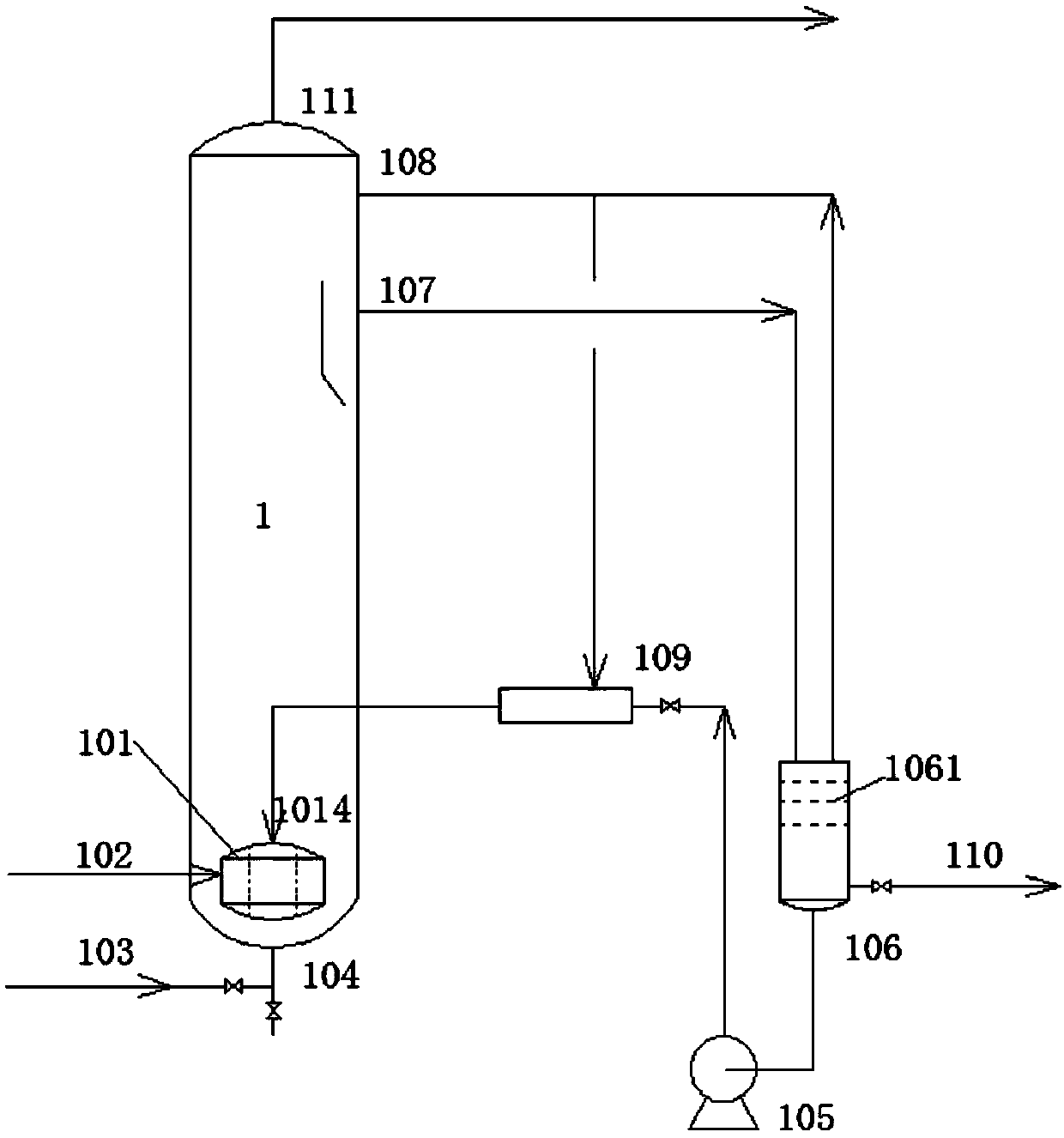

Ozone oxidation reactor and using method thereof

An ozone oxidation and reactor technology, which is applied in the field of chemical engineering, can solve the problems of limited efficiency and high power consumption of gas-water distribution devices, and achieve the effects of improving ozone utilization, high reaction speed, and improving gas-liquid mass transfer speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The biochemical effluent of a chemical plant uses the above-mentioned reactor for advanced treatment in a small test. The treatment capacity is 24L / h, the temperature is 25°C, and the COD of raw water is 100-150 mg / L.

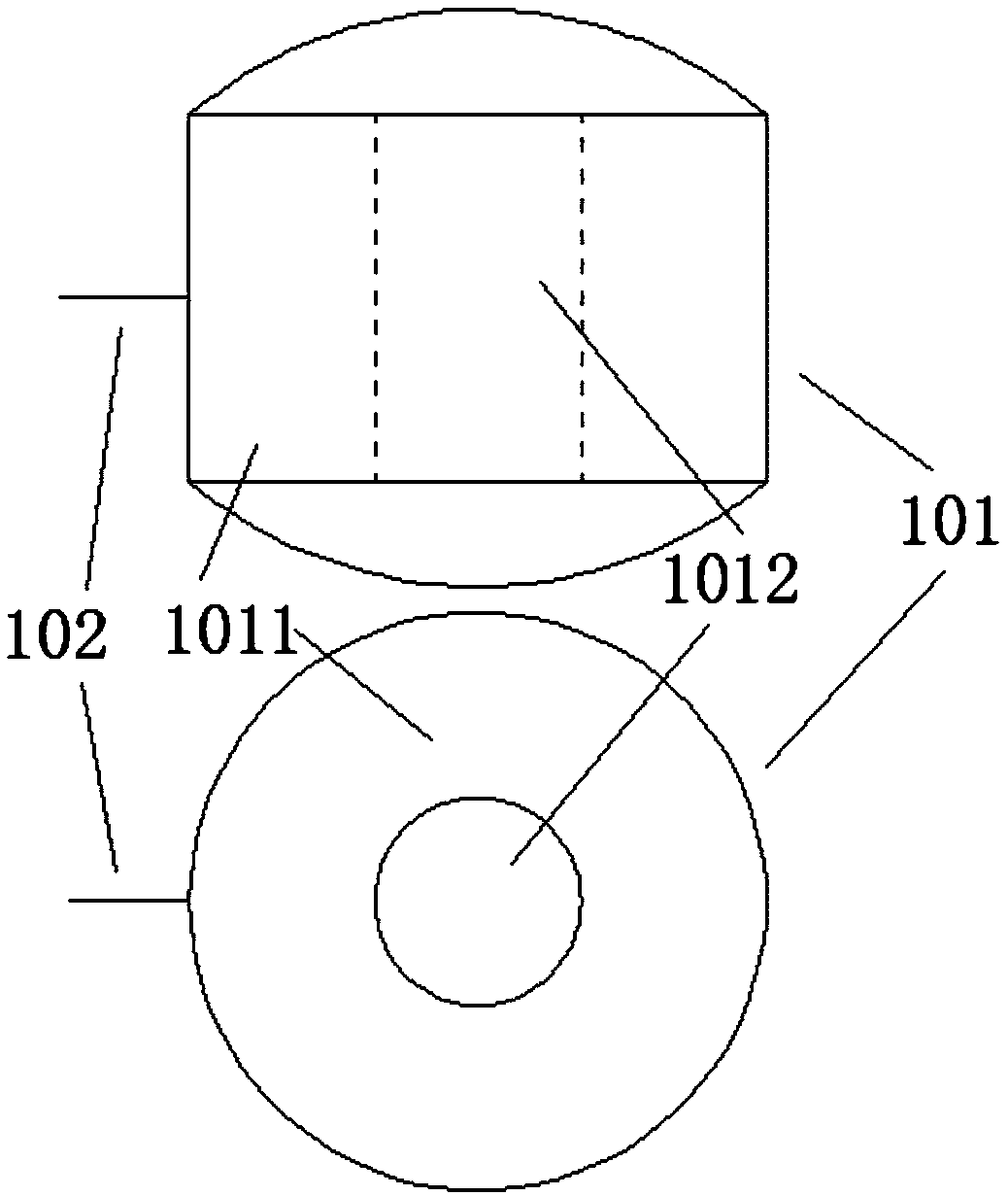

[0050] Ozone enters the gas cavity 1011 of the ultra-fine bubble distributor 101 through the gas inlet 103, and then enters the gas-liquid channel 1012 through the gas hole, and is transported by the high-speed liquid flow (flow rate greater than or equal to 1m) from the mixer 109 / s) cutting and dispersing into ultrafine bubbles, thereby forming an ultrafine bubble flow, the ultrafine bubble flow enters the bottom of the tower reactor 1 downward along the gas-liquid channel 1012, and is transported through the liquid inlet 103 The waste water and the catalyst at the bottom of the tower reactor 1 flow upward together. After the reaction, gas-liquid separation is performed at the upper part of the tower reactor 1. The gas is discharged through the gas outl...

Embodiment 2

[0053] The effluent of a coking wastewater mixed sedimentation tank is treated by the above-mentioned reactor, the treatment capacity is 20L / h, the temperature is 25°C, and the raw water COD is 136 mg / L. Ozone oxidation treatment is used in the ultra-fine bubble reaction, the residence time is 30min, the ozone concentration at the outlet of the ozone generator is about 100mg / L, the gas flow rate is 20L / h, and the COD of the effluent is less than 80mg / L.

Embodiment 3

[0055] The biochemical effluent of pesticide wastewater is treated with the above-mentioned reactor for advanced treatment small-scale test, the treatment capacity is 30L / h, and the COD of raw water is 200-300 mg / L. Ozone oxidation treatment is used in the ultra-fine bubble reaction, the residence time is 30min, the ozone concentration at the outlet of the ozone generator is about 100mg / L, the gas flow rate is 30L / h, and the COD of the effluent is less than 60mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com