Separation and extraction method of taurine

An extraction method and technology of taurine, applied in the direction of sulfonic acid preparation, chemical instruments and methods, preparation of organic compounds, etc., can solve problems affecting the quality of taurine, difficulty in extracting taurine, unfavorable total yield, etc. Achieve the effect of weak acidity, high solubility and high value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

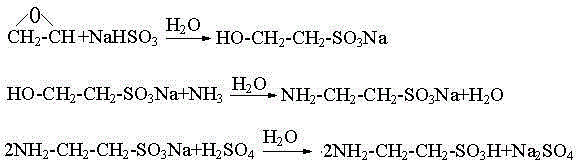

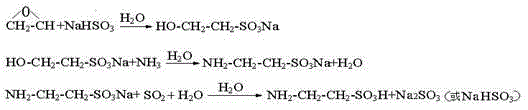

Method used

Image

Examples

Embodiment 1

[0022] Example 1: First, react ethylene oxide and sodium bisulfite aqueous solution to prepare sodium isethionate solution, then dissolve it into inorganic ammonia, put it into a high-temperature and high-pressure reactor for ammoniation, and then remove it by flash evaporation Inorganic ammonia, obtained water evaporation liquid containing 33.5% taurine. Take 657g of the above evaporating liquid, control the temperature below 40°C under water bath cooling, gradually introduce sulfur dioxide, the system releases heat, and the material crystallizes gradually thickens. When the pH value reaches 6.5, stop ventilation and gradually cool down to 33°C. No inorganic salt crystallization, suction filtration, washing with a small amount of ice water, drying to obtain 135g of crude taurine, content 93% (yield 57.1%), the mother liquor was cooled to 0°C under stirring, and filtered with an 80-mesh sieve. Wash with a small amount of ice water to obtain 222g of sodium sulfite crystals (41....

Embodiment 2

[0023] Example 2: In a 2000ml flask, take 657g of the above evaporated liquid, add 1000ml of mother liquor frozen to 0°C to reclaim taurine and sodium sulfite, under water bath cooling, control the temperature below 40°C, gradually feed sulfur dioxide, and the system will release Heat, the material gradually crystallizes, stop ventilation when the pH reaches 6.5, and gradually cool down to 0°C, at this time, taurine and sodium sulfite crystallize at the same time, the taurine crystals are finer, and the sodium sulfite crystals are thicker, maintain 0°C, stop stirring and let stand After 1 minute, pour out the upper layer of turbid liquid from the flask, filter the taurine with a filter cloth, return the mother liquor to the flask for stirring, let stand, and then filter again. After repeating 4 times, the upper layer is already relatively clear. The filter cake was washed with water, and 206 g of crude taurine was dried, with a content of 94.5% (yield 88.5%). Filter all the fe...

Embodiment 3

[0024] Example 3: In a 1000ml flask, take 657g of the above evaporated liquid, under cooling in a water bath, control the temperature below 40°C, gradually feed sulfur dioxide, the system exotherms, and the material gradually crystallizes. When the pH reaches 5.0, stop the aeration, and gradually Cool down to 0°C, let taurine fully crystallize, sodium bisulfite does not crystallize, maintain 0°C, pour out the turbid liquid from the flask, filter taurine with filter cloth, wash the filter cake with a small amount of ice water, and dry The crude product of taurine is 199.8g, the content is 92.5% (84% yield). 539g of sodium bisulfite solution (32.5% content, 95.6% yield, 6.5% taurine content) was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com