Patents

Literature

126 results about "SODIUM TAURATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

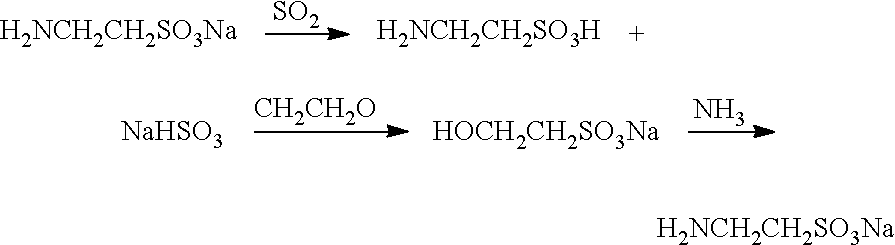

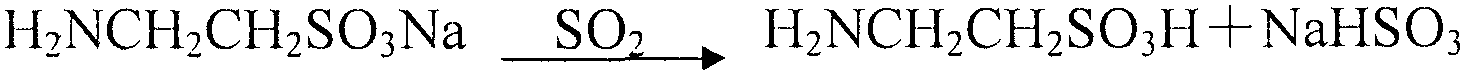

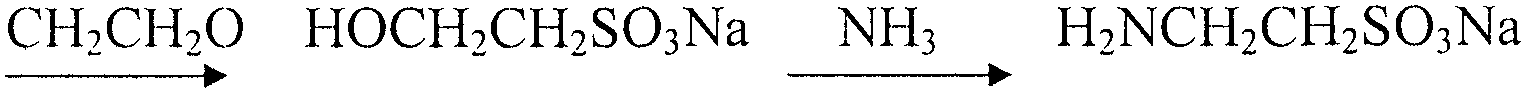

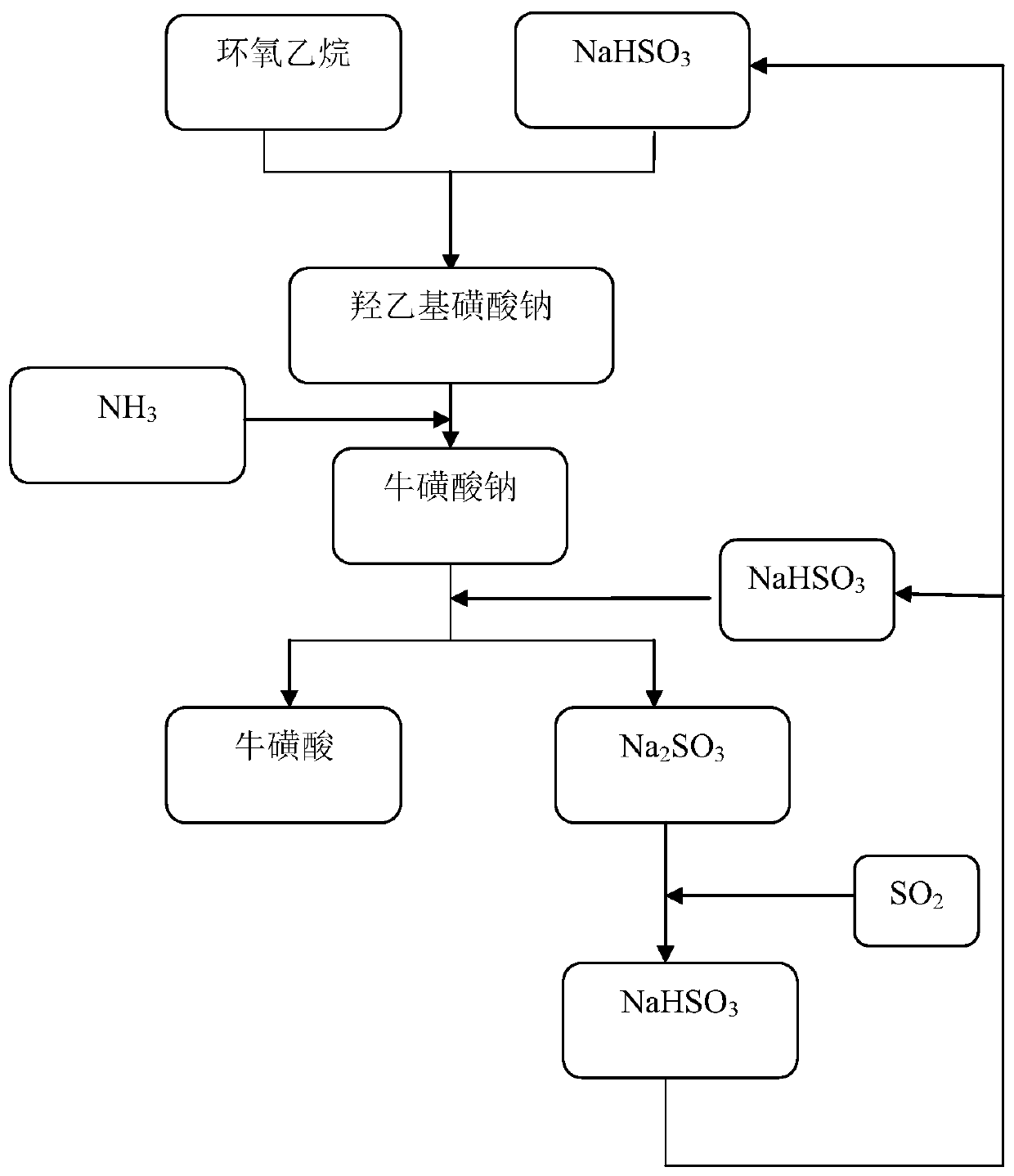

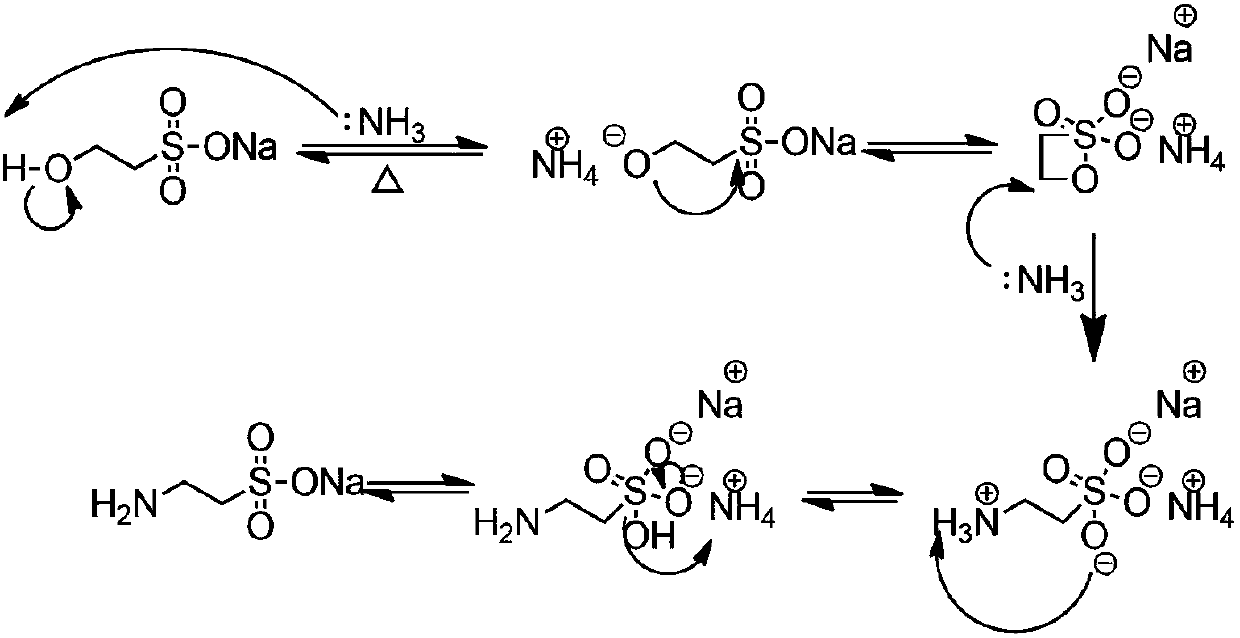

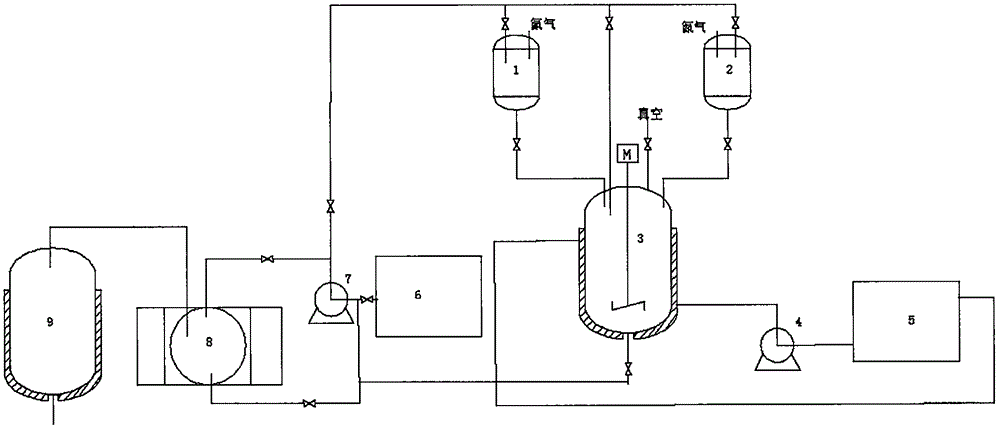

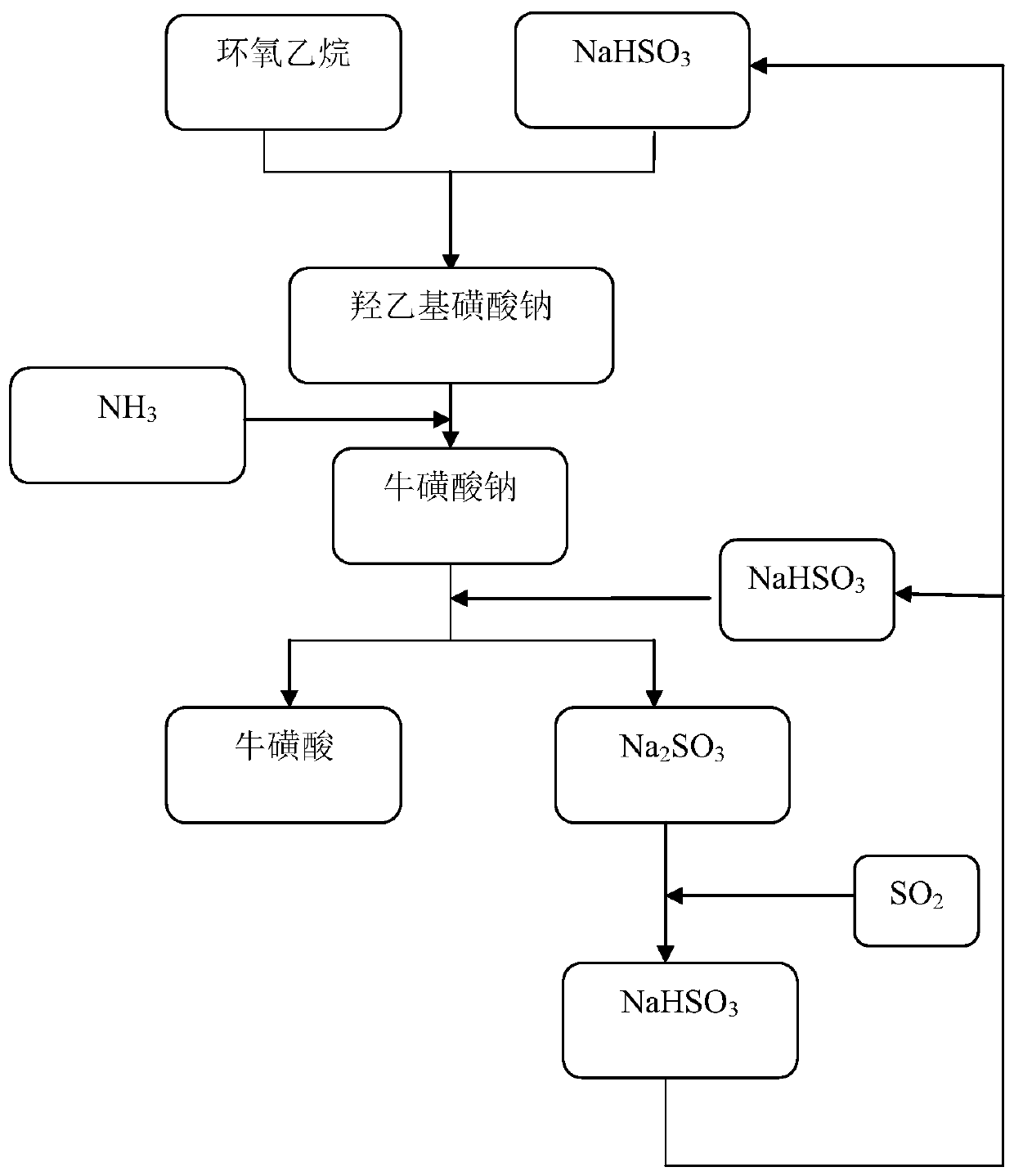

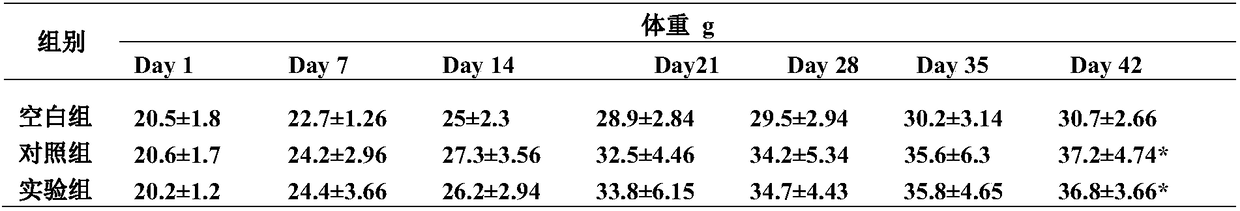

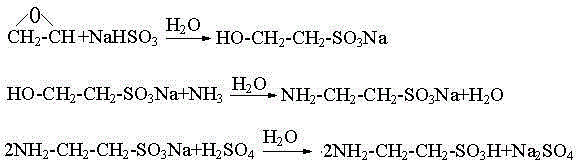

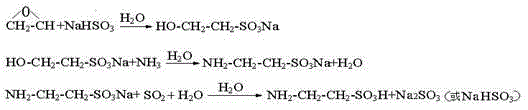

Synthesis of taurine

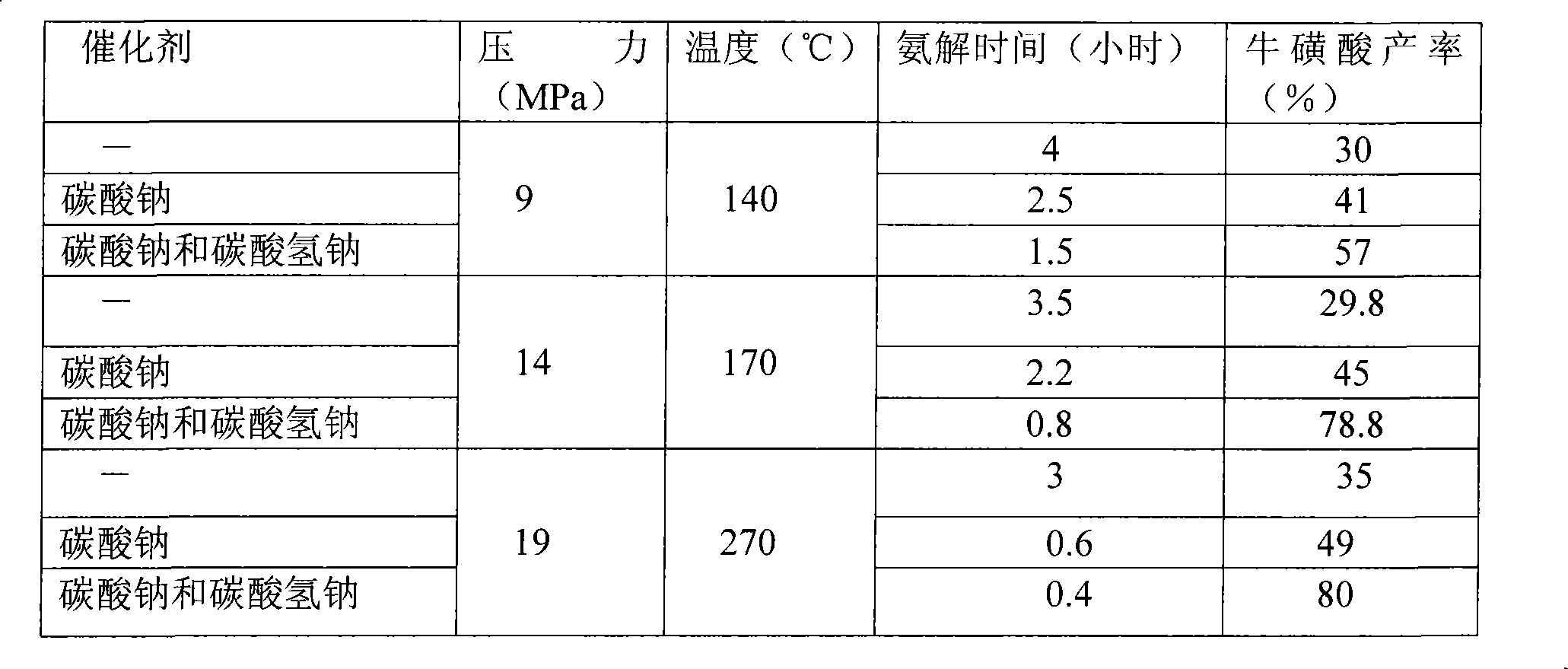

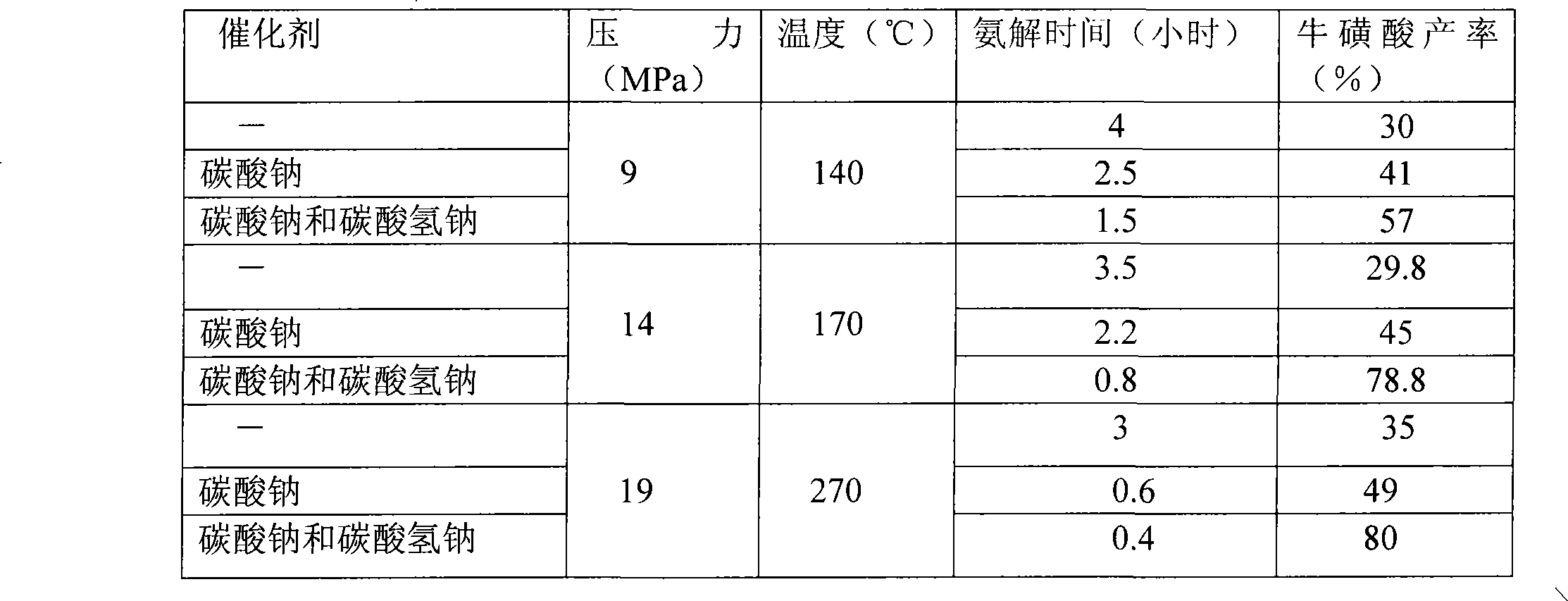

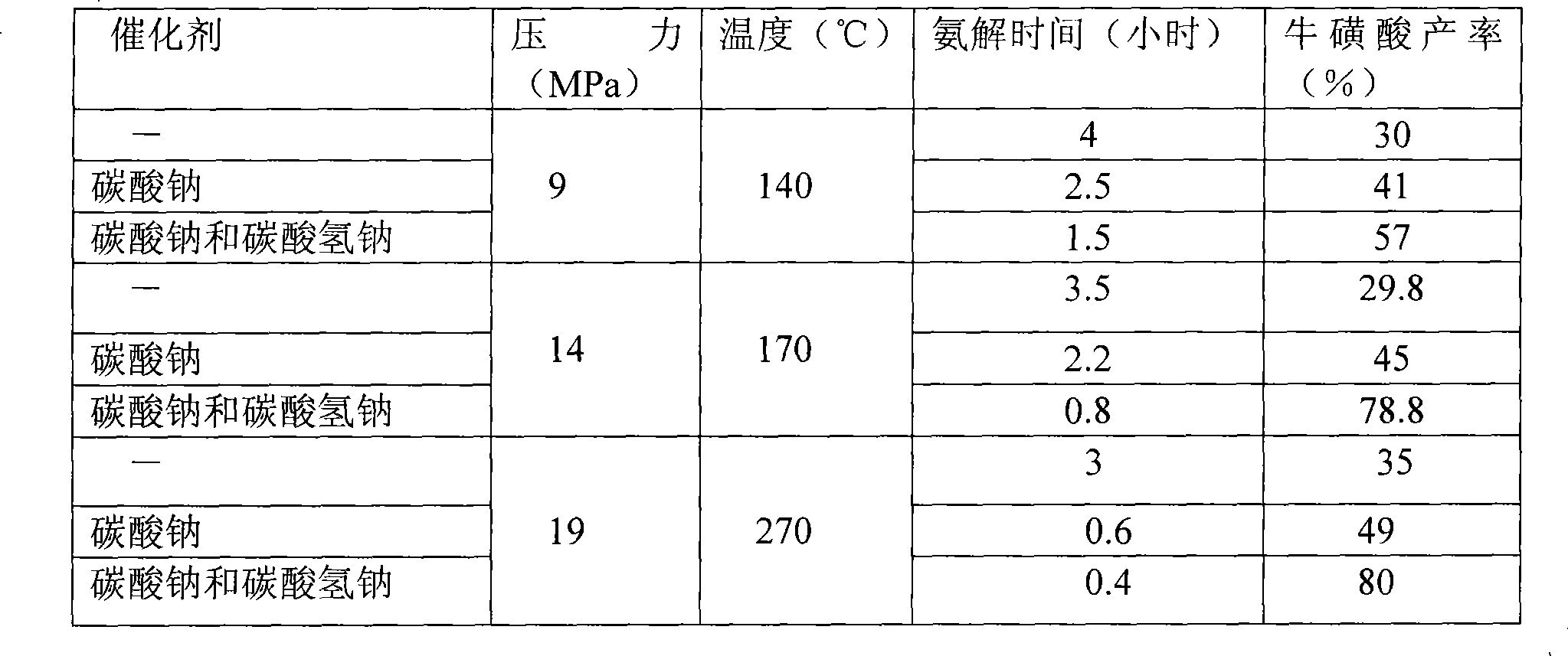

The invention relates to a method for synthesizing taurine, comprising the following steps: (1) according to the amount ratio of materials of 1:1 to 1:1.2, epoxy ethane and sodium bisulfite are subjected to addition reaction under 0.05 to 0.1MPa, with pH value of 6.5 to 7.5 and at a temperature between 75 and 85 DEG C to form hydroxyethyl sodium sulfonate; (2) the hydroxyethyl sodium sulfonate and liquid ammonia are subjected to ammonolysis reaction under 14 to 21MPa and at a temperature between 160 and 280 DEG C to generate sodium taurate, and the mass concentration of ammonia in the reaction liquid is 20 to 30 percent; and (3) neutralization: namely, the sodium taurate is neutralized by sulphuric acid to generate the taurine. The method for synthesizing the taurine has the advantages of short time, high yield and lower cost, and is easy for industrialized production.

Owner:王代龙 +1

Method for preparing taurine

The invention relates to a method for preparing taurine, comprising the following steps: epoxy ethane and sodium bisulfite are reacted under 0.05 to 0.1MPa, with pH value of 6.5 to 7.5 and at a temperature between 75 and 85 DEG C to form hydroxyethyl sodium sulfonate; the hydroxyethyl sodium sulfonate and liquid ammonia are subjected to ammonolysis reaction at under 14 to 21MPa and at a temperature between 160 and 280 DEG C to form ammonolysis solution containing sodium taurate; and the ammonolysis solution is evaporated to remove ammonia, neutralized by sulphuric acid, concentrated, crystallized, separated, pre-dried in a boiling drying device or a vibration fluidization drying device, and then added into a microwave drying device to be dried and sterilized to obtain the taurine. The method for synthesizing the taurine has the advantages of short time, high yield and lower cost, and is easy for industrialized production. The water content of a taurine wet product can be reduced to below 0.30 percent through combined application of pre-drying of the boiling drying device or the vibration fluidization drying device and microwave drying, and simultaneously the device has the function of sterilizing.

Owner:王代龙 +1

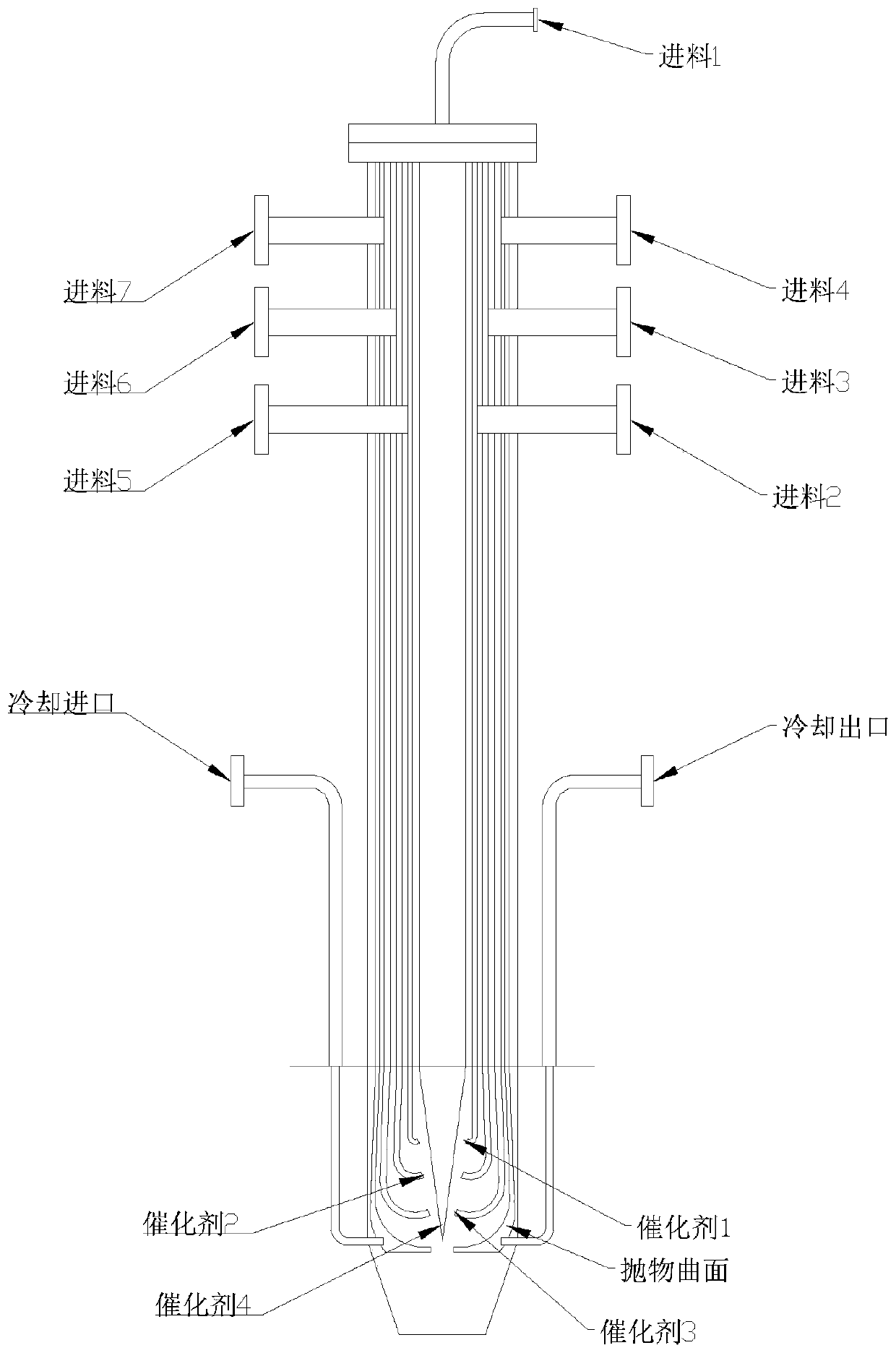

Method of preparing taurine

The invention relates to method for preparing taurine, comprising the following steps: (1) reacting epoxy ethane with sodium sulfite under 0.05 to 0.1MPa, with pH value of 6.5 to 7.5 and at temperature between 75 and 85 DEG C to obtain hydroxyethyl sodium sulfonate; (2) carrying out ammonolysis reaction on the hydroxyethyl sodium sulfonate and liquid ammonia under 14 to 21MPa and at temperature between 160 and 280 DEG C to obtain ammonolysis solution containing sodium taurate; (3) introducing the ammonolysis solution into a single flash evaporator for primary flash evaporating at a temperature between 160 and 200 DEG C and under 1.3 to 2.0MPa; introducing the flash evaporated liquid into a secondary flash evaporating and falling film evaporator, using the primary flash vapor as a heating medium to carry out flash evaporating and falling film evaporating on the primary flash evaporated liquid in the secondary flash evaporating and falling film evaporator at a temperature between 110 and 140 DEG C and at 0.1 to 0.6MPa; evaporating and concentrating the flash evaporated liquid subjected to secondary flash evaporating and falling film evaporating with flash vapor and steam as heating media in a multi-effect flash evaporating and falling film evaporator; and (4) neutralizing the sodium taurate by sulphuric acid to obtain the taurine. The method for preparing the taurine has the advantages of short time, high yield and low cost, and is easy for industrialized production. In addition, by primary flash evaporating and secondary flash evaporating processes, almost all the ammonia and 40% to 60% of water in the flash evaporated liquid can be removed, thus having double effects of removing ammonia and condensing.

Owner:王代龙 +1

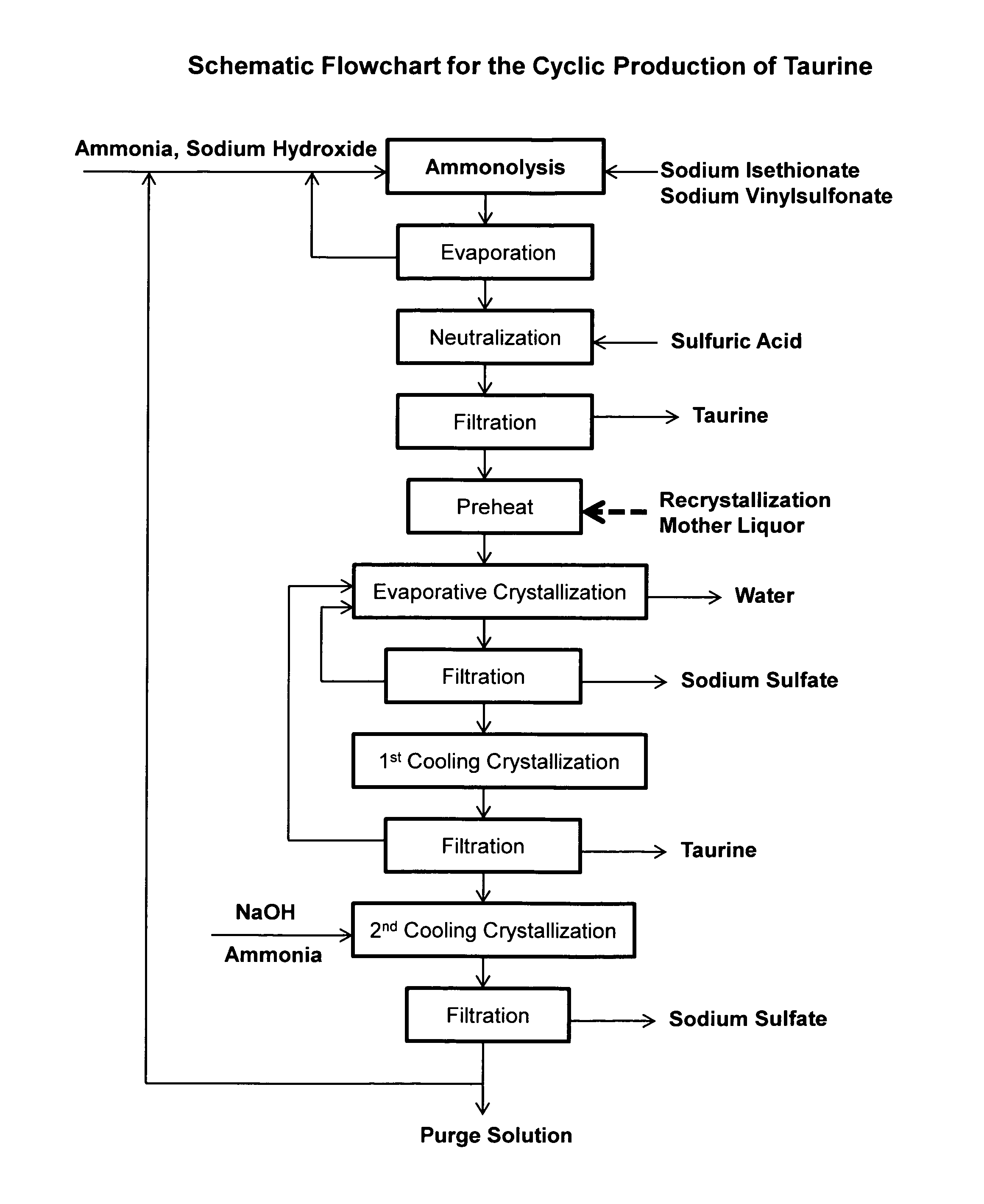

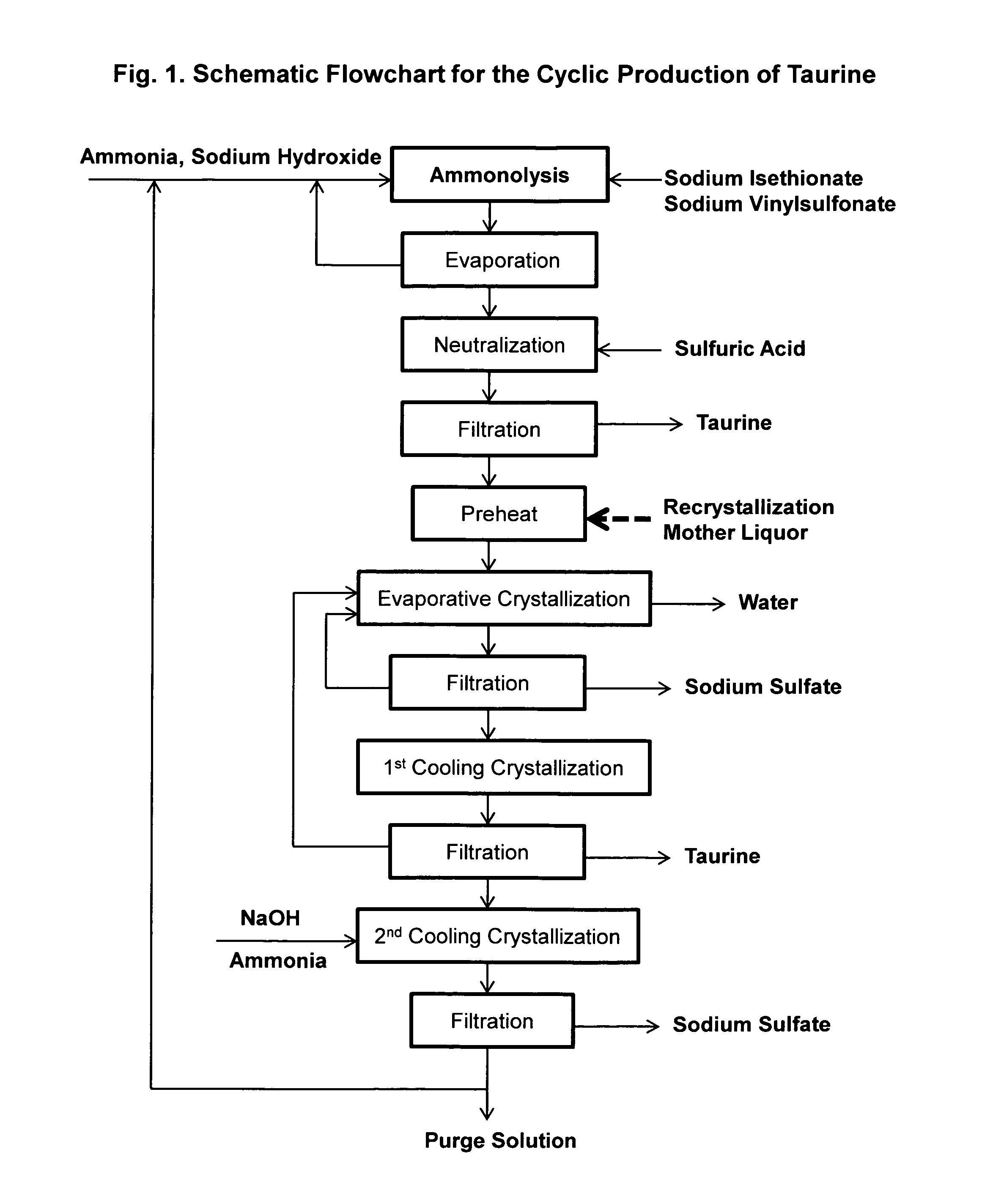

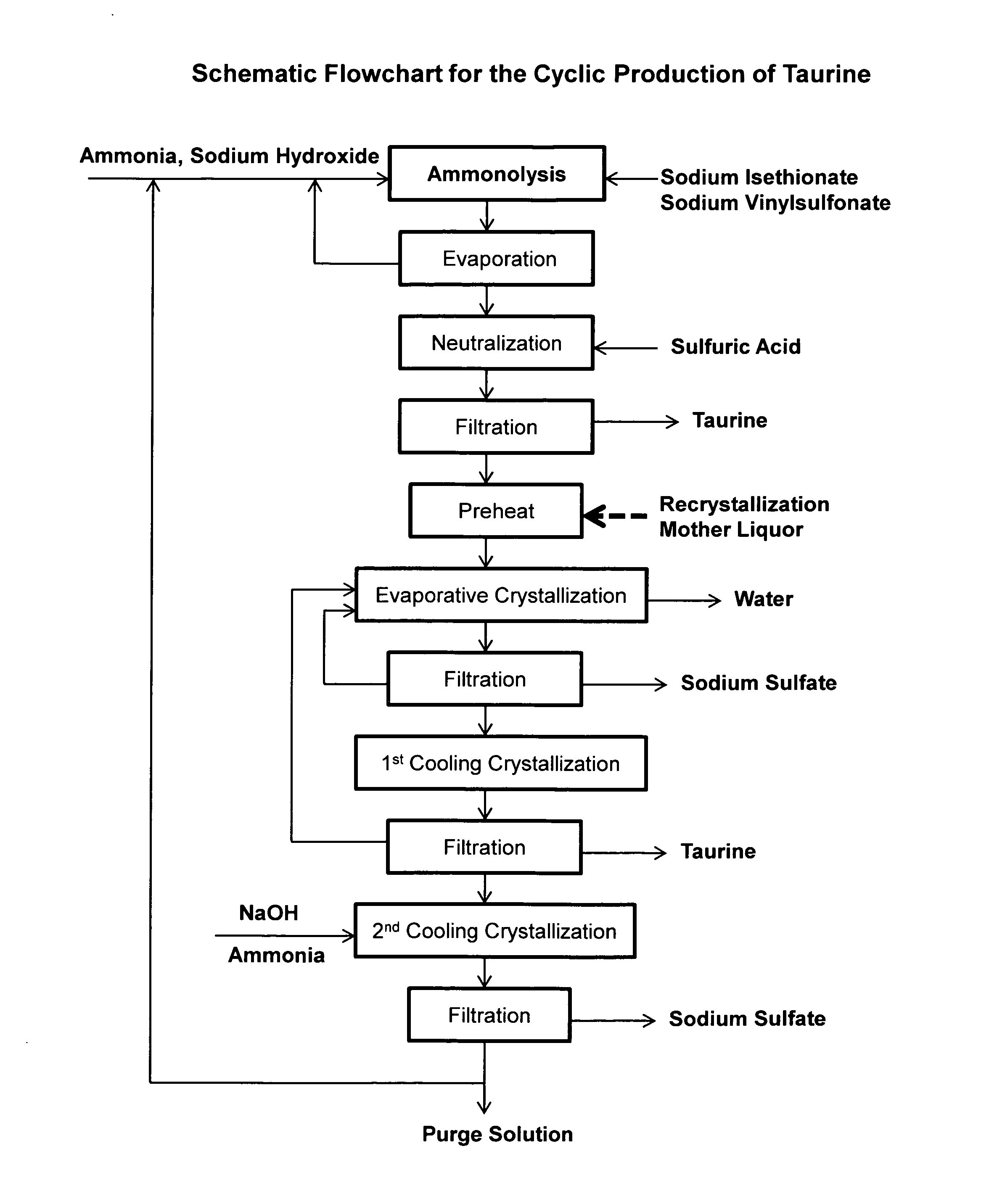

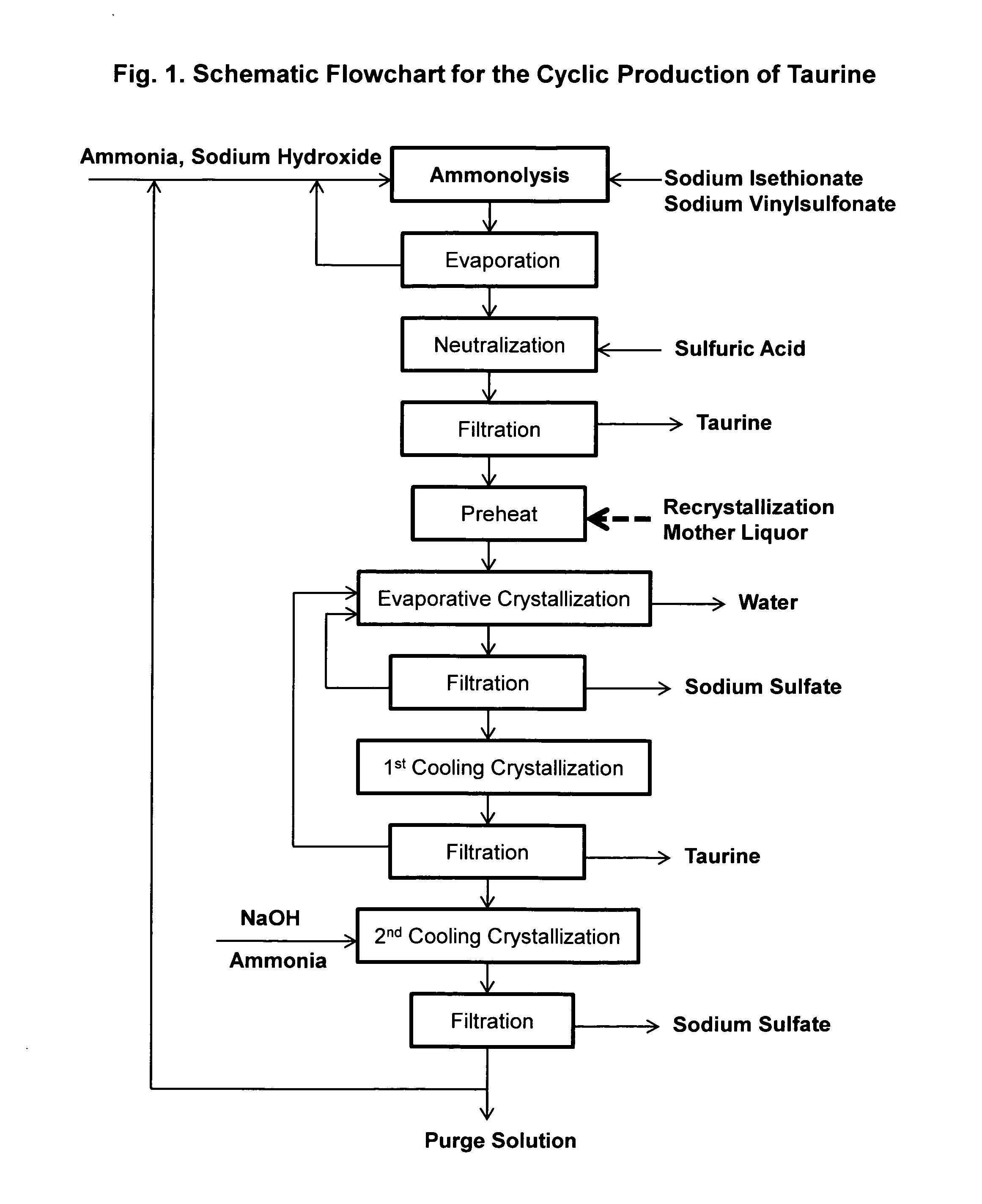

Cyclic process for the production of taurine from alkali isethionate

ActiveUS9428451B2Facilitate cooling crystallizationOrganic compound preparationSulfonic acids salts preparationCyclic processTaurine

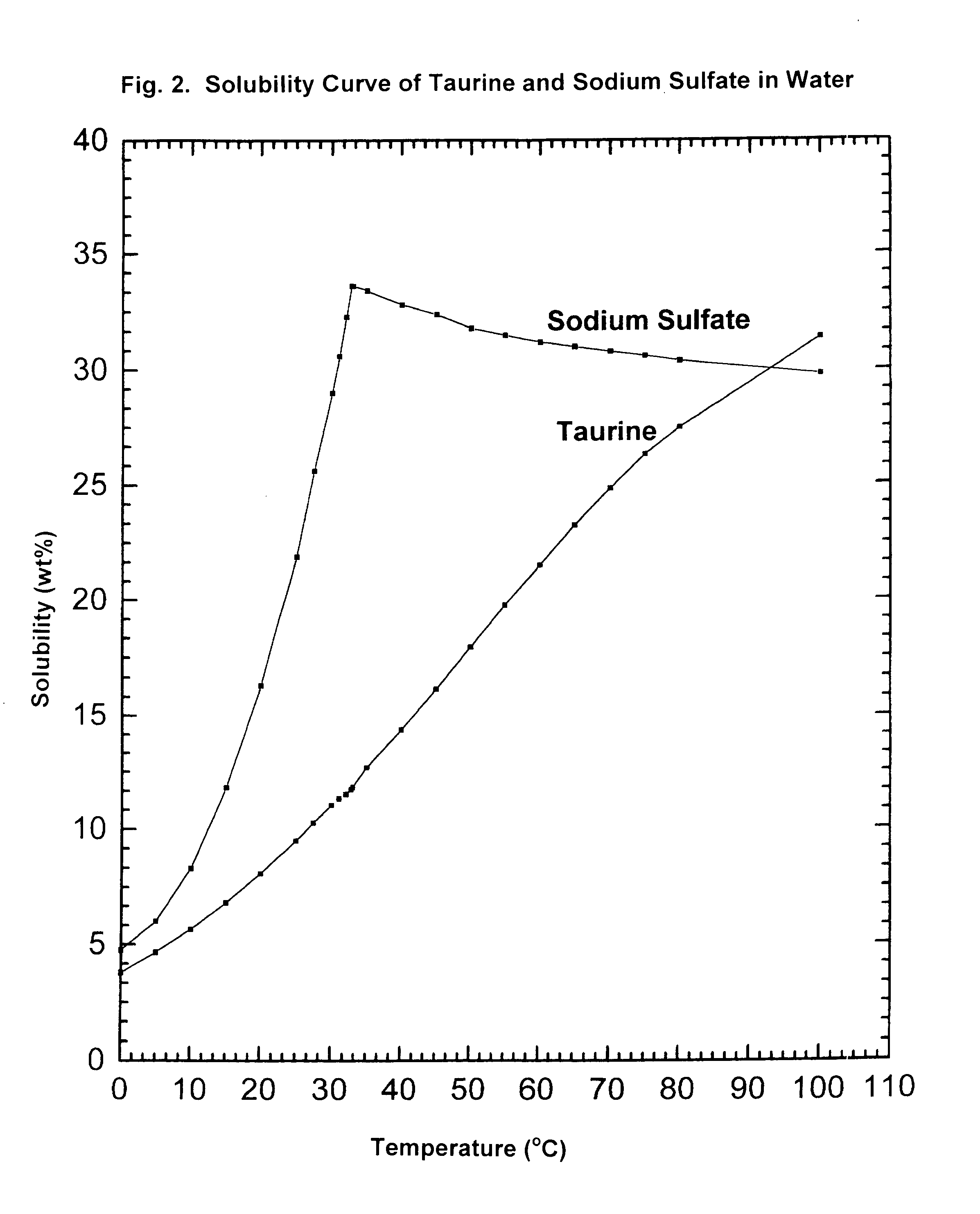

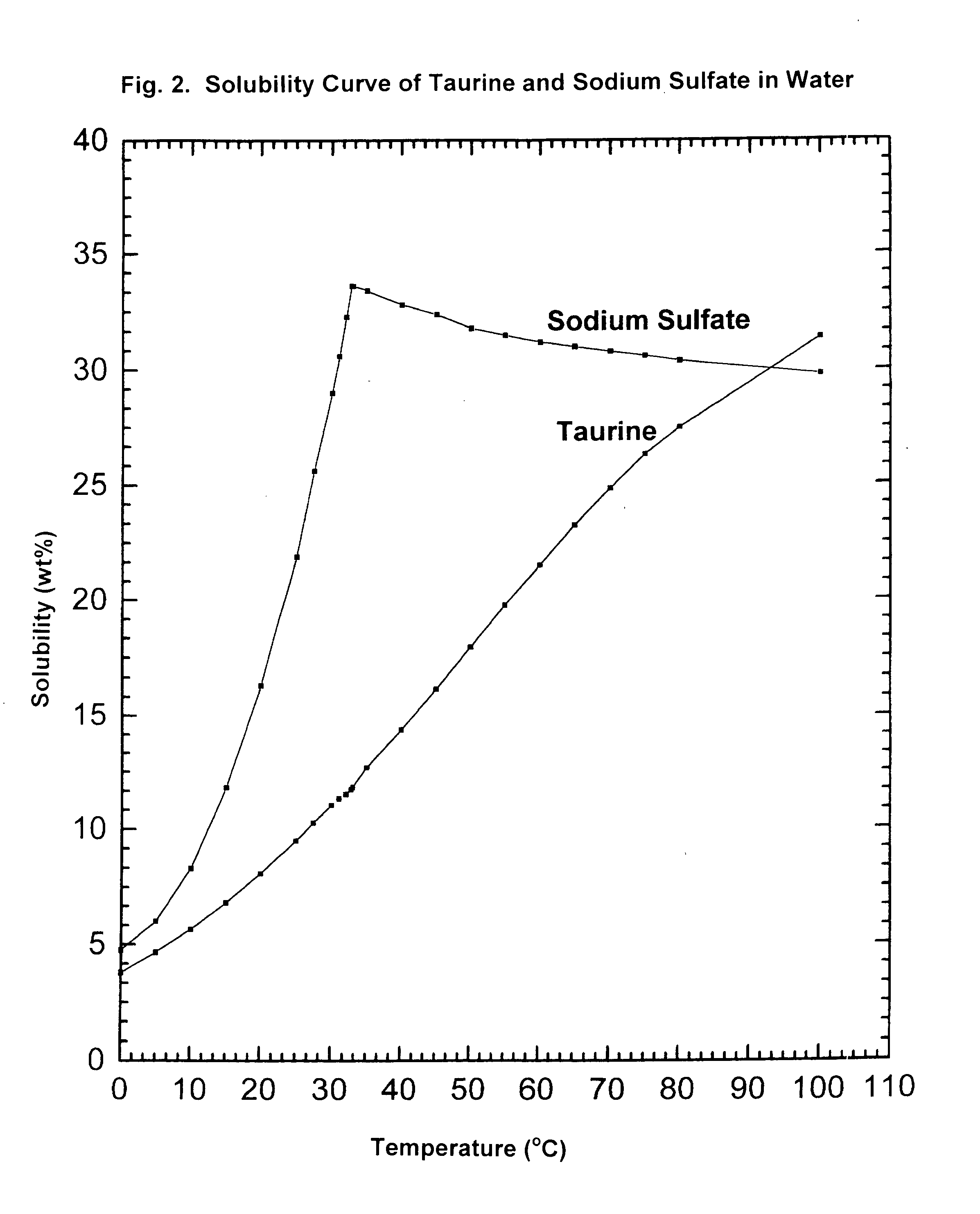

A cyclic process is disclosed for the production of taurine from alkali isethionate in a high overall yield by continuously converting the byproducts of the ammonolysis reaction, sodium ditaurinate and sodium tritaurinate, to sodium taurinate. Sodium sulfate and residual taurine in the crystallization mother liquor are efficiently separated by converting taurine into a highly soluble form of sodium taurinate or ammonium taurinate while selectively crystallizing sodium sulfate.

Owner:VITAWORKS IP LLC

Cyclic process for the production of taurine from alkali isethionate and alkali vinyl sulfonate

ActiveUS20150299114A1Facilitate cooling crystallizationOrganic compound preparationSulfonic acids salts preparationCyclic processSulfonate

The present invention discloses a cyclic process for the production of taurine from alkali isethionate and alkali vinyl sulfonate in a high overall yield of greater than 95% by continuously converting the byproducts of the ammonolysis reaction, sodium ditaurinate and sodium tritaurinate, to sodium taurinate. Sodium sulfate and residual taurine in the crystallization mother liquor are efficiently separated by converting taurine into a highly soluble form of sodium taurinate or ammonium taurinate while selectively crystallizing sodium sulfate.

Owner:VITAWORKS IP LLC

Process for producing taurine

InactiveUS20140121405A1Easy to produceIncrease profitOrganic compound preparationSulfonic acids salts preparationEthylene oxideSODIUM TAURATE

The present disclosure provides a process for producing taurine, includes: adjusting a PH value of a sodium taurate solution by a S4+ compound; introducing ethylene oxide into the sodium taurate solution to produce sodium hydroxyethyl sulfonate; separating crude taurine before or after introducing the ethylene oxide to the solution; and adding ammonia to the sodium hydroxyethyl sulfonate reaction solution to be reacted with the reaction solution to reproduce sodium taurate. The process for producing taurine of the present disclosure makes use of the balances of the sodium bases in the system, recycles the mother liquor until the sodium taurate is reproduced out of the reactions in the mother liquor, and thus is capable of allowing taurine to be synthesized and extracted.

Owner:QIANGJIANG YONGAN PHARMA

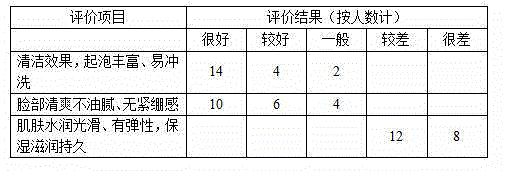

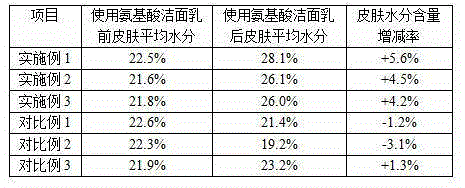

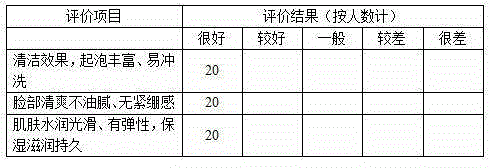

Amino acid facial cleanser and preparation method thereof

InactiveCN105147532AStay hydratedGood skin affinityCosmetic preparationsToilet preparationsSodium lactateMonosodium glutamate

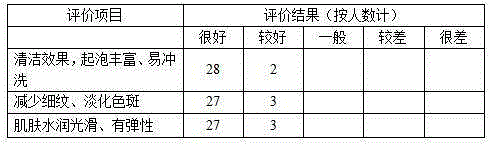

The invention belongs to the technical field of cosmetics and particularly relates to amino acid facial cleanser and a preparation method thereof. The amino acid facial cleanser comprises sodium lauroyl glutamate, sodium taurine laurate, sodium cocoyl glycinate, sorbitol, glycerin, sodium chloride, glycol distearate, cetearyl alcohol, sodium lactate, plant extracts, PEG(polyethylene glycol)-150 distearate, acrylate copolymers, EDTA (ethylene diamine tetraacetic acid) disodium, a preservative, essence and water. The amino acid facial cleanser is mild, skin-friendly, safe, non-irritating and capable of deeply cleaning skin, also can replenish water and whiten skin and can be used for a long time.

Owner:广州科玛生物科技股份有限公司

Preparation method for taurine

ActiveCN103382170ASolve pollutionAvoid it happening againOrganic compound preparationSulfonic acids salts preparationSalt sodiumEthylene oxide

Owner:QIANGJIANG YONGAN PHARMA

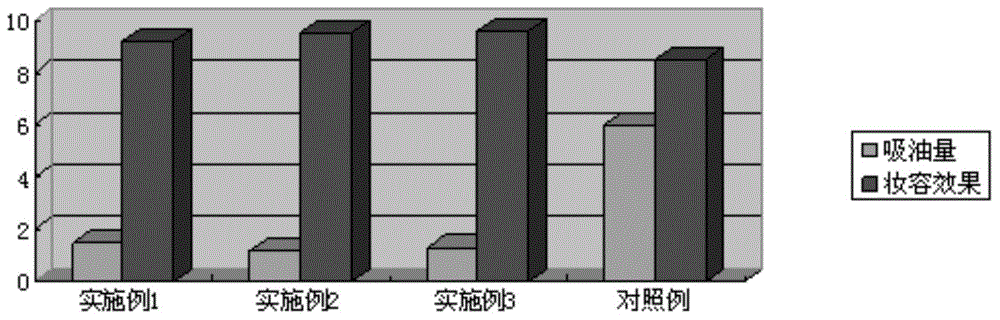

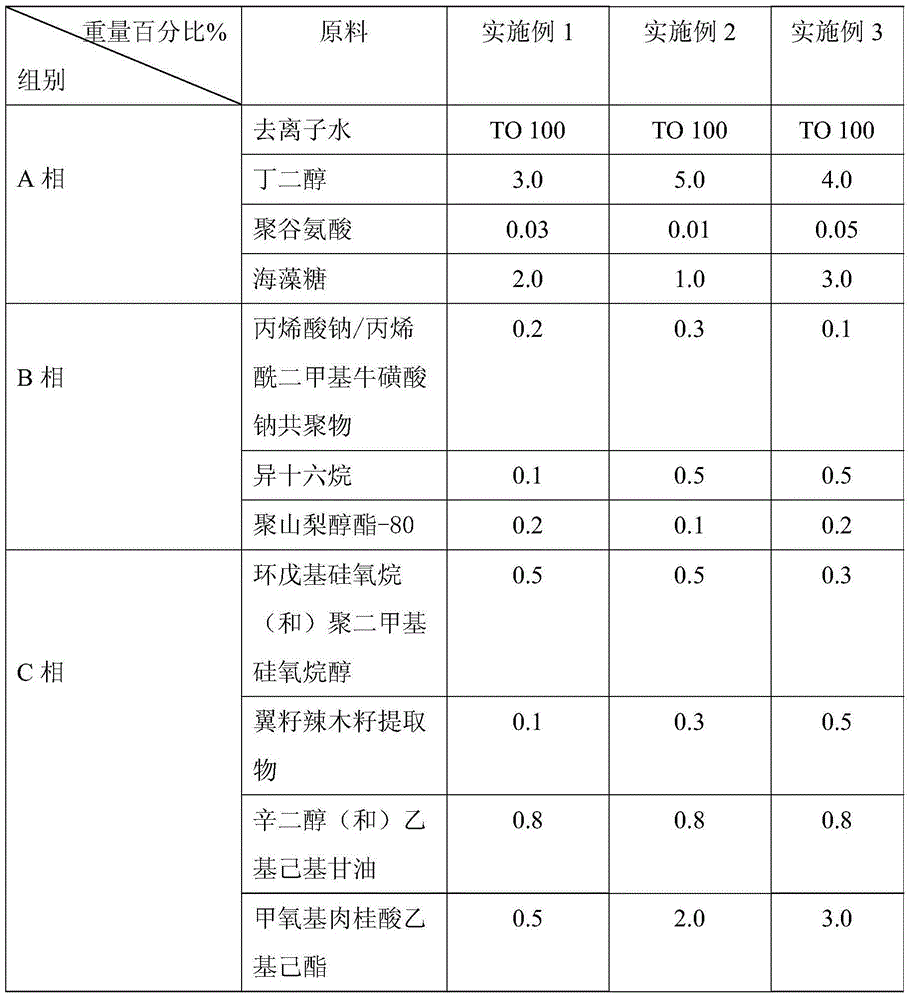

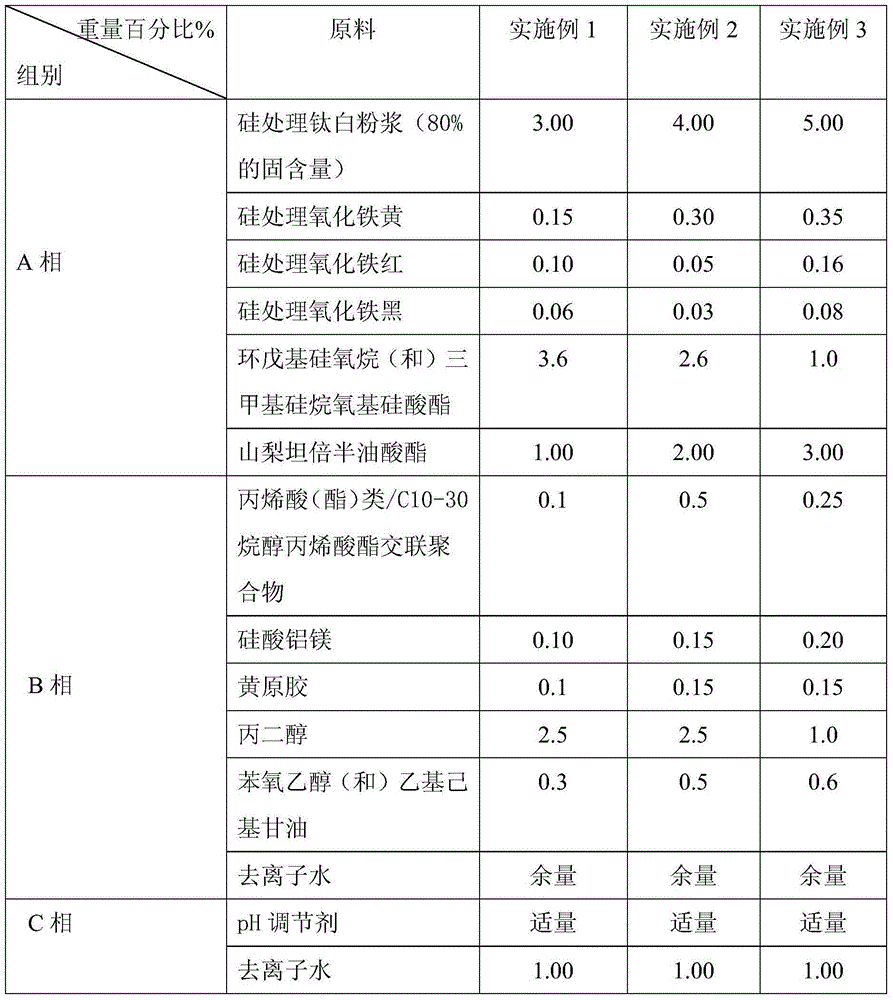

Makeup-free face cream containing enriched emulsion and preparation method of makeup-free face cream

InactiveCN104825371ANatural makeupIncrease moisture contentCosmetic preparationsToilet preparationsAluminum silicateButanediol

The invention provides a makeup-free face cream containing enriched emulsion and a preparation method of makeup-free face cream. The makeup-free face cream comprises, by weight percentage, 10.0-30.0% of enriched emulsion and 70.0-90.0% of liquid foundation, wherein the enriched emulsion comprises butanediol, polyglutamic acid, trehalose, sodium acrylate / acrylyl dimethyl sodium taurate polymer, isohexadecane, polysorbate-80, cyclopentyl siloxane (and) dimethiconol, moringa pterygosperma extracts and the like; the liquid foundation comprises physical skin whitening agent, colorant, cyclopentyl siloxane (and) trimethyl siloxy silicate ester, sorbitan sesquioleate, acrylic acid (ester) / C10-30 alkanol acrylic ester cross-linked polymer, magnesium aluminum silicate, xanthan gum, propylene glycol and the like. The makeup-free face cream is good in water and sweat resistance, natural in makeup feeling and easy to remove and has certain skin care effect.

Owner:广州智媛生物科技有限公司

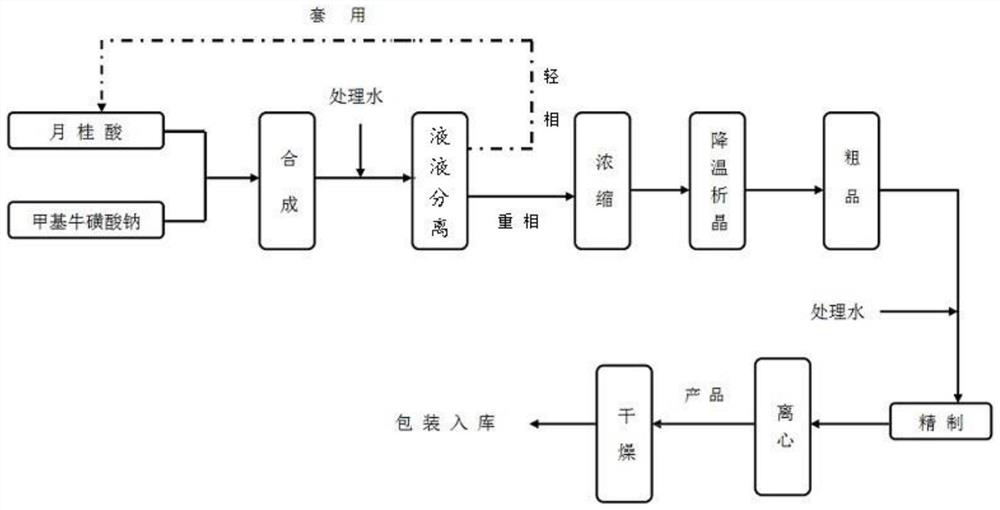

Rapid synthesis method for lauroyl-sodium methyl taurate

InactiveCN105175290AImprove conversion rateSimple processOrganic compound preparationSulfonic acids salts preparationACETIC ACID LIQUIDAlcohol ethyl

Owner:湖州新天字味精有限公司

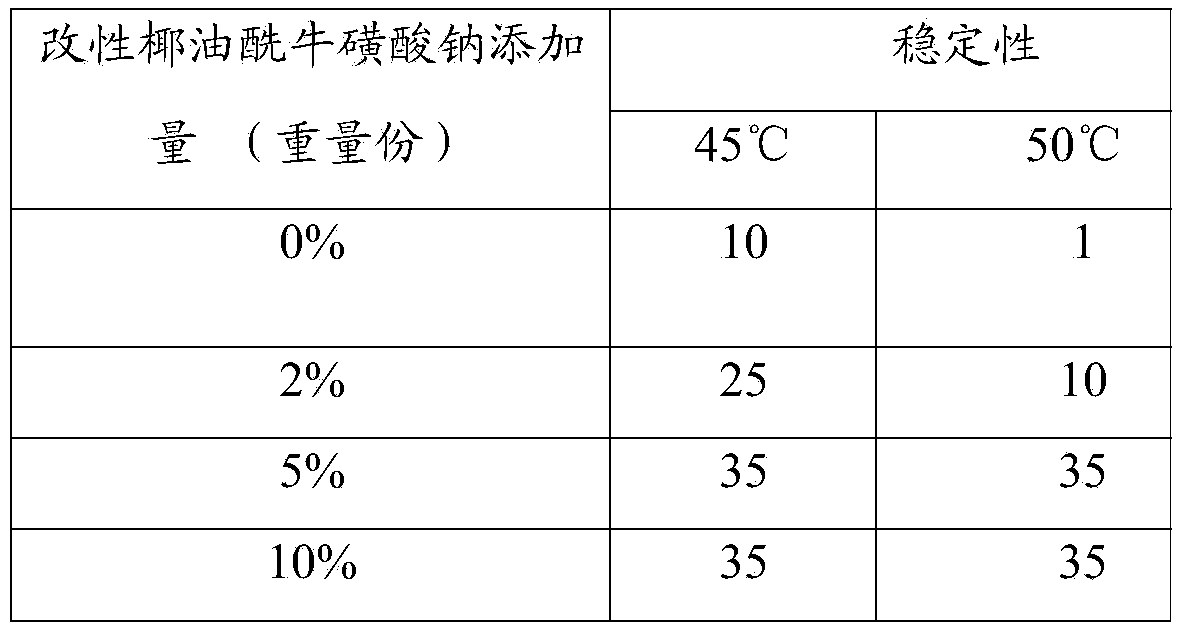

Liquid crystal thickener, preparation method and application thereof

ActiveCN103655240AGood suspensionImprove stabilityCosmetic preparationsHair cosmeticsSOAPLiquid crystal

The invention discloses a liquid crystal thickener which is modified sodium cocoyl taurate in a surface activity solution system. The liquid crystal thickener can be applied to an amino acid system and is compounded with an amino acid surfactant to achieve the self-thickening purpose to manufacture semitransparent or opal cream type facial cleanser; at 0-50 DEG C, the cream type facial cleanser is free from obvious change in appearance and touch; the system added with the liquid crystal thickener has no drawing property or adhesion; the liquid crystal thickener further can be applied to a soap-based system, so as to effectively reduce unsmooth feeling in the soap base water rinsing process and tensioning feeling after drying and enhance the stability of the soap-based product stored at high temperature; the liquid crystal thickener can be applied to a liquid shampoo system in order to obviously strengthen the grease and silicon oil suspension stability of the system. The liquid crystal thickener can be applied to most of anionic surfactant systems, and a little affected by salt and pH value in the systems.

Owner:GUANGZHOU BAFEORII CHEM

Mild silicone-oil-free shampoo in cation system and preparing method thereof

InactiveCN104997661AConvenient carePrevent split endsCosmetic preparationsHair cosmeticsBetaineCocamidopropyl betaine

The invention discloses mild silicone-oil-free shampoo in a cation system. According to the formula, the shampoo comprises an acrylic acid (acrylate) / steareth-20 methacrylate copolymer, cocamidopropyl glycine betaine, polyquaternium-10, lauroyl amphiprotic disodium oxalate, methyl cocoyl sodium taurate, behenyl trimethyl ammonium chloride, stearamide propyl dimethylamine, glycol distearate, quaternium-27, a scalp protective agent, cation conditioner, preservative, essence, a plant extract, a dandruff removal factor, a coix lacryma-jobi seed extractive, ricinic acid amide propyl ethyl dimethyl ammonio ethyl sulfate, and the balance water. The mild silicone-oil-free shampoo has the advantages that the shampoo does not contain sulfate, oxirane or silicone oil to avoid defects caused by the three materials, is good in biological degradability and has the effects of protecting and smoothing hair.

Owner:上海媚兰生物科技发展有限公司

Synthesis method for lauroyl-sodium methyl taurate

ActiveCN105175291AImprove conversion rateSimple processOrganic compound preparationSulfonic acids salts preparationAcetic acidEthylic acid

The invention discloses a high-conversion rate synthesis method for lauroyl-sodium methyl taurate. The high-conversion rate synthesis method comprises the following steps: mixing lauric acid with MgO, acetic acid and liquid paraffin; introducing nitrogen to replace air, heating to 100 DEG C to 110 DEG C and mixing for 5min; after heating, slowly dropwise adding N-sodium methyl taurate aqueous solution of which the mass fraction is 42 percent to 45 percent, controlling dropping speed so as to avoid the phenomenon that a large number of foams are generated from a reaction system and overflow, and continue to heat to 220 to 226 DEG C after the N-sodium methyl taurate aqueous solution is dropwise added and reacting for 4 to 5h; stop heating after the reaction is ended, and recovering. The high-conversion rate synthesis method disclosed by the invention is simple in process and easy in operation; the reaction time can be shortened, and the conversion rate (higher than 98 percent) of N-sodium methyl taurate is improved; after a crude product is recrystallized and dried, the purity of the crude product can reach more than 99 percent.

Owner:JIANGYIN HUACHANG FOOD ADDITIVE CO LTD

Preparation method of N-methyl sodium taurate

ActiveCN110903222AShorten the timeIncrease productivitySulfonic acids salts preparationMetal/metal-oxides/metal-hydroxide catalystsSulfonatePtru catalyst

The invention provides a preparation method of N-methyl sodium taurate. Firstly, sodium hydroxyethyl sulfonate is dissolved in water to form a homogeneous system solution. Secondly, methylamine and acatalyst are added into the homogeneous system solution, the reaction system is heated to react, and the catalyst is selected from Zn5 (Co3) 2 (OH) 6, Ni2ZrO4 and Zn5 (Co3) 2 (OH) 6 / Ni2ZrO4. Finally,the N-methyltaurine sodium sulfonate is obtained through demethylation, neutralization, crystallization separation and other steps. The yield of the N-methyltaurine sodium sulfonate can reach 85.0-95.0%, and the selectivity is greater than 98%.

Owner:WANHUA CHEM GRP CO LTD

Compound preparation for increasing ratio of AKK (akkermansia muciniphila) bacteria and pathogenic bacteria in intestines as well as preparation method and application thereof

ActiveCN108403930AImprove securityEffective regulationDispersion deliveryMetabolism disorderIntestinal structureElaeagnus angustifolia

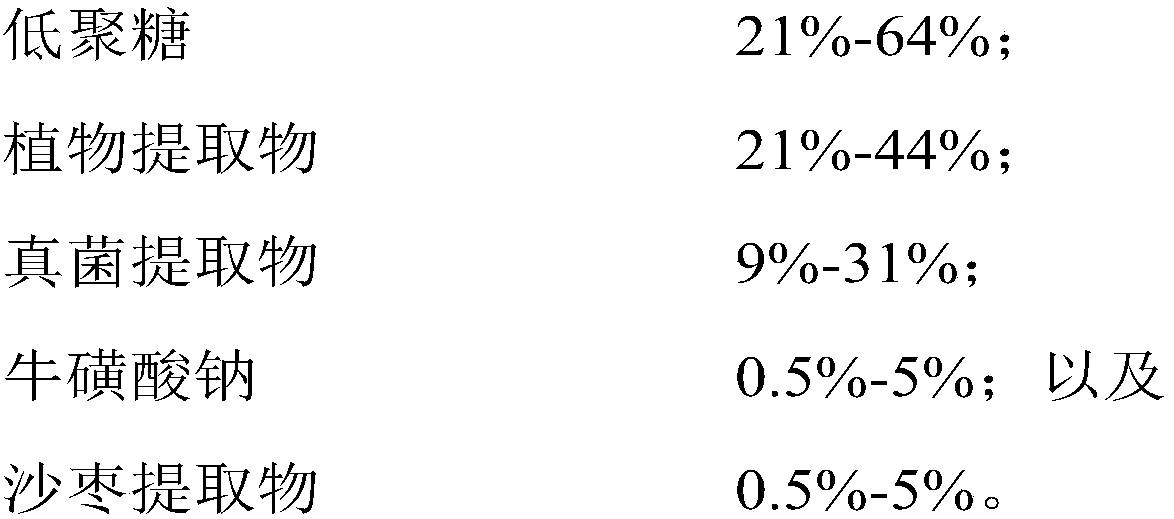

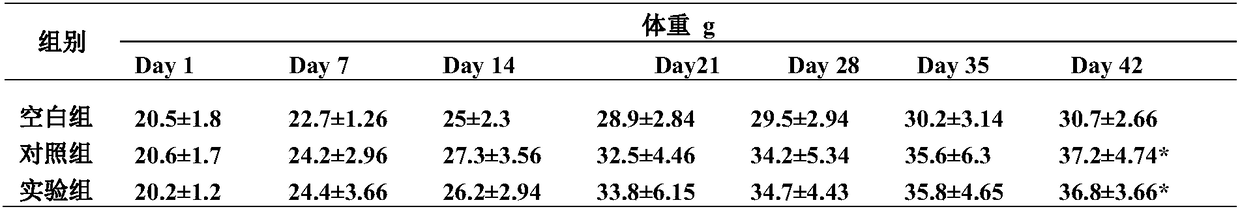

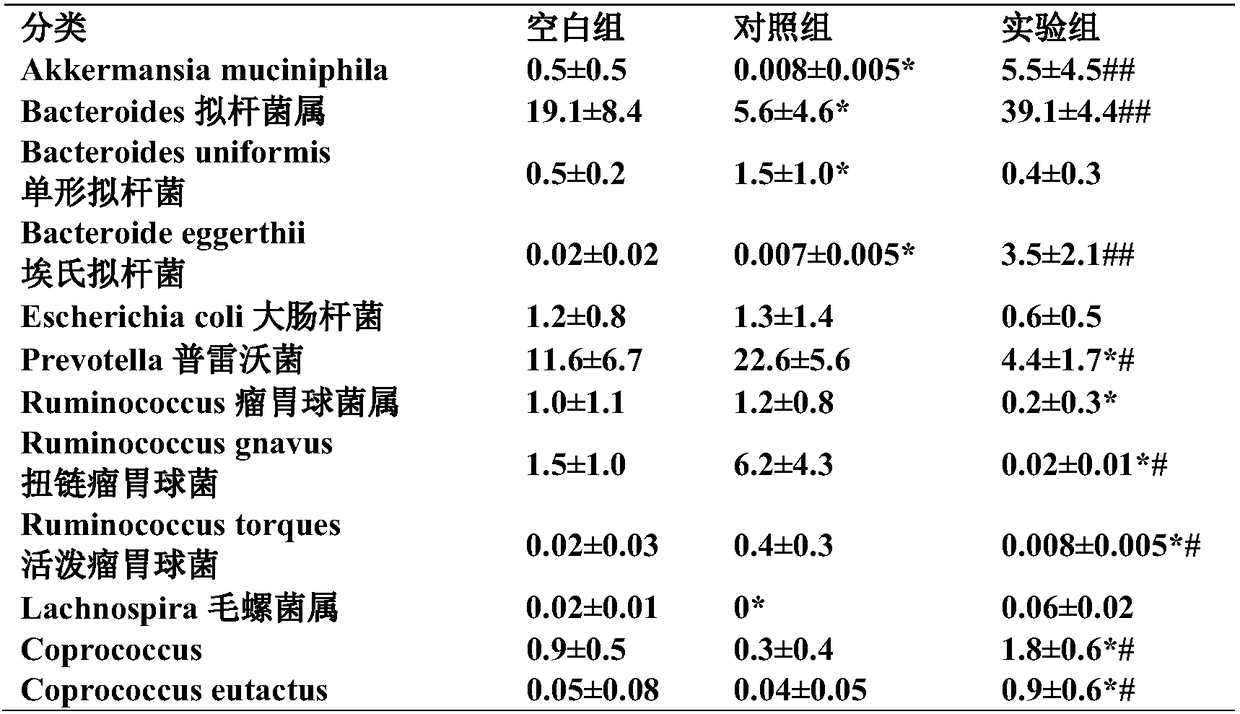

The invention provides a compound preparation for increasing ratio of AKK (akkermansia muciniphila) bacteria and pathogenic bacteria in intestines as well as a preparation method and application thereof, and relates to the field of oral preparations. The compound preparation for increasing the ratio of AKK bacteria to pathogenic bacteria in the intestines is prepared from the following raw materials in percentage by mass: 21% to 64% of oligosaccharide, 21% to 44% of plant extract, 9% to 31% of fungus extract, 0.5% to 5% of sodium taurate, and 0.5% to 5% of elaeagnus angustifolia extract. The compound preparation has the advantages that the safety is good, and the intestinal flora can be effectively regulated. The preparation method of the compound preparation comprises the following stepsof mixing the oligosaccharide, the plant extract, the fungus extract, sodium taurate and the elaeagnus angustifolia extract, and grinding, so as to obtain the compound preparation. The preparation method has the advantages that the technology is simple, and the industrialized production is easy. The application of the compound preparation for increasing the ratio of AKK bacteria to pathogenic bacteria in the intestines is characterized in that the compound preparation is used for preparing the oral preparation for increasing the abundance of the AKK bacteria in the intestines, and reducing theabundance of the pathogenic bacteria.

Owner:MEI YI TIAN BIOLOGICAL MEDICINE WUHAN CO LTD

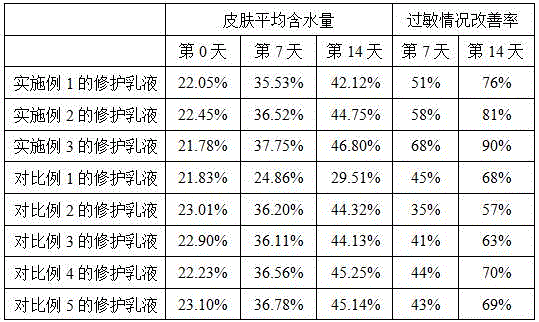

Repair emulsion focusing on sensitive skin root and preparation method and application of repair emulsion

ActiveCN106265341AUnique skin feelIncrease elasticityCosmetic preparationsToilet preparationsPotassiumPotassium Cetyl PHosphate

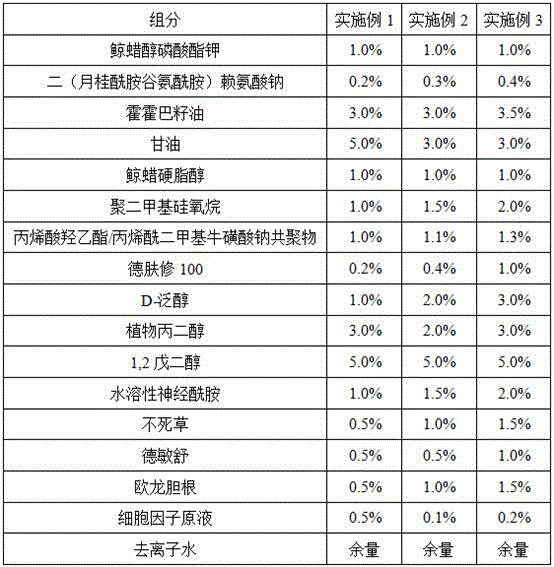

The invention discloses repair emulsion focusing on sensitive skin root. The repair emulsion is prepared from the following raw materials in percentage by mass: 0.8 to 1.5 percent of potassium cetyl phosphate, 0.2 to 1 percent of di(lauramide glutamine) lysine sodium, 2 to 10 percent of simmondsia chinensis seed oil, 3 to 10 percent of glycerinum, 1 to 2 percent of cetostearyl alcohol, 1 to 2.5 percent of polydimethylsiloxane, 1 to 2 percent of hydroxyethyl acrylate / acrylyl dimethyl sodium taurate copolymer, 0.2 to 2 percent of defuxiu 100, 1 to 3 percent of D-panthenol, 2 to 6 percent of propylene glycol plant, 5 to 6 percent of 1,2 pentanediol, 1 to 2 percent of water-soluble ceramide, 0.5 to 2 percent of dwarf lilyturf tuber, 0.5 to 1 percent of daily smooth, 0.5 to 2 percent of root of gentiana lutea, 0.05 to 0.5 percent of cytokines stoste and the balance of water. The repair emulsion disclosed by the invention focuses on repairing the sensitive skin, has efficient multiple effects of repairing, moisture-retention and increase of skin elasticity, and has an extremely good application prospect.

Owner:GUANGDONG MARUBI BIOLOGICAL TECH CO LTD

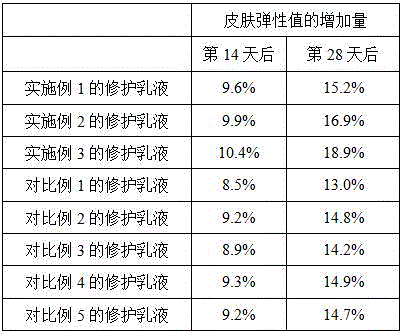

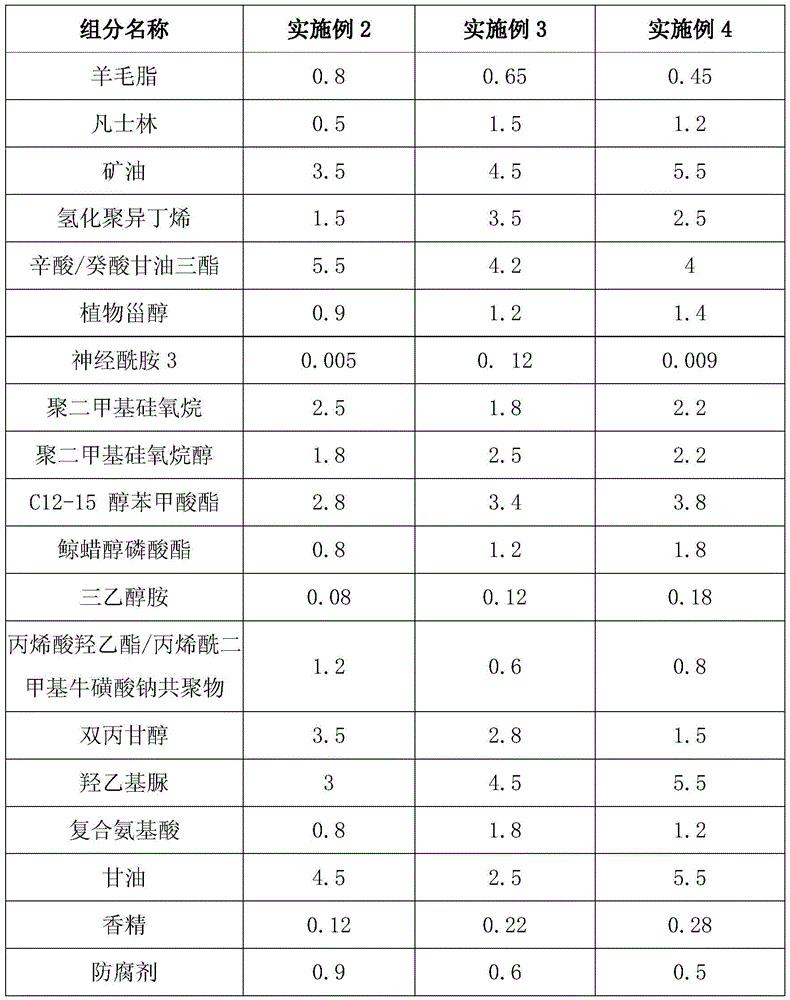

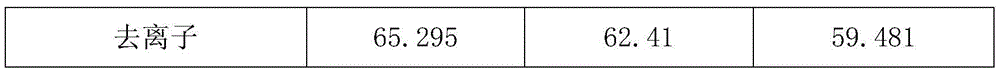

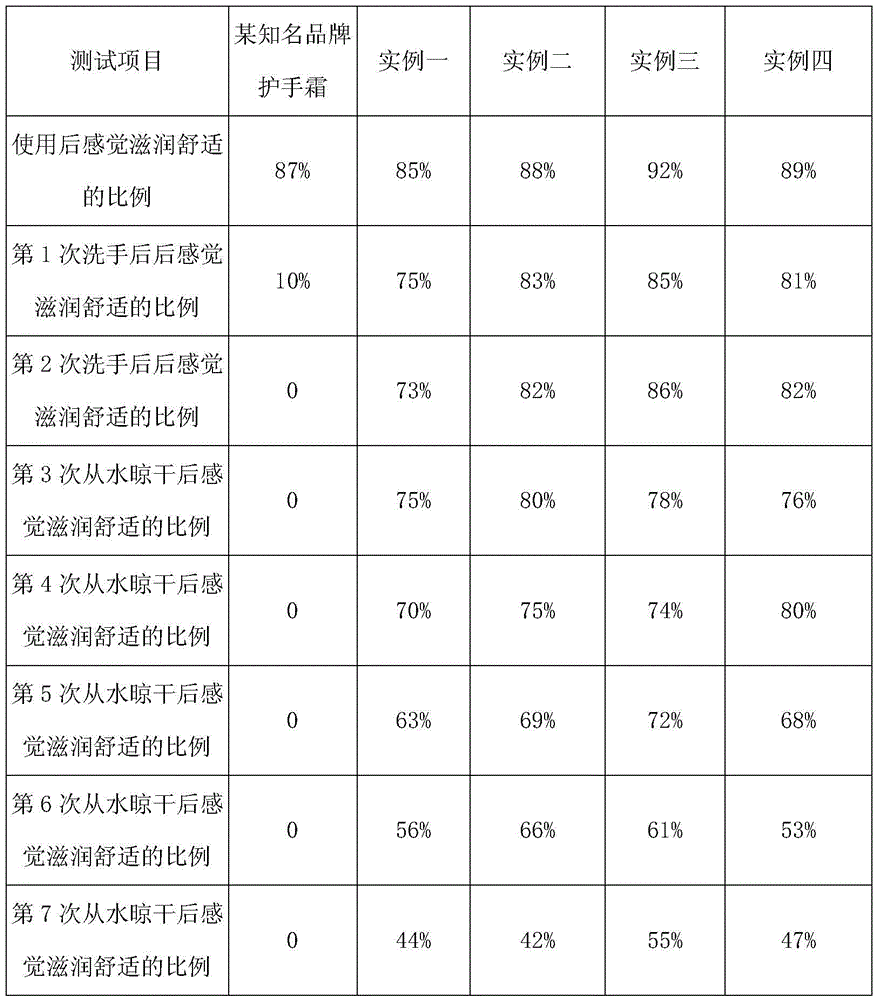

Wash-resisting hand cream and preparing method thereof

ActiveCN105596234AImprove wash resistanceIncrease contentCosmetic preparationsToilet preparationsAdditive ingredientGlycerol

The invention discloses a wash-resisting hand cream. The hand cream comprises wool fat, vaseline, mineral oil, hydrogenated polyisobutene, caprylic / capric triglyceride, phytosterol, ceramide 3, polydimethylsiloxane, dimethiconol, C12-15 alcohol benzoate, cetyl phosphate, triethanolamine, hydroxyethyl acrylate / acrylyl dimethyl sodium taurate copolymer, dipropylene glycol, hydroxyethylurea, compound amino acid, glycerol, essence, preservative and deionized water. Cetyl phosphate with high water resistance and a structure similar to that of skin is adopted for the wash-resisting hand cream, a wash-resisting protection film is formed after cetyl phosphate is matched with vaseline and mineral oil which are high in closure property, other nourishing ingredients not prone to migration under washing and various moisturizing and water reserving ingredients are also adopted, and then the functions of highly nourishing, moisturizing, repairing, anti-chapping and hand skin smoothing are realized and the content of the nourishing ingredients can still be high after multiple times of washing.

Owner:广州蜜妆生物科技有限公司

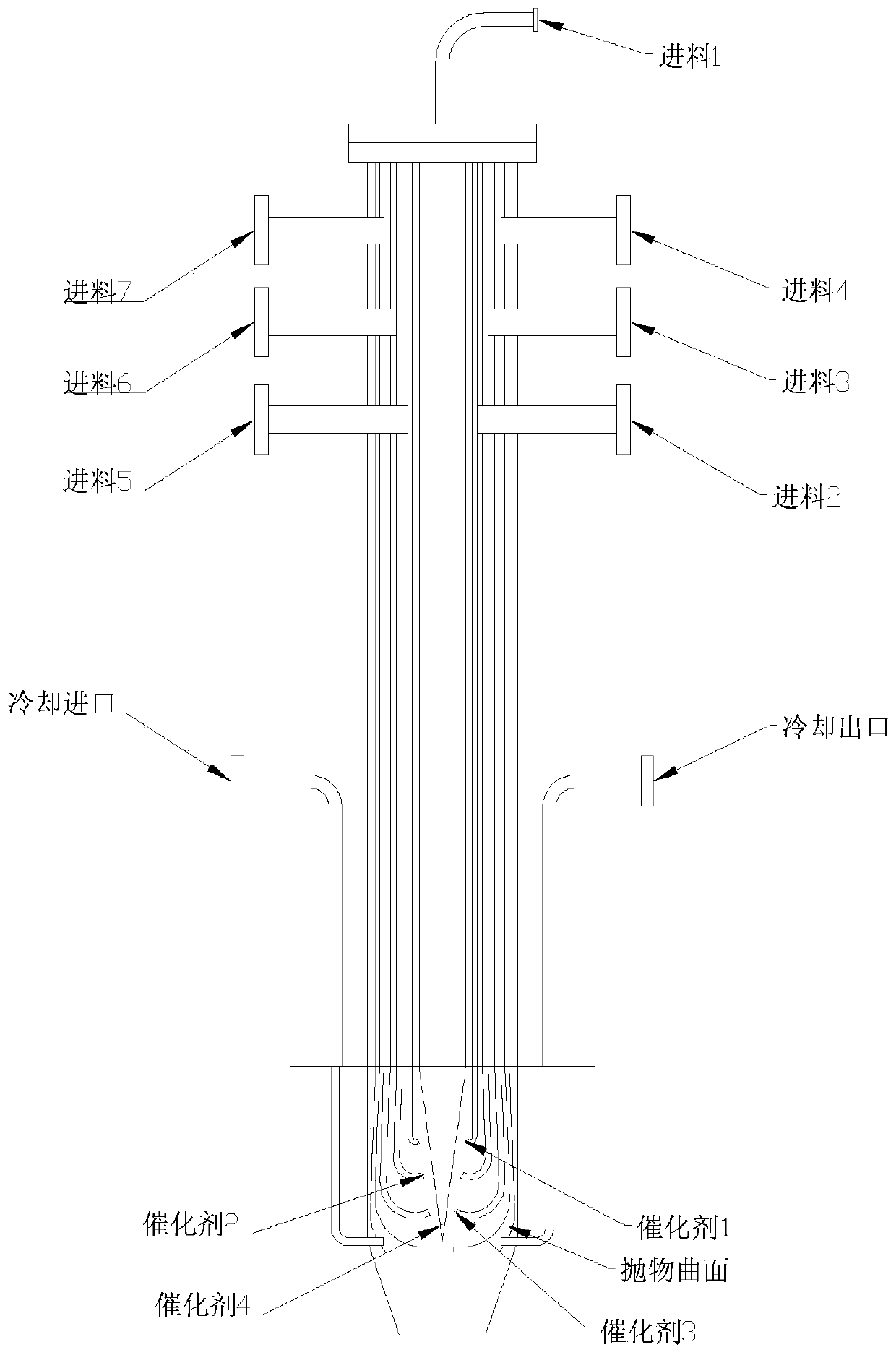

Separation and purification process of taurine

InactiveCN110590614ARealize cleaner productionAvoid transportOrganic compound preparationSulfonic acid preparationSolvent moleculeHydrogen ion

The invention relates to a separation and purification process of taurine and is applicable to methods for synthesizing taurine from ethylene oxide as a raw material. The process specifically comprises the following steps: mixing ethylene oxide with sodium hydrogen sulfite and other gas, liquid and solid-phase catalysts and nanoparticles by using an ionization multi-channel nozzle device so as toprepare sodium 2-hydroxyethanesulfonate, further performing high-temperature high-pressure treatment and concentration so as to prepare sodium taurate, and neutralizing a sodium taurate liquid by using sodium hydrogen sulfite; and in a ceramic nanometer-sized metallomolecular cage component, performing a self-assembling reaction on a three-tooth bridging ligand with sulfur and nitrogen and divalent nickel, palladium or platinum ions so as to establish a cubic metallic-organic cage in Oh symmetry, and performing exchange of hydrogen ions with sodium ions and solvent molecule catalysis simultaneously, so as to obtain the taurine. Mother liquor is subjected to concentration and separation to obtain sodium sulfite which is used as a raw material of an ethylene oxide reaction, an absorption andtransferring carrier of sulfur dioxide and a raw material for neutralizing the sodium taurate liquid. Waste liquid free circulation production of taurine can be achieved.

Owner:王建峰

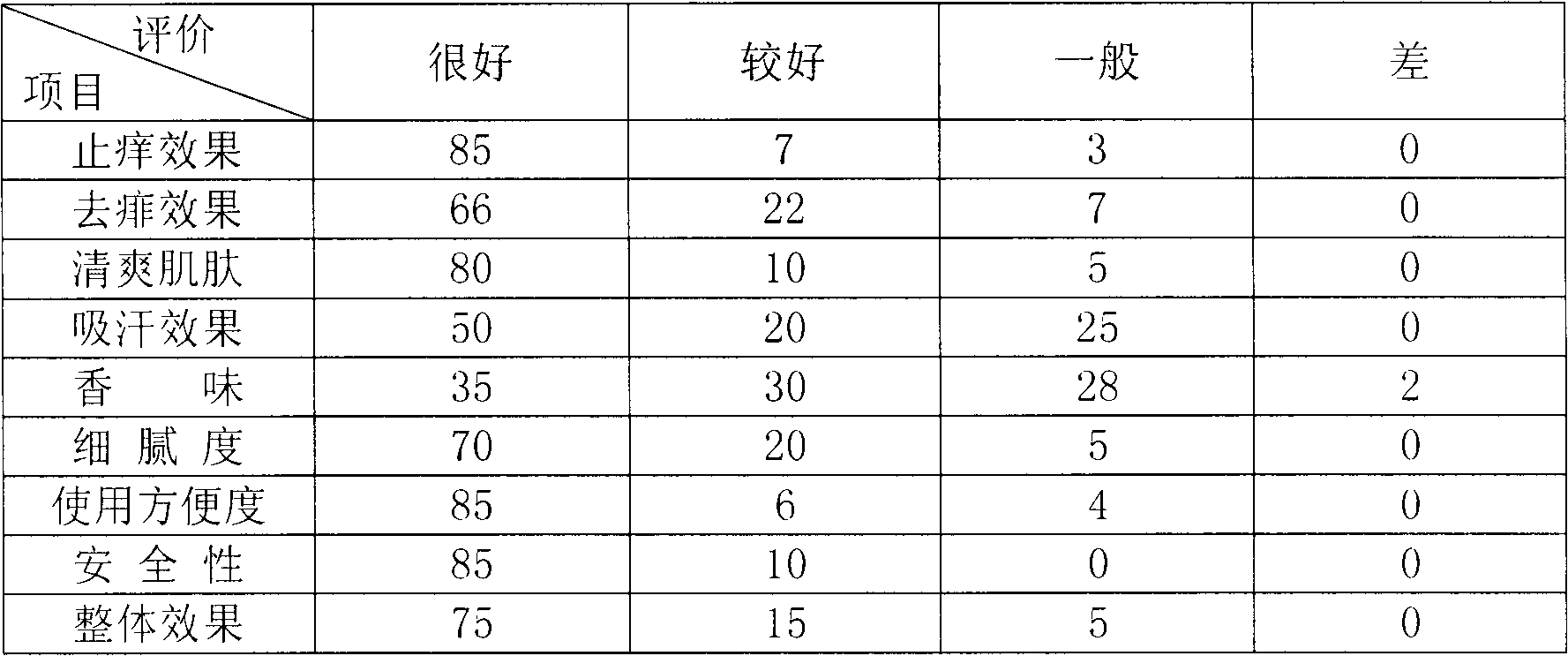

Body-smoothening gel added with nano pearl powder and preparation method of body-smoothening gel

InactiveCN102552101AImprove securityDry and lubricated feeling of useCosmetic preparationsToilet preparationsCross-linkDimethyl siloxane

The invention relates to a body-smoothening gel added with nano pearl powder and a preparation method of the body-smoothening gel. The body-smoothening gel is prepared by mixing, heating and emulsifying acrylates (ester)-like / C10-30 alkanol acrylic ester cross-linked polymer, glycerol, EDTA (Ethylene Diamine Tetraacetic Acid) disodium, dehydroxanthan gum, sodium acrylate / acrylyl dimethyl sodium taurate copolymer, acrylates (ester)-like cross-linked polymer, dimethyl silicone polymer, cyclohexasiloxane, mimusops elengi fruit oil, isohexadecane, triethanolamine, nano pearl powder, modified corn starch, zinc oxide, methyl hydroxybenzoate, propyl hydroxybenzoate, essence, honeysuckle extract, sophora flavescens extract and de-ionized water. According to the body-smoothening gel disclosed by the invention, the nano pearl powder and the modified corn starch are used to replace talcum powder in the traditional body-smoothening powder, so that natural effective components in the pearl powder are effectively utilized and the absorption effect of the skin on the effective components of pearl is improved; and the body-smoothening gel has the characteristics of favorable effects of relieving itching, removing prickly heat, absorbing sweat and the like and is the body-smoothening gel with high safety performance and no harm to a human body.

Owner:HAINAN JINGRUN PEARL BIOTECH

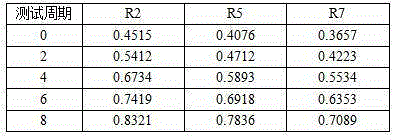

Method for producing taurine by virtue of bipolar ion exchange membrane technology

InactiveCN104593812AReduce investmentReduce the difficulty of post-processing processCellsElectrolytic organic productionHydrolysisSodium sulfate

The invention discloses a method for producing taurine by virtue of bipolar ion exchange membrane technology. The method comprises the following steps: (1) introducing an aqueous solution of sodium sulfate into anode and cathode chambers of a bipolar ion-exchange membrane electrodialyzer and simultaneously respectively introducing water and 8-10% aqueous solution of sodium taurate into a base chamber and a material liquid chamber of the bipolar ion-exchange membrane electrodialyzer; under the action of a direct current electric field, feeding sodium ions inside the anode chamber into the base chamber to be combined with hydroxide ions obtained by water dissociation to form sodium hydroxide together with the bipolar membrane, combining hydrogen ions obtained by water dissociation and taurine ions to form taurine by virtue of the bipolar membrane inside the material liquid chamber and feeding sodium ions inside the material liquid chamber to the cathode chamber, flowing aqueous solution of sodium sulfate out from the anode and cathode chambers, flowing a sodium hydroxide solution out from the base chamber and flowing a taurate solution out from the material liquid chamber; and (2) concentrating the taurate solution so that the crystallized product is precipitated and filtering the crystallized product to obtain taurate. The method has the advantages of no emission of pollutants, no addition of a large amount of chemicals, simple operation and short production cycle.

Owner:SHANDONG TIANWEI MEMBRANE TECH

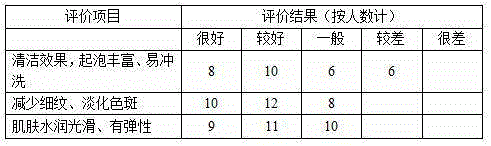

Anti-wrinkle cleansing lotion and preparation method thereof

ActiveCN105287331AStay hydratedGood skin affinityCosmetic preparationsToilet preparationsCellulosePunica

The invention belongs to the technical field of cosmetics, and in particular relates to an anti-wrinkle cleansing lotion and a preparation method thereof. The anti-wrinkle cleansing lotion consists of myristic acid, palmitic acid, stearic acid, glycerol, potassium hydroxide, sodium taurine laurate, sodium cocoyl glycinate, sodium lauroyl glutamate, C12-14 secondary-chain alkanol polyether-20, glycol distearate, propanediol, lactobacillus / punica granatum fruit fermentation product extract, arctic chlamydomonas essence, starfish essence, cortex acanthopanacis essence, a pearl extract, EDTA-Na2, hydroxypropyl methyl cellulose, methyl hydroxybenzoate, propyl hydroxybenzoate, methylisothiazolinone, essence and water. The anti-wrinkle cleansing lotion disclosed by the invention is gentle and skin-friendly, safe and non-irritant; and the cleansing lotion is capable of deeply cleansing skin, and meanwhile the cleansing lotion is capable of moisturizing and resisting wrinkles.

Owner:广州科玛生物科技股份有限公司

Sleeping mask containing sweet pea extract solution and preparation method thereof

InactiveCN103690456APromote absorptionNourishing and moisturizingCosmetic preparationsToilet preparationsBetaineAdditive ingredient

The invention discloses a sleeping mask containing sweet pea extract solution and a preparation method thereof. The sleeping mask containing the sweet pea extract solution disclosed by the invention is characterized by comprising the following components in percentage by weight: 2.0-7.5% of cyclomethicone, 1.2-5.8% of caprylic / capric triglyceride, 1.5-5.5% of camellia oil, 15-25% of glycerinum, 1.0-6.0% of dipropylene glycol, 1.0-5.5% of hydroxyethyl acrylate / acrylamide dimethyl sodium taurate copolymer, 0.2-0.6% of methylparaben, 0.5-2.5% of allantoin, 0-0.8% of xanthan gum, 0.2-0.6% of hydroxyethyl cellulose, 0.2-0.6% of EDTA (Ethylene Diamine Tetraacetic Acid) disodium, 0.5-2.5% of sodium hyaluronate, 0.5-2.5% of dipotassium glycyrrhizinate, 1.0-4.5% of viola tricolor extract, 1.5-4.5% of guava extract, 2.0-7.0% of betaine, 0.5-2.5% of pearl powder, 0.8-1.3% of sweet pea extract solution, 0.01-0.03% of essence, proper preservative, and the balance of deionized water. The sleeping mask containing the sweet pea extract solution disclosed by the invention contains gel substrate as the carrier, therefore, nutritional ingredients are absorbed more easily; the effects of nourishing, moisturizing, resisting wrinkling and resisting aging are obvious.

Owner:QINGDAO HIFUN MARINE BIOLOGICAL TECH

Cream shampoo for scalp itching relieving and preparation method thereof

The invention relates to cream shampoo for scalp itching relieving and a preparation method thereof. The cream shampoo comprises, by mass, the following components of 0.5-2.5 parts of olive oil, four to ten parts of stearic acid, four to 12 parts of glycerinum, 10-20 parts of laurinol polyoxyethylene ether sodium, one to four parts of glycol distearate, 0.5-1.2 parts of carboxymethylcellulose, 0.06-0.14 part of salicylanilide, 0.2-0.6 part of oleoyl sodium methyl taurate, 0.2-0.5 part of xanthan gum, two to seven parts of potassium hydroxide, 0.5-1.2 parts of selenium sulfide, 42-55 parts of water, 0.08-0.15 part of essence, 0.5 to two parts of borneol, 0.5 to two parts of rosin and 0.3 to one part of fructus kochiae. The cream shampoo can clean hair and the scalp effectively and fast, foam is exquisite and easy to wash off, and meanwhile the cream shampoo can effectively restrain itching caused by the dry scalp, and has the refreshing effect.

Owner:JIANGSU QILIKANG SKIN PHARMA

Taurine synthesis method

ActiveCN111320558AIssues that do not affect yieldHigh yieldOrganic compound preparationSulfonic acids salts preparationTaurine synthesisSodium Isethionate

The invention provides a safe and efficient taurine synthesis method. The taurine synthesis method comprises the following steps: adding sodium hydrogen sulfite and ethylene oxide to prepare sodium isethionate; carrying out ammonolysis on sodium hydroxyethyl sulfonate and liquid ammonia at a high temperature to obtain sodium taurate; acidifying sodium taurate, and carrying out crystallization to obtain a taurine pure product. Before addition reactions, impurities are filtered by a nano-filtration membrane, and the side reaction influence is eliminated. The method has the advantages of mild ammonolysis reaction conditions and shortened reaction retention time, and the industrial production is safe and efficient.

Owner:WANHUA CHEM GRP CO LTD

Preparation method for sodium fatty acyl methyl taurate

InactiveCN106588709ASolve environmental problems of emissionsSolve environmental problemsOrganic compound preparationSulfonic acids salts preparationSolubilityAcyl group

The invention discloses a preparation method for sodium fatty acyl methyl taurate. According to the method, an organic solvent is not used for performing crystallization and re-crystallization, and a byproduct-centrifugal filter liquor in a reaction process is recycled, so that the environment and health problems caused by use of the solvent and the environmental protection problem of salt-containing and acid-containing wastewater discharge in a purification process in the past are solved. A frozen recovered filter liquor is added in a freezing crystallization process, so that the temperature is reduced; and sodium chloride in the filter liquor is used for performing seeding, and the effects of crystal seeds and crystal nucleuses are achieved, so that the graining in the process is quick, wrapped impurities due to non-crystal agglomeration are reduced, and the prepared product is higher in purity and higher in content. The freezing crystallization is combined with the freezing centrifugation, so that the crystal solubility is reduced and the product yield is increased. Through optimized selection of a process route, the process is advanced and rational, can be realized by using a general device, and is simple in operation, relatively high in economic benefit and relatively low in environmental pollution.

Owner:ZHANGJIAGANG GREAT CHEM

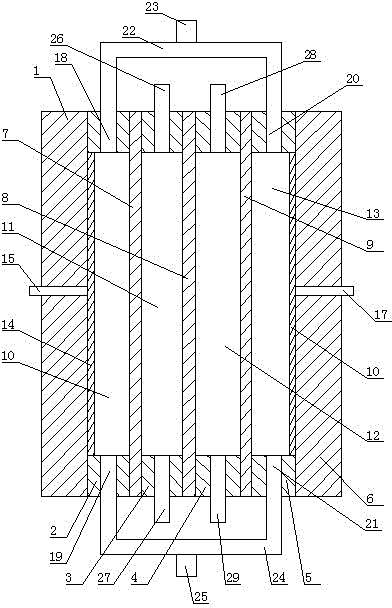

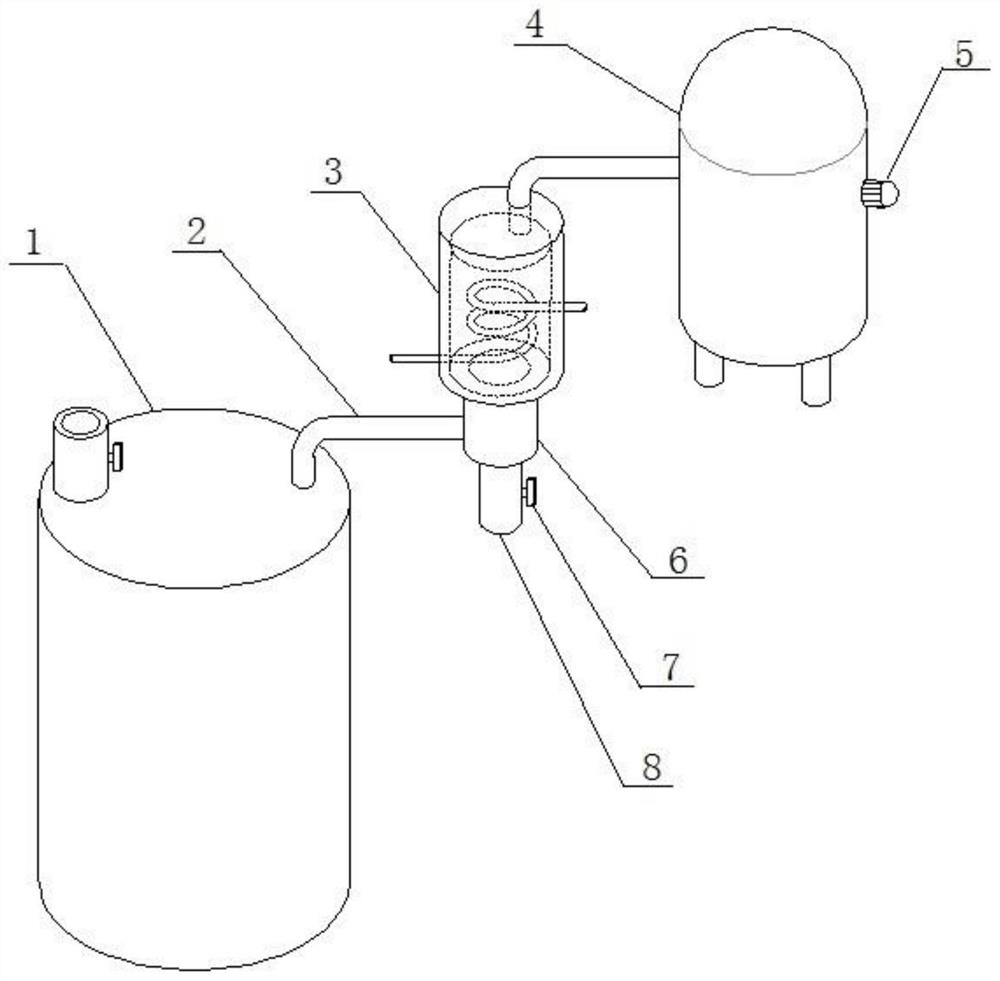

Taurine separation and purification device

InactiveCN110551045ARealize cleaner productionAvoid transportOrganic compound preparationSulfonic acids salts preparationSolventHigh pressure

The invention relates to a taurine separation and purification device. The taurine separation and purification device is suitable for a method for synthesizing taurine by taking oxirane as a raw material. The method specifically includes the steps that an ionization multi-channel nozzle device is utilized to mix the oxirane with sodium hydrogen sulfite and other gas, liquid and solid phase catalysts through nanoparticles to prepare sodium 2-hydroxyethanesulfonate, then sodium taurate is prepared through the high temperature and high pressure and concentration, and the sodium hydrogen sulfite is adopted to neutralize sodium taurate material liquid; and in a ceramic nano metal molecular cage assembly, through a self-assembly reaction of a tridentate bridging ligand containing organic sulfurand nitrogen and bivalent nickel, palladium or platinum ions, a cubic metal-organic cage with O<h> symmetry is constructed, meanwhile, exchange of hydrogen ions and sodium ions and solvent molecular catalysis are accommodated, and thus the taurine is obtained. A mother solution is concentrated and separated to obtain sodium sulfite to serve as a raw material of an oxirane reaction, a carrier for absorption and transport of sulfur dioxide, and a raw material for neutralization of the sodium taurate material liquid. Waste-liquid-free cycle production of the taurine is achieved.

Owner:王建峰

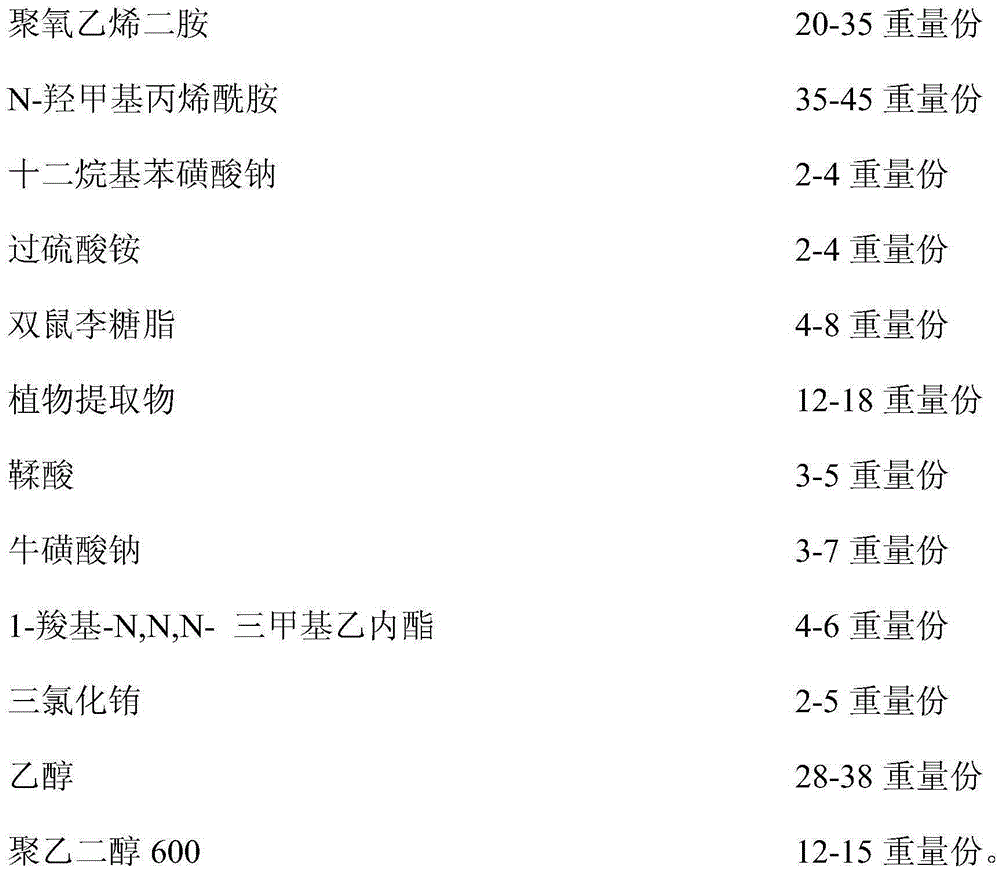

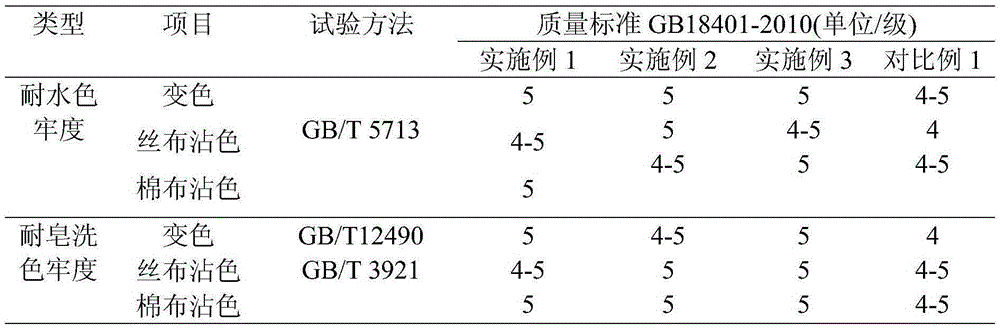

Printing and dyeing auxiliary agent, and preparation method and application thereof

InactiveCN105256613AHigh color fastnessGood color protectionDyeing processPolyethylene glycolEuropium

The invention provides a printing and dyeing auxiliary agent. The printing and dyeing auxiliary agent is prepared from the following raw materials: 20 to 35 parts by weight of polyethylene glycol diamine, 35 to 45 weight parts of N-hydroxymethyl acrylamide, 2 to 4 weight parts of sodium dodecylbenzene sulfonate, 2 to 4 weight parts of ammonium persulfate, 4 to 8 weight parts of di-rhamnolipid, 12 to 18 parts by weight off plant extract, 3 to 5 weight parts of tannin, 3 to 7 weight parts of sodium taurate, 4 to 6 weight parts of 1-carboxy-N,N,N-trimethylmethanaminium inner salt, 2 to 5 weight parts of europium chloride, 28 to 38 weight parts of ethyl alcohol and 12 to 15 weight parts of polyethylene glycol 600. The printing and dyeing auxiliary agent prepared by the preparation method has good effects on improving color fastness, protecting color, and preventing color fading, and also has the functions of resisting bacteria and preventing static electricity.

Owner:朱忠良

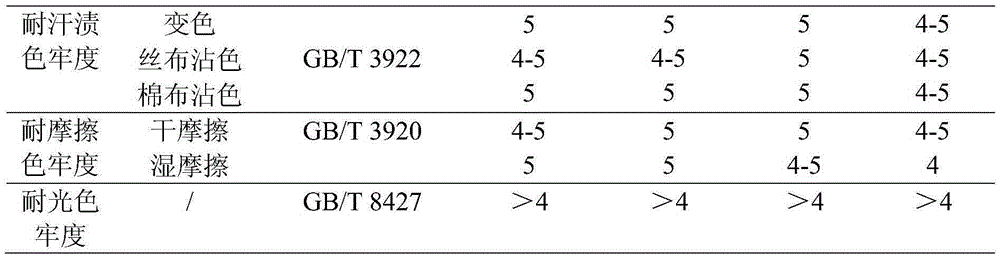

Composite preparation for improving SCFA producing strains in intestinal tract, and preparation method and application thereof

ActiveCN108567901AImprove securityEffective regulationMetabolism disorderAlgae medical ingredientsBacteroidesPhylum Firmicutes

The invention relates to a composite preparation for improving SCFA producing strains in the intestinal tract, and a preparation method and application thereof, and relates to the field of oral preparations. The composite preparation in the embodiment of the invention is prepared from the following raw materials in percentage by mass: 22%-63% of oligosaccharide, 22%-43% of a plant extract, 10%-30%of a fungal extract, 0.5%-5% of sodium taurate and 0.5%-5% of a radix aastragali extract. The composite preparation is safe and can effectively regulate intestinal flora. The preparation method of the composite preparation comprises the steps of mixing and grinding the oligosaccharide, the plant extract, the fungal extract, the sodium taurine and the radix aastragali extract. The process is simple and facilitates industrialized production. The composite preparation can be used to prepare an oral preparation for reducing the ratio of Phylum Firmicutes / Bacteroides in the intestinal tract and increasing the proportion of the SCFA producing strains.

Owner:MEI YI TIAN BIOLOGICAL MEDICINE WUHAN CO LTD

Separation and extraction method of taurine

InactiveCN104628609AReduce energy consumptionProcess safety and environmental protectionOrganic compound preparationSulfonic acid preparationSolubilitySulfite salt

The invention relates to a separation and extraction method of taurine. The separation and extraction method of taurine comprises following steps: oxirane is reacted with sodium bisulfite aqueous solution so as to obtain a sodium hydroxyethyl sulfonate solution; inorganic ammonia is dissolved into the sodium hydroxyethyl sulfonate solution, an obtained mixture is delivered into a pressure reactor for ammonification, and a sodium taurate aqueous solution is obtained via flash distillation; the sodium taurate aqueous solution is subjected to blending, and is reacted with neutralizer sulfur dioxide in a neutralization reactor until a reaction endpoint is reached. According to the separation and extraction method, at a relatively temperature, taurine solubility is relatively low, crystals are fine, and density is low; sodium sulfite is low in solubility and possesses crystal water, crystals are coarse, and density is high; sodium bisulfate is high in solubility, and crystallization is not easily caused at low temperature; so that separation of taurine with inorganic salts is realized via settling separation and sieve filtering at low temperature, excellent effects are achieved; by products, including sodium sulfite and sodium bisulfate, which are high in additional value are obtained; and recycling can be realized. The separation and extraction is safe and friendly to the environment, and can be used for industrialized production; cost is low; yield is high; quality is high; and energy consumption is low.

Owner:SHANDONG FANGMING PHARMACEUTICAL CO LTD

Preparation method of sodium methyl lauroyl taurate

ActiveCN114181119ASimple processEasy to operateOrganic compound preparationSulfonic acids salts preparationPtru catalystReaction temperature

The invention provides a preparation method of sodium methyl lauroyl taurate, which comprises the following steps: firstly, adding lauric acid into a reaction system, introducing nitrogen to replace air, and heating until the lauric acid is completely molten; the temperature of lauric acid is controlled to be 100-140 DEG C, a sodium methyl taurate aqueous solution is injected according to the molar ratio of lauric acid to sodium methyl taurate being (2.0-3.5): 1, the temperature is increased to 230-250 DEG C, and a reflux reaction is conducted for 4-8 hours; after the reaction is completed, mixing the reacted material with pure water, cooling and carrying out liquid-liquid separation; and concentrating the heavy phase, cooling and crystallizing to obtain a crude product of sodium methyl lauroyl taurate, recrystallizing with pure water, centrifugally separating, and drying to obtain the product. The process is simple and convenient to operate, a catalyst is not used, the reaction is smoothly carried out by controlling the reaction proportion and reaction temperature of lauric acid and sodium methyl taurate, water phase extraction is adopted, no impurity is brought into the whole reaction system, the conversion rate reaches 95% or above, and the product purity can reach 99% or above.

Owner:湖北天安日用化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com