Repair emulsion focusing on sensitive skin root and preparation method and application of repair emulsion

A technology based on sensitive skin and roots, applied in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve problems such as poor overall effect, achieve unblocked pores, efficient skin repair, and skin barrier repair Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

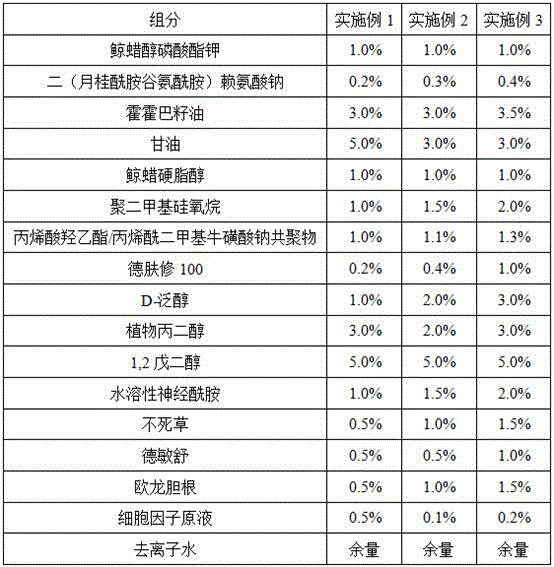

Embodiment 1

[0075] Example 1 Preparation of a repairing emulsion that focuses on the roots of sensitive skin

[0076] 1. The specific steps are:

[0077] (1) Add 3.0% jojoba seed oil, 1.0% cetearyl alcohol, 1.0% polydimethylsiloxane, and 0.2% Defuxiu 100 into the oil phase beaker, stir and heat up to 80°C, add 1.0% potassium cetyl phosphate (do not stop stirring), keep warm for 15 minutes for later use, and obtain the oil phase raw material.

[0078] (2) 5% glycerin, 0.2% bis(lauroamide glutamine) sodium lysine, 1.0% copolymer, 1.0% D-panthenol, 3% plant propylene glycol, 5.0% 1,2 pentanediol and other Add a certain amount of water into the water phase beaker, stir and heat up to 85°C, and keep it warm for 20 minutes for later use to obtain the water phase raw material.

[0079] (3) Slowly add the oil phase raw materials into the water phase beaker, stir at 500rpm, keep the vacuum degree -0.04Mpa, and then homogenize, the homogenization speed is 2800rpm, and the homogenization time is 3...

Embodiment 2

[0082] Example 2 Preparation of a repairing emulsion with a focus on sensitive skin roots

[0083] 1. The specific steps are:

[0084] (1) Add 3.0% jojoba seed oil, 1.0% cetearyl alcohol, 1.5% polydimethylsiloxane, and 0.4% Defuxiu 100 into the oil phase beaker, stir and heat up to 85°C, add 1.0% potassium cetyl phosphate (do not stop stirring), keep warm for 10 minutes for later use, and obtain the oil phase raw material.

[0085] (2) 3% glycerin, 0.3% bis(laurylamide glutamine) sodium lysine, 1.1% copolymer, 2.0% D-panthenol, 2% plant propylene glycol, 5.0% 1,2 pentanediol and other A certain amount of water was added to the water phase beaker, stirred and heated to raise the temperature, heated to 90°C, and kept for 15 minutes for later use to obtain the water phase raw material.

[0086] (3) Slowly add the oil phase raw materials into the water phase beaker, stir at 500rpm, keep the vacuum degree -0.06Mpa, and then homogenize, the homogenization speed is 2800rpm, and the...

Embodiment 3

[0089] Example 3 Preparation of a repairing lotion with a focus on sensitive skin roots

[0090] 1. The specific steps are:

[0091] (1) Add 3.5% jojoba seed oil, 1.0% cetearyl alcohol, 2.0% polydimethylsiloxane, and 1.0% Defuxiu 100 into the oil phase beaker, stir and heat up to 85°C, add 1.0% potassium cetyl phosphate (do not stop stirring), keep warm for 15 minutes for later use, and obtain the oil phase raw material.

[0092] (2) 3% glycerin, 0.4% bis(lauramide glutamine) sodium lysine, 1.3% hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer, 3.0% D-panthenol, 3 % plant propylene glycol, 5.0% 1,2-pentanediol and the rest of water were added to the water phase beaker, stirred and heated to raise the temperature, heated to 90°C, and kept for 20 minutes for later use to obtain the water phase raw material.

[0093] (3) Slowly add the oil phase raw materials into the water phase beaker, stir at 500rpm, maintain a vacuum of -0.05Mpa, and then perform homogenizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com