Bottom-mounted micro-interface enhanced reaction device and method for residual oil hydrogenation reaction

A residual oil hydrogenation, bottom-mounted micro-technology, applied in chemical instruments and methods, hydrocarbon oil cracking, petroleum industry, etc., can solve the problems of high safety risk, high investment, high material consumption, etc., and achieve low process severity and production. The effect of high safety and low cost per ton of product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

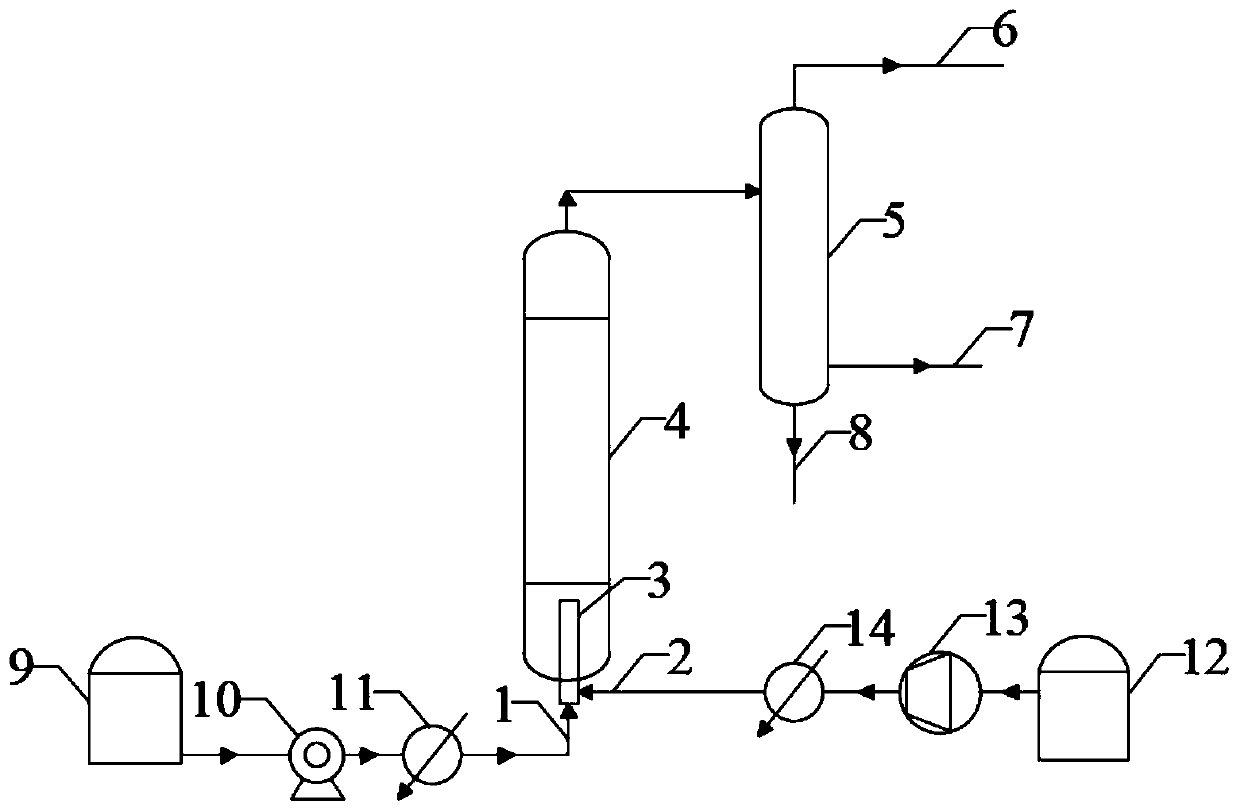

[0033] This embodiment specifies the device structure of the present invention, as figure 1 The shown below-mounted micro-interface strengthening reaction device for residual oil hydrogenation reaction includes:

[0034] Suspension bed reactor 4, the top is provided with the second outlet;

[0035] Air intake device, including a hydrogen buffer tank 12, a compressor 13 and a hydrogen preheater 14 connected in sequence, for raw gas delivery;

[0036] The liquid inlet device includes a residual oil raw material tank 9, a feed pump 10 and a residual oil preheater 11 connected in sequence, for raw material liquid transportation;

[0037] At least one bubble breaker is arranged at the bottom of the suspended bed reactor 4, and the bubble breaker is provided with a gas phase inlet, a liquid phase inlet and a first discharge port, and the first discharge port is connected to the suspension bed reactor; the gas phase The inlet is connected to the hydrogen preheater 14 of the air int...

Embodiment 2

[0041] This embodiment takes the hydrogenation ring-opening reaction of residual oil as an example to specifically illustrate an implementation of the method of the present invention.

[0042] The raw material residual oil is produced from the residual oil raw material tank 9, and after passing through the plunger pump 10 and then the residual oil preheater 11, it enters the microbubble breaker 3 through the liquid phase inlet 1, and the raw material hydrogen gas is extracted from the hydrogen gas raw material tank 12 at the same time , after passing through the compressor 13 and then the hydrogen preheater 14, it enters the pneumatic bubble breaker 3 from the bottom through the gas phase inlet 2, wherein the volume ratio of hydrogen and residual oil is 1000:1, and the two phases are in the microbubble breaker 3 Fully mixed under the action of hydrogen, and the hydrogen is broken into 300 ~ 500μm bubbles to increase the contact area of the two phases. Then the mixed material...

Embodiment 3

[0046] The difference between this example and Example 2 is that the volume ratio of hydrogen and residual oil is 300:1, the two phases are fully mixed under the action of the bubble breaker 3, and the hydrogen is broken into 500μm-1mm bubbles .

[0047] The reaction pressure in the bubble breaker is 1 MPa, and the reaction temperature is 480°C. The suspension bed reactor 4 adopts a carbon-supported iron-based catalyst with a particle size of 100nm-1000μm. Airspeed control is 1.5h -1 . The light oil yield was 79%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com