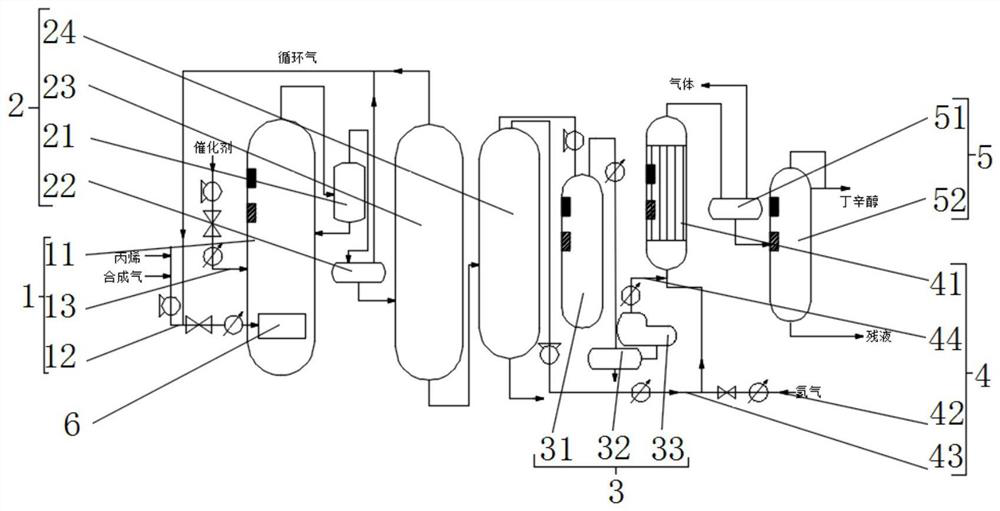

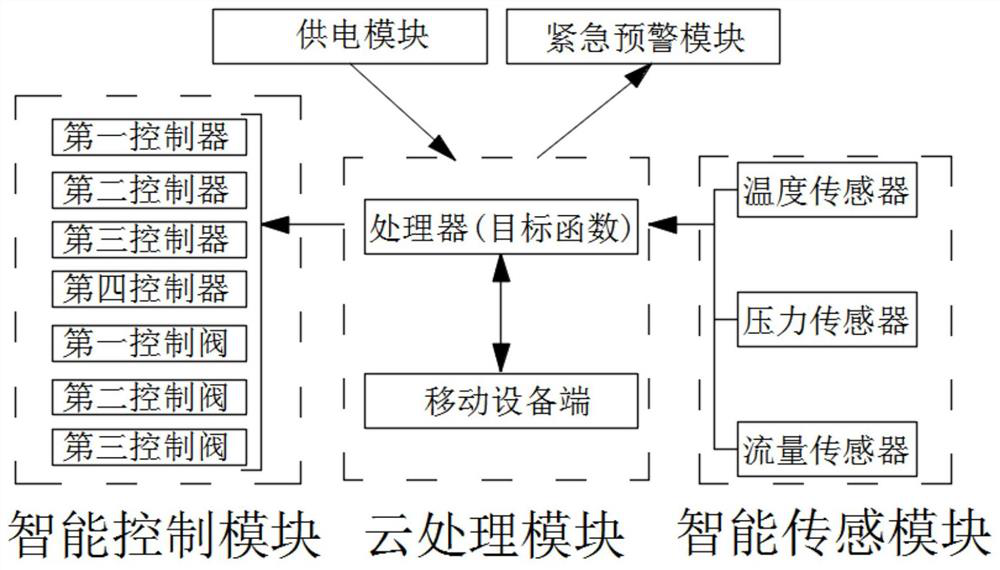

Intelligent control reaction system and process for preparing butyl octanol through carbonylation of propylene

An intelligent control, propylene carbonyl technology, applied in the preparation of carbon-based compounds, hydroxyl compounds, carbon monoxide reaction preparation, etc., can solve the problem of low system reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0134] Acrylic alcohol was prepared using the above system and process for propylene alcohol, wherein:

[0135] The catalyst in the process is a ruthenium catalyst triphenylphosphine solution;

[0136] The syngas consists of carbon monoxide, propane, hydrogen and methane;

[0137] The reaction temperature in the carbonyl synthesis reactor was 81 ° C, and the reaction pressure was 0.7 MPa;

[0138] The gas-liquid ratio in the micro-interface generator is 240: 1;

[0139] The feed molar ratio of propylene and syngas is 3: 2.

Embodiment 2

[0141] Acrylic alcohol was prepared using the above system and process for propylene alcohol, wherein:

[0142] The catalyst in the process is a ruthenium catalyst triphenylphosphine solution;

[0143] The syngas consists of carbon monoxide, propane, hydrogen and methane;

[0144] The reaction temperature in the carbonyl synthesis reactor was 83 ° C, and the reaction pressure was 0.8 MPa;

[0145] The gas-liquid ratio in the micro-interface generator is 270: 1;

[0146] The feed molar ratio of propylene and syngas is 2: 1.

Embodiment 3

[0148] Acrylic alcohol was prepared using the above system and process for propylene alcohol, wherein:

[0149] The catalyst in the process is a ruthenium catalyst triphenylphosphine solution;

[0150] The syngas consists of carbon monoxide, propane, hydrogen and methane;

[0151] The reaction temperature in the carbonyl synthesis reactor was 85 ° C, and the reaction pressure was 0.9 MPa;

[0152] The gas-liquid ratio in the micro-interface generator is 300: 1;

[0153] The molar ratio of propylene and synthetic gas is 5: 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com