Preparation method for taurine

A technology of taurine and sodium taurine, which is applied in the preparation of sulfonic acid, sulfonate, and organic compounds, etc., can solve problems such as consumption of a large amount of steam, waste of raw materials, low yield, etc., and solve environmental pollution. , The effect of reducing production cost and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of preparation method of taurine provided by the embodiment of the present invention comprises the following steps: taking the sodium taurine solution into S 4+ After the pH value of the compound is adjusted, the crude taurine is separated by crystallization, and at the same time, the separated mother liquor is passed through ethylene oxide to convert it into sodium isethionate, and ammonia is added to react to regenerate sodium taurine.

[0024] In addition, taurine can also be produced through the following steps: take sodium taurine solution in S 4+ After the compound adjusts the pH value, continue to pass through ethylene oxide to generate a mixed solution of sodium isethionate and taurine, then separate the crude taurine, and then add ammonia to the mother liquor after separation to regenerate sodium taurine.

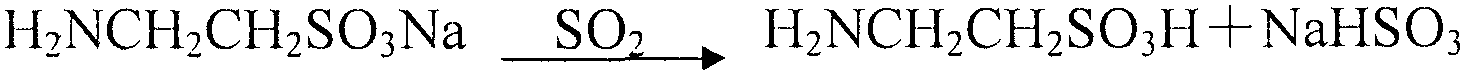

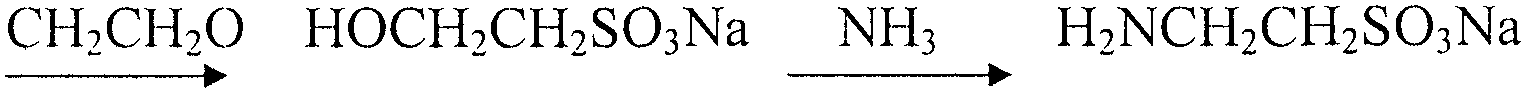

[0025] The reaction principle is as follows:

[0026]

[0027]

Embodiment 1

[0029] Take 500ml, 46% sodium taurine solution in the reaction flask, and slowly feed SO with stirring 2 Stop at pH 5.5, drop to normal temperature and filter to obtain the crude product of taurine, move the filtrate into the reaction flask, and slowly feed ethylene oxide (the amount of sodium taurate and ethylene oxide in the solution) at 72°C under stirring. The ratio of the amount of substance is 1: 1), until the reaction reaches the end point (determined with the number of iodine drops), then this reaction solution is supplemented with 1015g NH 3 ·H 2 O, heated to 250°C in a high-pressure reactor, with a pressure of 4.05 MPa, reacted for 1 hour, cooled down and discharged, evaporated to catch ammonia, and obtained sodium taurine solution. Taurine content was determined by HPLC, SO 3 2- Content and sodium isethionate content are determined by ion chromatography; The results are as follows, in mass percent:

[0030] Crude Taurine: Quantity: 243g

[0031] Taurine content...

Embodiment 2

[0037] Take 500ml, 46% sodium taurine solution in the reaction flask, and slowly feed SO with stirring 2 Stop at pH 5.5, then slowly feed ethylene oxide at 75°C (the ratio of sodium taurate to ethylene oxide in the solution is 1: 1.1), until the reaction reaches the end point (use iodine drop count Determine), down to normal temperature and filter to get the crude product of taurine, then add 1005g NH to this reaction solution 3 ·H 2 O, heated to 253°C in a high-pressure reactor, with a pressure of 4.1MPa, reacted for 1 hour, cooled down and discharged, evaporated to catch ammonia, and obtained sodium taurine solution. Result is as follows, by mass percent:

[0038] Crude Taurine: Quantity: 242g

[0039] Taurine content: 86.78%

[0040] SO 3 2- Content: 1.9%

[0041] Sodium taurine solution: Quantity: 616g

[0042] Sodium taurine content (folded taurine): 39.15%

[0043] Sodium isethionate content: 49.62%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com