Preparation system and process of alpha-olefin-fluorostyrene polymer

A fluorostyrene preparation system technology, applied in the field of α-olefin-fluorostyrene polymer preparation system, can solve the problem of low product yield, achieve enhanced mass transfer, reduce liquid film thickness, and improve polymerization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

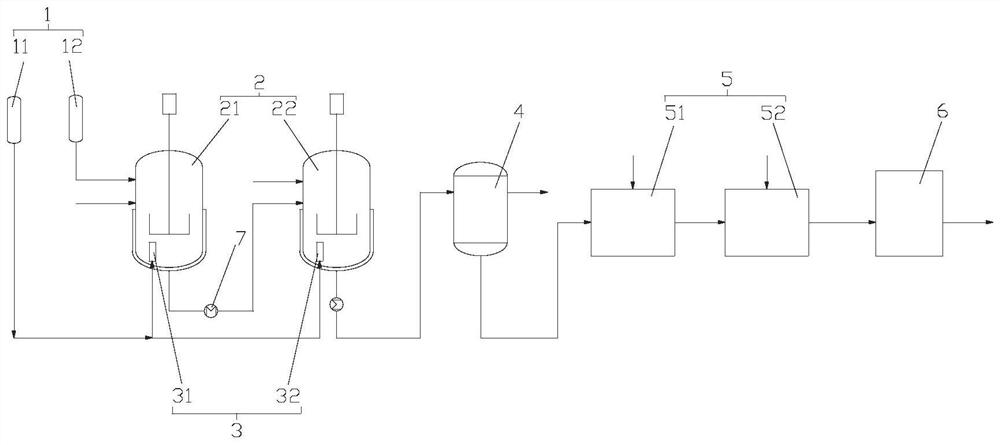

Image

Examples

Embodiment 1

[0064] Use the system and process of the present invention to prepare alpha olefin-fluorostyrene polymers, wherein:

[0065] The α-olefin monomer is ethylene, the fluorostyrene monomer is p-fluorostyrene, the solvent in the first reactor is deionized water, the solvent in the second reactor is saturated brine, and the emulsifier is sodium dodecylsulfonate , a mixture of sodium lauryl sulfate and sodium laurylamine hydrochloride, and the initiator is hydrogen peroxide solution.

[0066] During pre-emulsification, the stirring rate of the first reactor is 100r / min; during emulsification, the stirring rate of the first reactor is 300r / min, and the reaction temperature is 55°C; during demulsification, the stirring rate of the second reactor The speed is 800r / min, and the reaction pressure is 1atm.

[0067] α olefin monomer, fluorostyrene monomer and α olefin-fluorostyrene polymer were detected before and after operation, and the conversion rate of α olefin monomer was 98.6%, and ...

Embodiment 2

[0069] Use the system and process of the present invention to prepare alpha olefin-fluorostyrene polymers, wherein:

[0070] The α-olefin monomer is ethylene, the fluorostyrene monomer is p-fluorostyrene, the solvent in the first reactor is deionized water, the solvent in the second reactor is saturated brine, and the emulsifier is sodium dodecylsulfonate , a mixture of sodium lauryl sulfate and sodium laurylamine hydrochloride, and the initiator is hydrogen peroxide solution.

[0071] During pre-emulsification, the stirring rate of the first reactor was 130r / min; during emulsification, the stirring rate of the first reactor was 320r / min, and the reaction temperature was 58°C; during demulsification, the stirring rate of the second reactor was The speed is 850r / min, and the reaction pressure is 3atm.

[0072] α olefin monomer, fluorostyrene monomer and α olefin-fluorostyrene polymer were detected before and after operation, and the conversion rate of α olefin monomer was 99.2...

Embodiment 3

[0077] Use the system and process of the present invention to prepare alpha olefin-fluorostyrene polymers, wherein:

[0078] The α-olefin monomer is a mixture of ethylene and propylene, the fluorostyrene monomer is a mixture of o-fluorostyrene, p-fluorostyrene and m-fluorostyrene, the solvent in the first reactor is deionized water, and the solvent in the second reactor is The solvent is saturated saline, the emulsifier is a mixture of sodium dodecylsulfonate, sodium dodecyl sulfate and sodium dodecylamine hydrochloride, and the initiator is hydrogen peroxide solution.

[0079] During pre-emulsification, the stirring rate of the first reactor is 170r / min; during emulsification, the stirring rate of the first reactor is 410r / min, and the reaction temperature is 55°C; during demulsification, the stirring rate of the second reactor The speed is 900r / min, and the reaction pressure is 5atm.

[0080] α olefin monomer, fluorostyrene monomer and α olefin-fluorostyrene polymer were de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com