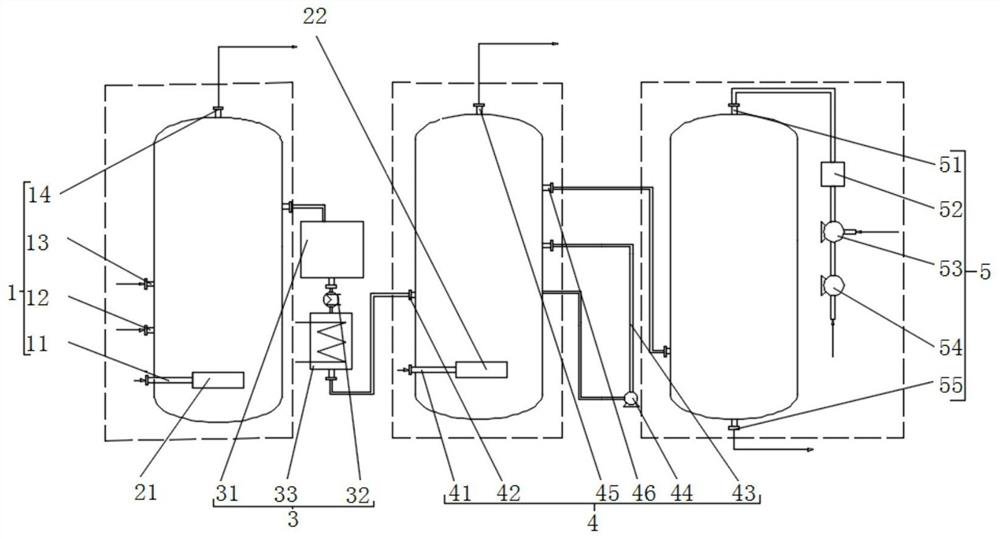

System and process for preparing hydrogen peroxide based on anthraquinone method

A technology of hydrogen peroxide and anthraquinone method, applied in peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, separation method, chemical instrument and method, etc., can solve the problem of low system reaction efficiency , to achieve the effect of ensuring the reaction rate, improving the hydrogenation efficiency and reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Use above-mentioned system and process to carry out anthraquinone method to prepare hydrogen peroxide, wherein:

[0089] In the process, the reaction temperature in the hydrogenation tower is 38°C, the reaction pressure is 0.05MPa, the anthraquinone content is 220g / L, and the flow rate of the working fluid containing anthraquinone derivatives is 130h -1 , the gas-liquid ratio in the first micro-interface generator is 300:1.

[0090] In the process, the reaction temperature in the oxidation tower is 35°C, the reaction pressure is 0.10MPa, and the flow rate of the hydrogenation solution containing 2-ethylhydroanthraquinone is 140h -1 , the gas-liquid ratio in the second micro-interface generator is 400:1.

[0091] After testing, after using the system and process, the hydrogenation efficiency is 14.2g / L, the oxidation efficiency is 13.9g / L, and the conversion rate of oxidation reaction is 97.9%.

Embodiment 2

[0093] Use above-mentioned system and process to carry out anthraquinone method to prepare hydrogen peroxide, wherein:

[0094] In the process, the reaction temperature in the hydrogenation tower is 39°C, the reaction pressure is 0.15MPa, the anthraquinone content is 235g / L, and the flow rate of the working fluid containing anthraquinone derivatives is 135h -1 , the gas-liquid ratio in the first micro-interface generator is 350:1.

[0095] In the process, the reaction temperature in the oxidation tower is 37°C, the reaction pressure is 0.13MPa, and the flow rate of the hydrogenation solution containing 2-ethylhydroanthraquinone is 145h -1 , the gas-liquid ratio in the second micro-interface generator is 420:1.

[0096] After testing, after using the system and process, the hydrogenation efficiency is 14.6g / L, the oxidation efficiency is 14.3g / L, and the conversion rate of the oxidation reaction is 97.9%.

Embodiment 3

[0098] Use above-mentioned system and process to carry out anthraquinone method to prepare hydrogen peroxide, wherein:

[0099] In the process, the reaction temperature in the hydrogenation tower is 42°C, the reaction pressure is 0.30MPa, the anthraquinone content is 245g / L, and the flow rate of the working fluid containing anthraquinone derivatives is 147h -1 , the gas-liquid ratio in the first micro-interface generator is 400:1.

[0100]In the process, the reaction temperature in the oxidation tower is 40°C, the reaction pressure is 0.15MPa, and the flow rate of the hydrogenation solution containing 2-ethylhydroanthraquinone is 152h -1 , the gas-liquid ratio in the second micro-interface generator is 450:1.

[0101] After testing, after using the system and process, the hydrogenation efficiency is 14.7g / L, the oxidation efficiency is 14.4g / L, and the conversion rate of the oxidation reaction is 98.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com