Micro-interface enhanced reaction system and method for preparing polypropylene

A reaction system and technology of polypropylene, which is applied in the field of micro-interface strengthening reaction system for preparing polypropylene, can solve the problems of low gas utilization rate, high temperature and pressure, and difficult to obtain a breakthrough improvement in reaction performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

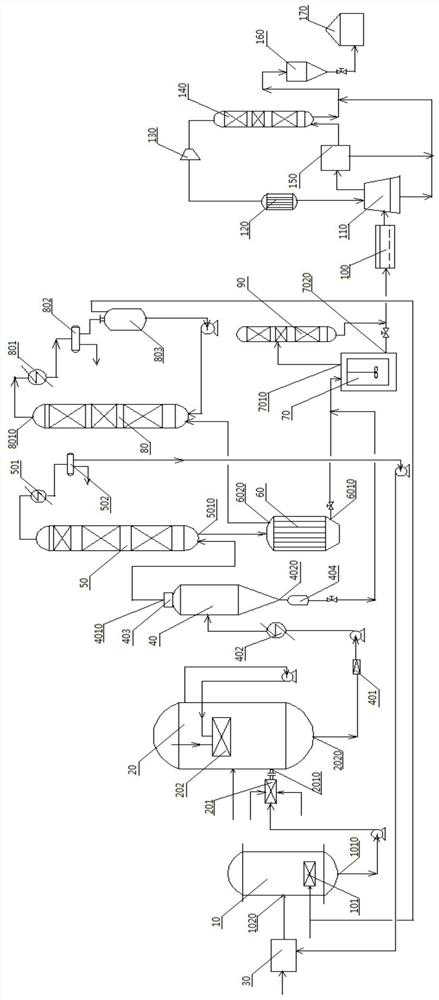

[0076] refer to figure 1 Shown is the enhanced reaction system for preparing polypropylene of the present invention, which includes a pre-polymerization reactor 10 and a polymerization reactor 20, and the inside of the pre-polymerization reactor 10 is provided with pre-polymerization micro-bubbles for dispersing broken materials into micro-bubbles. Interface generator 101, the propylene delivery pipeline passes through the wall surface of described prepolymerization reactor 10 and connects described prepolymerization microinterface generator 101, in order to pass propylene into the inside of described prepolymerization microinterface generator; The reactor 20 is provided with a micro-interface generating unit for dispersing the crushed material into micro-bubbles.

[0077] It should be emphasized that the micro-interface generator set includes a first micro-interface generator 201 and a second micro-interface generator 202, the first micro-interface generator 201 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com