Separation and purification process of taurine

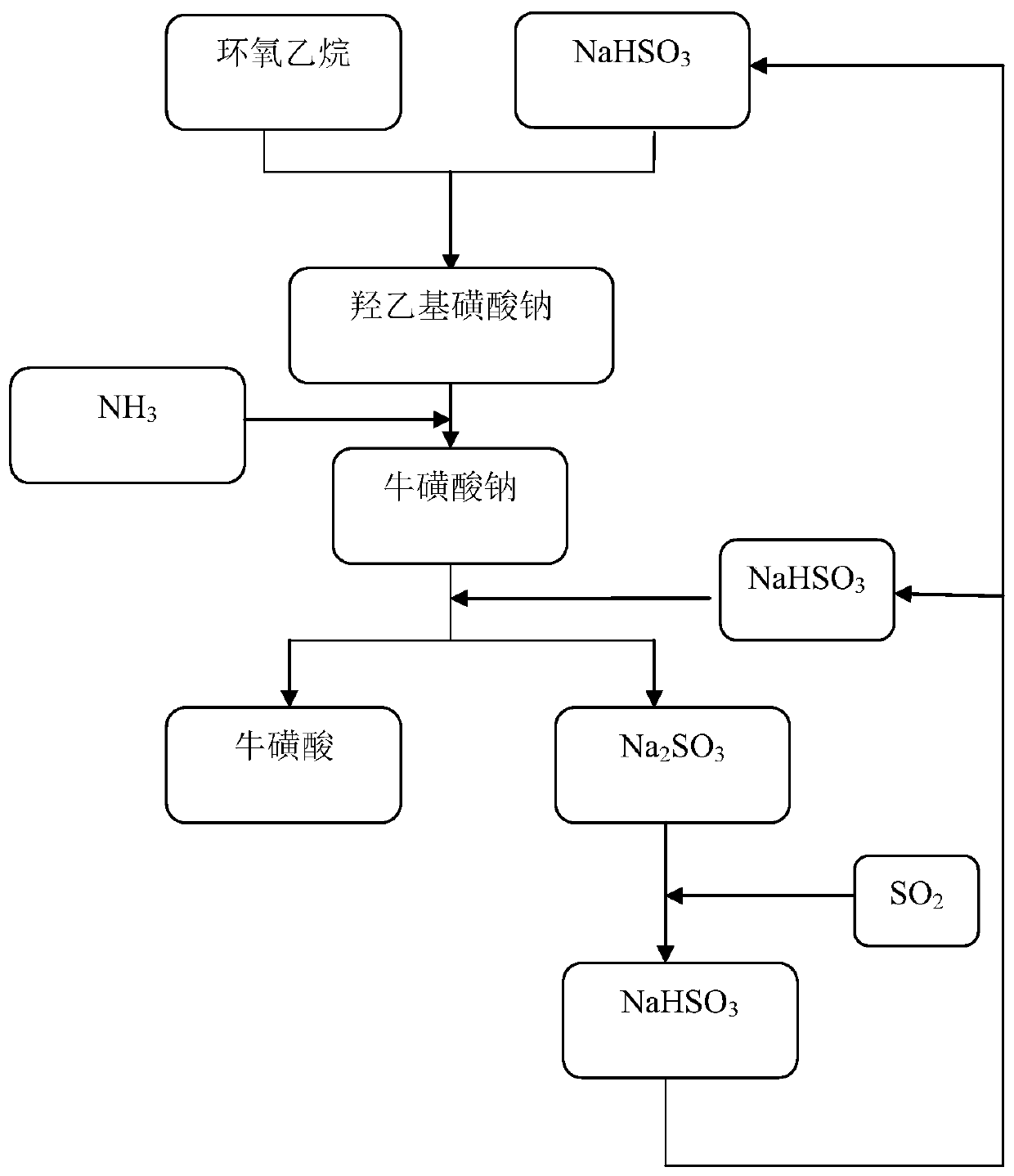

A technology for separation and purification of taurine, which is applied in the field of separation and purification of taurine, can solve the problems of low added value of sodium sulfate and increase of production and processing costs, and achieve the effect of clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

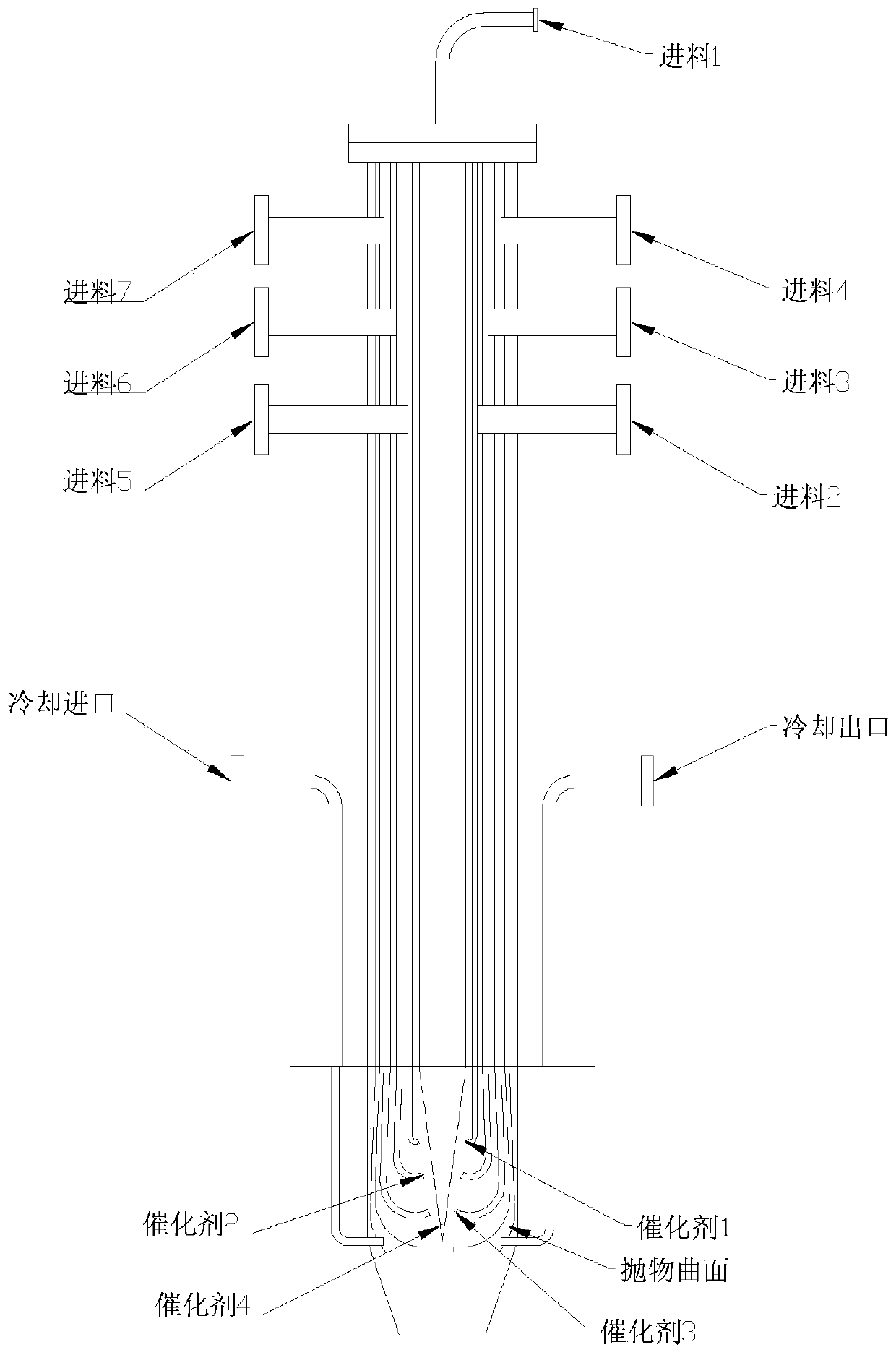

[0031] Pass ethylene oxide into sodium bisulfite solution, specifically, mix ethylene oxide and sodium bisulfite through an ionized multi-channel nozzle device under the action of a catalyst to prepare sodium isethionate The reaction temperature of the solution is 60-75°C, the molar ratio of ethylene oxide to sodium bisulfite is controlled at 1.05-1.10, the pH value during the reaction is controlled at 5.7-6.3, and the yield of sodium isethionate is greater than 95%. .

[0032] In the synthesis section, the mother liquor and supplementary ammonia gas, ammonia water or liquid ammonia are ammonolyzed with sodium isethionate to sodium taurine through an ionized multi-channel nozzle device, and sodium iminodisulfonate and N- Sodium triethanesulfonate is also converted to sodium taurate.

[0033] The sodium taurine solution obtained through high temperature and high pressure synthesis reaction is added to sodium bisulfite to neutralize to pH=5.0-9.0, the temperature is 20-40 DEG C...

Embodiment 2

[0039] Pass ethylene oxide into sodium bisulfite solution, specifically, mix ethylene oxide and sodium bisulfite through an ionized multi-channel nozzle device under the action of a catalyst to prepare sodium isethionate The reaction temperature of the solution is 60-75°C, the molar ratio of ethylene oxide to sodium bisulfite is controlled at 1.05-1.10, the pH value during the reaction is controlled at 5.7-6.3, and the yield of sodium isethionate is greater than 95%. .

[0040] Sodium isethionate is mixed with the reused mother liquor through an ionized multi-channel nozzle device, and then ammonia gas, ammonia water or liquid ammonia is supplemented through the ionized multi-channel nozzle device, and the ammonia content is controlled at 24-34% (w / v ), into the synthesis tower. The reaction temperature is controlled at 230-280°C, the pressure is controlled at 16-21MPa, and the residence time of the material in the tower is not less than 30 minutes. Ammonolysis of sodium ise...

Embodiment 3

[0047] Pass ethylene oxide into sodium bisulfite solution, specifically, mix ethylene oxide and sodium bisulfite through an ionized multi-channel nozzle device under the action of a catalyst to prepare sodium isethionate The reaction temperature of the solution is 60-75°C, the molar ratio of ethylene oxide to sodium bisulfite is controlled at 1.05-1.10, the pH value during the reaction is controlled at 5.7-6.3, and the yield of sodium isethionate is greater than 95%. .

[0048] Sodium isethionate is mixed with the reused mother liquor through an ionized multi-channel nozzle device, and then ammonia gas, ammonia water or liquid ammonia is supplemented through the ionized multi-channel nozzle device, and the ammonia content is controlled at 24-34% (w / v ), into the synthesis tower. The reaction temperature is controlled at 230-280°C, the pressure is controlled at 16-21MPa, and the residence time of the material in the tower is not less than 30 minutes. Ammonolysis of sodium ise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com