Grease epoxidation reaction device

A technology of epoxidation reaction and cyclic reaction, which is applied in organic chemistry, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of insufficient contact mixing, unfavorable industrial amplification, and affecting product quality, etc., and achieve energy consumption and Low production cost, small investment and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto:

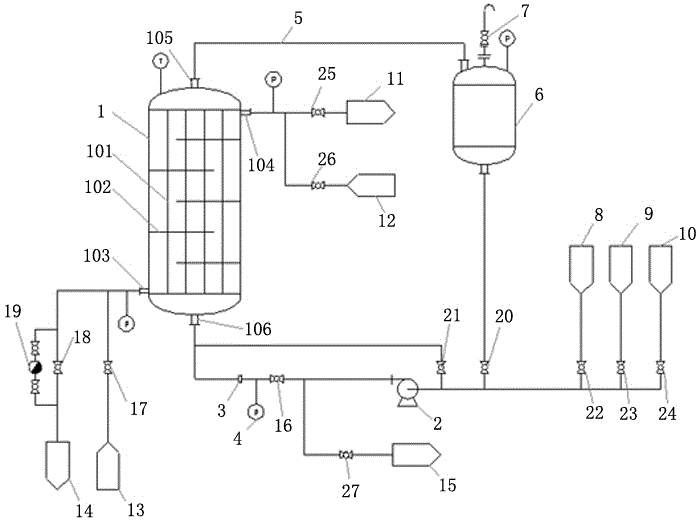

[0021] Such as figure 1 As shown, a kind of grease epoxidation reaction device of the present invention comprises the reaction tank 1, the intermediate tank 6, the circulation pump 2 and the hydraulic cavitator 3 that are connected successively to form the circulation reaction system through the reaction circulation pipeline 5, and the reaction The upper end of the head of the tank 1 is provided with a material circulation outlet 105, the lower end of the head is provided with a material circulation inlet 106, the material circulation outlet 105 and the material circulation inlet 106 are connected to the reaction circulation pipeline 5, and the input end of the circulation pump 2 is provided with a grease inlet 8, Hydrogen peroxide inlet 9 and formic acid inlet 10, the output end of the circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com