Taurine synthesis method

A synthetic method, the technology of taurine, applied in the direction of sulfonic acid preparation, sulfonate preparation, chemical instruments and methods, etc., can solve problems such as high temperature and high pressure, achieve the effects of increasing yield, mild reaction conditions, and avoiding continuous accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

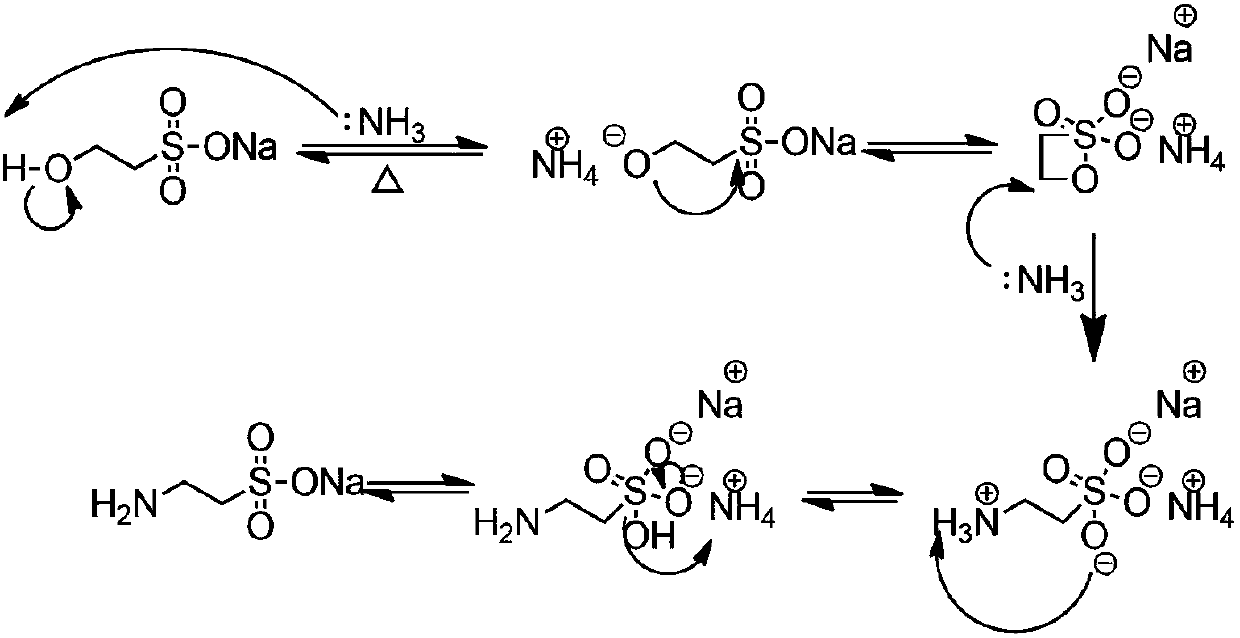

Method used

Image

Examples

Embodiment 1

[0037] Add 1000g of the prepared sodium bisulfite solution (24wt%) into the reactor, control the temperature at 45°C, then feed 106.7g of ethylene oxide, adjust the reaction pressure to 2bar, and stop the experiment after 45min. After cooling to room temperature, the addition reaction solution was selectively filtered using a PM280 nanofiltration membrane at a filtration temperature of 30°C and a pressure of 1 bar. After filtration, water was added for preparation. Add ruthenium hydroxide supported on zirconia with a loading capacity of 3% in a 1L high-pressure reactor in advance, the addition amount is 16.8g; take 700g of the prepared sodium isethionate solution (18.0wt%) and add it to the 1L high-pressure reactor During the process, feed liquid ammonia to make the concentration reach 19.0wt%, raise the temperature of the reaction system to 110°C, maintain the system pressure at 4MPa, and react for 30min. The yield of sodium taurate obtained by the ammonolysis reaction is 96.3...

Embodiment 2

[0039] Add 1000g of sodium bisulfite solution (10wt%) prepared into the reaction kettle, control the temperature at 25°C, then feed 50.8g of ethylene oxide, adjust the reaction pressure to 1bar, and stop the experiment after 10min. After cooling to room temperature, the addition reaction solution was selectively filtered using a PMS600 nanofiltration membrane at a filtration temperature of 10°C and a pressure of 0.1 bar. After filtration, water was added for preparation. Add 4% catalyst zirconia-supported ruthenium hydroxide in a 1L high-pressure reactor in advance, the addition amount is 17.6g; take 705g of the prepared sodium isethionate solution (10.0wt%) and add it to the 1L high-pressure reactor During the process, feed liquid ammonia to make the concentration reach 30.0wt%, raise the temperature of the reaction system to 80°C, maintain the system pressure at 1MPa, react for 10min, and the yield of sodium taurate obtained by the ammonolysis reaction is 70.7%. After the re...

Embodiment 3

[0041] Add 1000g of sodium bisulfite solution (30wt%) prepared into the reaction kettle, control the temperature at 95°C, then feed 126.9g of ethylene oxide, adjust the reaction pressure to 7bar, and stop the experiment after 70min. After cooling to room temperature, the addition reaction solution was selectively filtered using a PM280 nanofiltration membrane at a filtration temperature of 50°C and a pressure of 5 bar. After filtration, water was added for preparation. In advance in 1L high-pressure reactor, add the catalyst titanium oxide supported ruthenium hydroxide that load is 5%, add-on 2.84g (0.8wt%); Get the sodium isethionate solution (40wt%) after allocating 711g and add to In a 1L high-pressure reactor, feed liquid ammonia to make the concentration reach 25.0wt%, raise the temperature of the reaction system to 150°C, maintain the system pressure at 5.5MPa, and react for 60min. The yield of sodium taurate obtained by the ammonolysis reaction is 75.4%. After the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com