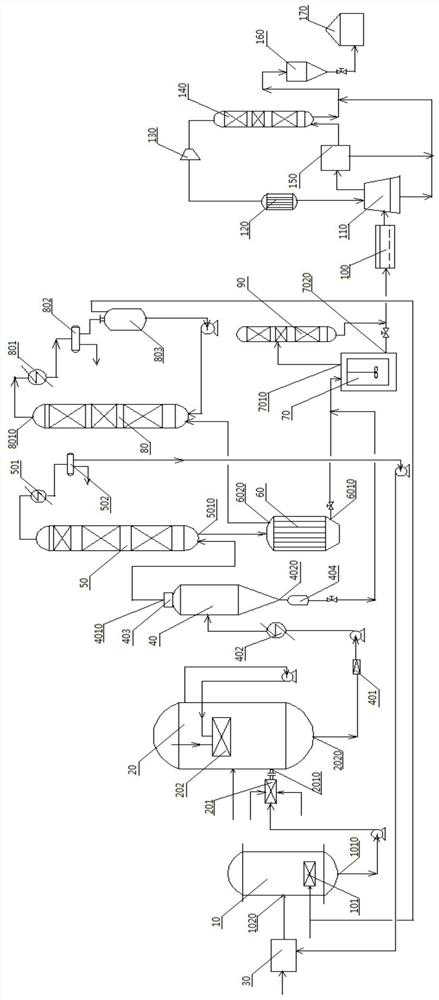

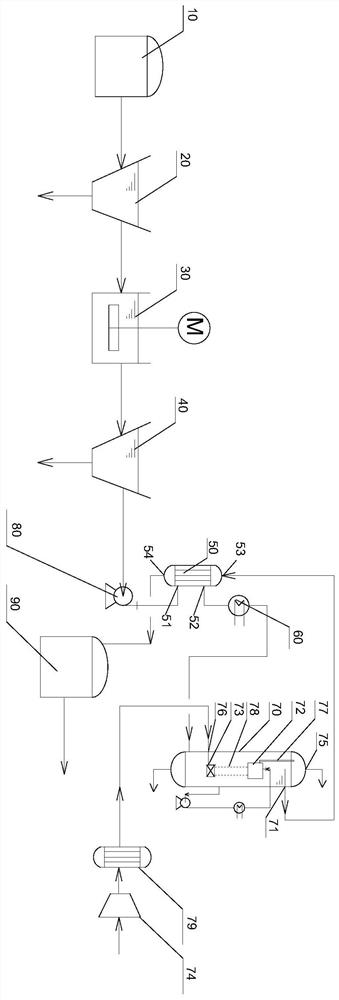

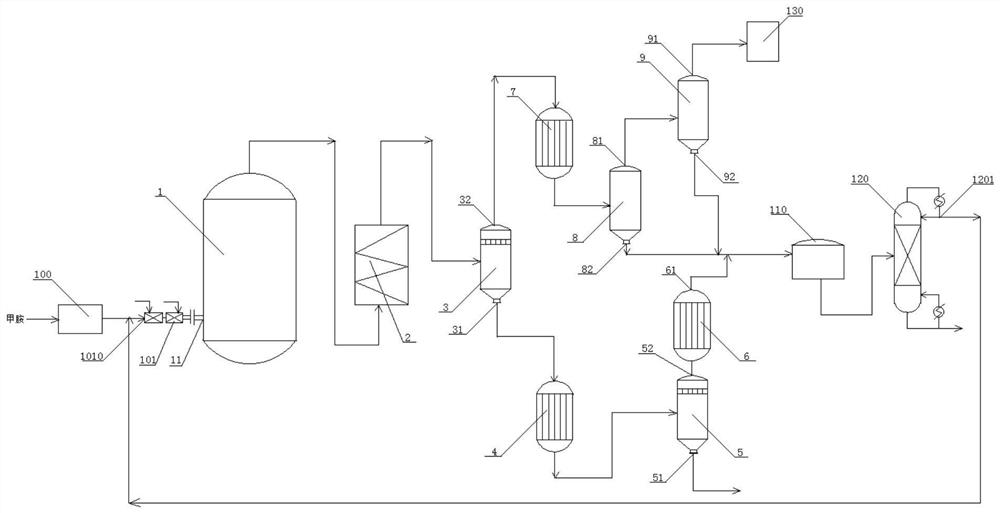

Reaction system and process for preparing butyl octanol through propylene carbonylation based on micro-interface reinforcement

InactiveCN112479815AImprove reaction efficiencyFlexible Range AdjustmentOrganic compound preparationPreparation by hydrogenationPtru catalystOctanol

The invention relates to a reaction system and process for preparing butyl octanol through propylene carbonylation based on micro-interface enhancement. The reaction system comprises a carbonyl synthesis unit, a butyraldehyde treatment unit, a butyraldehyde condensation unit, a hydrogenation reaction unit, a purification unit and a micro-interface generator. According to the invention, propylene and synthesis gas are treated by additionally arranging a micro-interface generator, and are crushed to form micron-scale bubbles, and the micron-scale bubbles and a rhodium catalyst triphenylphosphinesolution are mixed to form a gas-liquid emulsion to increase the phase interface area of a gas phase and a liquid phase and achieve the effect of enhancing mass transfer within a lower preset operation condition range, so that the carbonyl synthesis efficiency of propylene and synthesis gas is improved, the propylene reaction efficiency and utilization rate are improved, the propylene utilizationrate is increased, the production cost of butyl octanol is reduced, and the requirements of existing circular economy are met.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

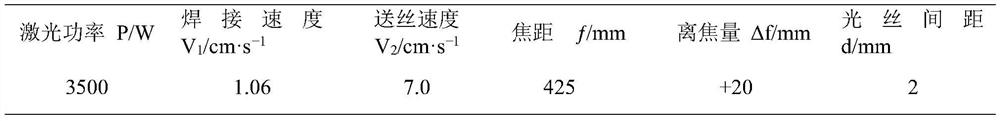

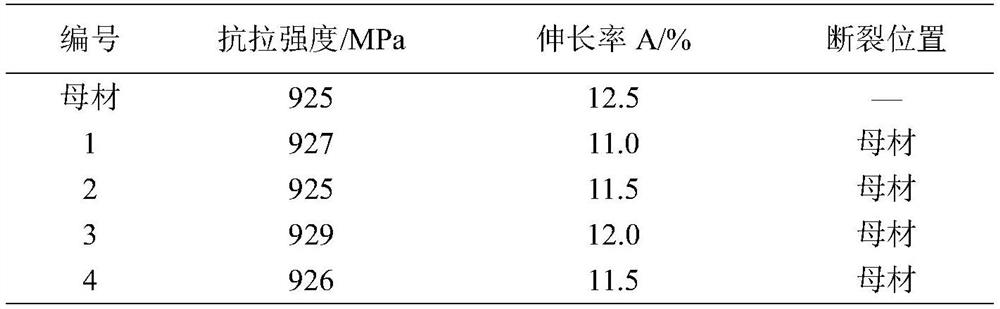

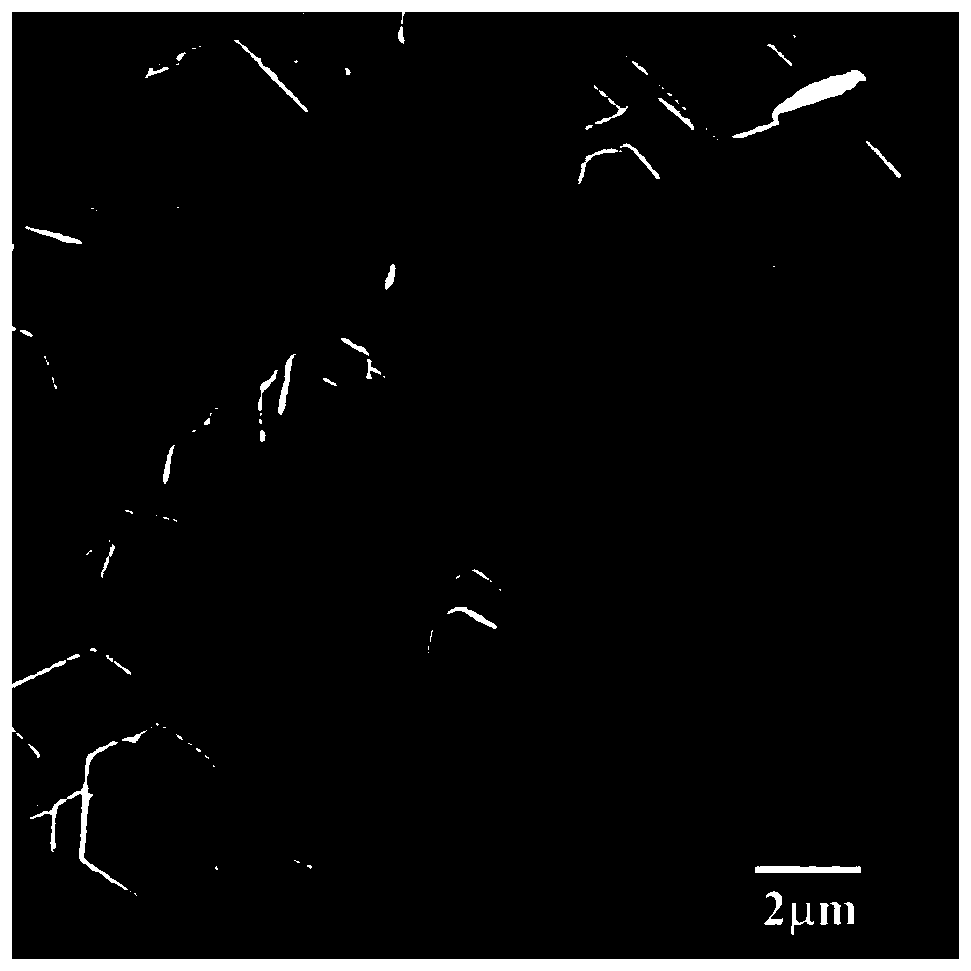

TC4 titanium alloy solid welding wire for large-thickness ultra-narrow-gap laser wire filling welding and preparation method thereof

ActiveCN112872654AWill not affect subsequent weldingDoes not affect welding qualityWelding/cutting media/materialsSoldering mediaPlastic packagingIngot

The invention discloses a TC4 titanium alloy solid welding wire for large-thickness ultra-narrow-gap laser wire filling welding and a preparation method thereof. The invention belongs to the technical field of welding materials. The invention provides the TC4 titanium alloy solid welding wire for large-thickness ultra-narrow-gap laser wire filling welding and the preparation method thereof. The solid welding wire is prepared from chemical components in percentage by mass as follows: 5.0%-7.0% of Al, 4.0%-6.0% of V, 1.5%-2.5% of Mo, 0.2%-0.5% of Cr, 0.5%-1.5% of Zr and the balance of Ti. The method comprises the following steps: weighing raw materials according to the chemical components of the welding wire, mixing the raw materials, pressing into an electrode block, welding into a consumable electrode, carrying out primary smelting to obtain a primary cast ingot, carrying out secondary smelting to obtain a titanium alloy cast ingot, turning a skin, cutting a dead head, forging into a square billet, rolling, drawing, straightening and polishing to obtain a wire material, carrying out vacuum annealing, carrying out drawing diameter reduction, stress relief annealing and cleaning in a vacuum tube type annealing furnace, winding on a wire reel, and vacuum plastic packaging to obtain the large-thickness ultra-narrow-gap TC4 titanium alloy solid welding wire for laser wire filling welding.

Owner:HARBIN WELDING INST LTD

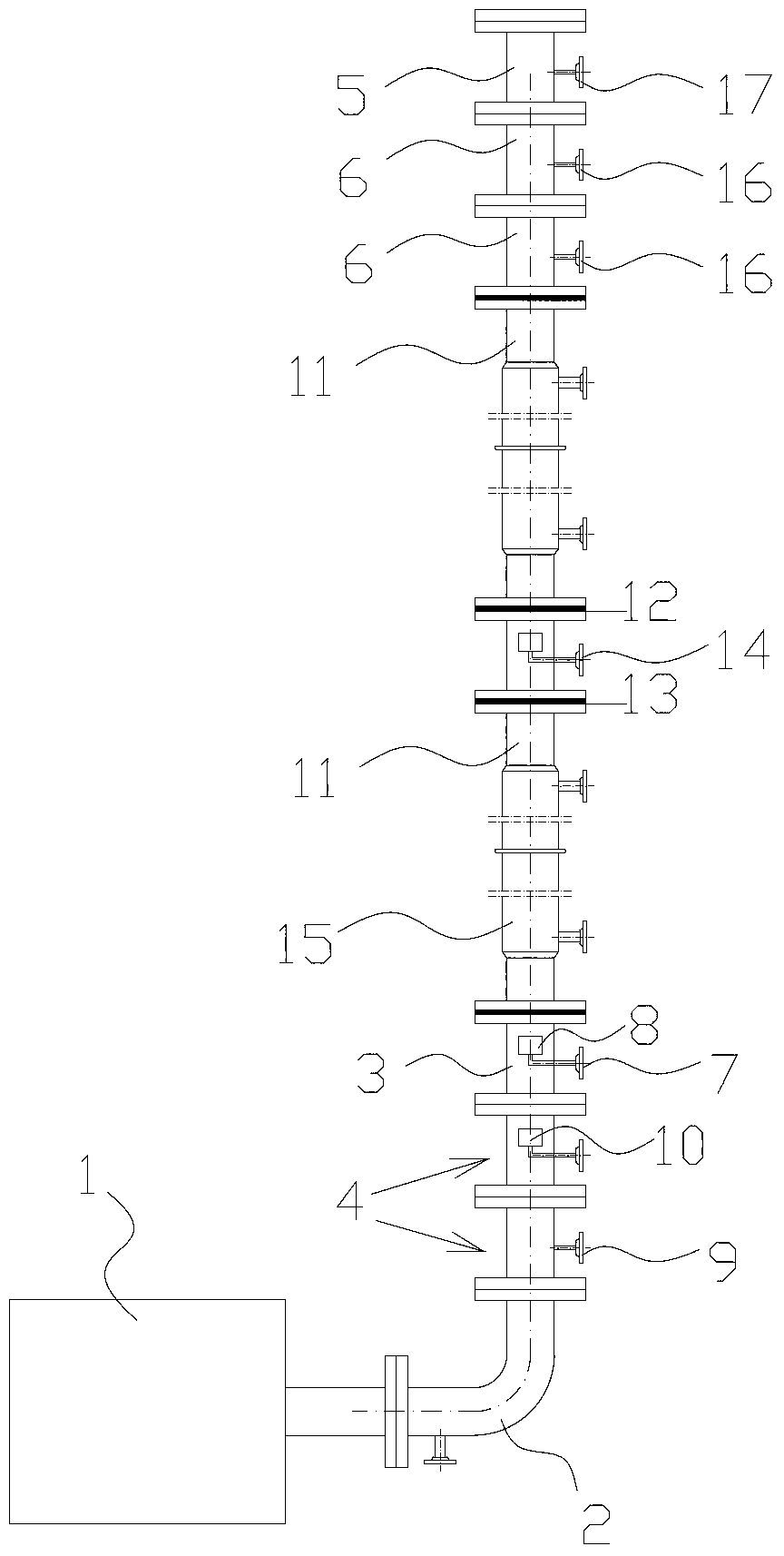

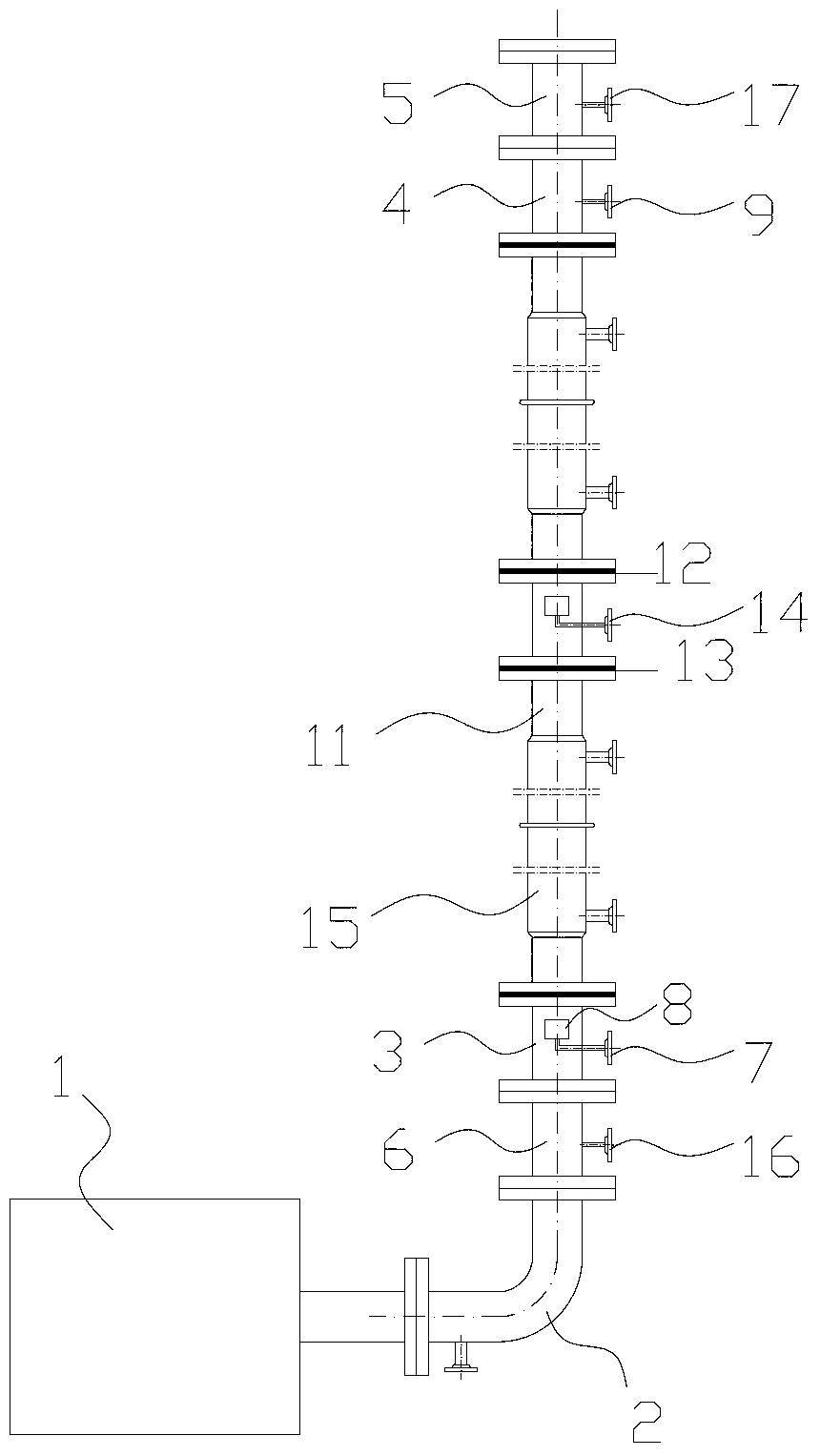

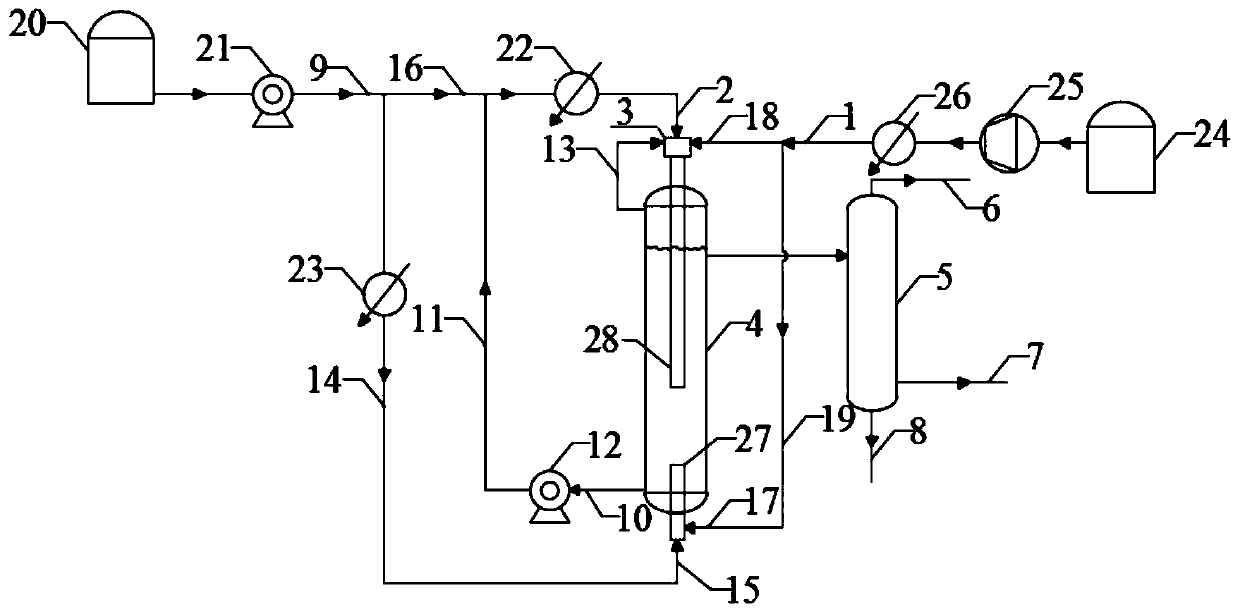

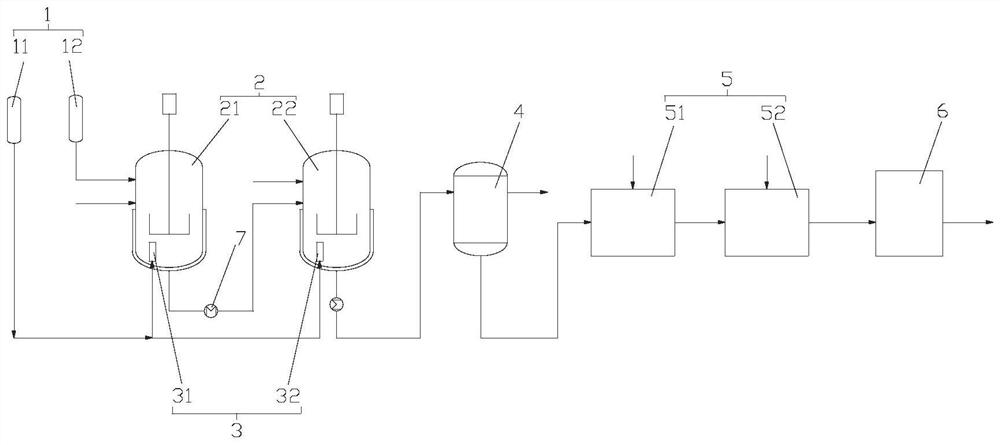

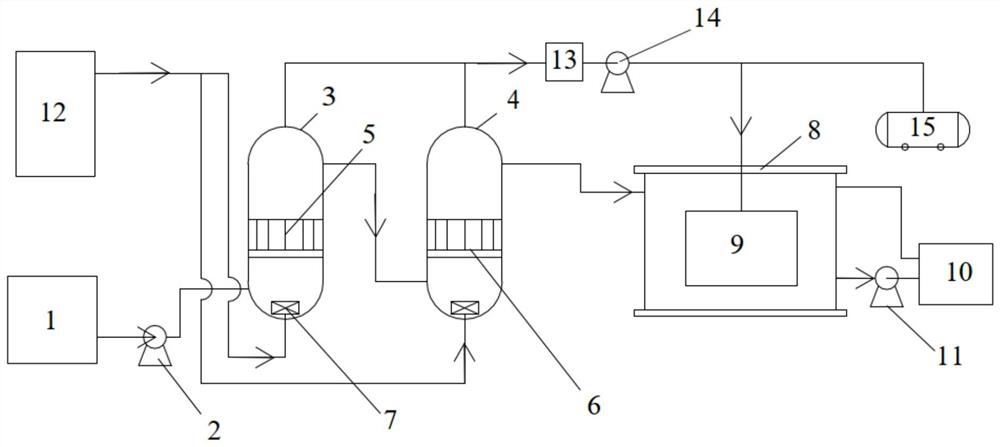

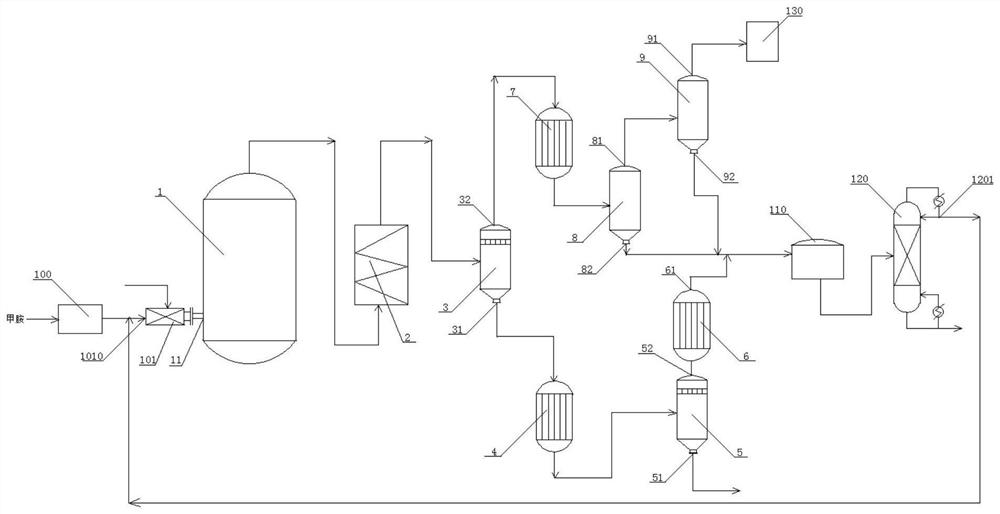

Reaction system and method for preparing formic acid through carbon dioxide hydrogenation

InactiveCN112321409AImprove reaction efficiencyEasy to operateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystHydrogenation reaction

The invention provides a reaction system and a method for preparing formic acid by hydrogenating carbon dioxide. The reaction system for preparing formic acid by hydrogenating carbon dioxide comprisesa first reaction rectifying tower, a second reaction rectifying tower and a fine reactor, a hydrogen inlet, a carbon dioxide inlet and a solvent and catalyst mixing inlet are sequentially formed in the side wall of the reaction rectifying tower from top to bottom; a pneumatic micro-interface generator and a hydraulic micro-interface generator are arranged in the reaction rectifying tower, the pneumatic micro-interface generator is arranged between tower plates in the reactive distillation tower, is communicated with the hydrogen inlet and is used for dispersing and crushing incoming hydrogen,and the hydraulic micro-interface generator is arranged close to the bottom of the reaction rectifying tower, and is communicated with the carbon dioxide inlet and is used for dispersing and crushingentering carbon dioxide; and the solvent and catalyst mixing inlet is formed in the bottom of the reaction rectifying tower. The reaction system provided by the invention reduces the temperature andpressure of the hydrogenation reaction.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

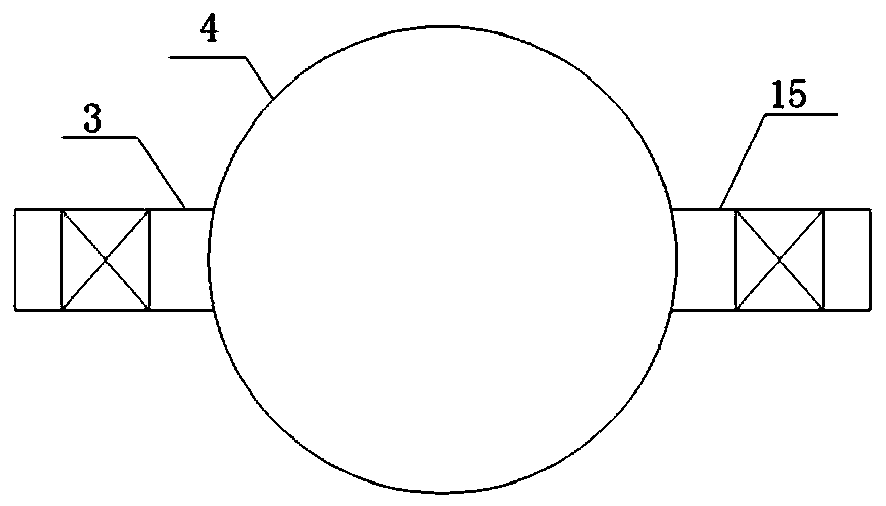

Oscillatory flow reactor of packed bed

The invention discloses an oscillatory flow reactor of a packed bed. The oscillatory flow reactor comprises an oscillation generating mechanism, an inlet segment, a reaction segment and an outlet segment which are sequentially connected, wherein the inlet segment is composed of an air inlet segment and a liquid inlet segment which are connected in series, and the outlet segment is composed of an air outlet segment and a liquid outlet segment which are connected in series; the air inlet segment is provided with an air feeding hole and an air distributor located at the downstream of an air discharging hole; the liquid inlet segment is provided with a liquid feeding hole and a liquid distributor located at the downstream of a liquid discharging hole; the reaction segment is provided with a vertically-arranged reaction tube which is filled with filler or solid catalyst particles in the middle, a supporting device at the bottom and a pressing device at the top. The oscillatory flow reactor of the packed bed is suitable for industrial gas-liquid reaction taking the liquid phase as a main body, gas-liquid-liquid reaction or gas-liquid-solid three-phase reaction system containing a solid catalyst and can continuously and stably operate for a long term.

Owner:吴嘉

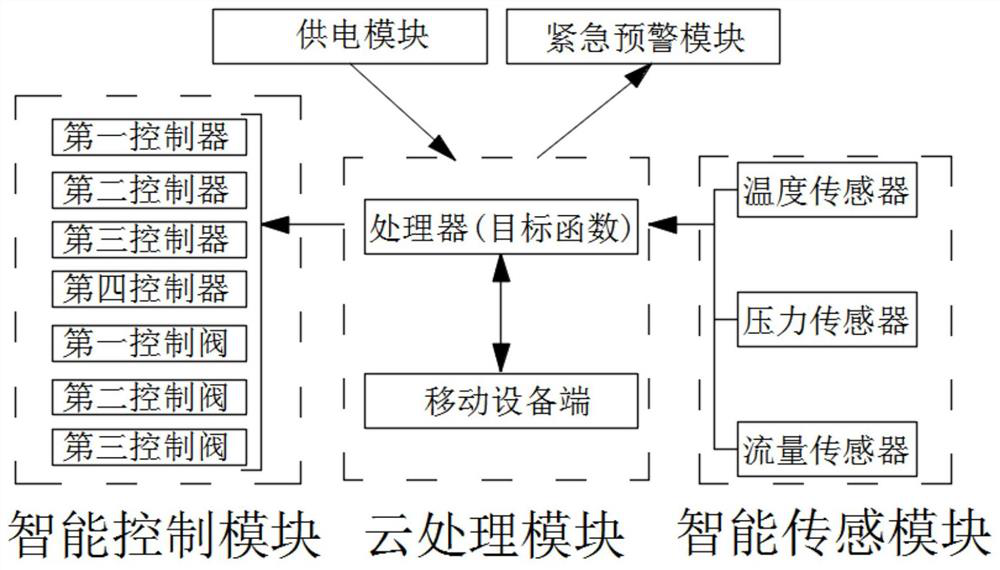

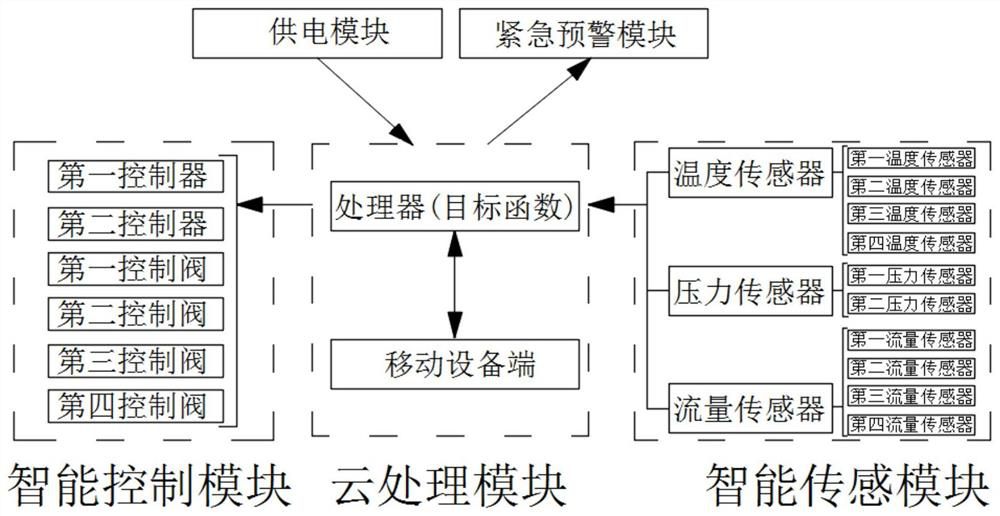

Intelligent control reaction system and process for preparing butyl octanol through carbonylation of propylene

PendingCN112479840AImprove reaction efficiencyFlexible Range AdjustmentOrganic compound preparationPreparation by hydrogenationPtru catalystOctanol

The invention relates to an intelligent control reaction system and process for preparing butyl octanol through carbonylation of propylene. The intelligent control reaction system comprises an OXO unit, a butyraldehyde treatment unit, a butyraldehyde condensation unit, a hydrogenation reaction unit, a purification unit, a micro-interface generator and an intelligent control unit. According to theinvention, propylene and synthesis gas are treated by additionally arranging the micro-interface generator, the propylene and the synthesis gas are crushed to form micron-scale bubbles, and the micron-scale bubbles and a triphenylphosphine solution of a rhodium catalyst are mixed to form a gas-liquid emulsion, so the phase interface area of a gas phase and a liquid phase is increased, the OXO efficiency of the propylene and the synthesis gas is improved, the utilization rate of propylene is improved, and the production cost of butanol and octanol is reduced; and through the intelligent controlunit, a worker can know the real-time condition of each data returned by intelligent sensing modules at any time through mobile equipment, and can realize accurate control on the inner temperature and inner pressure of the whole reactor by changing preset values, so reaction efficiency is further improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

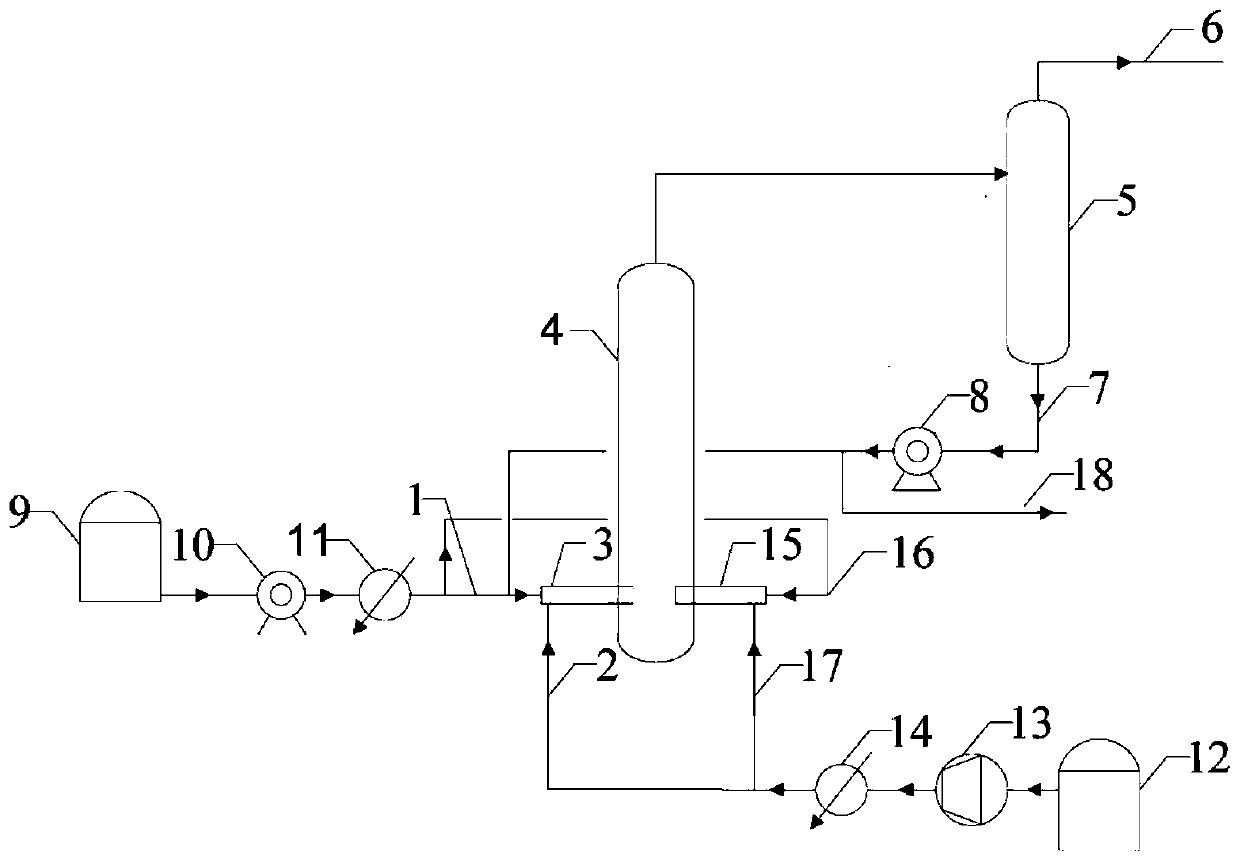

Vertically-opposite-jetting type micro-interface enhanced reaction device and method

PendingCN111495288AImprove solubilityIncreased phase boundary areaHydrocarbon oil crackingChemical/physical processesThermodynamicsPtru catalyst

The invention discloses a vertically-opposite-jetting type micro-interface enhanced reaction device and method. The vertically-opposite-jetting type micro-interface enhanced reaction device comprisesa bubbling type reactor, an air inlet device, a liquid inlet device, at least two bubble breakers, a three-phase separator and a circulating pump. Hydrogen and a residual oil raw material with a catalyst are preheated and then enter the bubble breakers to form micron-sized bubble systems; then the micron-sized bubble systems are respectively fed into the bubbling type reactor from first dischargeholes in the bubble breaker at the top and the bubble breaker at the bottom; the micron-sized bubble systems are oppositely jetted in the bubbling type reactor, and a hydrogenation reaction is conducted under the action of the catalyst. The reaction device and method provided by the invention have the advantages of ultralow hydrogenation reaction pressure, small gas-liquid ratio, large gas-liquidmass transfer area, high reaction rate, low energy consumption, flexible process, high production safety and the like.

Owner:NANJING UNIV +1

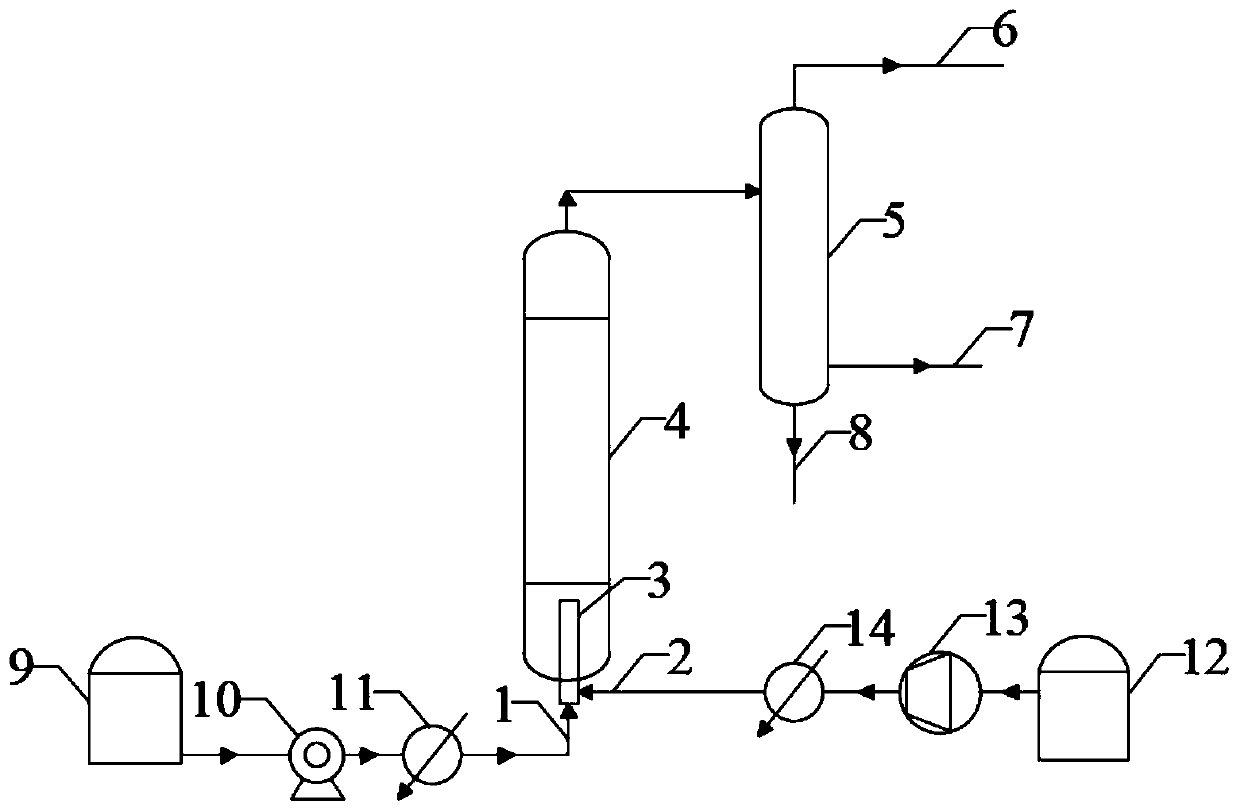

Bottom-mounted micro-interface enhanced reaction device and method for residual oil hydrogenation reaction

InactiveCN111482144AImprove solubilityIncreased phase boundary areaHydrocarbon oil crackingChemical/physical processesPhysicsSlag

The invention discloses a bottom-mounted micro-interface enhanced reaction device and method for residual oil hydrogenation reaction. The bottom-mounted micro-interface enhanced reaction device comprises a suspended bed reactor, an air inlet device, a liquid inlet device, at least one bubble breaker and a three-phase separator. Hydrogen and a residual oil raw material with a catalyst are preheatedand then enter the bubble breakers to form a micron-sized bubble system, and then the micron-sized bubble system enters the suspended bed reactor, flows from bottom to top and is subjected to a hydrogenation reaction under the action of the catalyst. After the reaction, the product enters the three-phase separator for separation, the gas is discharged from a gas phase outlet, the liquid is extracted from a liquid phase outlet, the solid slag is discharged from a solid phase outlet, and the gas, the liquid and the solid slag are separately collected for subsequent treatment. The reaction device and method provided by the invention have the advantages of ultralow hydrogenation reaction pressure, small gas-liquid ratio, large gas-liquid mass transfer area, high reaction rate, low energy consumption, flexible process, high production safety and the like.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Formic acid preparation system and method

InactiveCN112479852AImprove reaction efficiencyEasy to operateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsFormic acidMass transfer rate

The invention provides a formic acid preparation system and method. The formic acid preparation system comprises a reactive distillation column, and a hydrogen inlet, a carbon dioxide inlet and a solvent and catalyst mixed inlet are sequentially formed in the side wall of the reactive distillation column from top to bottom; a plurality of micro-interface generators are arranged in the reactive distillation column, the micro-interface generators are arranged among a plurality of tower plates in the reactive distillation column, and one of the micro-interface generators is communicated with a hydrogen inlet and is used for dispersing and crushing incoming hydrogen; another micro-interface generator is communicated with a carbon dioxide inlet and is used for dispersing and crushing entering carbon dioxide, and the rest micro-interface generators are communicated with the hydrogen inlet or the carbon dioxide inlet. The formic acid preparation system solves the problems of low reaction rateand low mass transfer rate between reaction phase interfaces in the prior art, lowers the temperature and pressure of the hydrogenation reaction, and enhances the reaction efficiency.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

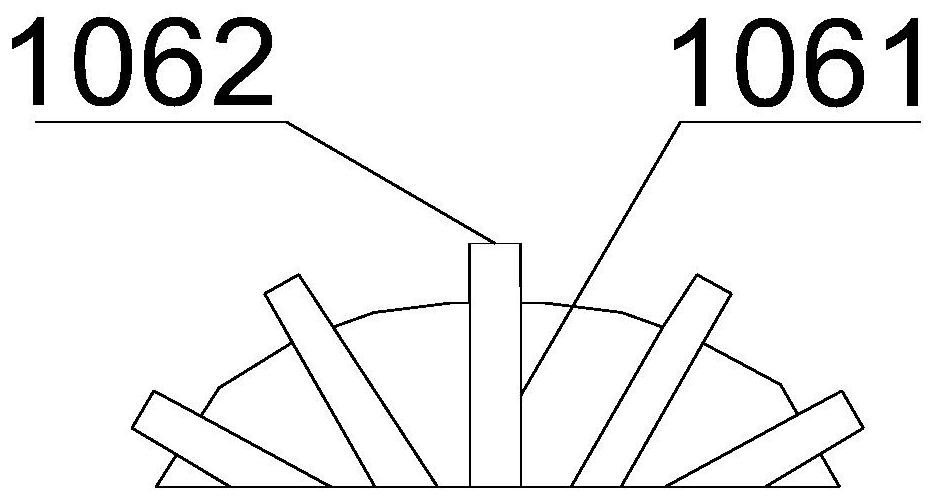

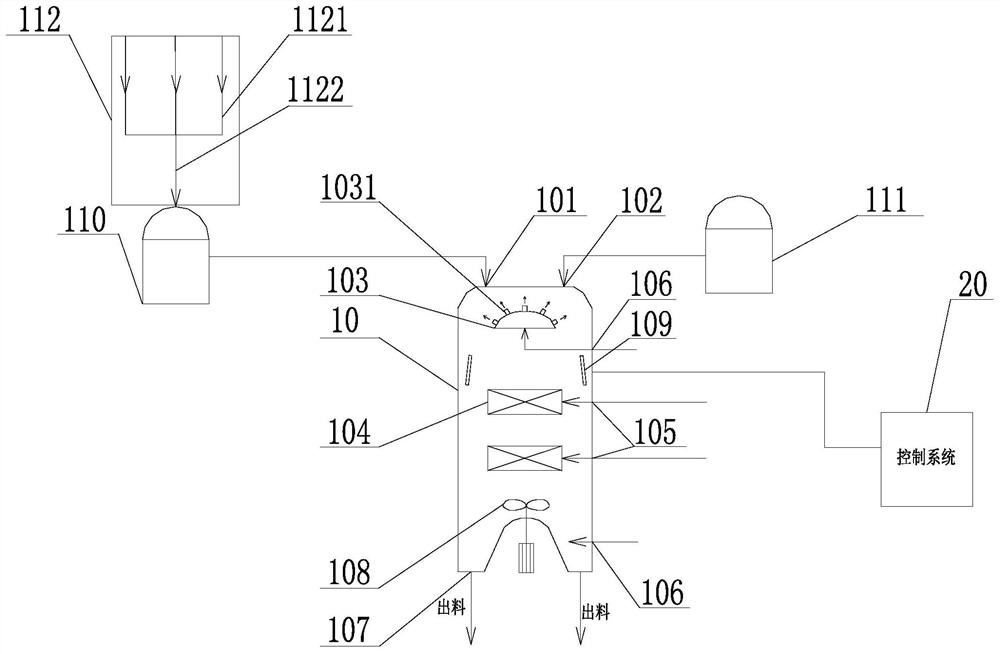

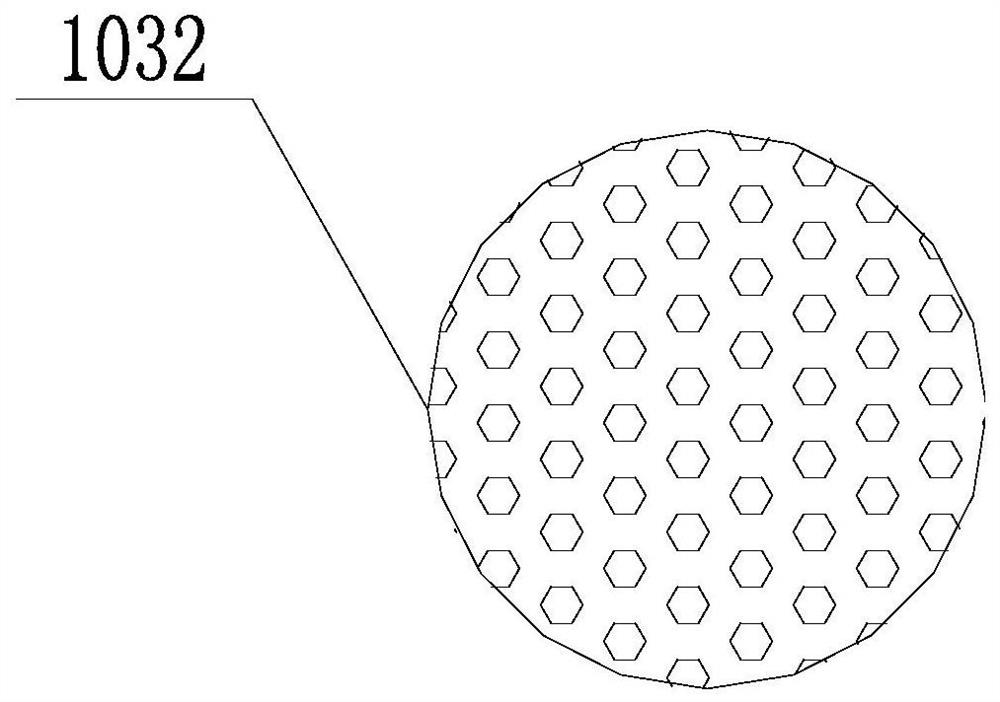

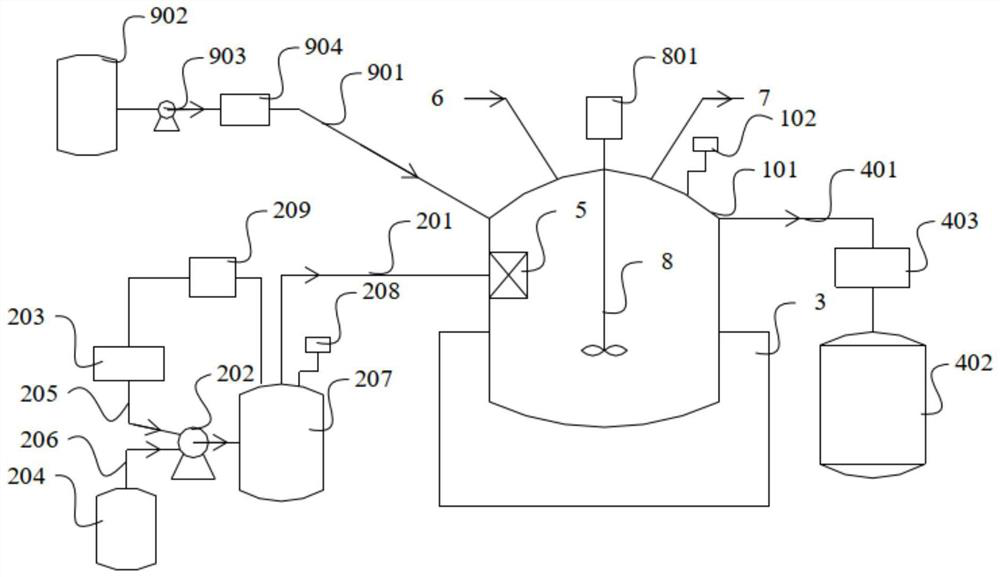

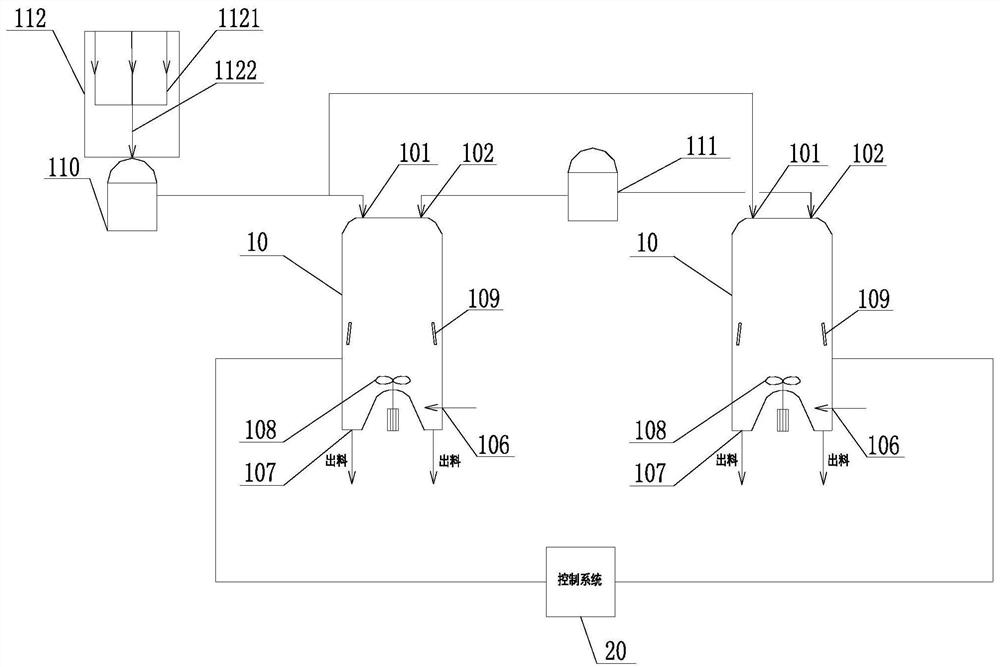

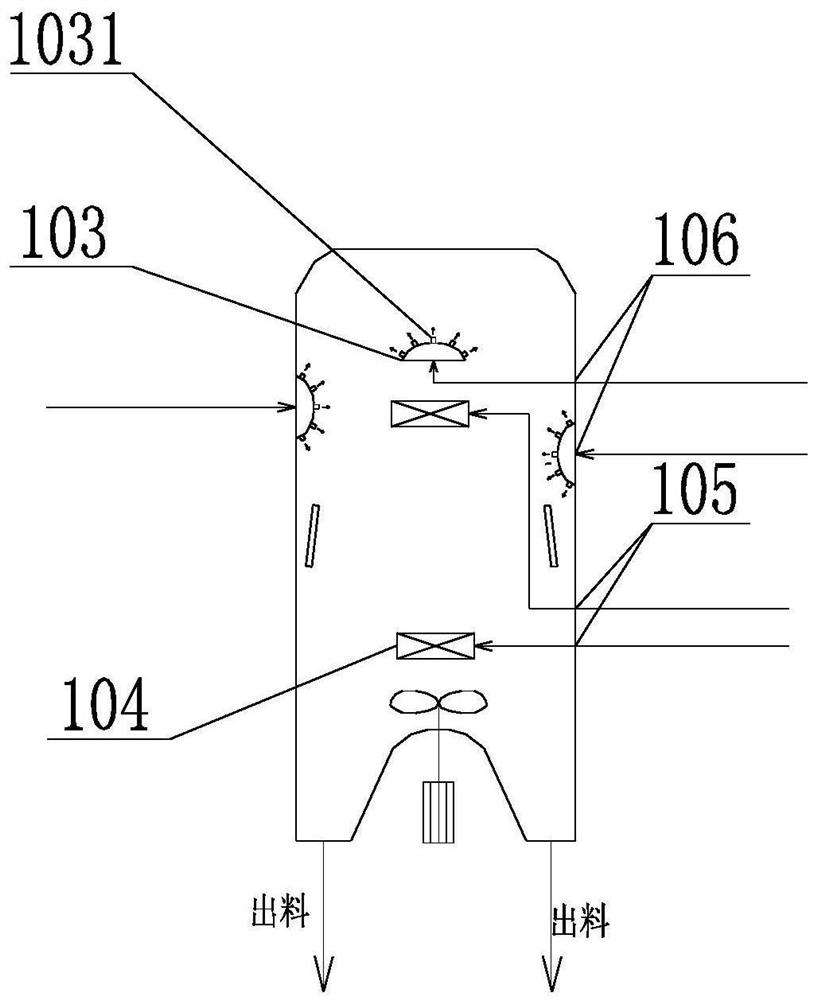

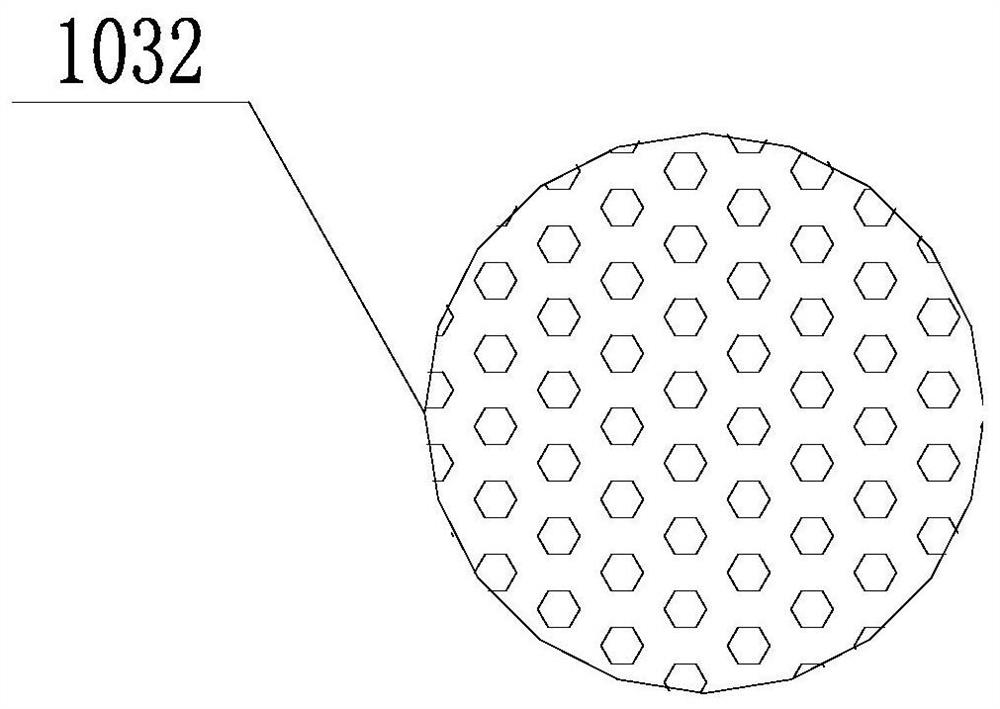

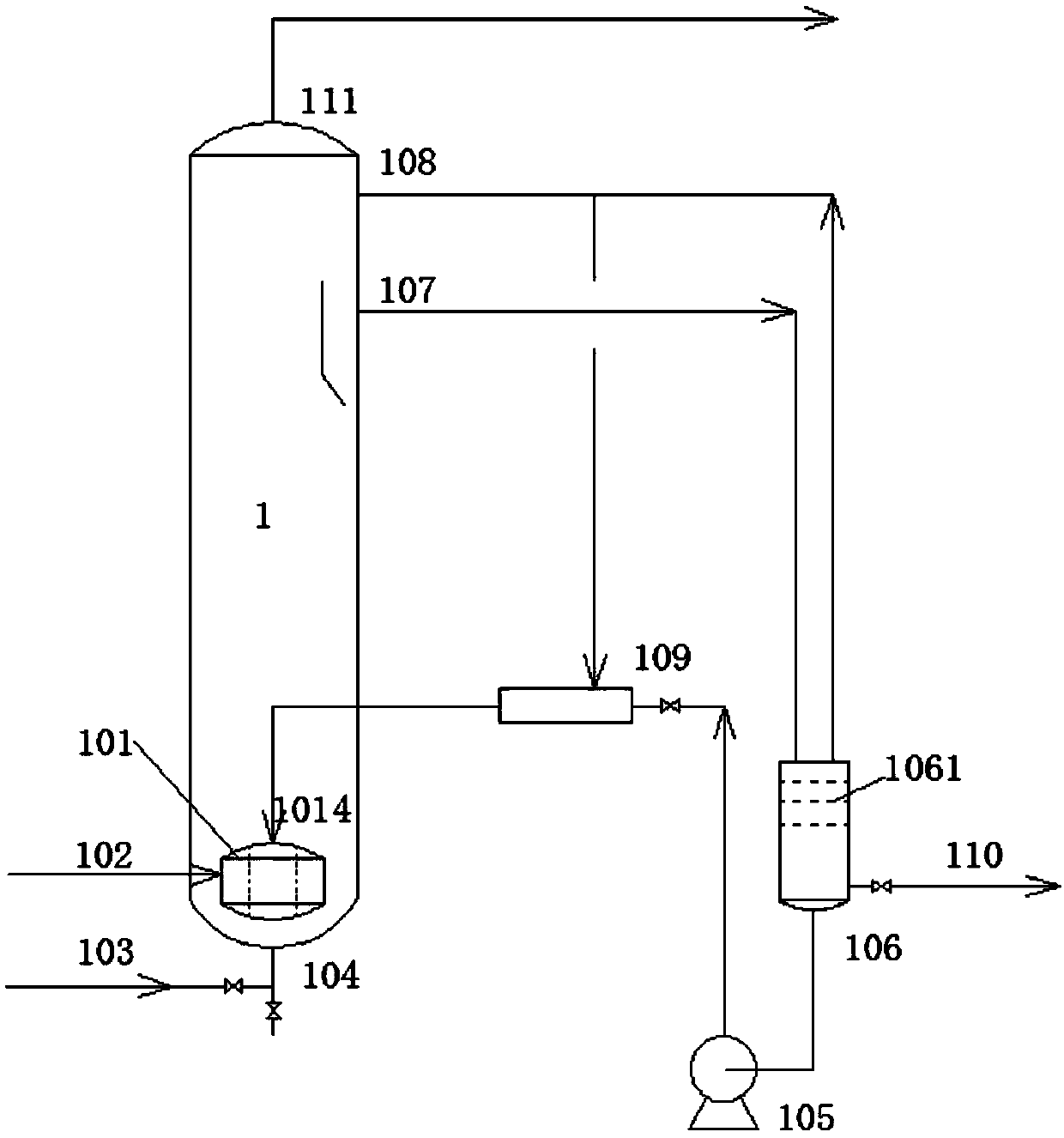

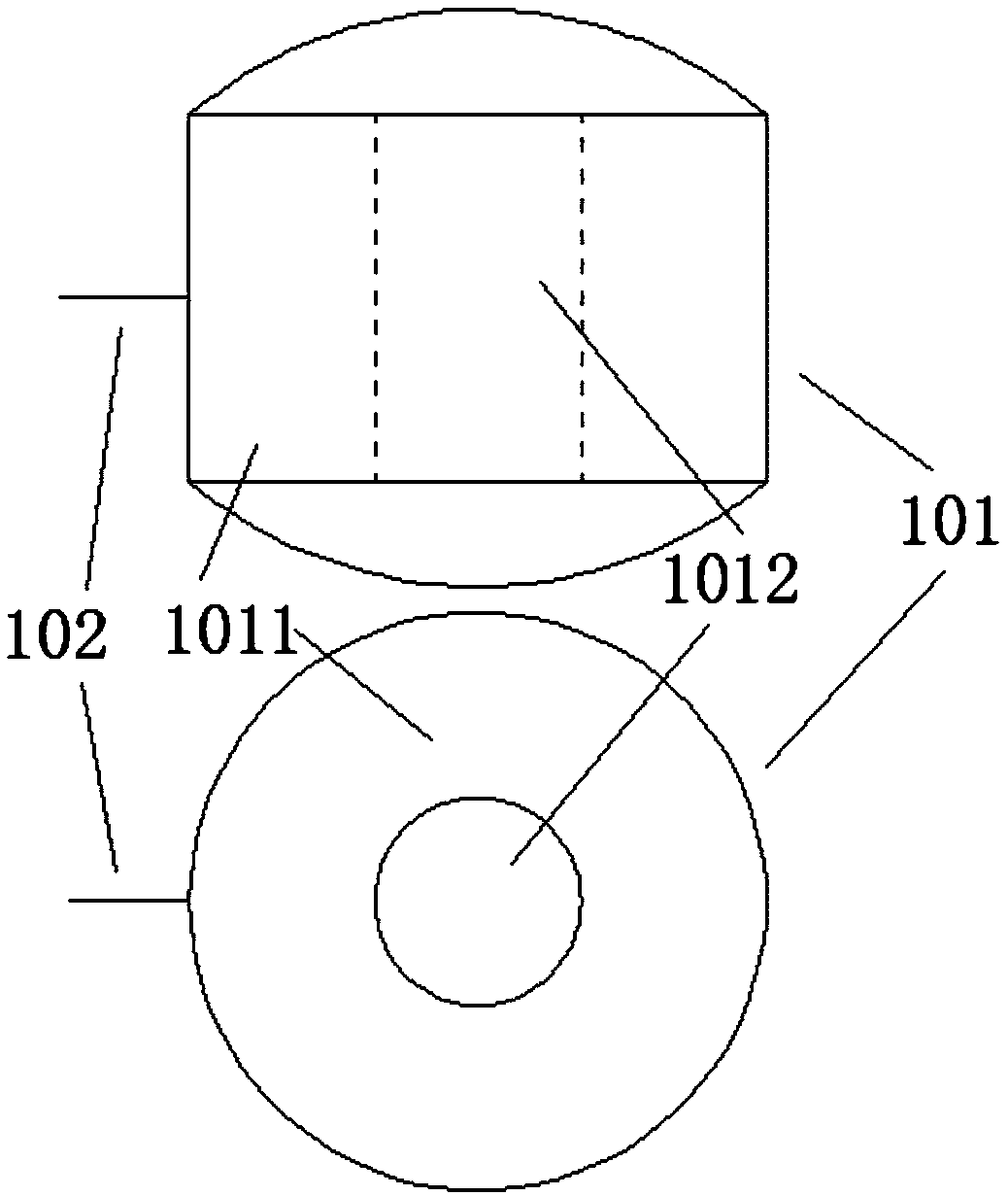

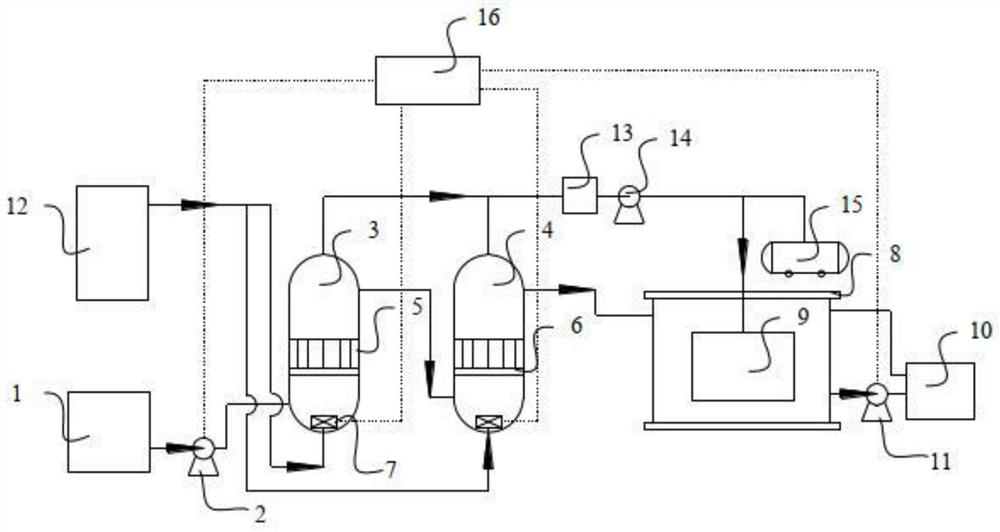

Micro-interface fermentation system and fermentation method thereof

PendingCN112300919AIncrease dissolved oxygen concentrationIncrease the mass transfer area of the phase boundaryBioreactor/fermenter combinationsBiological substance pretreatmentsControl systemProcess engineering

The invention provides a micro-interface fermentation system and a fermentation method thereof. The micro-interface fermentation system comprises a fermentation tank and a control system. The top of the fermentation tank is provided with a bacterial liquid inlet and a feed liquid inlet for bacterial liquid and feed liquid to enter, and the bottom of the fermentation tank is provided with a liquidoutlet for discharging fermentation products; liquid ejectors and two micro-interface generators are arranged in the fermentation tank, the two micro-interface generators are arranged at the bottom inthe fermentation tank side by side from top to bottom, the liquid ejector is arranged at the upper part in the fermentation tank, and a cleaning water inlet and air inlets are formed in the side wallof the fermentation tank; and the air inlets are communicated into the micro-interface generators through pipelines and are in one-to-one correspondence with the micro-interface generators. The micro-interface fermentation system provided by the invention solves the problem of low fermentation efficiency caused by the fact that air and fermentation liquor cannot be fully mixed in the fermentationtank in the prior art, and saves the labor cost of cleaning and field operation.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

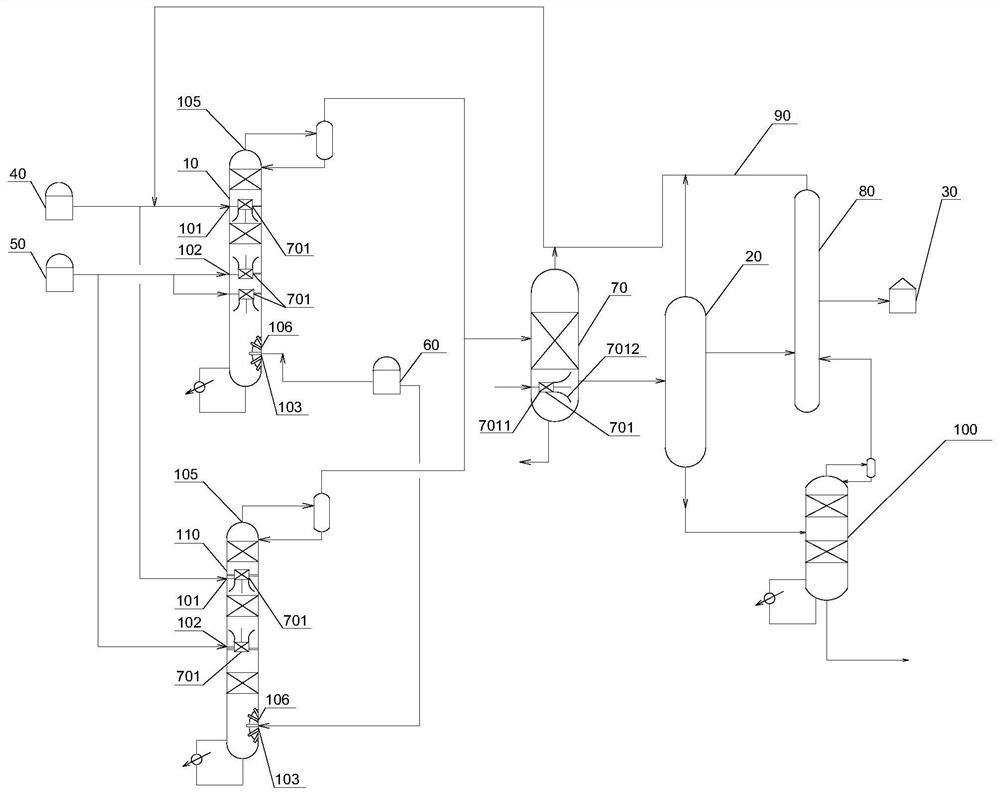

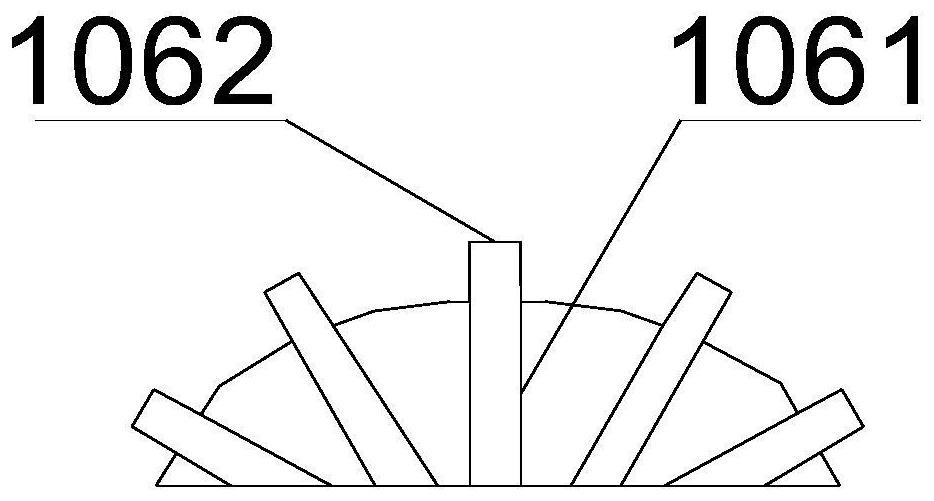

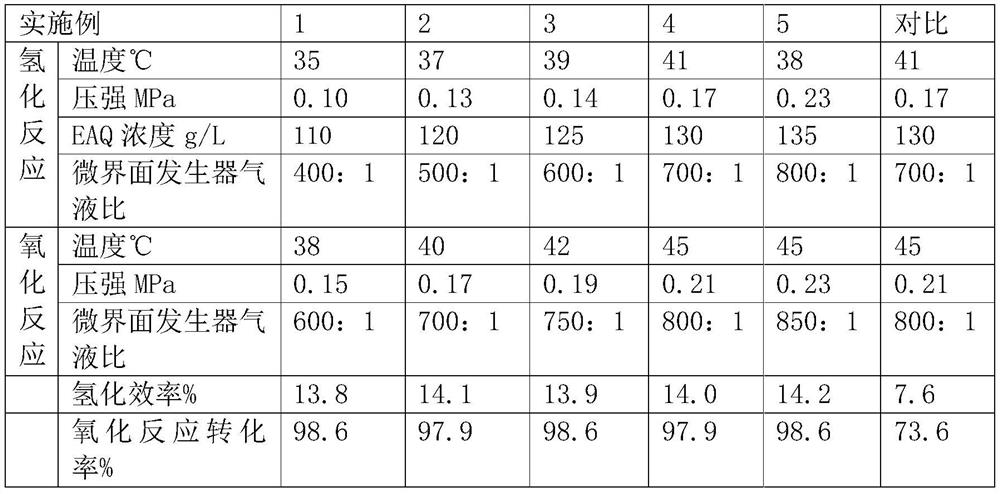

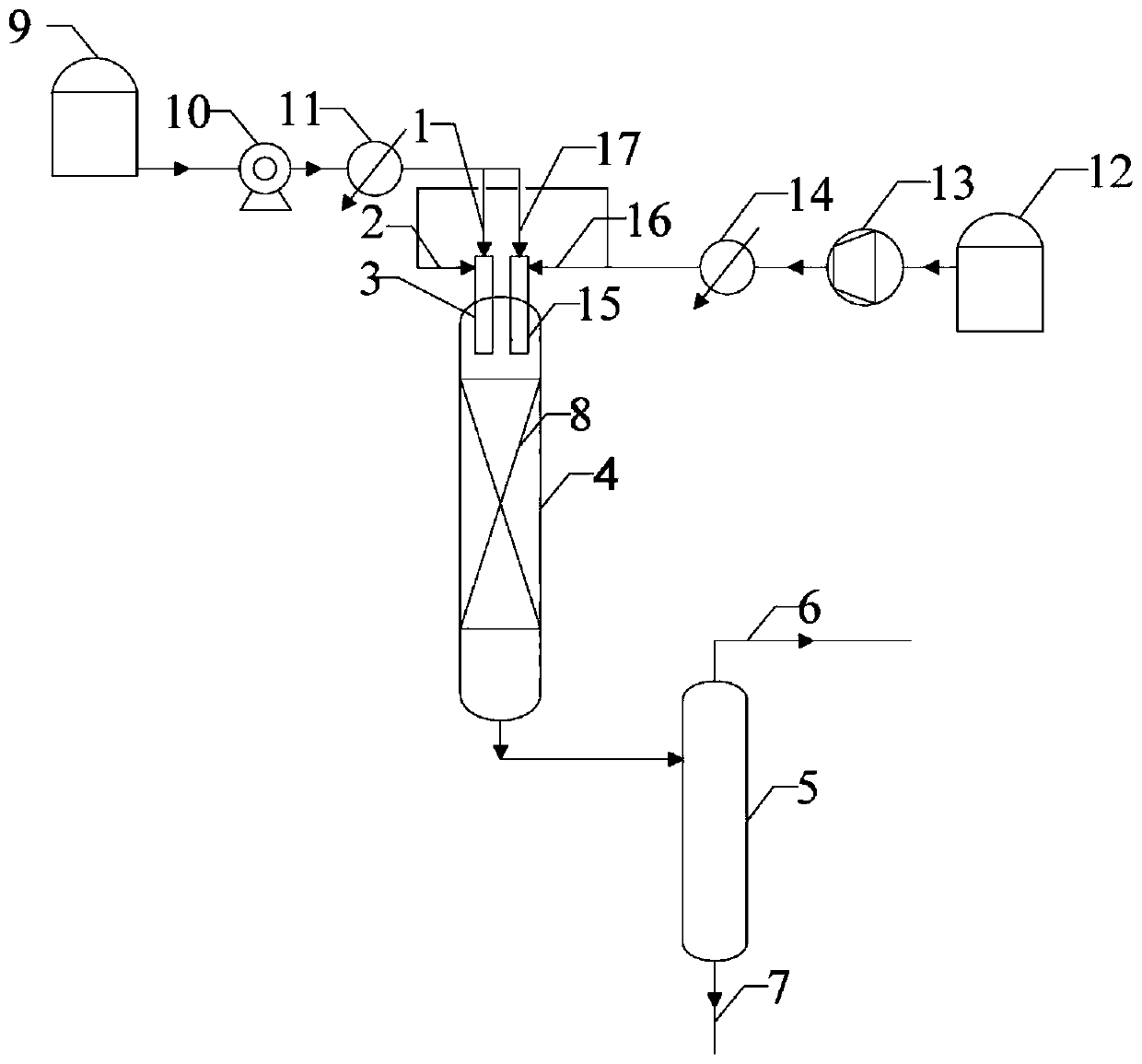

System and process for preparing hydrogen peroxide based on anthraquinone method

InactiveCN112499592AIncreased phase boundary areaImprove hydrogenation efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesUsing liquid separation agentAnthraquinonesEmulsion

The invention relates to a system and process for preparing hydrogen peroxide based on an anthraquinone method. The system comprises a hydrogenation tower, a micro-interface generator, a filtering andcooling unit, an oxidation tower and an extraction tower. Hydrogen is crushed to form micron-sized bubbles, and the micron-sized bubbles are mixed with an anthraquinone derivative-containing workingsolution or a 2-ethylanthraquinone-containing hydrogenated solution to form a gas-liquid emulsion, so that the phase interface area of a gas phase and a liquid phase is increased, the effect of enhancing mass transfer within a relatively low preset operation condition range is achieved, the hydrogenation and oxidation efficiency of the anthraquinone derivative-containing working solution is improved, the hydrogen reaction rate is improved, the cost is saved, and the risk is reduced. A mixture of 2-ethylanthraquinone and hydrogen peroxide is extracted through the extraction tower, countercurrent extraction is carried out on a water phase from top to bottom and the mixture from bottom to top, and rapid extraction is realized.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Wet oxidation treatment system for industrial wastewater, and method thereof

PendingCN112479340AIncreased phase boundary areaEnhanced mass transferWater treatment parameter controlSpecific water treatment objectivesIndustrial waste waterBuffer tank

The invention provides a wet oxidation treatment system for industrial wastewater, and a wet oxidation treatment method using the system. The wet oxidation treatment system comprises: a reaction tankinternally provided with a reaction chamber and a stirring device; a heating device used for heating the reaction cavity; a gas-liquid separation device connected with the discharge hole of the reaction tank; an initiator adding device connected with the reaction tank through a feeding pipeline and further comprising an initiator storage tank and a preheater; an oxygen production device communicated with the reaction tank through an oxygen pipeline and comprising an air compressor, a buffer tank, a booster pump and a gas steel cylinder; and a micro-interface generator arranged in the reactioncavity and used for smashing gas from the oxygen pipeline into bubbles, so that the bubbles and the industrial wastewater form a gas-liquid emulsion, the phase interface area of the gas and the liquidis increased, the reaction rate is increased, and the reaction pressure intensity is reduced.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

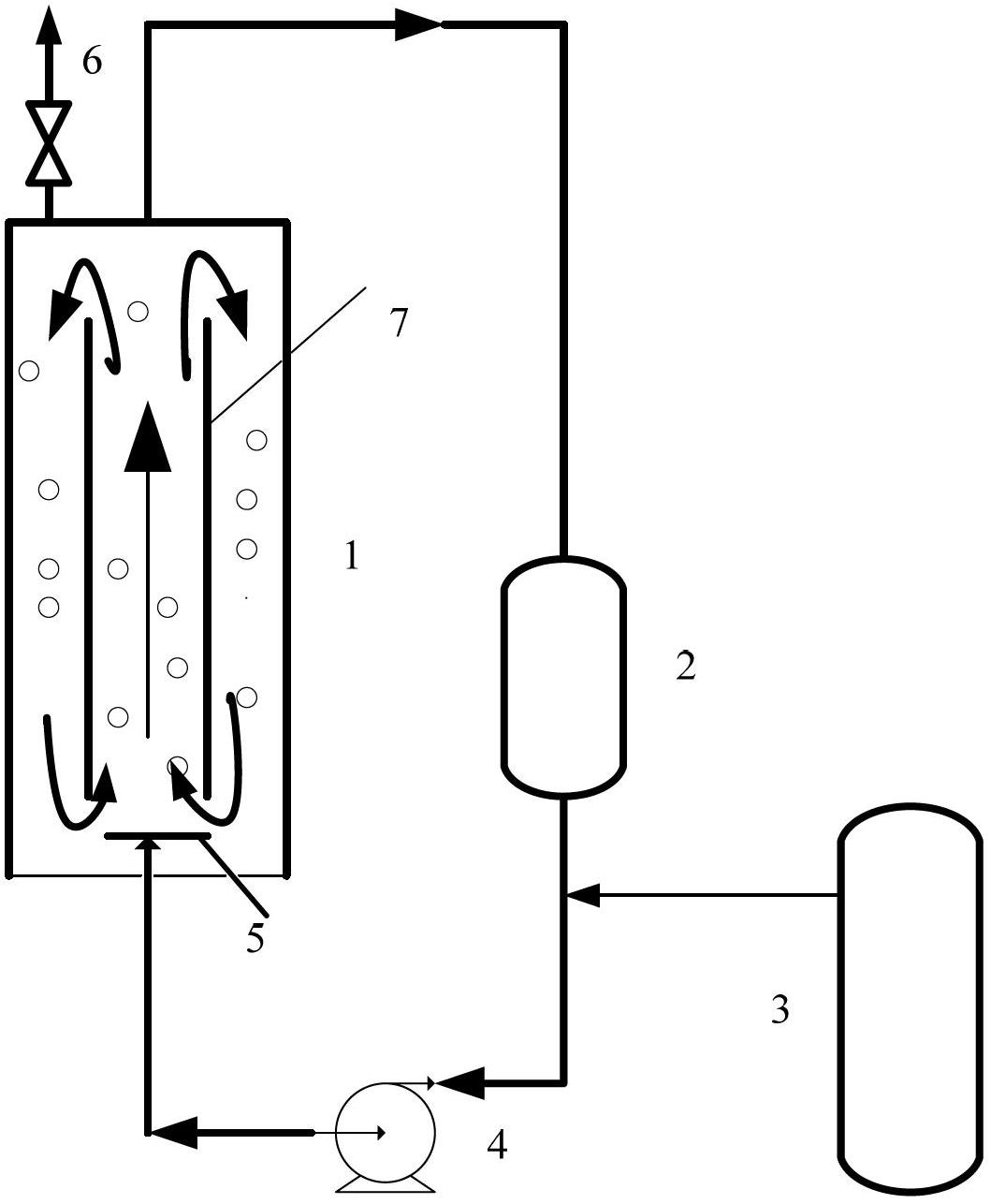

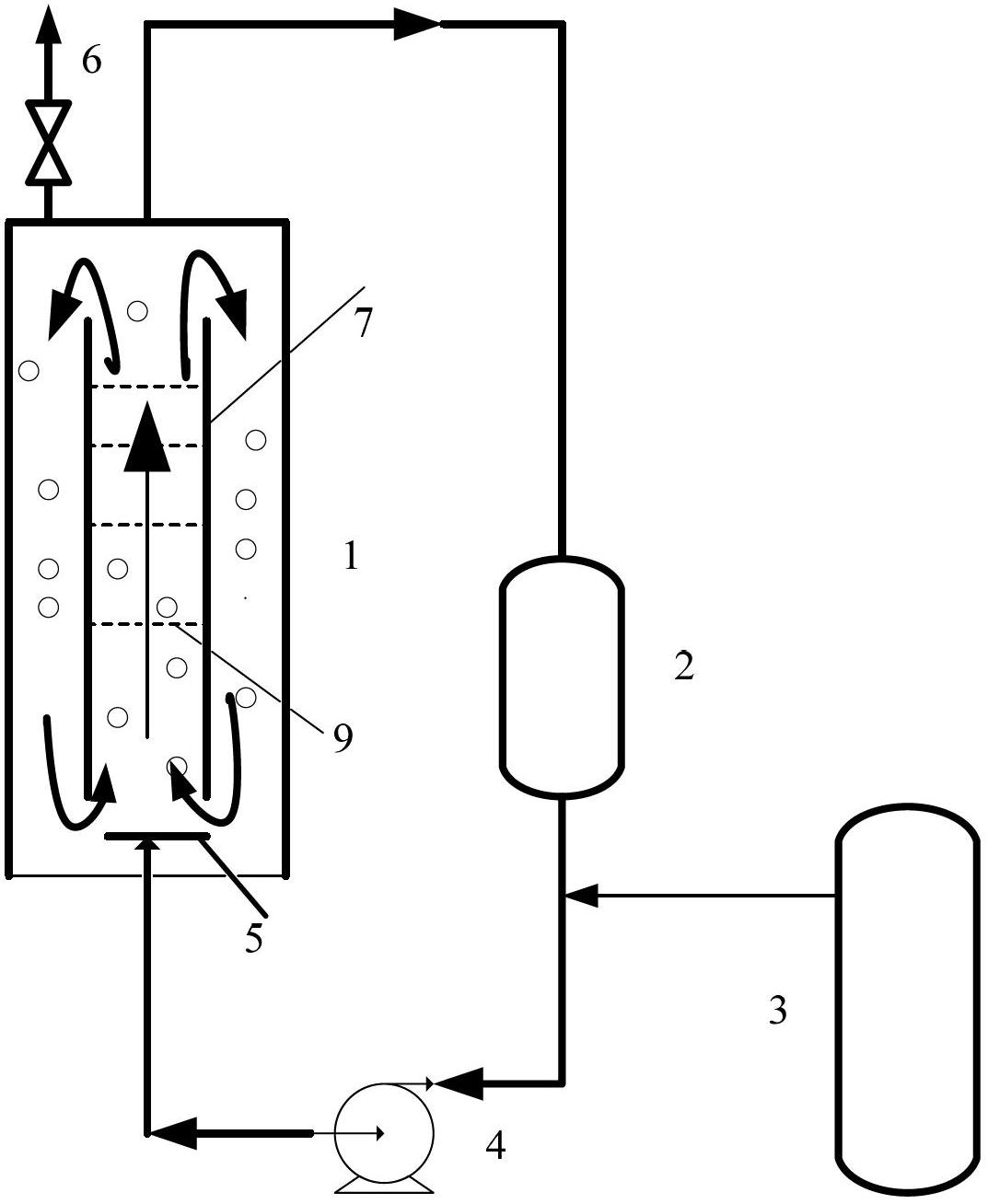

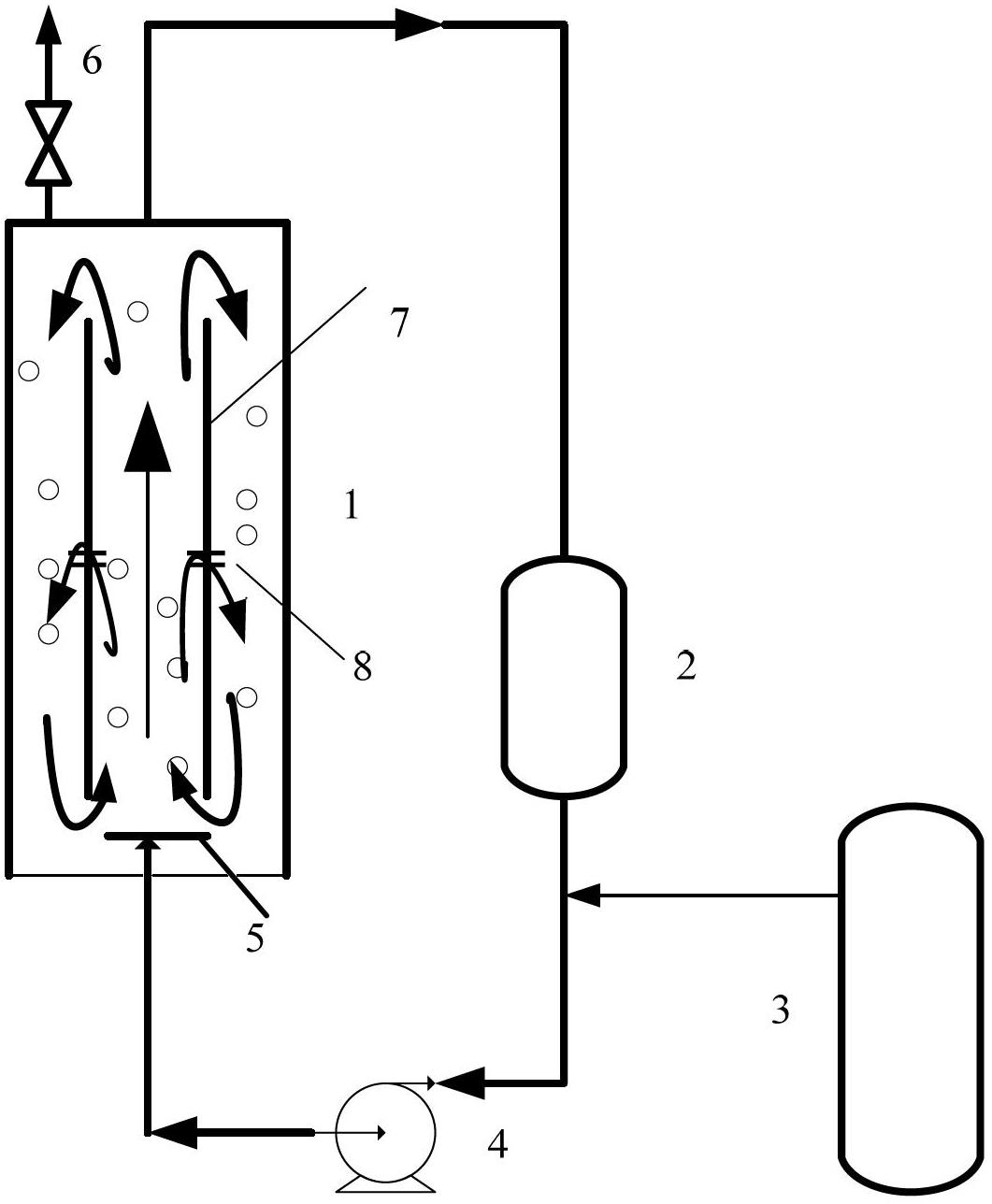

Method for copolymerizing carbon dioxide and propylene oxide with circulation flow reactor

The invention belongs to the field of chemical engineering technique and equipment, and particularly relates to a method for continuously producing polycarbonate by copolymerizing carbon dioxide and propylene oxide with a circulation flow reactor. The method comprises the following steps: introducing dry inert gas to replace atmosphere and remove water in the circulation flow reactor; adding propylene oxide, catalyst and carbon dioxide; copolymerizing the carbon dioxide and the propylene oxide under certain temperature and pressure to generate polycarbonate; and separating to obtain the aliphatic polycarbonate product, wherein the unreacted raw materials and gas are redistributed into the circulation flow reactor for cyclic utilization. The circulation flow reactor comprises a reactor shell, a raw material gas inlet, a gas distributor, a guide flow cylinder, a liquid feed port and a gas outlet, wherein a multilayer large-pore screen can be arranged in the guide flow cylinder, so that the circulating flow is divided into at least two stage when the pores of the guide flow cylinder wall are opened. The invention has the advantages of simple structure, low investment, good gas-liquid contact, good mass transfer, short time, high efficiency and the like, and is convenient to operate.

Owner:BEIJING RISUN TECH CO LTD

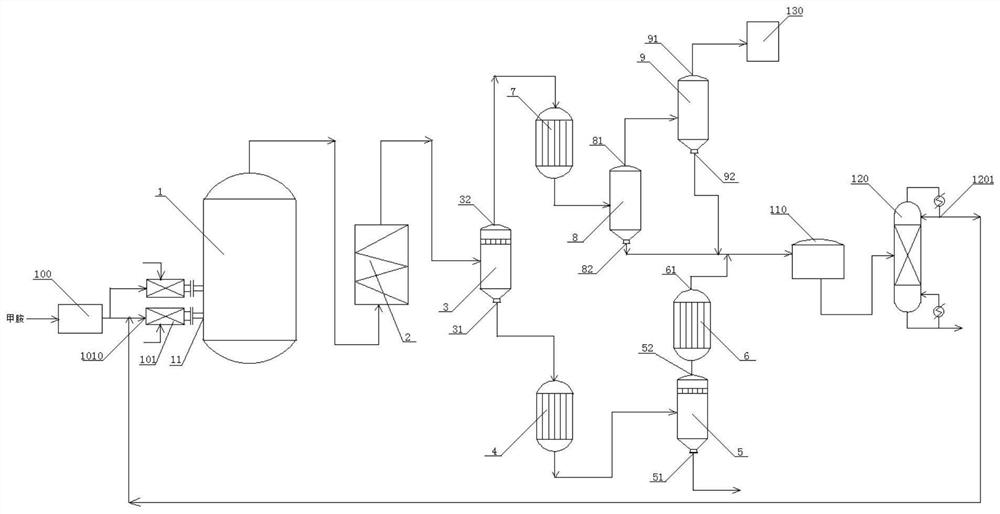

Enhanced micro-interface reaction system and method for preparing formic acid by hydrogenating carbon dioxide

PendingCN112403006AImprove reaction efficiencyEasy to operateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystHydrogenation reaction

The invention provides a reinforced micro-interface reaction system and method for preparing formic acid through carbon dioxide hydrogenation. The reinforced micro-interface reaction system for preparing formic acid through carbon dioxide hydrogenation comprises a first reactive distillation column, a second reactive distillation column and a fine reactor, wherein the first reactive distillation column and the second reactive distillation column are connected in parallel; a hydrogen inlet, a carbon dioxide inlet and a solvent and catalyst mixing inlet are sequentially formed in the side wallsof the first reactive distillation tower and the second reactive distillation tower from top to bottom; a flow-separating micro-interface generator is arranged in each of the first reaction rectifyingtower, the second reaction rectifying tower and the fine reactor, wherein the flow-separating micro-interface generator is formed by arranging a plurality of flow-separating channels on a micro-interface generator body; and the hydrogen inlet and the carbon dioxide inlet are connected with any of the flow-separating micro-interface generator arranged in the first reaction rectifying tower and thesecond reaction rectifying tower. According to the enhanced micro-interface reaction system, the temperature and pressure of hydrogenation reaction are reduced.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

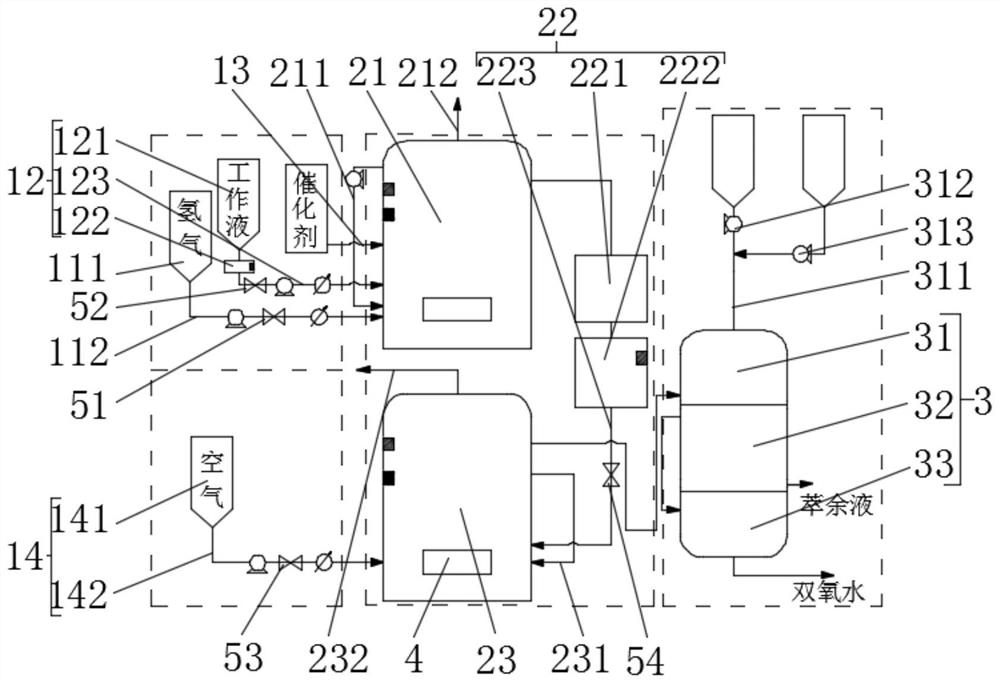

Automatic strengthening system and process for preparing hydrogen peroxide based on anthraquinone method

InactiveCN112499593AWith additional pressureNot easy to merge with each otherPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAnthraquinonesAutomatic control

The invention relates to an automatic strengthening system and process for preparing hydrogen peroxide based on an anthraquinone method. The automatic strengthening system comprises a raw material supply unit, a reaction unit, a separation unit, a micro-interface generator and an automatic control unit. According to the invention, the micro-interface generator is arranged in the reaction unit, hydrogen and air are crushed into micron-sized small bubbles in the micro-interface generator, and the micro-bubbles have additional pressure and are not easy to coalesce with each other when colliding with each other, so that the hydrogen has a larger phase interface area compared with hydrogen before being crushed, therefore, the hydrogen microbubbles can be more easily mixed with an anthraquinonederivative-containing working solution to form a gas-liquid emulsion, and the air bubbles can be more easily mixed with a 2-ethylanthraquinone-containing hydrogenated solution to form a gas-liquid emulsion, thereby achieving the effect of enhancing mass transfer within a lower preset operation condition range, and increasing the yield of hydrogenation reaction and oxidation reaction.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

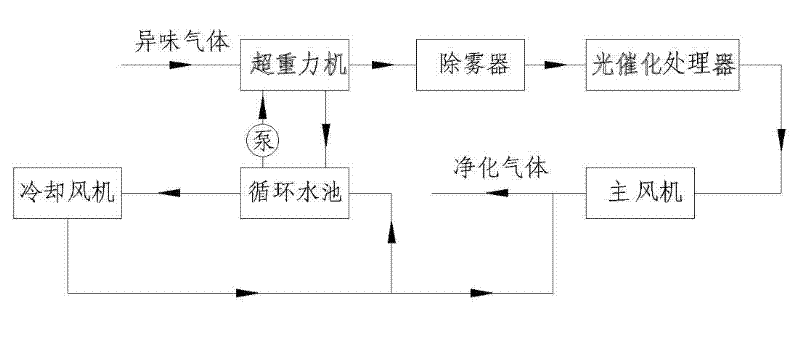

Process for removing tobacco odour

InactiveCN102335539AIncrease flow rateIncrease the effective specific surface areaCombination devicesHypergravityHazardous substance

The invention discloses a process for removing tobacco odour, which comprises the following steps of: removing dust and watersoluble harmful substances or constituents in gas to be treated by using a wet scrubber, removing water mist in the gas by using a demister, oxidizing the harmful substances or constituents in the gas by using a photocatalytic odour processor, and discharging the processed gas to the air by using a main air blower. The wet scrubber is a hypergravity gas dust-removing and sulphur-removing integrated machine, the gas to be treated is washed with circulating water, and the circulating water is cooled by a cooling air blower. The photocatalytic odour processor is a tube self-cleaning photocatalytic odour processor. The hypergravity gas dust-removing and sulphur-removing integrated machine and the photocatalytic odour processor can be used independently and combined for use. Both the hypergravity gas dust-removing and sulphur-removing integrated machine (Patent No. ZL200920233065.5) and the tube self-cleaning photocatalytic odour processor (Patent No. 201010273561.0) are inventions of the applicant, have applied the national patent, and are batch-produced, and are put on the market and gained public praise.

Owner:JIANGSU HUAZHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Erythromycin processing system and processing method thereof

InactiveCN112322478AImprove fermentation effectImprove fermentation capacityBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyEngineering

The invention provides an erythromycin processing system and a processing method thereof. The erythromycin processing system comprises a fermentation device and a control system, wherein the fermentation device is formed by connecting two fermentation tanks in parallel, a bacterial liquid inlet and a feed liquid inlet for bacterial liquid and feed liquid to enter are formed in the top of each fermentation tank, a liquid outlet is formed in the bottom of each fermentation tank and is used for discharging a fermentation product; liquid ejectors and micro-interface generators are arranged in eachfermentation tank, the micro-interface generator positioned at the upper part is close to the top of the fermentation tank, the micro-interface generator positioned at the lower part is close to thebottom of the fermentation tank, the liquid ejectors are arranged at the upper part in the fermentation tank, two liquid ejectors are respectively arranged on the side walls of the fermentation tank,and another liquid ejector is arranged opposite to the micro-interface generator at the upper part. The erythromycin processing system solves the problem that air and fermentation liquor cannot be fully mixed in the fermentation tank in the prior art.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

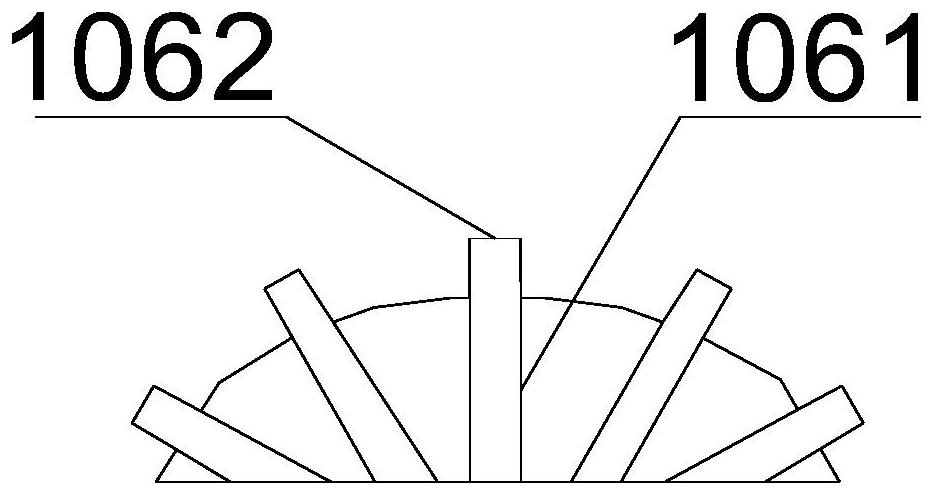

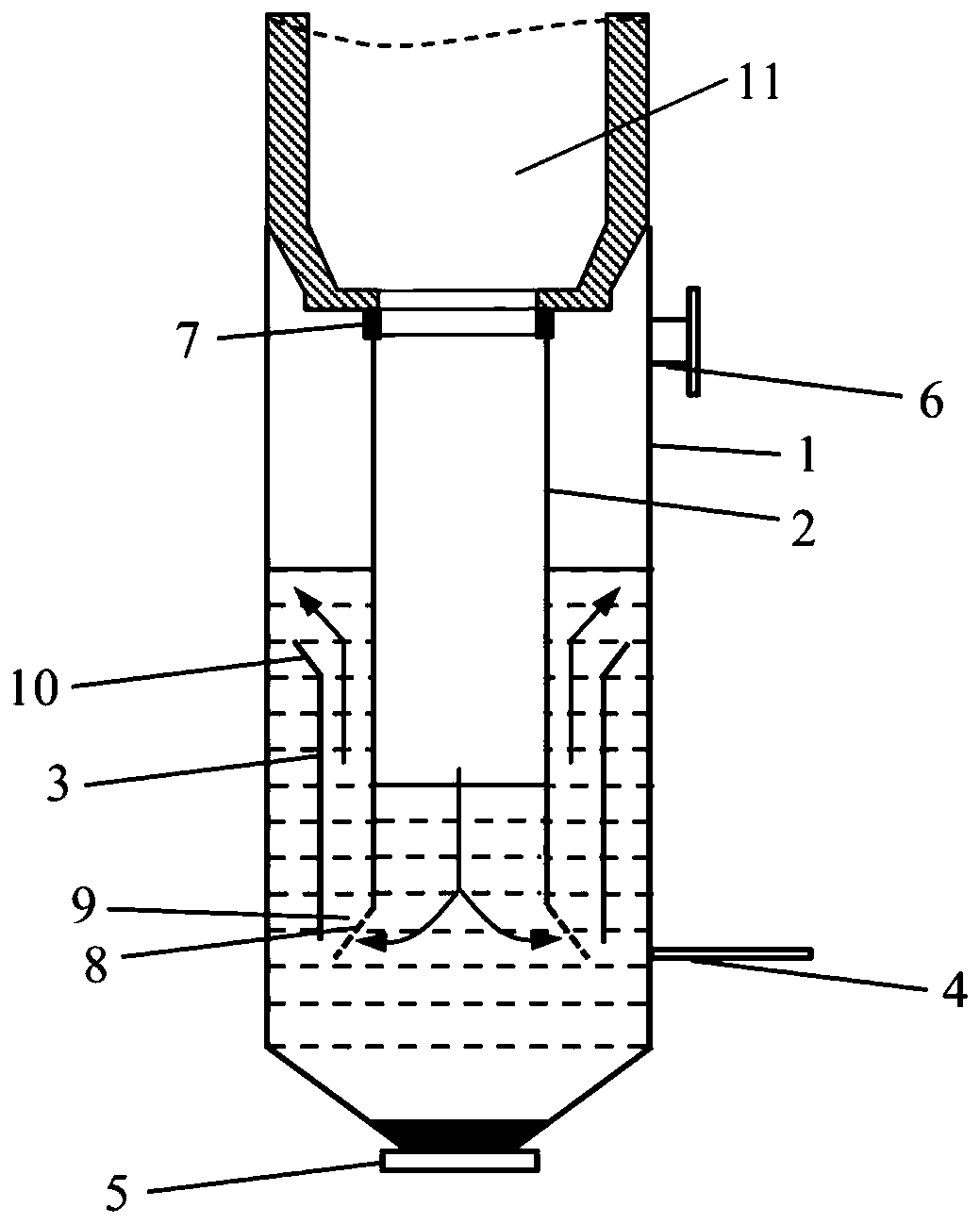

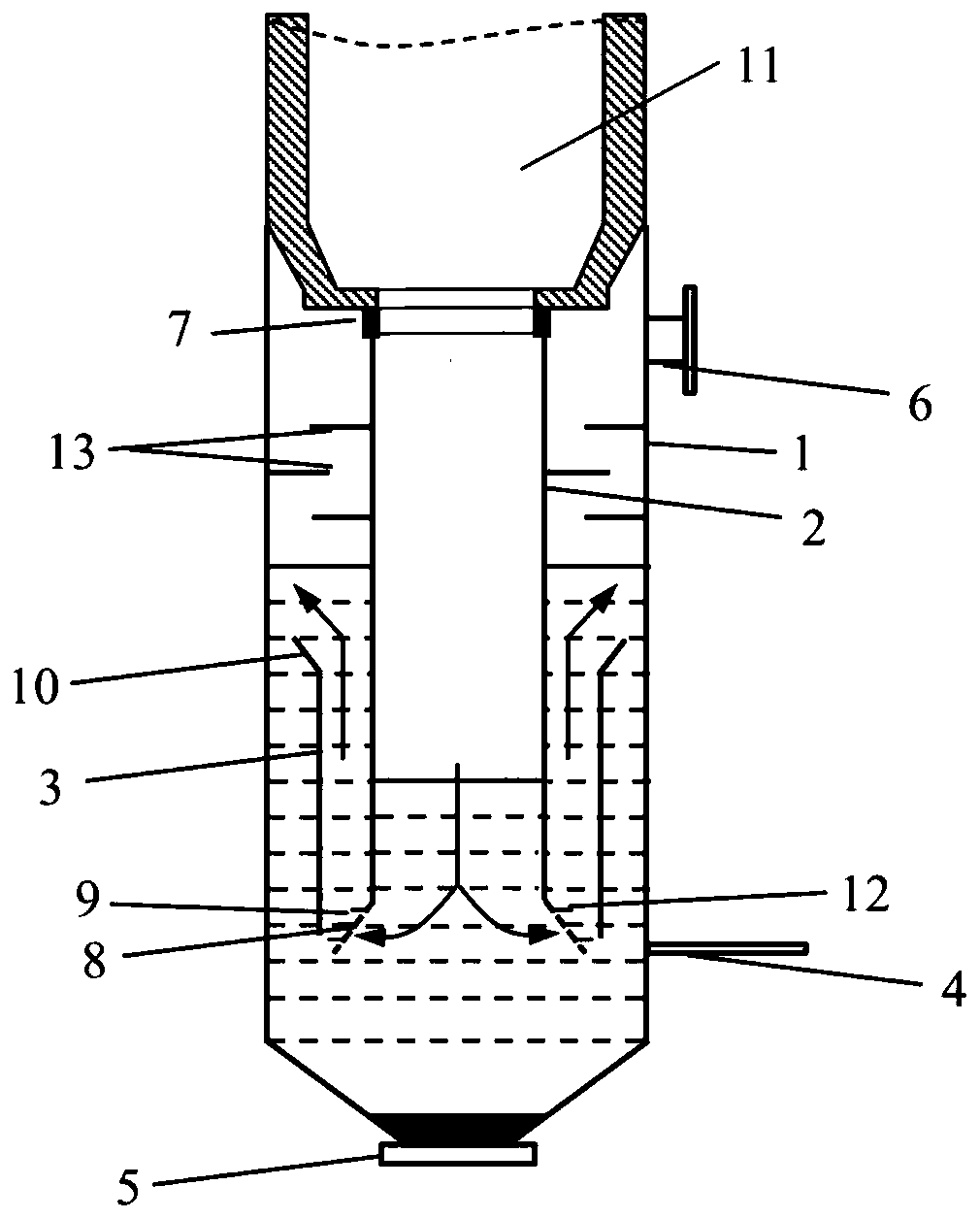

Gasification furnace chilling chamber containing flow-guiding cylinder and application method thereof

PendingCN110846083AIncreased phase boundary areaImproving the Effect of Humidification, Dust Removal, Ash Removal and CoolingGasification processes detailsGranular/pulverulent flues gasificationSyngasDust control

The invention provides a gasification furnace chilling chamber containing a flow-guiding cylinder and an application method thereof. The gasification furnace chilling chamber comprises a shell, wherein a downcomer is arranged in the shell; the outer side of the downcomer is sleeved by a coaxial flow-guiding cylinder; an annular gap is formed between the flow-guiding cylinder and the downcomer; oneend of the downcomer is connected with a gasification furnace; the other end of the downcomer is provided with a gas distribution device which is a conical section in butt joint with the outer edge of the downcomer; and the conical section is provided with gas holes. According to the invention, liquid circulation is formed through arrangement of the flow-guiding cylinder, so deposition of fine coal ash particles is prevented, and the problem of blockage caused by fine particles is effectively solved; meanwhile, through arrangement of the gas distribution device, small bubbles can be effectively formed; the phase boundary area of the bubbles is increased; the humidifying, dust-removing, ash-removing and cooling effects of a water bath are greatly improved; thus, the situation that synthesis gas carries excessive coal ash to enter a next working section is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Ozone oxidation reactor and using method thereof

PendingCN111217441ASmall pressure dropIncrease gas-liquid mass transfer areaWater/sewage treatment apparatusWater/sewage treatment by oxidationThermodynamicsPtru catalyst

The invention discloses an ozone oxidation reactor, which comprises a mixer, a gas phase balance pipe, a tower type reactor and an ultrafine bubble distributor at the lower portion in the tower type reactor, wherein the ultrafine bubble distributor comprises a gas cavity communicated with a gas inlet and a gas-liquid channel vertically arranged in the gas cavity, the gas-liquid channel is a pipeline penetrating through the gas cavity, gas holes communicated with the gas cavity are formed in the side wall of the pipeline, the tower type reactor comprises a gas outlet and a circulating liquid outlet at the upper portion, a liquid inlet is communicated with the bottom of the tower type reactor, the circulating liquid outlet penetrates through the wall of the tower type reactor and is communicated with the gas-liquid channel through a liquid circulating pipeline, a circulating pump and a mixer are arranged on the liquid circulating pipeline, and the inlet of the mixer is communicated withthe upper portion of the tower type reactor through the gas phase balance pipe. The ozone oxidation reactor disclosed by the invention has the advantages of good catalyst fluidization performance, small gas pressure drop, large gas-liquid mass transfer reaction area, almost 100% utilization of gas, high reaction speed and the like.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

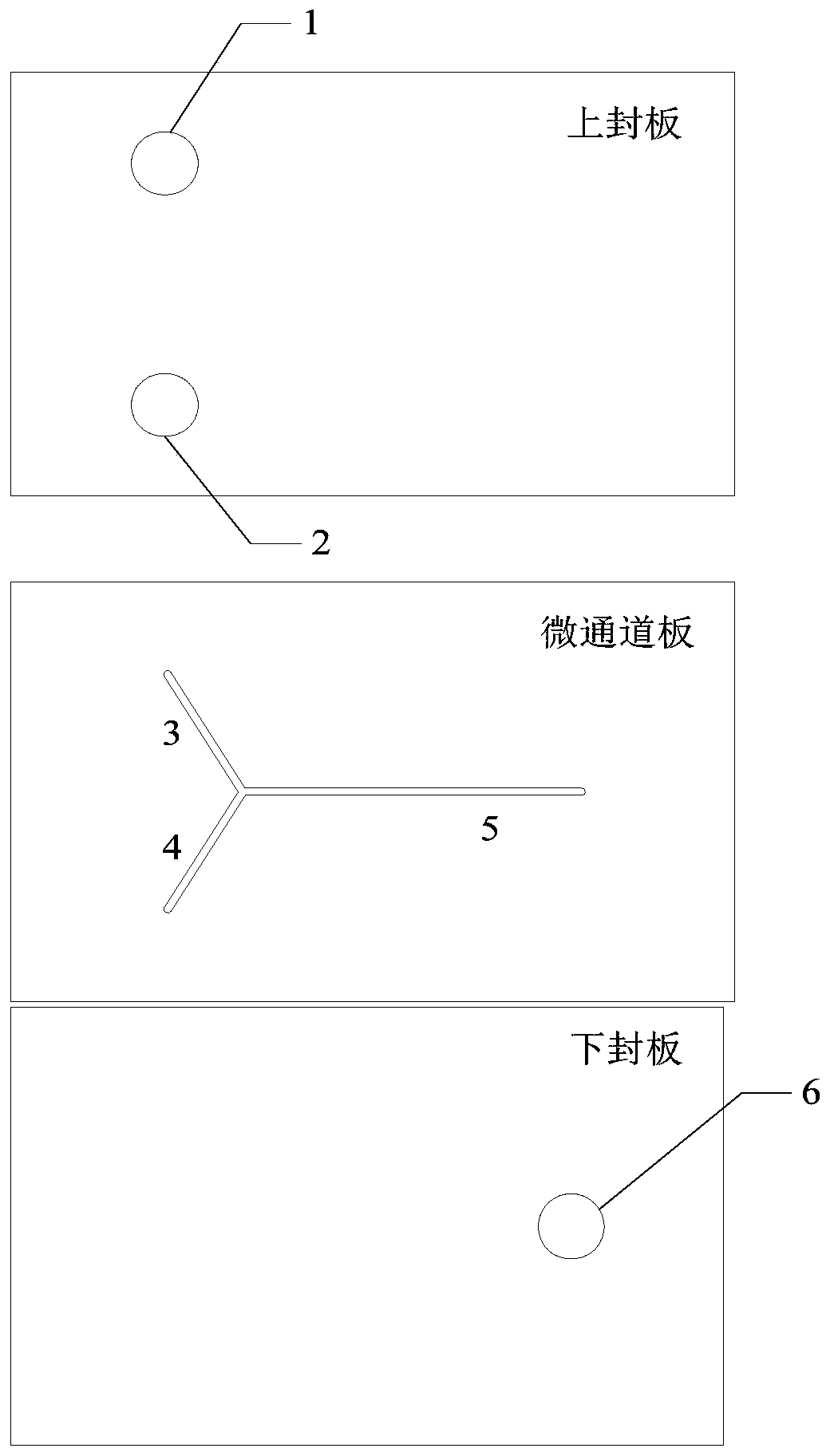

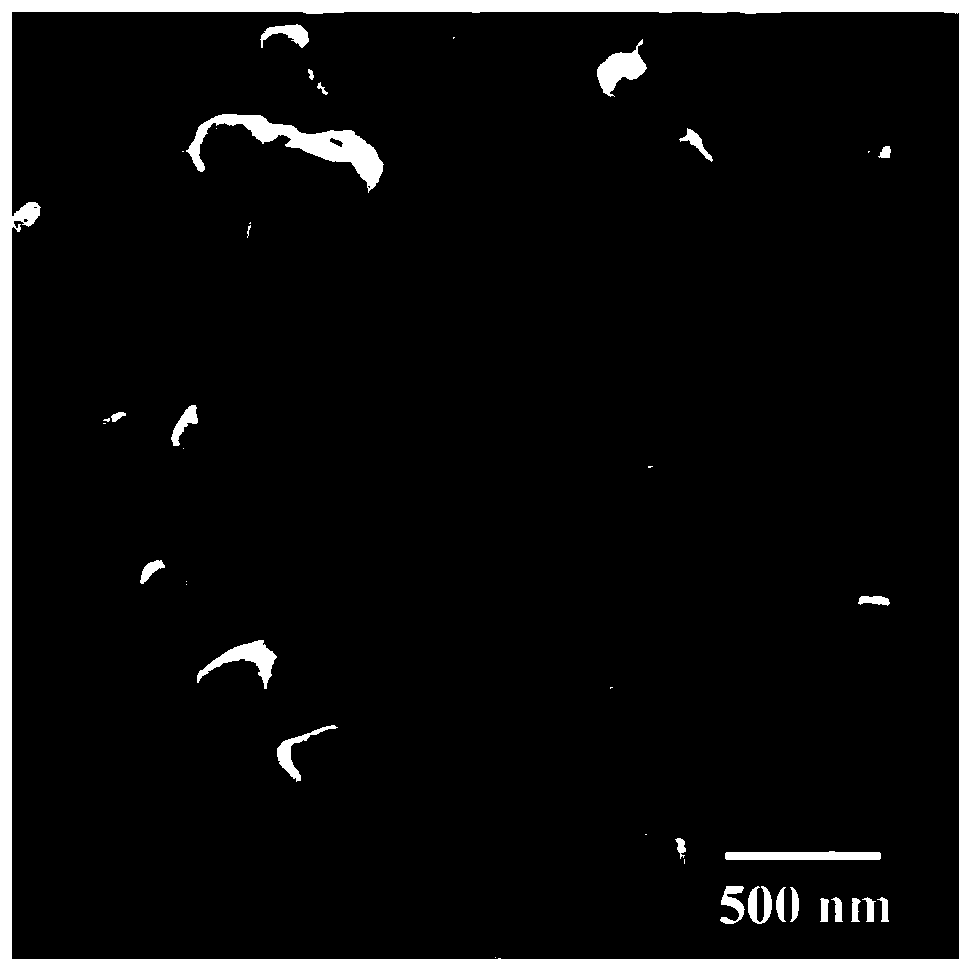

Preparation method of shape-controllable magnesium hydroxide with low specific surface area

The invention provides a method for adjusting and controlling magnesium hydroxide with the low specific surface area. The shape-controllable magnesium hydroxide with the low specific surface area is prepared through a method of combination of the precipitation process of a confined space and hydro-thermal treatment, wherein the specific surface area is equal to or smaller than 5 m<2> / g. The methodcomprises the specific processes: a magnesium chloride aqueous solution and a sodium hydroxide aqueous solution are prepared correspondingly and continuously introduced into a microreactor to be subject to a precipitation reaction, reaction slurry is subjected to hydro-thermal treatment twice after flowing out from the microreactor, after hydro-thermal treatment is completed, the slurry is centrifuged, washed and dried, and then the magnesium hydroxide with the low specific surface area is obtained. The shape of the magnesium hydroxide with the low specific surface area can be adjusted and controlled by changing the molar ratio of Mg2+ and OH-. The precipitation process is achieved in the microreactor, the reaction process is semicontinuous and easy to amplify, and thus an obtained product is low in specific surface area, controllable in shape and good in lot-to-lot repeatability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Micro-interface enhanced reaction system and method for preparing polypropylene

The invention provides a micro-interface enhanced reaction system for preparing polypropylene. The system is characterized by comprising a prepolymerization reactor and a polymerization reactor whichare connected in sequence, the prepolymerization reactor is provided with a prepolymerization micro-interface generator used for dispersing crushed materials into micro-bubbles, and the polymerizationreactor is provided with a micro-interface generator set used for dispersing the crushed materials into micro-bubbles; a polymerization reaction product outlet is formed in the bottom of the polymerization reactor and is connected with a flash tank for decomposing a catalyst in a polymer; a product outlet for discharging a polypropylene product is formed in the bottom of the flash tank. The micro-interface generator is arranged on the prepolymerization reactor, and meanwhile, the micro-interface generator unit is arranged on the polymerization reactor, so that the mass transfer area between agas-phase material and a liquid-phase material is increased, the reaction efficiency is improved, and the energy consumption is reduced; and moreover, the temperature and the pressure in the polymerization reactor are reduced, and the safety and the stability of the whole system are improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Preparation system and process of alpha-olefin-fluorostyrene polymer

ActiveCN112500513AFully contactedIncreased phase boundary areaPolymer scienceMass transfer resistance

The invention relates to a system and process for preparing an alpha-olefin-fluorostyrene polymer. The system comprises a monomer storage tank, a reaction unit, a micro-interface generator, a filter,a washing unit, a drying box and a heat exchanger. According to the invention, the alpha-olefin monomer is crushed to form micron-scale bubbles, the micron-scale bubble can be fully mixed with fluorostyrene and an additive to form a gas-liquid emulsion, and the alpha-olefin and fluorostyrene in the system can be in full contact with the additive by fully mixing the gas phase and the liquid phase,so that the polymerization efficiency of the system is improved; and meanwhile, the micron-scale bubbles and the materials are mixed to form the gas-liquid emulsion, and the raw materials are fully mixed, so that the phase interface area of a gas phase and a liquid phase is increased, the thickness of a liquid film is reduced, the mass transfer resistance is reduced, and the effect of enhancing mass transfer in a lower preset operation condition range is achieved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Caprolactam production wastewater treatment system and method

ActiveCN113087252AIncreased phase boundary areaImprove mass transfer effectWater contaminantsMultistage water/sewage treatmentPtru catalystThermodynamics

The invention provides a caprolactam production wastewater treatment system and method. The treatment system comprises a raw water tank, a wastewater heat exchanger, a wastewater heater and an oxidation reactor which are sequentially connected, wherein a material inlet, a material outlet, a heat source inlet and a heat source outlet are formed in the wastewater heat exchanger; oxidized water from the oxidation reactor enters the wastewater heat exchanger from the heat source inlet, the heat source outlet is connected with a finished product tank, the material inlet is connected with the raw water tank, the material outlet is connected with the wastewater heater, a micro-interface generation system is arranged in the oxidation reactor, and the micro-interface generation system is used for dispersing the crushed gas into bubbles. According to the treatment system, after the micro-interface generator is arranged, the contact of thereaction phase interface is improved, and a good wastewater treatment effect can be obtained without using a catalyst or by adding a small amount of the catalyst.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Black and odorous water body treatment system and method

InactiveCN112479349AReduce buoyancyIncreased phase boundary areaWater treatment parameter controlSpecific water treatment objectivesFluid phaseGas phase

The invention provides a black and odorous water body treatment system and a black and odorous water body treatment method applying the system. The black and odorous water body treatment system comprises a water inlet tank, an ozone generator, an oxidation tower, an MABR reactor, a water outlet tank and a tail gas destroying device, wherein a micro-interface generator is also arranged at the bottom of the oxidation tower and is used for crushing gas emitted by the ozone generator into bubbles. According to the invention, the micro-interface generator can smash bubbles into micron-sized bubbles, so that the phase interface area between a gas phase and a liquid phase is increased, and ozone gas can be better dissolved in black and odorous water to form a gas-liquid emulsion for increasing the reaction efficiency; and the ozone gas in the black and odorous water body is crushed into small bubbles, and the volume of the gas is reduced, so that the floating buoyancy of the bubbles is reduced, the retention time of the ozone gas in the black and odorous water body is prolonged, and the reaction efficiency is further improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Laterally-arranged micro-interface enhanced reaction device and method for hydrogenation reactions of residual oil

InactiveCN111495287AImprove solubilityIncreased phase boundary areaHydrocarbon oil crackingChemical/physical processesPtru catalystVapor–liquid separator

The invention discloses a laterally-arranged micro-interface enhanced reaction device and method for hydrogenation reactions of residual oil. The laterally-arranged micro-interface enhanced reaction device comprises a bubbling type reactor, a gas inlet device, a liquid inlet device, at least one bubble breaker, a gas-liquid separator and a circulating pump. Hydrogen and a residual oil raw materialwith a catalyst are preheated and then enter the bubble breakers to form a micron-sized bubble system; then the micron-sized bubble system enters the bubbling type reactor and flows from bottom to top, and a hydrogenation reaction is carried out under the action of the catalyst; and a product obtained after completion of the reaction enters the gas-liquid separator for separation, gas is discharged from a gas phase outlet, liquid with the catalyst enters the circulating pump from a liquid phase outlet and is subsequently conveyed, a part of the liquid is extracted as hydrogenated oil, and therest part of the liquid circularly enters the bubble breaker and is used for bubble breaking according to process requirements. The reaction device and method provided by the invention have the advantages of ultralow hydrogenation reaction pressure, small gas-liquid ratio, large gas-liquid mass transfer area, high reaction rate, low energy consumption, flexible process, high production safety andthe like.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Remote control system and method for black and odorous water

InactiveCN112479348AReduce buoyancyIncreased phase boundary areaWater treatment parameter controlGas treatmentFluid phaseControl system

The invention provides a black and odorous water remote control system and a black and odorous water remote control method applying the system. The black and odorous water remote control system comprises a water inlet tank, an ozone generator, an oxidation tower, an MABR reactor, a water outlet tank, a tail gas destroying device and an intelligent control unit, wherein a micro-interface generatoris also arranged at the bottom of the oxidation tower and is used for crushing gas emitted by the ozone generator into bubbles. According to the invention, the micro-interface generator can smash bubbles into micron-sized bubbles, so that the phase interface area between a gas phase and a liquid phase is increased, and ozone gas can be better dissolved with black and odorous water to form a gas-liquid emulsion for increasing the reaction efficiency; and the ozone gas in the black and odorous water is crushed into small bubbles, and the volume of the gas is reduced, so that the floating buoyancy of the bubbles is reduced, the retention time of the ozone gas in the black and odorous water is prolonged, and the reaction efficiency is further improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Intelligent reaction system and method for preparing N-methyl sodium taurate

InactiveCN112047861AImprove securityImprove stabilityProcess control/regulationTransportation and packagingSodium IsethionateSODIUM TAURATE

The invention provides an intelligent reaction system and method for preparing Nmethyl sodium taurate, and the system comprises an amination reaction kettle, an amination reaction product from the amination reaction kettle enters a first gas-liquid separation tank after reaction through a tubular reactor, and the side wall of the amination reaction kettle is provided with a raw material inlet, Theraw material inlet is provided with a microinterface generator used for dispersing crushed materials into microbubbles, the side wall of the microinterface generator is provided with a methylamine inlet, and the methylamine inlet is connected with a vaporizer so as to vaporize methylamine. According to the intelligent reaction system for preparing the N-methyl sodium taurate, the microinterface reactor is arranged at the raw material inlet of the amination reaction kettle, so that the problem of low reaction efficiency of the system due to the fact that methylamine and sodium isethionate cannot be fully mixed in the reaction kettle in the prior art is solved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Top-mounted gas-liquid enhanced emulsification fixed bed reaction device and method

InactiveCN111482136AImprove solubilityIncreased phase boundary areaMixing methodsTransportation and packagingPtru catalystVapor–liquid separator

The invention discloses a top-mounted gas-liquid enhanced emulsification fixed bed reaction device and method. The top-mounted gas-liquid enhanced emulsification fixed bed reaction device comprises afixed bed reactor, at least one bubble breaker, a gas-liquid separator, a feeding pump, a gas inlet device and a liquid inlet device. A gas raw material and a liquid raw material are preheated and then respectively enter the bubble breakers from a gas phase inlet and a liquid phase inlet, gas is broken into micron-sized bubbles, the micron-sized bubbles are mixed with liquid to form a gas-liquid emulsion, and the gas-liquid emulsion then enters the fixed bed reactor from top to bottom; the micron-sized bubbles have the characteristics of low speed and difficulty in coalescence and keep the original form when penetrating through a catalyst bed layer, so that a stable gas-liquid enhanced emulsification fixed bed reaction system is formed; and a product obtained after the reaction enters a gas-liquid separator from a second discharge port, gas-liquid two-phase separation is carried out, and gas and liquid are collected separately for subsequent treatment. The device and the method have the advantages of low operation pressure, large gas-liquid mass transfer phase interface area, high apparent reaction speed, high gas utilization rate, low investment, low energy consumption, flexible process and the like.

Owner:NANJING UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com