A kind of preparation method and application of si-o-c polyether-based organosilicon elastomer gel

A technology based on polyether and silicone, which is applied in the direction of medical preparations containing active ingredients, skin care preparations, pharmaceutical formulations, etc., and can solve problems such as limitations, restrictions on the scope of use of elastomers, and limited hydrophilicity of elastomer emulsions. , to achieve the effect of moisturizing the skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

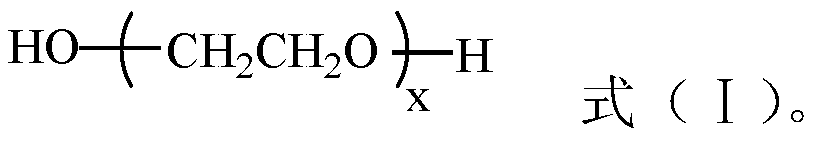

[0026] (1) In a 1000mL round-bottom four-neck flask, weigh 100.0g of hydrogen-containing polysiloxane with a Si-H content of 0.5% and a viscosity of 30.0cSt at 25°C, and 269.4g of polyethylene glycol 1 (where x= 20, average number average molecular weight M n =898), the ratio of the alcoholic hydroxyl group to the Si-H bond in the material is 1.2:1, and 369.4g of ethanol is added as a solvent (the solvent accounts for 50% of the material ratio), the temperature is raised to 60°C under mechanical stirring, and aluminum acetylacetonate is added As a catalyst, the amount added is 1% of the total amount of materials, and kept at this temperature for 6.0 hours. After the reaction, the solvent was removed under reduced pressure to obtain a silicone elastomer powder 1

[0027] (2) Take 100.0g of silicone elastomer powder 1 and add it to a 1000mL open beaker, and add 400.0g of linear small molecular polysiloxane with a viscosity of 6.0cSt at 25°C. At this time, the proportion of disp...

Embodiment 2

[0029] (1) In a 1000mL round-bottom four-neck flask, weigh 25.0g of hydrogen-containing polysiloxane with a Si-H content of 0.5% and a viscosity of 30.0cSt at 25°C, and 166.4g of polyethylene glycol 2 (where x= 50, average number average molecular weight M n =2218), the ratio of alcoholic hydroxyl group and Si-H bond in the material is 1.2:1, and add 191.4g n-propanol as solvent (solvent accounts for material ratio and be 50%), be warming up to 80 ℃ under mechanical stirring, add acetyl Zinc acetonate is used as a catalyst, the addition amount is 1% of the total amount of materials, and the reaction is kept at this temperature for 6.0h. After the reaction, the solvent was removed under reduced pressure to obtain a silicone elastomer powder 2 .

[0030] (2) Take 100.0g of silicone elastomer powder 2 and add it to a 1000mL open beaker, and add 400.0g of linear small molecular polysiloxane with a viscosity of 1.0cSt at 25°C. At this time, the proportion of dispersant is 80%. Af...

Embodiment 3

[0032] (1) In a 1000mL round-bottom four-neck flask, weigh 25.0g of hydrogen-containing polysiloxane with a Si-H content of 1.0% and a viscosity of 5.0cSt at 25°C, and 134.7g of polyethylene glycol 1 (wherein x= 20, average number average molecular weight M n =898), the ratio of alcoholic hydroxyl group and Si-H bond in the material is 1.2:1, and add 106.5g isopropanol as solvent (solvent accounts for material ratio and be 40%), be warming up to 50 ℃ under mechanical stirring, add acetyl Iron acetone is used as a catalyst, the addition amount is 2% of the total amount of materials, and the reaction is kept at this temperature for 6.0h. After the reaction, the solvent was removed under reduced pressure to obtain a silicone elastomer powder 3 .

[0033] (2) Take 100.0g of silicone elastomer powder 3 and add it to a 1000mL open beaker, and add 400.0g of linear small molecular polysiloxane with a viscosity of 50.0cSt at 25°C. At this time, the proportion of dispersant is 80%. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com