Patents

Literature

48results about How to "Increase the mass transfer area of the phase boundary" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-interface preparation system and method of cyclic carbonate

PendingCN112058191AIncrease the mass transfer area of the phase boundarySolve the problem of reduced reaction efficiencyOrganic chemistryChemical/physical/physico-chemical microreactorsPtru catalystCarbonate ester

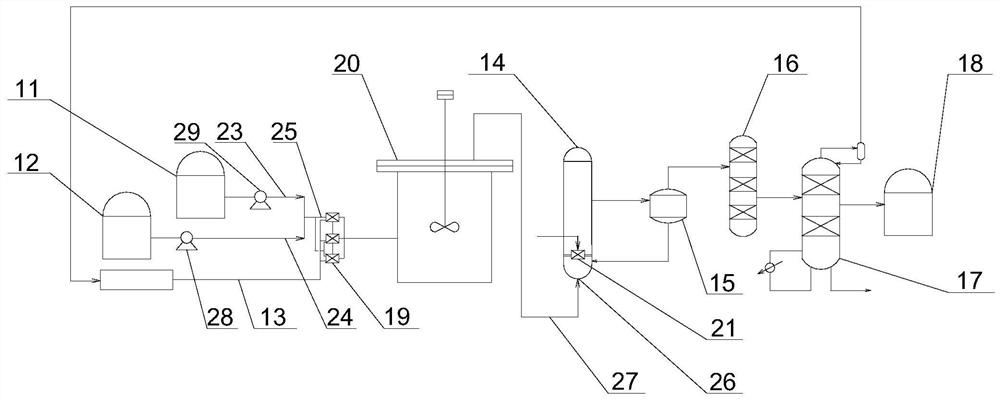

The invention provides a micro-interface preparation system and method of cyclic carbonate. The micro-interface preparation system comprises a stirring kettle and a carboxylation reaction kettle; andthe stirring kettle and the carboxylation reaction kettle are both filled with an ionic liquid catalyst; a micro-interface unit is arranged on the side face of the stirring kettle and composed of a plurality of external micro-interface generators; carbon dioxide is introduced into a main pipeline of the micro-interface unit, and at the same time is connected with two branch pipelines, namely, an oxidizing agent conveying pipeline and an olefin conveying pipeline, and the carbon dioxide is led into the micro-interface unit from a gas source conveying pipeline. And the carbon dioxide, an oxidizing agent and olefin enter the micro-interface unit, so that the carbon dioxide gas can be crushed into micron-grade micro-bubbles. According to the micro-interface preparation system, the phase boundary mass transfer area between carbon dioxide and cyclic carbonate generated in situ in a carboxylation reaction process is increased, sufficient mixing is conducted, and then the carboxylation reaction is conducted.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

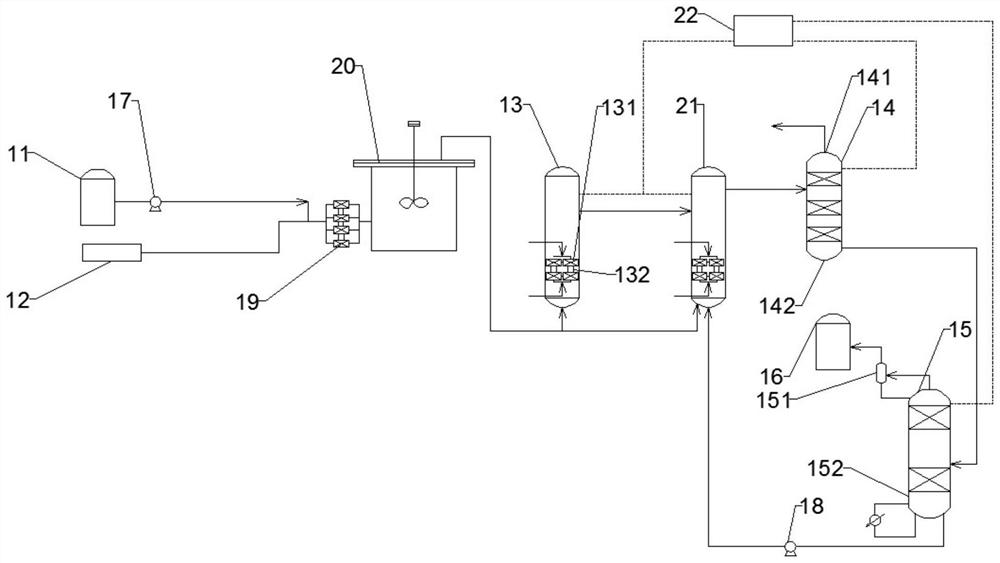

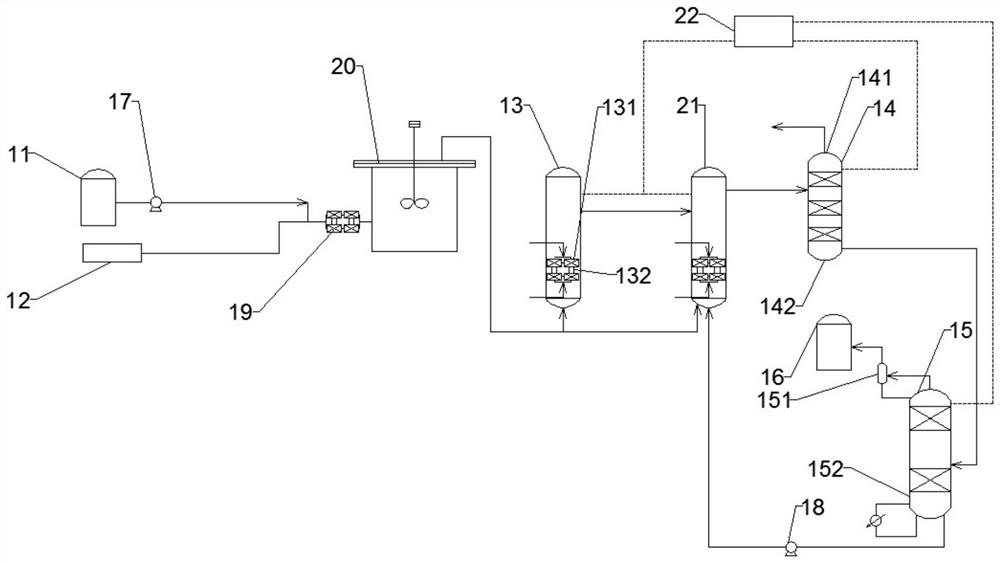

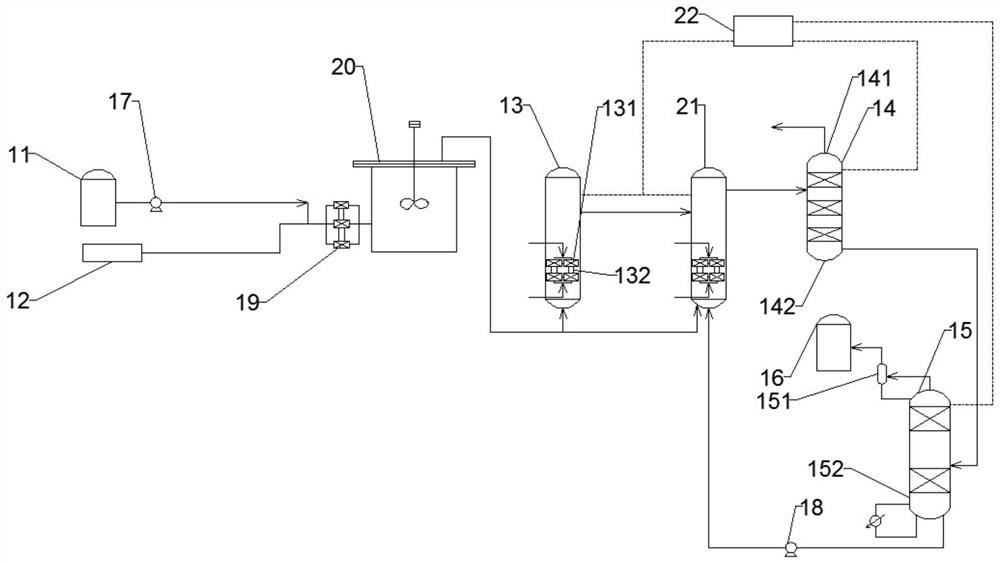

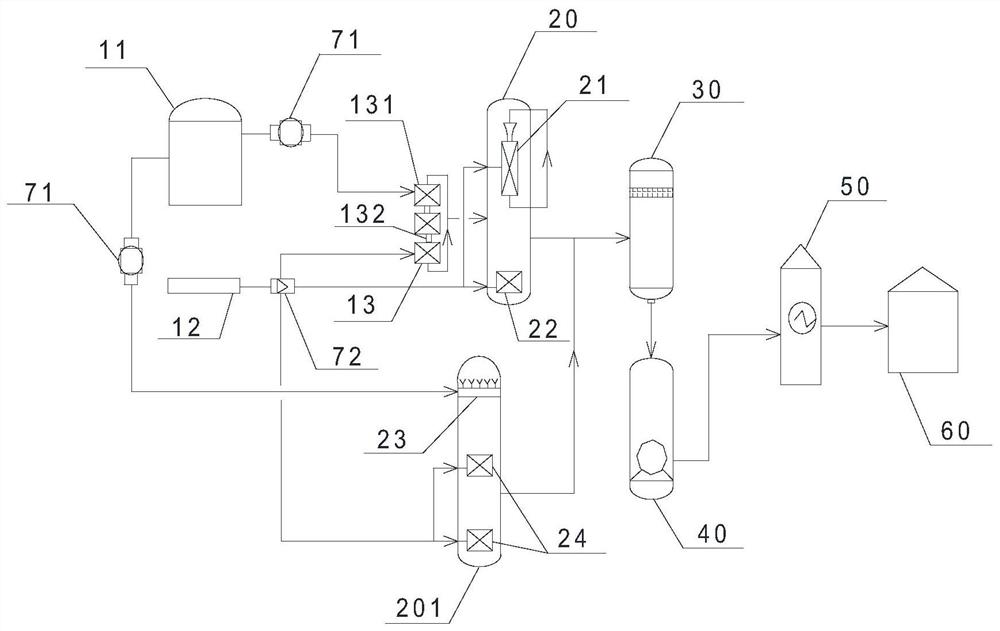

Reinforced micro-interface preparation system and method of cyclic carbonate

InactiveCN111961026AImprove fusion effectFully dispersed and brokenProductsOrganic chemistryPtru catalystCarbonate ester

The invention provides a reinforced micro-interface preparation system and a method of cyclic carbonate, the preparation system comprises a stirring kettle, a first carboxylation reaction kettle and asecond carboxylation reaction kettle, and the stirring kettle, the first carboxylation reaction kettle and the second carboxylation reaction kettle are all filled with an ionic liquid catalyst; a micro-interface unit is arranged on the side surface of the stirring kettle and consists of a plurality of external micro-interface generators. According to the reinforced micro-interface preparation system, the phase boundary mass transfer area between carbon dioxide and cyclic carbonate generated in situ in the carboxylation reaction process is increased; and the carbon dioxide and the cyclic carbonate are fully mixed and then subjected to the carboxylation reaction, so that the problem that the carbon dioxide and the cyclic carbonate cannot be fully mixed in the reaction kettle in the prior art is solved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

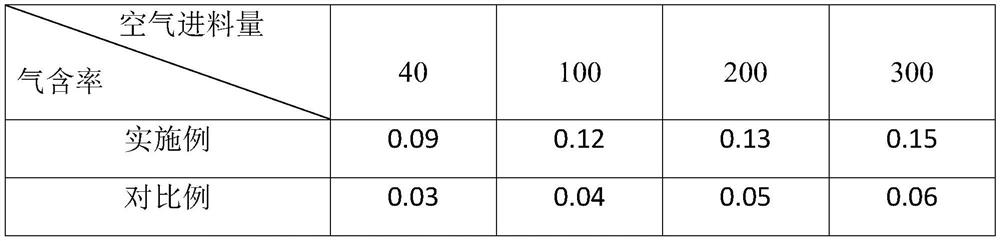

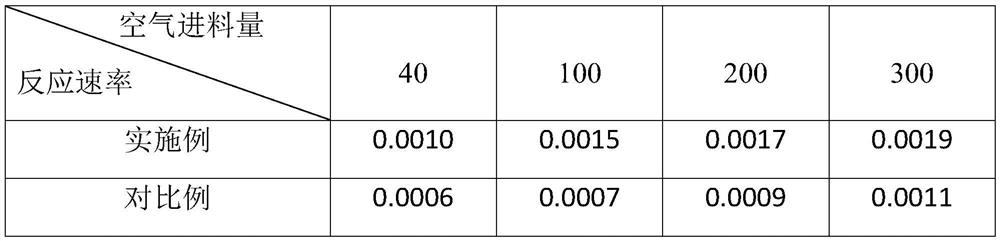

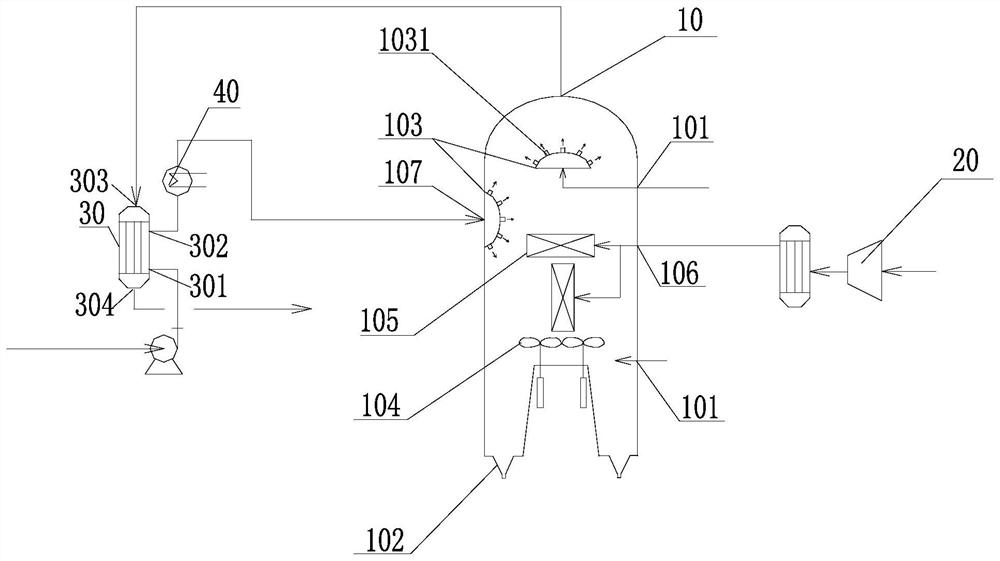

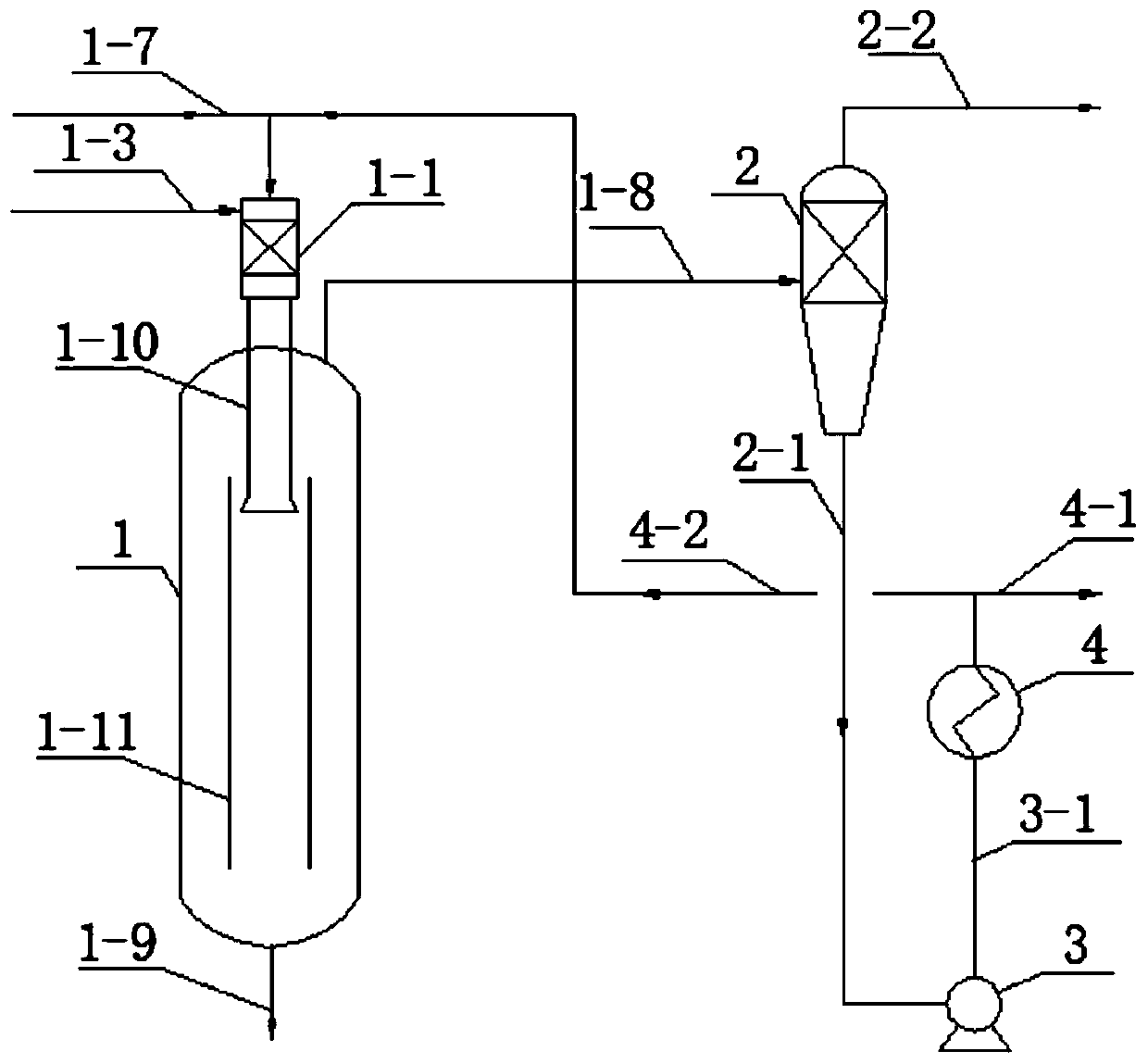

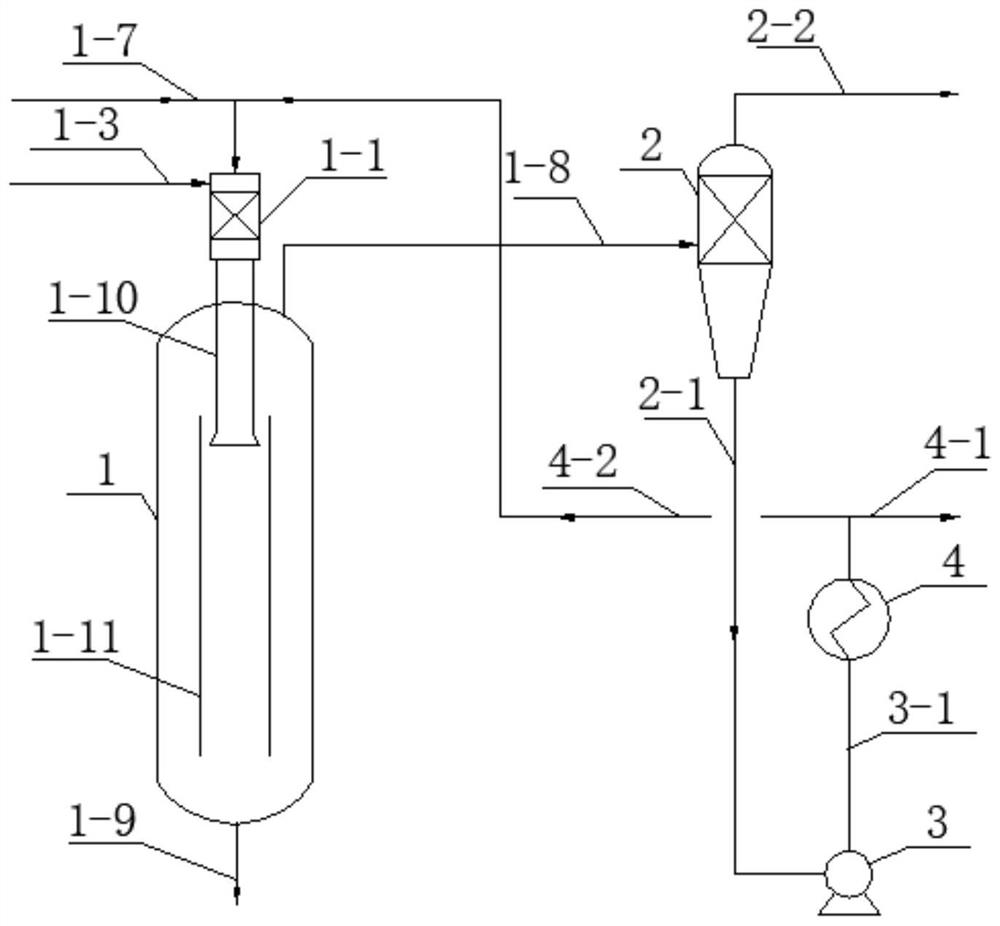

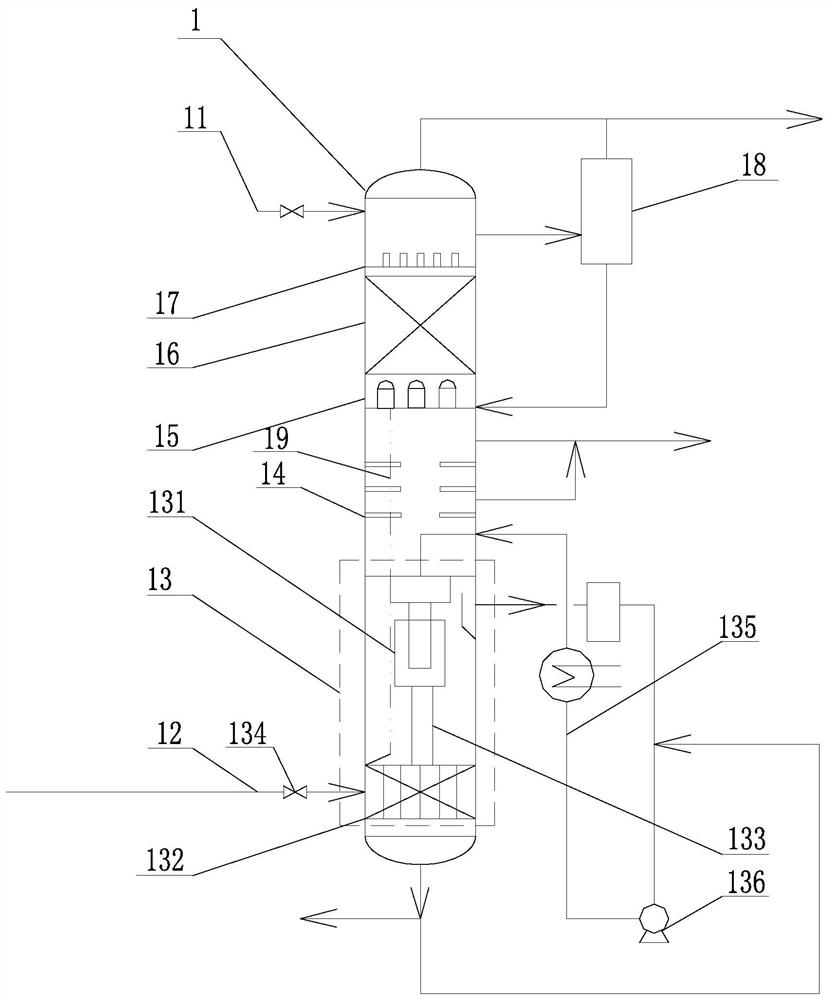

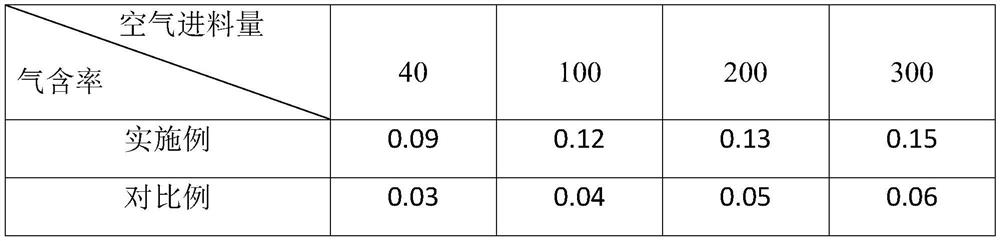

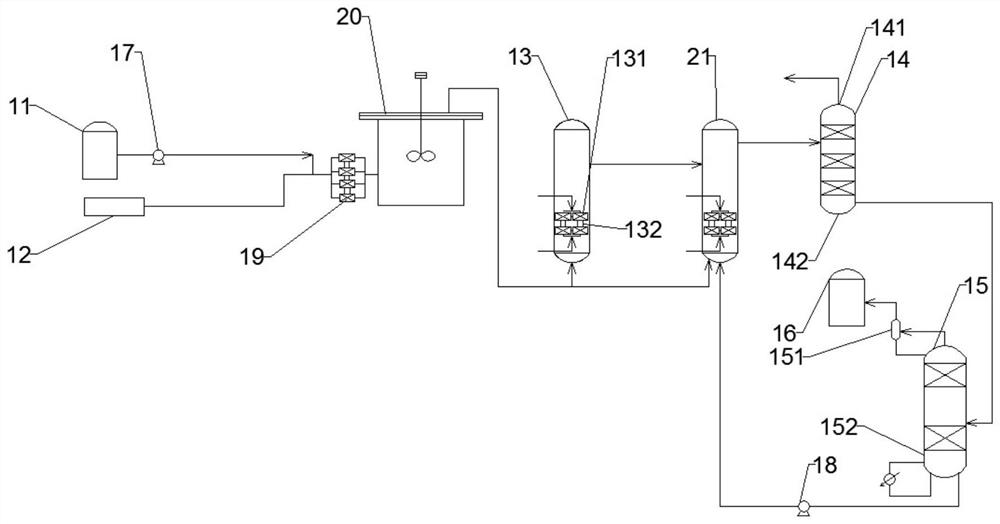

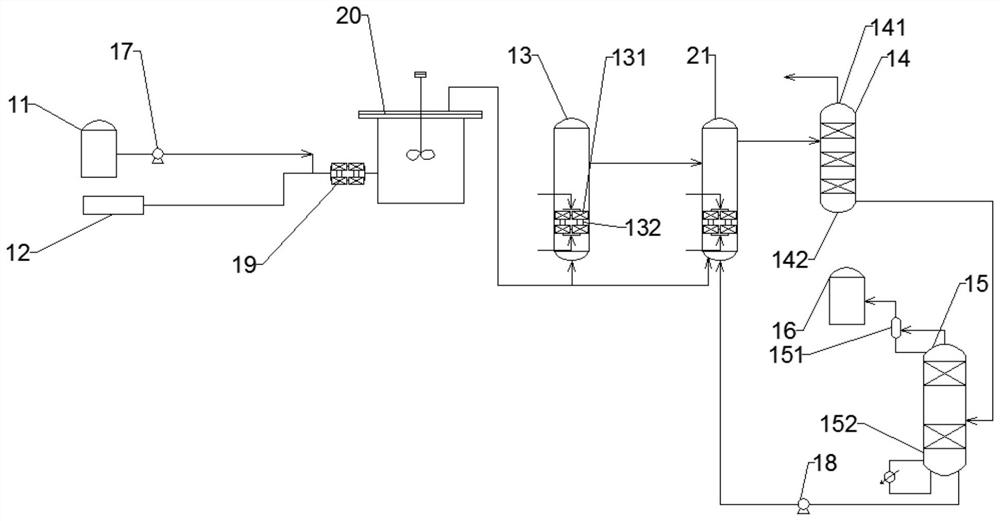

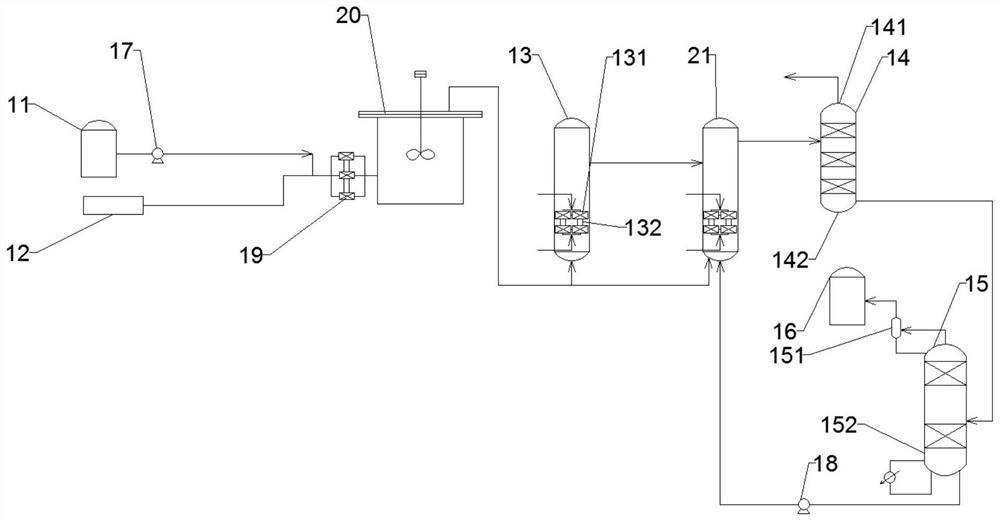

Micro-interface reaction system and method for ammonium sulfite oxidation

InactiveCN112755767AIncrease the mass transfer area of the phase boundaryTake advantage ofGas treatmentMixing methodsPhysical chemistryReaction system

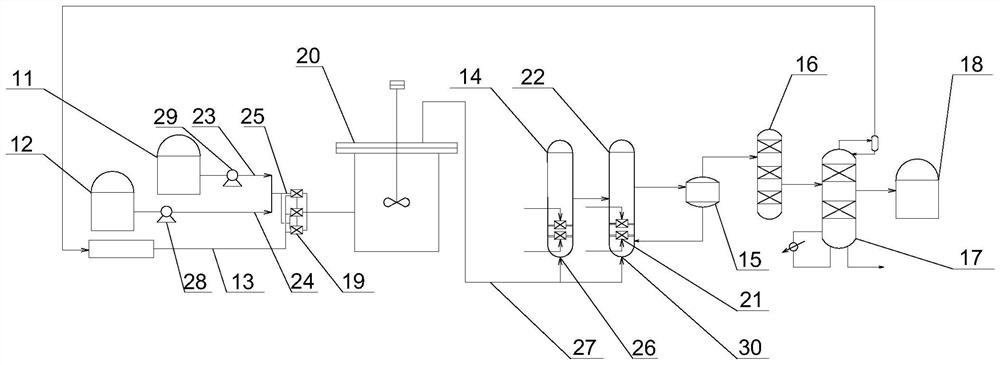

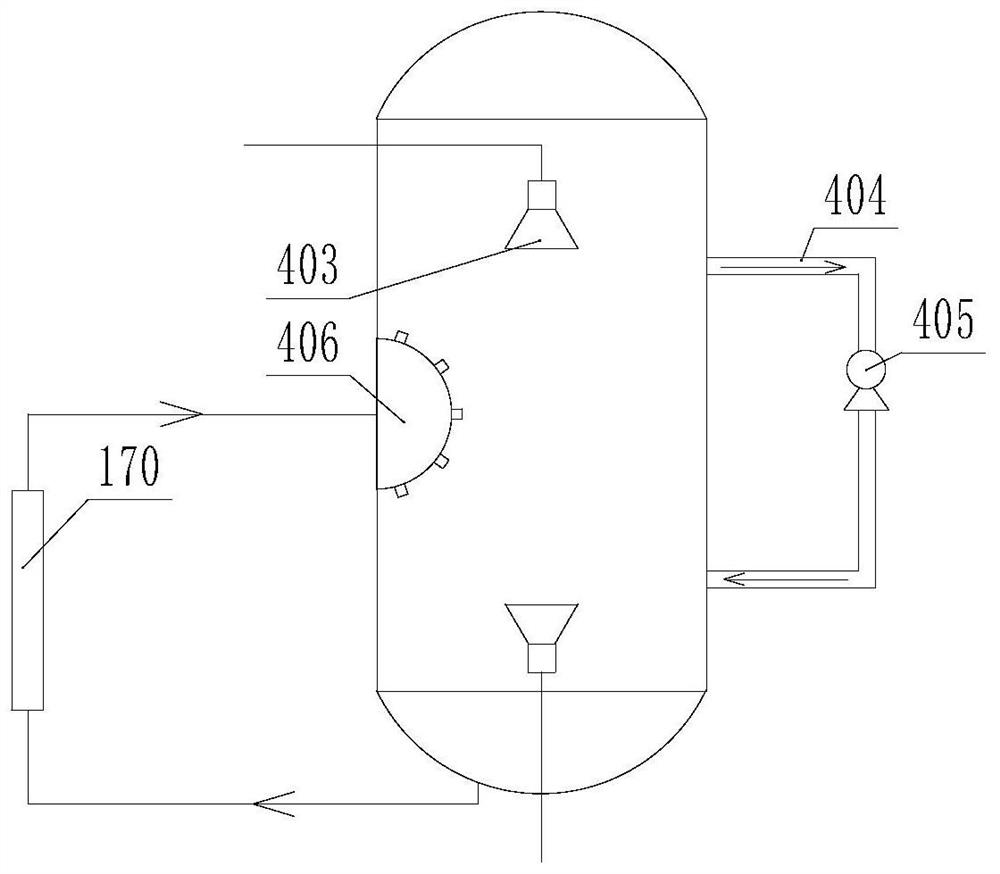

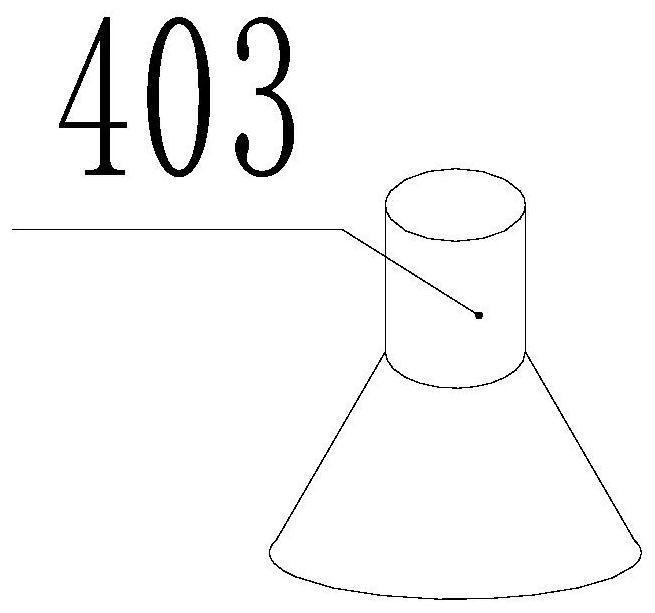

A micro-interface reaction system for ammonium sulfite oxidation comprises an oxidation reactor, an ammonium sulfite storage tank, an oxygen inlet pipeline and external micro-interface generators; a hydraulic micro-interface generator and an oxygen micro-interface generator are arranged in the oxidation reactor, and the oxygen inlet pipeline is connected with the oxygen micro-interface generator and the hydraulic micro-interface generator; a micro-interface unit is arranged on the side surface of the oxidation reactor, is composed of a plurality of external micro-interface generators, and is connected with the ammonium sulfite storage tank and the oxygen inlet pipeline, so that oxygen and an ammonium sulfite solution enter the micro-interface unit to be crushed and dispersed; and the crushed and dispersed oxygen microbubbles enter the oxidation reactor along with the ammonium sulfite solution. The reaction system provided by the invention ensures full utilization of gas, and improves the gas content and the reaction efficiency.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

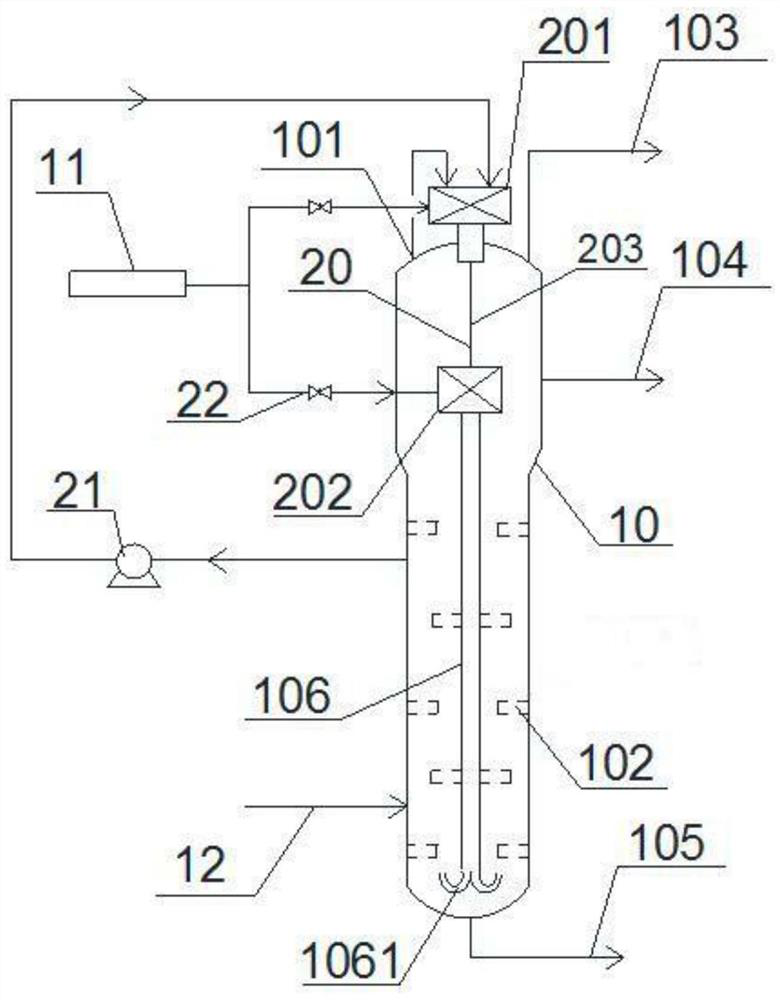

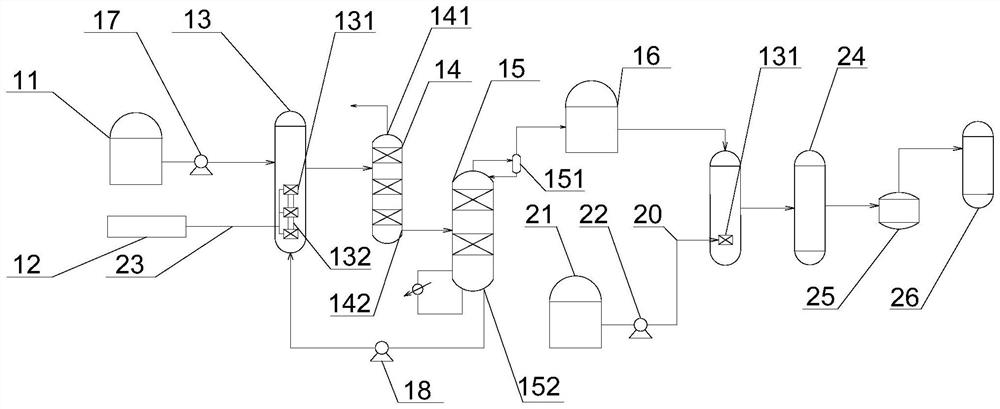

Micro-interface reaction system and method for preparing ethylene glycol by gas-phase catalytic hydration method

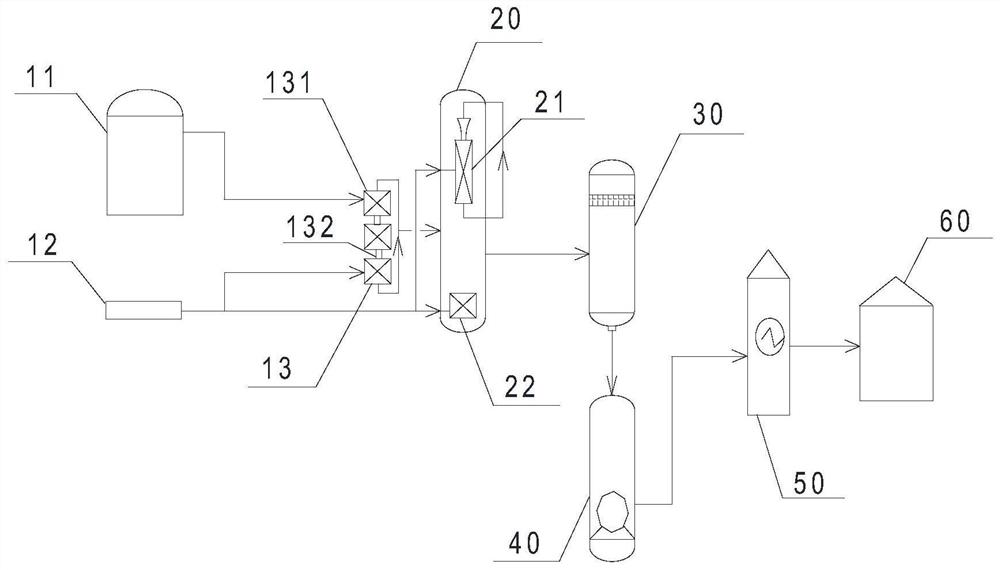

InactiveCN112521250AReduce dependenceImprove mass transfer effectOrganic compound preparationDistillation separationHydration reactionEthylene oxide

The invention provides a micro-interface reaction system for preparing ethylene glycol by a gas-phase catalytic hydration method. The micro-interface reaction system comprises a first hydration reaction rectifier, a second hydration reaction rectifier and a first evaporation tower, the first hydration reaction rectifier is connected with the second hydration reaction rectifier in parallel; an agent adding pipeline and an ethylene oxide inlet are sequentially arranged on the side walls of the first hydration reaction rectifier and the second hydration reaction rectifier from top to bottom; a hydraulic micro-interface generator is arranged in the first hydration reaction rectifier; the hydraulic micro-interface generator is connected with an ethylene oxide inlet in the side wall of the firsthydration reaction rectifier so as to disperse and crush the ethylene oxide entering the hydraulic micro-interface generator. The micro-interface reaction system is low in equipment energy consumption, low in cost, high in safety, controllable in reaction and high in raw material conversion rate, equivalently, a reaction system with higher operability is provided for the field of ethylene glycolpreparation, and the micro-interface reaction system is worthy of wide application and popularization.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

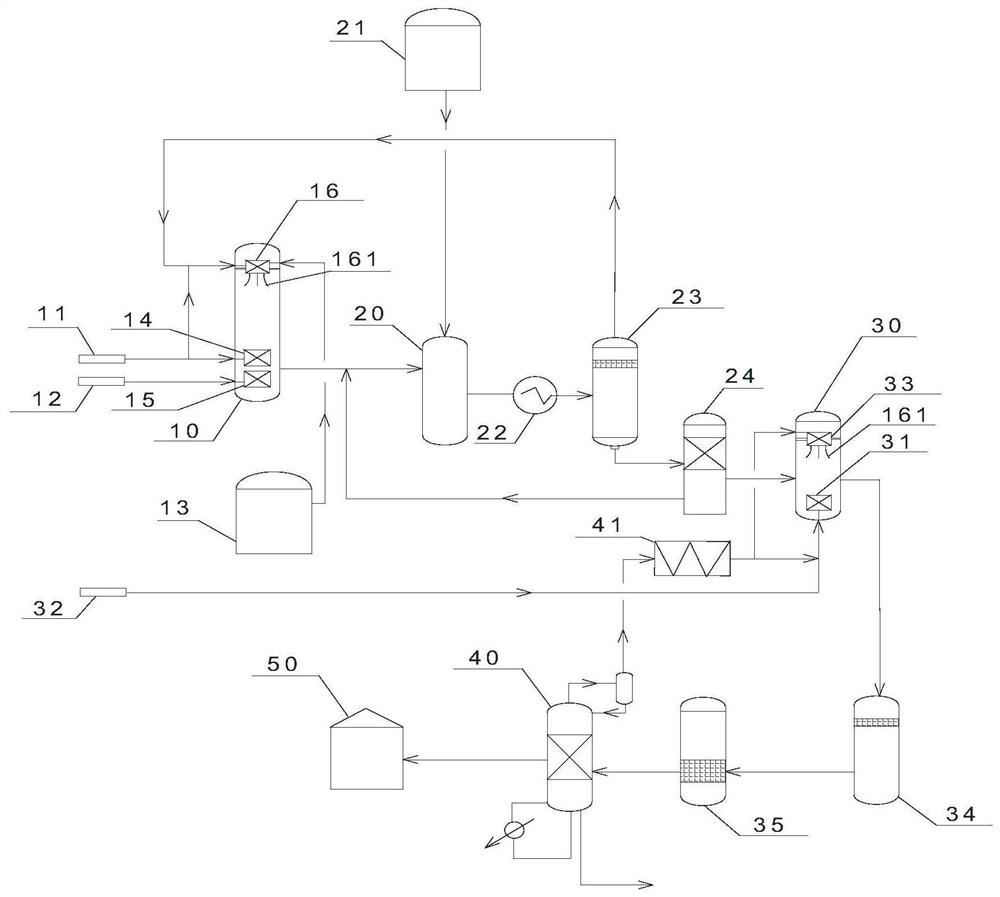

Enhanced reaction system and process for preparing acetic acid through methanol carbonylation

InactiveCN111362792AImprove operational efficiencySave production resourcesLiquid-gas reaction as foam/aerosol/bubblesChemical/physical/physico-chemical stationary reactorsCarbonyl groupCarbonylation

The invention provides an enhanced reaction system and process for preparing acetic acid through methanol carbonylation, and belongs to the technical field of acetic acid preparation. The enhanced reaction system comprises: a feeding unit used for storing and conveying carbon monoxide and methanol; and a carbonylation reaction kettle internally provided with a micro-interface generator, connectedwith the feeding unit and used as a place for a carbonylation reaction, wherein the micro-interface generator is used for crushing carbon monoxide bubbles into micro-bubbles with the diameter of micron grade before the carbonylation reaction in order to increase the phase boundary mass transfer area between the carbon monoxide and the methanol in the carbonylation reaction process and enhance thecarbonylation reaction efficiency. According to the enhanced reaction system and process for preparing acetic acid through methanol carbonylation, the problem that in the prior art, carbon monoxide and methanol cannot be fully mixed in a carbonylation reaction kettle, and consequently the reaction efficiency of the system is reduced is solved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

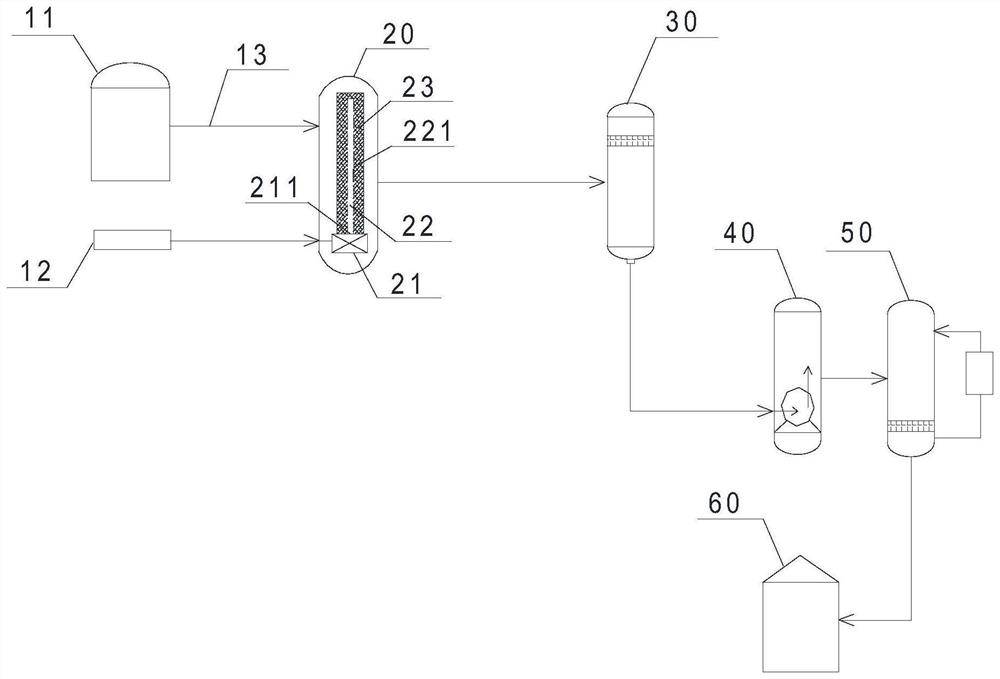

Microinterface preparation device and method for butanol and octanol

ActiveCN113058517AReduce thicknessImprove mass transfer efficiencyLiquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationPtru catalystHydrogenation reaction

The invention provides a microinterface preparation device for butanol and octanol. The microinterface preparation device comprises a carbonyl synthesis tower, an isomer separator, a first hydrogenation reactor and a hydrogen cylinder, the carbonyl synthesis tower is connected with the isomer separator; the first hydrogenation reactor comprises a reactor body, a circulating pipeline is arranged on one side of the reactor body, an inlet of the circulating pipeline is communicated with the upper part of the reactor body, and an outlet of the circulating pipeline is communicated with the lower part of the reactor body; two opposite distributors are arranged in the reactor body; a hemispherical catalyst ejector is arranged on the side wall of the reactor body; and the catalyst ejector is arranged between the two distributors along the vertical direction. The microinterface preparation device disclosed by the invention is high in material conversion rate, low in energy consumption, low in cost, high in safety, low in required reaction temperature and pressure, less in side reaction and worthy of wide popularization and application.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

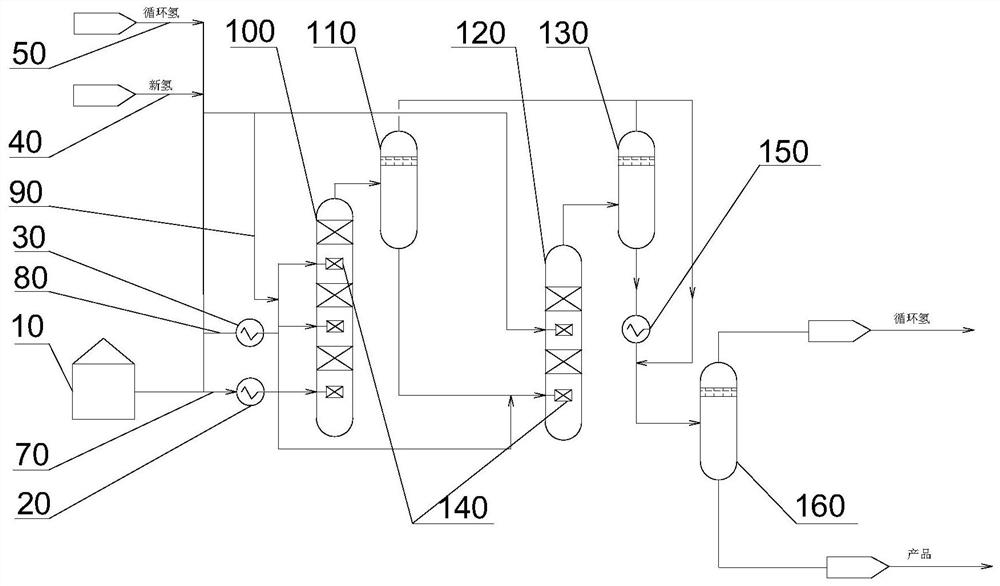

Petroleum resin hydrogenation reaction system and method

PendingCN112058185AAchieving Mixed Reinforcement ResponsesImprove mass transfer effectChemical/physical/physico-chemical microreactorsFoam dispersion/preventionThermodynamicsPtru catalyst

The invention provides a petroleum resin hydrogenation reaction system and method. The reaction system comprises a pre-hydrogenation reactor provided with a plurality of catalyst bed layers. Micro-interface generators are arranged between catalyst bed layers in the pre-hydrogenation reactor. A raw material inlet and a hydrogen inlet are respectively formed in the side wall of the pre-hydrogenationreactor, hydrogen is preheated by a hydrogen preheater and then enters the micro-interface generators from the hydrogen inlet, and a raw material petroleum resin solution is preheated by a raw material preheater and then enters the micro-interface generators from the raw material inlet. After the reaction system provided by the invention is combined with the micro-interface generators, the energyconsumption is reduced, the reaction temperature is reduced, the reaction yield is improved, the utilization rate of raw materials is improved, particularly the utilization rate of hydrogen is improved, and meanwhile, the productivity is effectively improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Wet oxidation enhanced micro-interface system

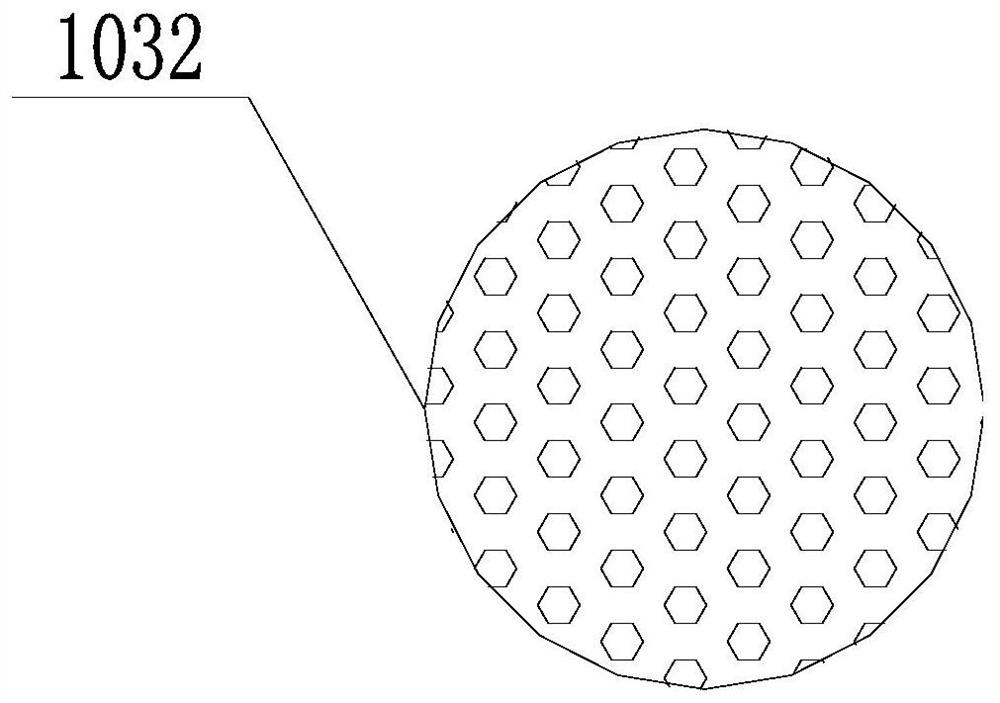

InactiveCN112340916AIncrease the mass transfer area of the phase boundaryIncrease concentrationSpecific water treatment objectivesHollow article cleaningEffluentHeat exchanger

The invention provides a wet oxidation enhanced micro-interface system. The system comprises a wastewater heat exchanger, a wastewater heater and an oxidation reactor; the wastewater heat exchanger isprovided with a material inlet, a material outlet, a heat source inlet and a heat source outlet; oxidized water from the oxidation reactor enters the wastewater heat exchanger from the heat source inlet, and the material outlet is connected with the wastewater heater; liquid outlets are formed in flat parts on two sides of a convex plane on the bottom surface of the oxidation reactor; a liquid inlet and a wastewater inlet are formed in the side wall of the oxidation reactor; liquid ejectors are arranged in the oxidation reactor, the tops of the liquid ejectors are semi-circular arc surfaces,a plurality of ejection holes are sequentially distributed in the semi-circular arc surfaces, the liquid inlet is connected with the bottom of the liquid ejector positioned at the upper part through apipeline, and the wastewater inlet is connected with the bottom of the liquid ejector positioned on the side wall through a pipeline. According to the wet oxidation enhanced micro-interface system, the cost of cleaning and field operation is saved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

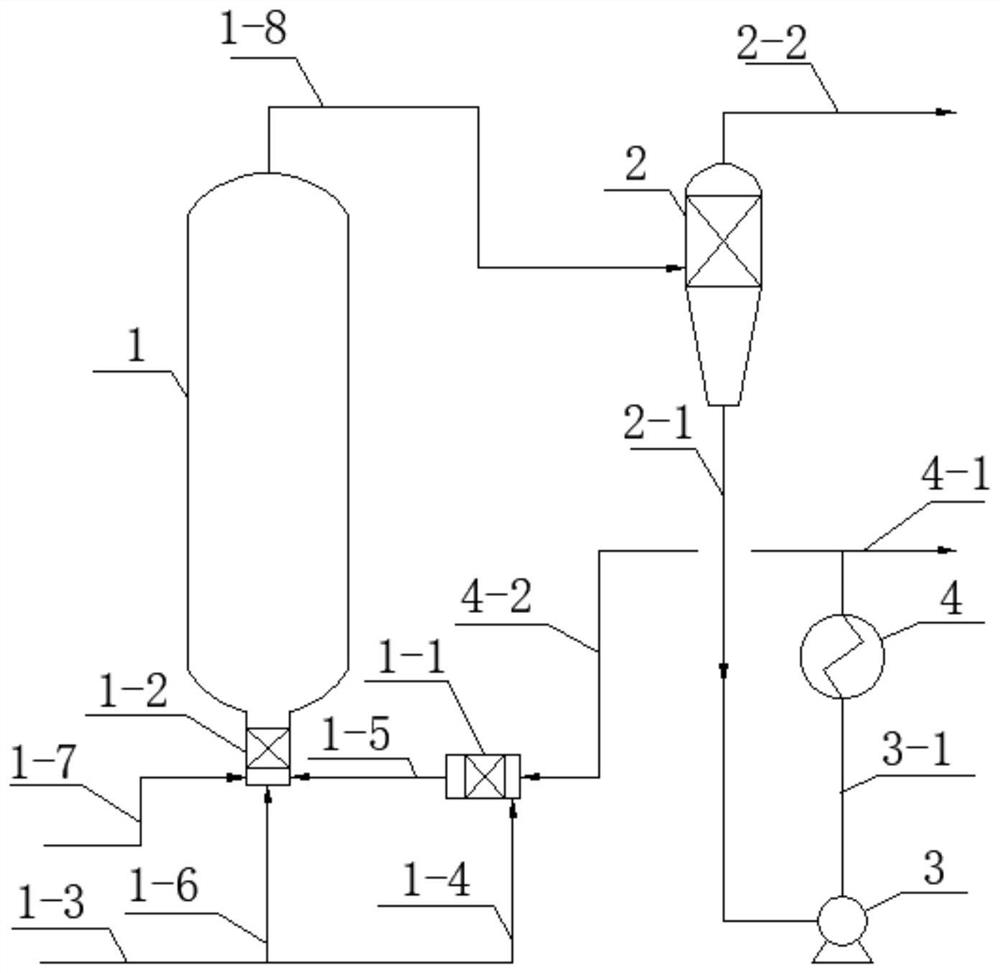

Oil-coal co-hydrogenation micro-interface enhanced emulsification bed reaction system

InactiveCN111359547AIncrease the mass transfer area of the phase boundaryImprove mass transfer efficiencyPressurized chemical processTransportation and packagingThermodynamicsEmulsion

The invention provides an oil-coal co-hydrogenation micro-interface enhanced emulsification bed reaction system. The system comprises: an emulsification bed reactor used as a reaction chamber in an oil-coal co-hydrogenation reaction process; and a micro-interface generator connected with the emulsification bed reactor, wherein the micro-interface generator is used for crushing the hydrogen into micro-bubbles with the diameter of micron grade in the micro-interface generator in a preset manner before the hydrogen and residual oil-pulverized coal mixed liquid in the hydrogenation reaction process enters the emulsification bed reactor main body, the hydrogen is introduced into the residual oil-pulverized coal mixed solution to increase the phase boundary mass transfer area between the hydrogen and the residual oil-pulverized coal mixed solution in the reaction process and improve the mass transfer efficiency between reaction phases, and the oil-coal co-hydrogenation reaction is enhanced under the conditions of preset temperature and pressure intensity. The problems of low mass transfer rate and influence on the overall reaction rate caused by small phase boundary contact area betweenhydrogen and the residual oil-pulverized coal mixed liquid in the use process of the existing emulsion bed hydrogenation reaction strengthening system are effectively solved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

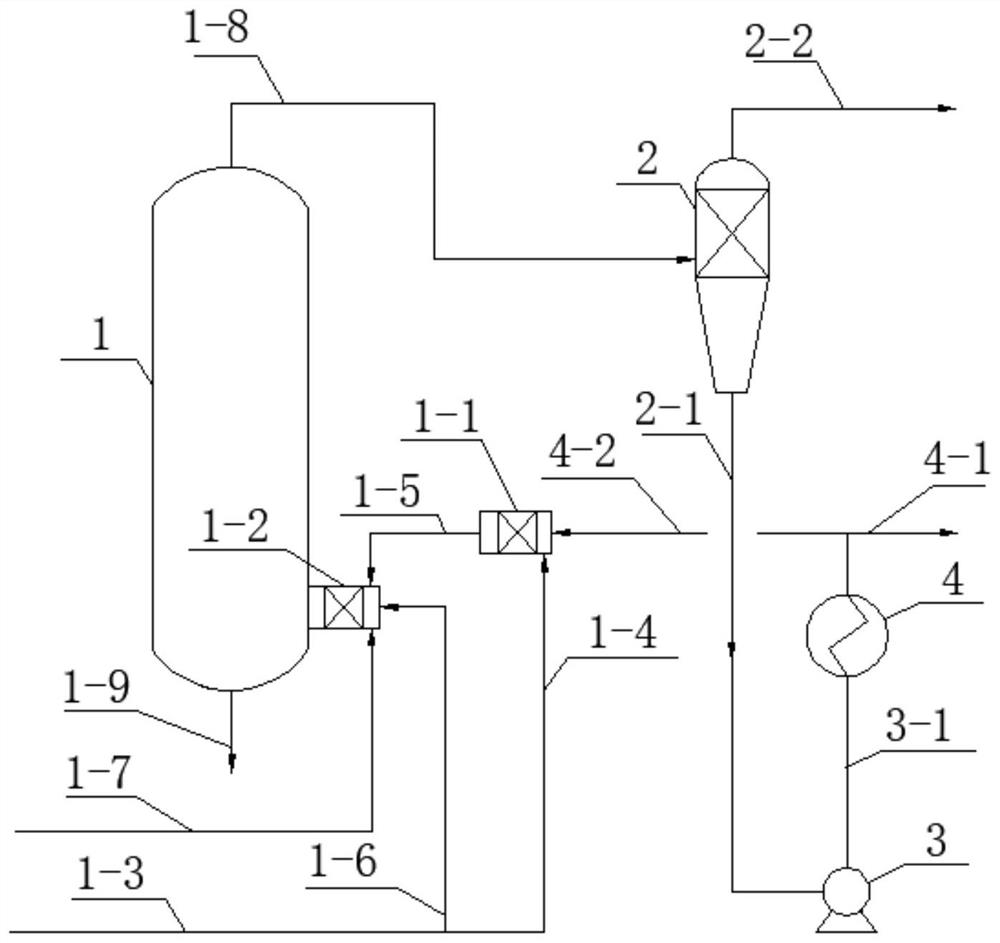

Coal tar hydrogenation micro-interface emulsification bed enhanced reaction system

PendingCN111686654AIncrease the mass transfer area of the phase boundaryImprove mass transfer efficiencyPressurized chemical processTransportation and packagingEmulsionReaction rate

The invention provides a coal tar hydrogenation micro-interface emulsification bed enhanced reaction system, which comprises: an emulsification bed reactor used as a reaction chamber in a coal tar hydrogenation reaction process; a micro-interface generator, which is arranged on the emulsifying bed reactor and is used for crushing the hydrogen into micro-bubbles with the diameter of micron grade inthe micro-interface generator in a preset manner before the hydrogen and coal tar mixed solution in the hydrogenation reaction process enters the emulsifying bed reactor main body; the hydrogen is introduced into the coal tar mixed solution to increase the phase boundary mass transfer area between the hydrogen and the coal tar mixed solution in the reaction process and improve the mass transfer efficiency between reaction phases, and thereby the coal tar hydrogenation reaction is enhanced under the conditions of preset temperature and pressure intensity. According to the invention, the problem that the overall reaction rate is influenced due to low mass transfer rate caused by small phase boundary contact area between hydrogen and coal tar mixed liquor in the use process of the existing emulsion bed hydrogenation reaction strengthening system is effectively solved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

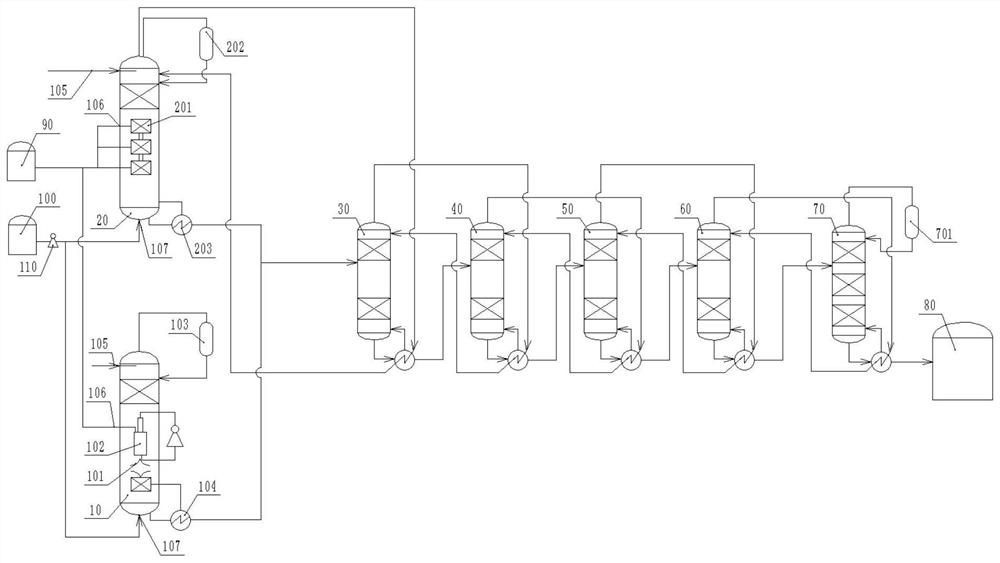

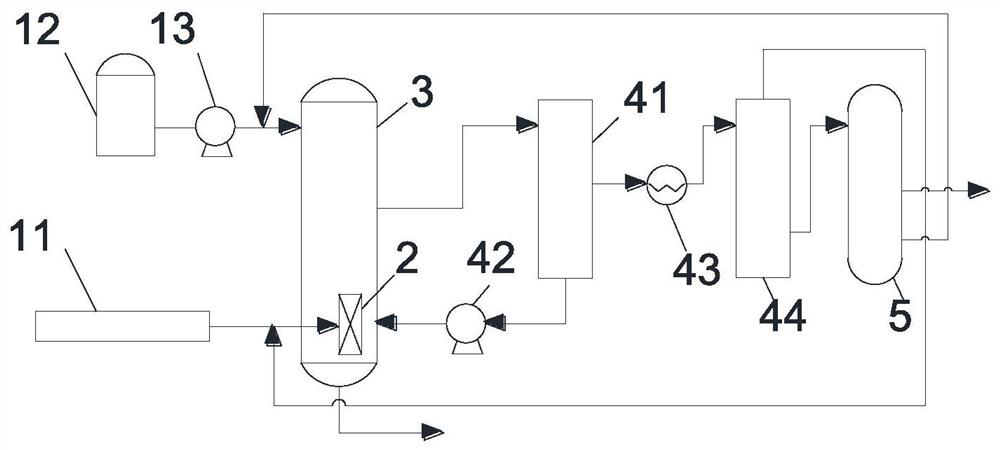

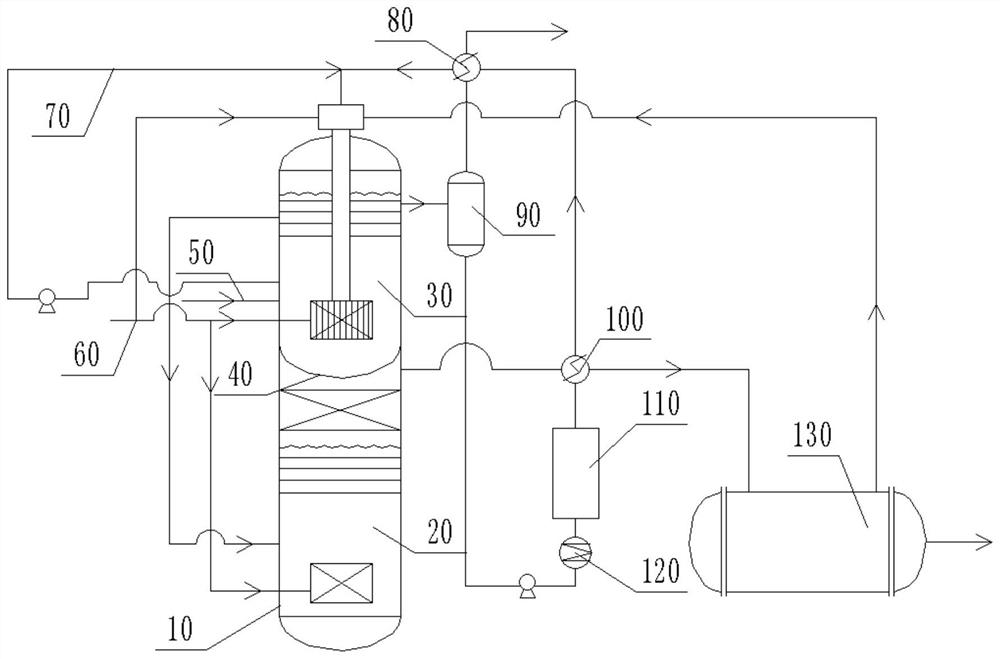

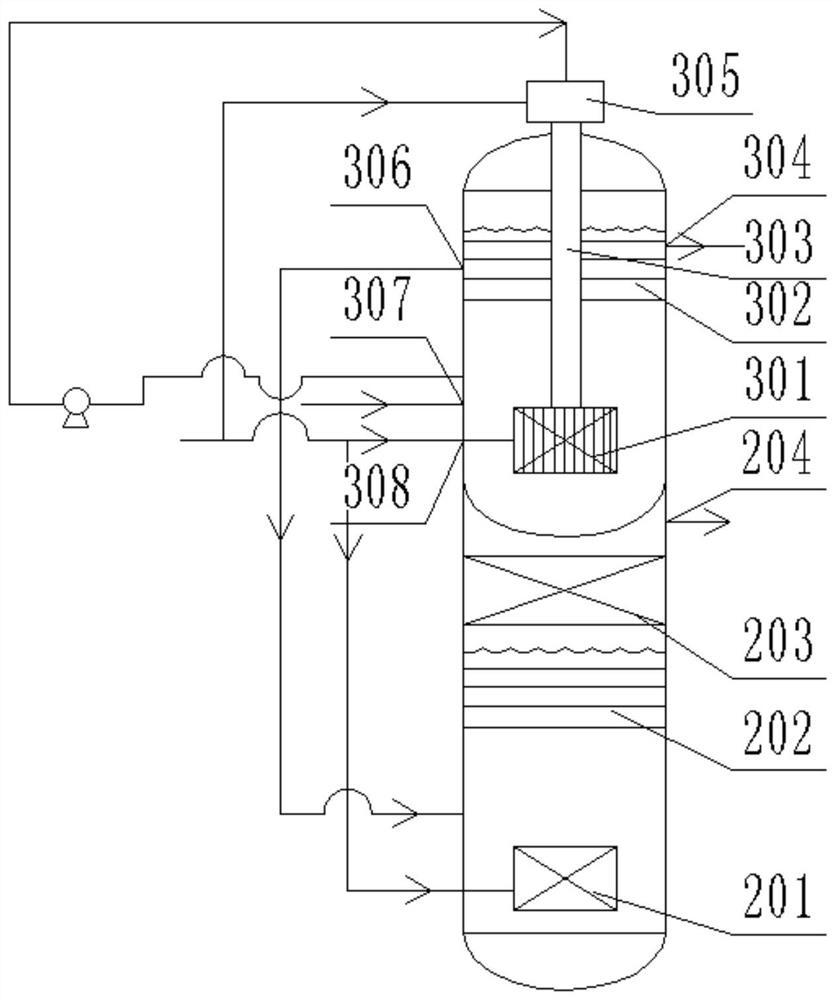

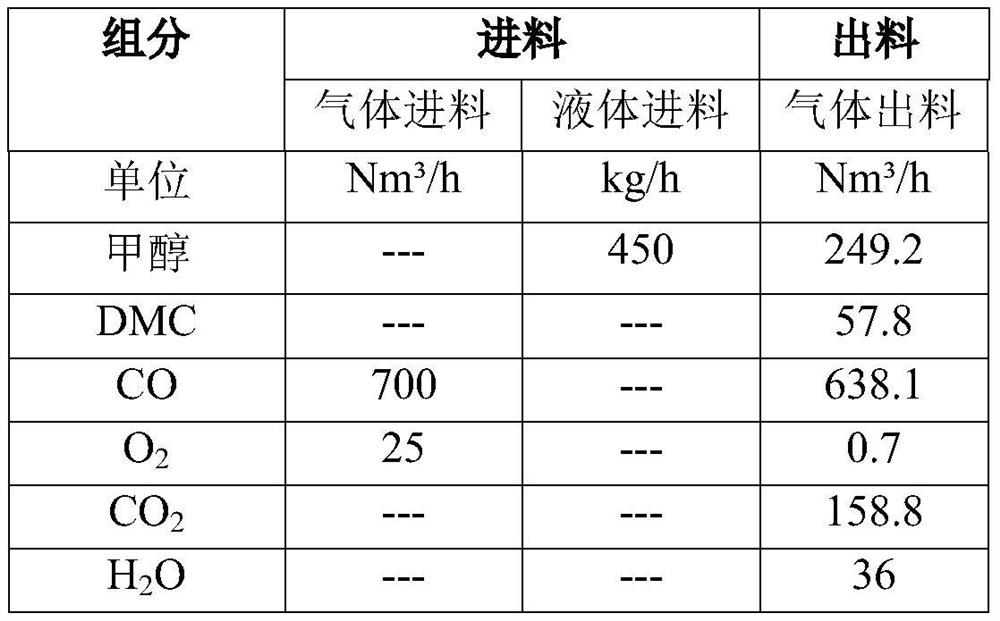

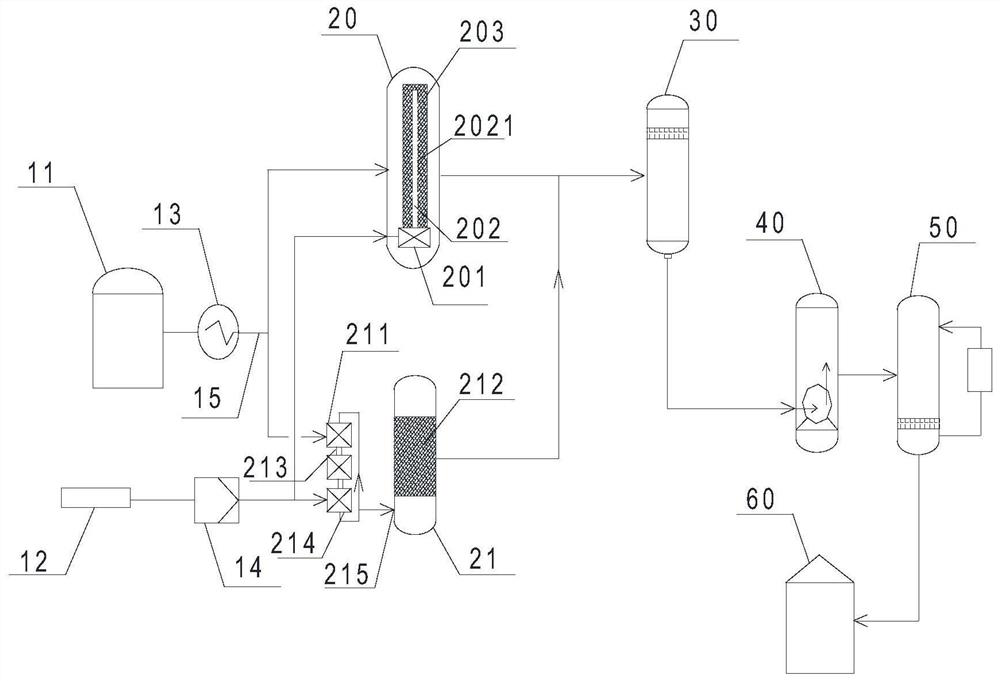

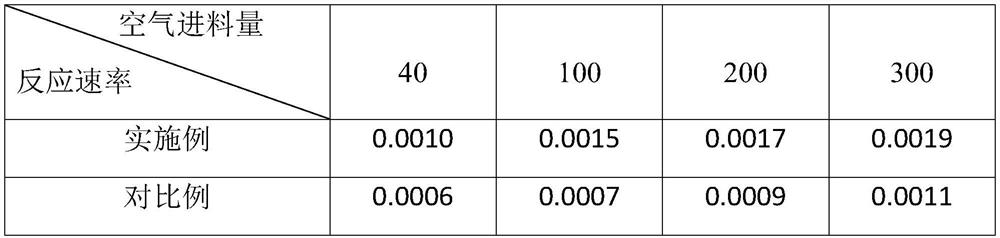

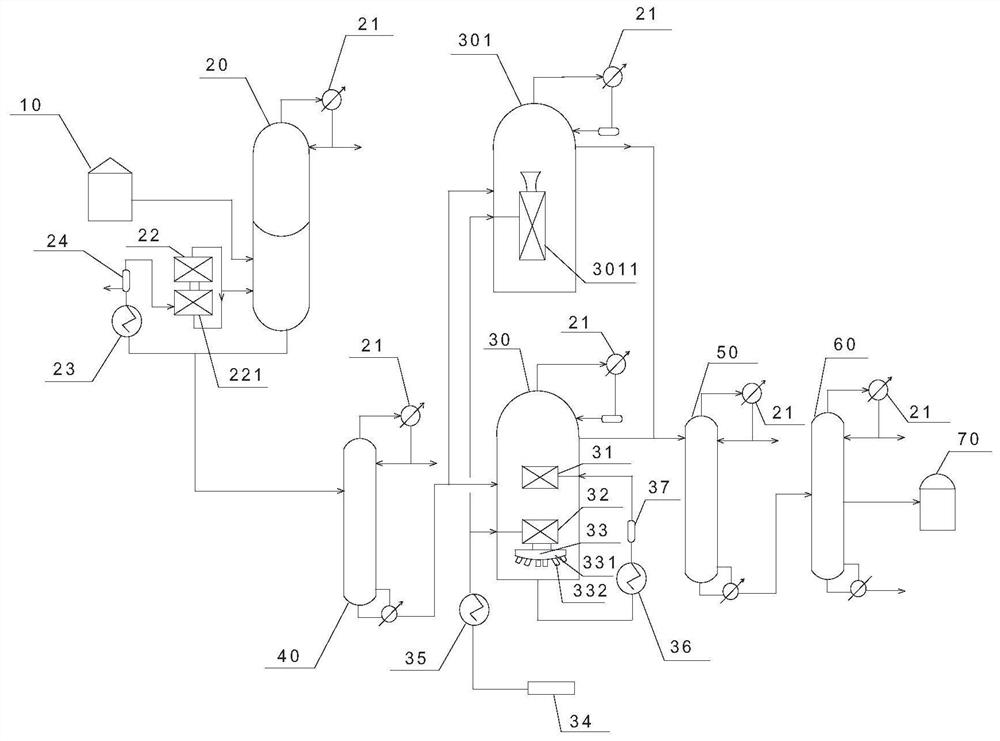

Reaction system and process for synthesizing dimethyl carbonate through liquid-phase oxidative carbonylation of methanol

PendingCN112479882ASolve the problem of reduced productivityIncrease the mass transfer area of the phase boundaryChemical/physical/physico-chemical microreactorsPreparation from carbon monoxide and oxygenFluid phaseMixed gas

The invention provides a reaction system and process for synthesizing dimethyl carbonate through liquid-phase oxidative carbonylation of methanol. The system comprises: a feeding unit used for storingand conveying mixed gas of carbon monoxide and oxygen and a methanol liquid; a reaction kettle internally provided with a micro-interface generator, connected with the feeding unit and used as a place for oxidative carbonylation reaction; a gas-liquid separation unit connected with the reaction kettle and used for carrying out gas-liquid separation on the oxidative carbonylation reaction product;and a rectifying tower connected with the gas-liquid separation unit and used for rectifying the crude product dimethyl carbonate obtained by gas-liquid separation. According to the reaction system and process for synthesizing dimethyl carbonate through liquid-phase oxidative carbonylation of methanol, the problem that in the prior art, the yield of dimethyl carbonate is reduced due to the fact that methanol and mixed gas of carbon monoxide and oxygen cannot be fully mixed in an oxidative carbonylation reaction kettle is solved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Immediate dehydration DMC preparation system and preparation method

InactiveCN113499739AAdequate responseImprove conversion ratePreparation from carbon monoxide and oxygenChemical/physical processesThermodynamicsReaction temperature

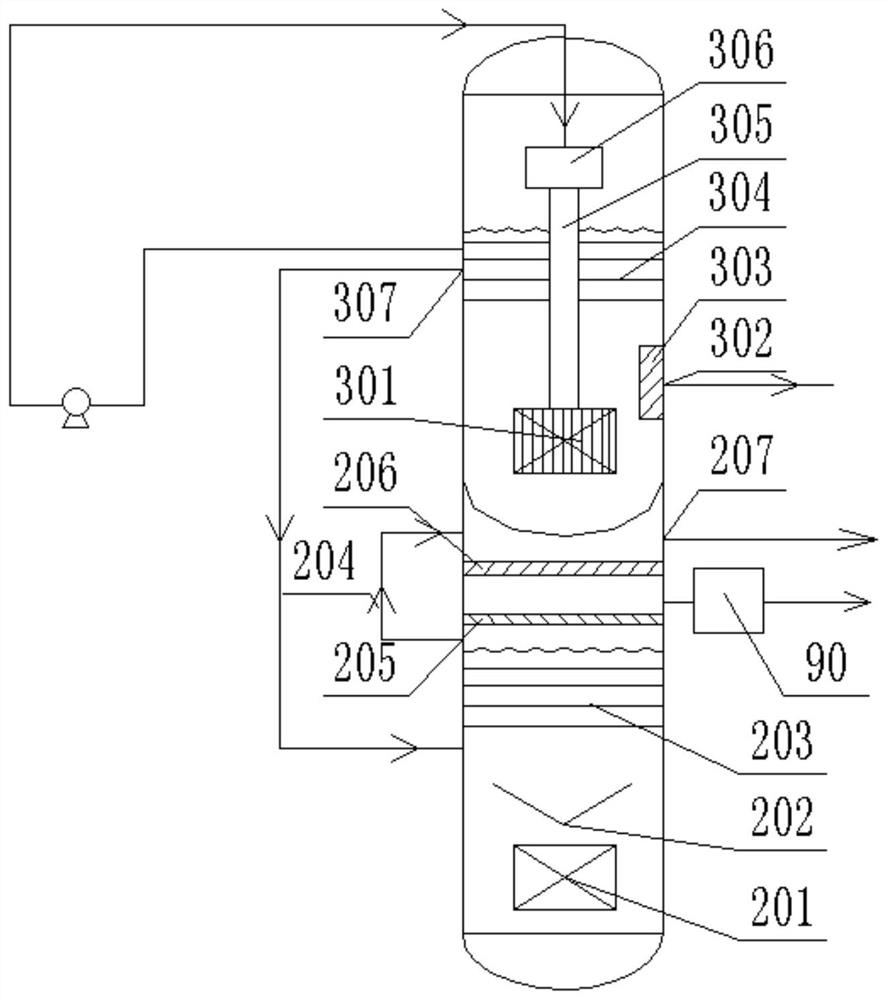

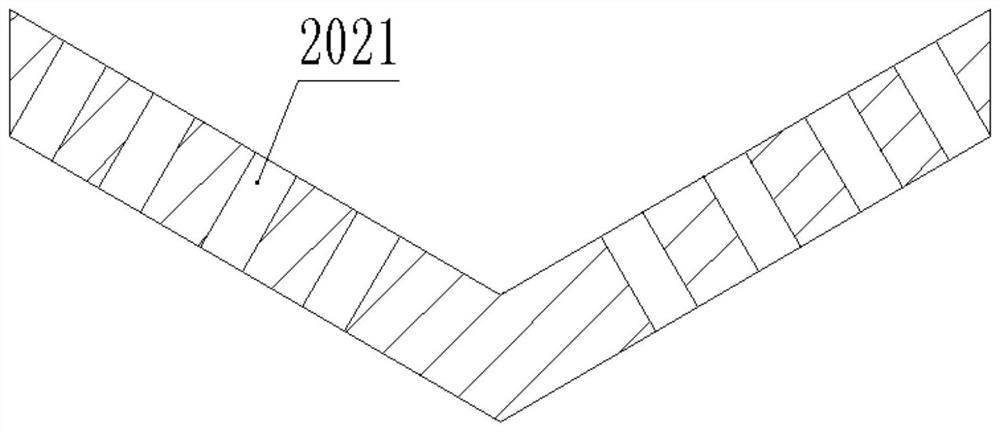

The present invention provides an instant dehydration DMC preparation system and preparation method, wherein the instant dehydration DMC preparation system comprises: a reactor, and the middle of the reactor is provided with a partition plate; a first reaction zone is arranged above the partition plate, and a second reaction zone is arranged below the partition plate; a methanol inlet and a mixed gas inlet are formed in the side wall of the first reaction zone; the methanol inlet is connected with a methanol pipeline; a first micro-interface generator is arranged in the first reaction zone, and the first micro-interface generator is connected with the mixed gas inlet; the first micro-interface generator is positioned below a first liquid level in the first reaction region; a second micro-interface generator is arranged above the first micro-interface generator, and a micro-bubble outlet is formed in the position, tightly attached to the first micro-interface generator, above the first micro-interface generator; and a bottom outlet of the second micro-interface generator is connected with a micro-bubble pipeline. The preparation system disclosed by the invention is low in required reaction temperature and pressure, few in side reaction, high in methanol conversion rate and worthy of wide popularization and application.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

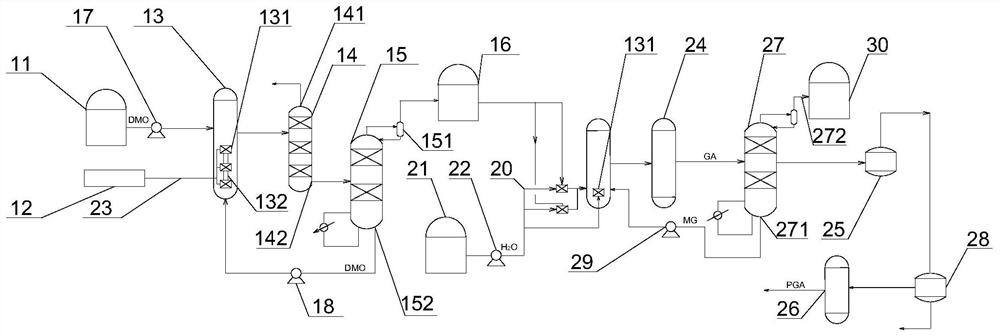

Reinforced micro-interface preparation system and method of polyglycolic acid

PendingCN112156731AFully dispersed and brokenImprove hydrogenation reaction performanceChemical/physical/physico-chemical microreactorsPipeline systemsThermodynamicsHydrogenation reaction

The invention provides a reinforced micro-interface preparation system and method of polyglycolic acid. The reinforced micro-interface preparation system comprises a hydrogenation reactor, a hydrogenfeeding pipeline, a hydrolysis reactor and a water vapor feeding pipeline, an oxalate feeding pipeline is arranged on the side wall of the hydrogenation reactor, a micro-interface unit is arranged inthe hydrogenation reactor, and the micro-interface unit is formed by sequentially arranging a plurality of micro-interface generators from top to bottom; the hydrogen feeding pipeline penetrates through the side wall of the hydrogenation reactor and enters the micro-interface unit, so that hydrogen is crushed into micron-sized micro-bubbles in the micro-interface unit in advance before hydrogenation reaction. According to the enhanced micro-interface preparation system, the micro-interface unit is arranged in the hydrogenation reactor, and the micro-interface generator is arranged on the sidesurface of the hydrolysis reactor, so that hydrogen is crushed into micro-bubbles before hydrogenation reaction of hydrogen and dimethyl oxalate, and the phase boundary mass transfer area between hydrogen and dimethyl oxalate is increased.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

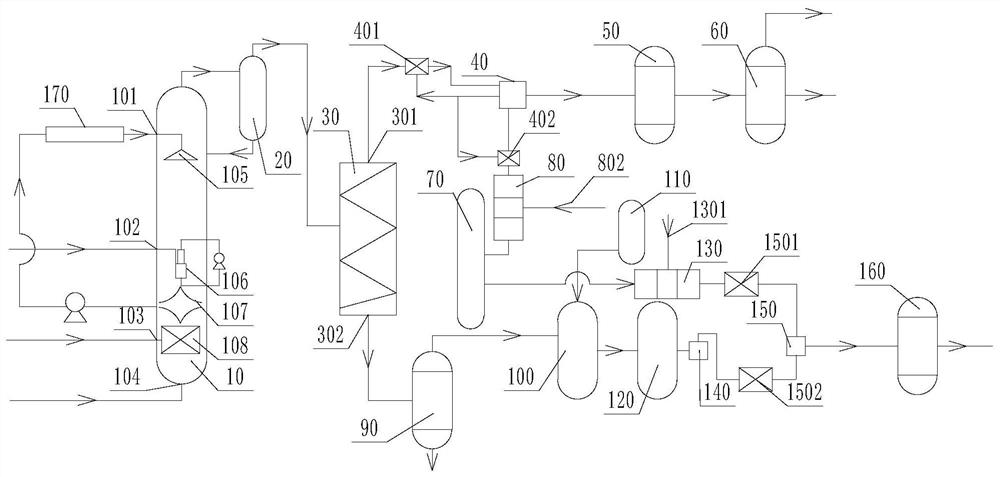

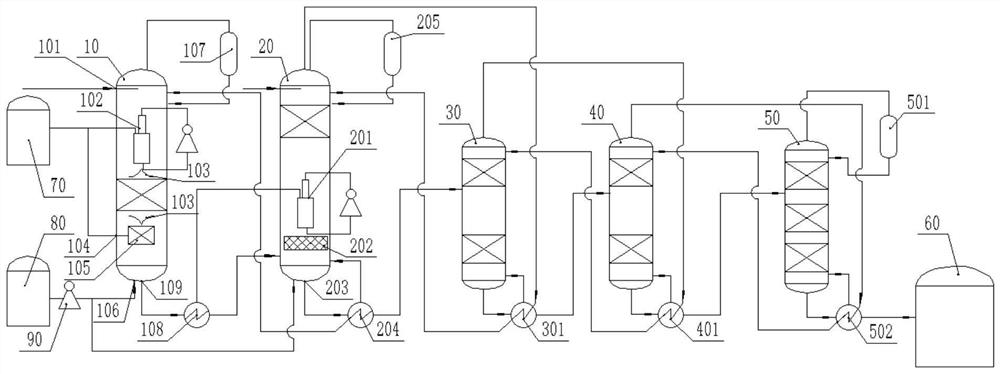

Micro-interface reaction system and method for preparing ethylene glycol by oxalate method

InactiveCN112452268AIncrease the mass transfer area of the phase boundarySolve low production efficiencyOrganic compound preparationChemical/physical/physico-chemical microreactorsHydrogenation catalysisFixed bed

The invention discloses a micro-interface reaction system for preparing ethylene glycol by an oxalate method. The micro-interface reaction system comprises a first reaction tank, an upper micro-interface generator, a lower micro-interface generator, a first shunting type micro-interface generator and a hydrogenation reaction tank, a nitric oxide gas inlet pipeline and an oxygen gas inlet pipelineare arranged on the side wall of the first reaction tank, the oxygen gas inlet pipeline is connected with a first shunting type micro-interface generator and an upper micro-interface generator, the nitric oxide gas inlet pipeline is connected with a lower micro-interface generator, and the first reaction tank is connected with a methanol storage tank; a product obtained after the reaction in the first reaction tank enters a fixed bed reactor for a coupling reaction, a product obtained after the reaction in the fixed bed reactor sequentially passes through a cooler, a gas-liquid separation tankand a regeneration tower to enter a hydrogenation reaction tank for hydrogenation catalysis, and a product obtained after the hydrogenation catalysis reaction in the hydrogenation reaction tank sequentially passes through a high-pressure separator, a low-pressure flash tank and a rectifying tower; and ethylene glycol is obtained in the rectifying tower through rectifying. According to the micro-interface reaction system, the pressure and the temperature during reaction are reduced.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Intelligent micro-interface reaction system and method for preparing ethylene glycol by ethylene oxide method

InactiveCN112717846AIncrease the mass transfer area of the phase boundarySolve stressOrganic compound preparationChemical/physical/physico-chemical microreactorsEthylene oxidePhysical chemistry

The invention provides an intelligent micro-interface reaction system and method for preparing ethylene glycol through an ethylene oxide method. The intelligent micro-interface reaction system comprises a first reactor, a second reactor and a stirring kettle, and the stirring kettle is filled with a NaHCO3 agent material; a micro-interface unit is arranged on the outer side of the stirring kettle and is formed by arranging a plurality of external micro-interface generators; a main pipeline introduced into the micro-interface unit is connected with an ethylene oxide feeding pipeline and a water source pipeline at the same time, ethylene oxide is introduced into the micro-interface unit from a gas source conveying pipeline, and a water source enters the micro-interface unit to be used for breaking ethylene oxide gas into micron-sized micro-bubbles; the micro-interface units are arranged on the outer side of the stirring kettle and in the reactor, so that ethylene oxide and the water source are crushed into the micro-bubbles before reaction, the phase boundary mass transfer area between the ethylene oxide and the water source is increased, full-automatic control is realized through the intelligent control system, and the working efficiency is improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

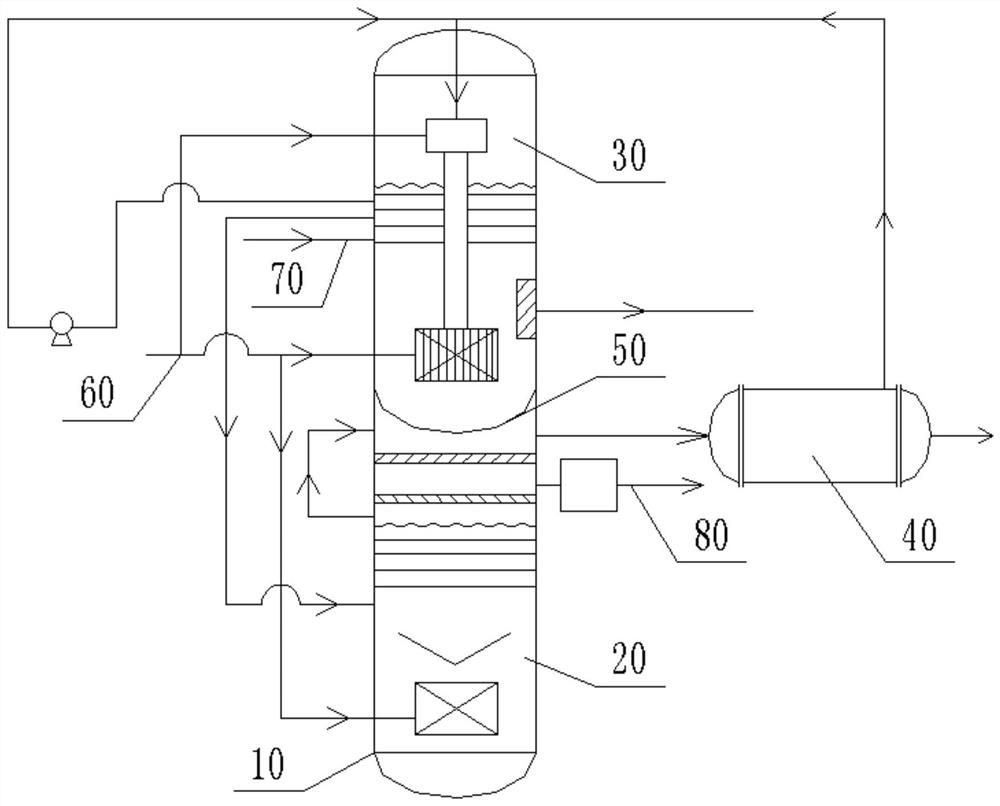

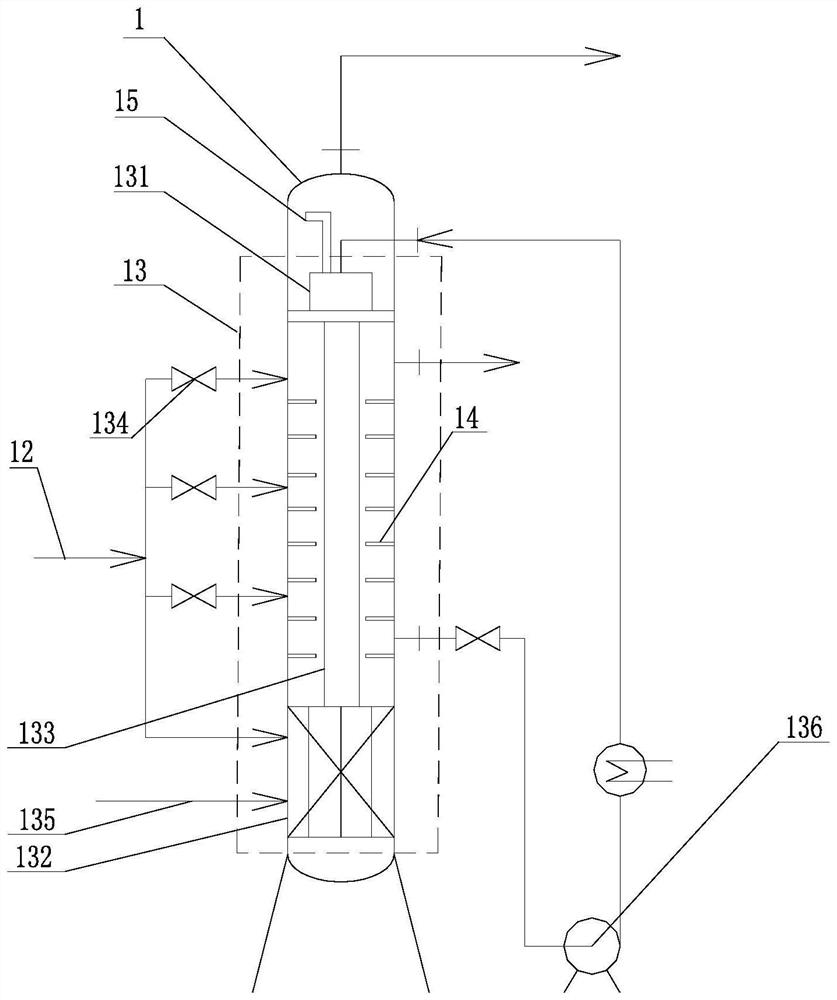

Micro-interface enhanced oxidation system and method for preparing hydrogen peroxide

ActiveCN113479851ASimple and efficient operationHigh purityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesFluid phaseHydrogen peroxide

The invention provides a micro-interface enhanced oxidation system and method for preparing hydrogen peroxide. The micro-interface enhanced oxidation system comprises an oxidation reaction tower, wherein a liquid phase pipeline for conveying hydrogenated anthraquinone is arranged at the top of the side surface of the oxidation reaction tower, and a gas phase pipeline for conveying air is arranged at the bottom of the side surface of the oxidation reaction tower; a liquid distributor, a filler section, a liquid receiving disc and a mixed micro-interface unit are sequentially arranged in the oxidation reaction tower from top to bottom; and the mixed micro-interface unit comprises an upper micro-interface generator and a lower micro-interface generator which communicate with each other along a vertical direction, hydroanthraquinone is conveyed into the mixed micro-interface unit, is distributed by the liquid distributor, sequentially descends and then is mixed, dispersed and crushed with air in the mixed micro-interface unit. By adopting the micro-interface enhanced oxidation system, the utilization rate of oxygen can be increased, an occupied area is small, and operation is simple and convenient.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Ultra-efficient low-pressure gas source micro-interface enhanced biological fermentation device and method

PendingCN113512483APromote absorptionIncrease the mass transfer area of the phase boundaryBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyLand resources

The invention provides an ultra-efficient low-pressure gas source micro-interface enhanced biological fermentation device. The device comprises a fermentation tank, the top of the fermentation tank is provided with a composite micro-interface generator, the composite micro-interface generator comprises a pneumatic micro-interface generator and a hydraulic micro-interface generator, and the pneumatic micro-interface generator is connected with the hydraulic micro-interface generator through a connecting channel; and the composite micro-interface generator is connected with a CO inlet pipeline for crushing and dispersing CO into CO microbubbles. The composite micro-interface generator is arranged at the top in the fermentation tank, CO is crushed and dispersed into micron-sized bubbles, the phase boundary mass transfer area between CO and fermentation raw materials is increased, CO is more easily absorbed by the fermentation raw materials, the utilization rate of the fermentation raw materials and CO is increased in the production process, resources are saved, meanwhile, the occupied area is reduced, and land resources are saved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Ultrasonic wastewater treatment device and method

ActiveCN114477577AImprove the efficiency of wastewater treatmentReduce energy consumptionWater treatment parameter controlSpecific water treatment objectivesReverse osmosisUltrasonic generator

The invention provides an ultrasonic wastewater treatment device, which comprises a tank body and an oxidation reactor, the tank body is cooperatively provided with a first ultrasonic generator used for degrading polysaccharide macromolecules, the first ultrasonic generator can be built-in or external, and the first ultrasonic generator is connected with a wastewater pipeline. A first ultrasonic generator is arranged in the tank body, a reverse osmosis membrane is arranged above the first ultrasonic generator, a water phase outlet is formed in the side wall of the top of the tank body, the water phase outlet is connected with a liquid inlet of an oxidation reactor, a hydraulic micro-interface generator for breaking and dispersing gas into microbubbles is arranged in the oxidation reactor, and the hydraulic micro-interface generator is communicated with a gas inlet pipeline; a product outlet is formed in the bottom of the oxidation reactor and is used for discharging a product. By combining the ultrasonic technology and the wet oxidation technology, the efficient and energy-saving wastewater treatment effect is achieved, polysaccharide macromolecules are degraded into micromolecular organic matter through the ultrasonic technology, and the wastewater treatment efficiency is further improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Built-in instant dehydration micro-interface reinforced DMC preparation system and method

InactiveCN113499738APlay a supporting roleGood application effectPreparation from carbon monoxide and oxygenChemical/physical processesMicrobubblesMechanical engineering

The invention provides a built-in instant dehydration micro-interface reinforced DMC preparation system and method, wherein the system comprises a reaction tower; the middle part of the reaction tower is provided with a sealing plate; a first reaction section is arranged above the sealing plate, and a second reaction section is arranged below the sealing plate; the side wall of the first reaction section is connected with a methanol pipeline and a mixed gas pipeline from top to bottom; a first micro-interface generator is arranged in the first reaction section, a second micro-interface generator is arranged above the first micro-interface generator, and the first micro-interface generator and the second micro-interface generator are both connected with the mixed gas pipeline so as to disperse and crush mixed gas into micron-level microbubbles; a microbubble outlet is formed above the first micro-interface generator and clings to the first micro-interface generator; and a bottom outlet of the second micro-interface generator is connected with a micro-bubble pipeline. The preparation system disclosed by the invention is low in required reaction temperature and pressure, few in side reaction, high in methanol conversion rate and worthy of wide popularization and application.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Enhanced reaction system and method for preparing ethylene glycol by gas-phase catalytic hydration method

PendingCN112441883AFully reflectIncrease profitOrganic compound preparationBulk chemical productionHydration reactionEthylene oxide

The invention provides an enhanced reaction system for preparing ethylene glycol by a gas-phase catalytic hydration method. The enhanced reaction system comprises a hydration reaction rectifier, an enhanced hydration reaction rectifier and an evaporation tower; an ethylene oxide inlet is formed in the side wall of the hydration reaction rectifier; a water inlet is formed in the bottom of the hydration reaction rectifier; and a pneumatic type micro-interface generator and a first hydraulic type micro-interface generator are arranged in the hydration reaction rectifier, and the pneumatic type micro-interface generator is arranged below the first hydraulic type micro-interface generator. The enhanced reaction system provided by the invention has the advantages of few equipment components, small occupied area, low energy consumption, low cost, high safety, controllable reaction and high raw material conversion rate, equivalently provides a reaction system with stronger operability for thefield of ethylene glycol preparation, and is worthy of wide popularization and application.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

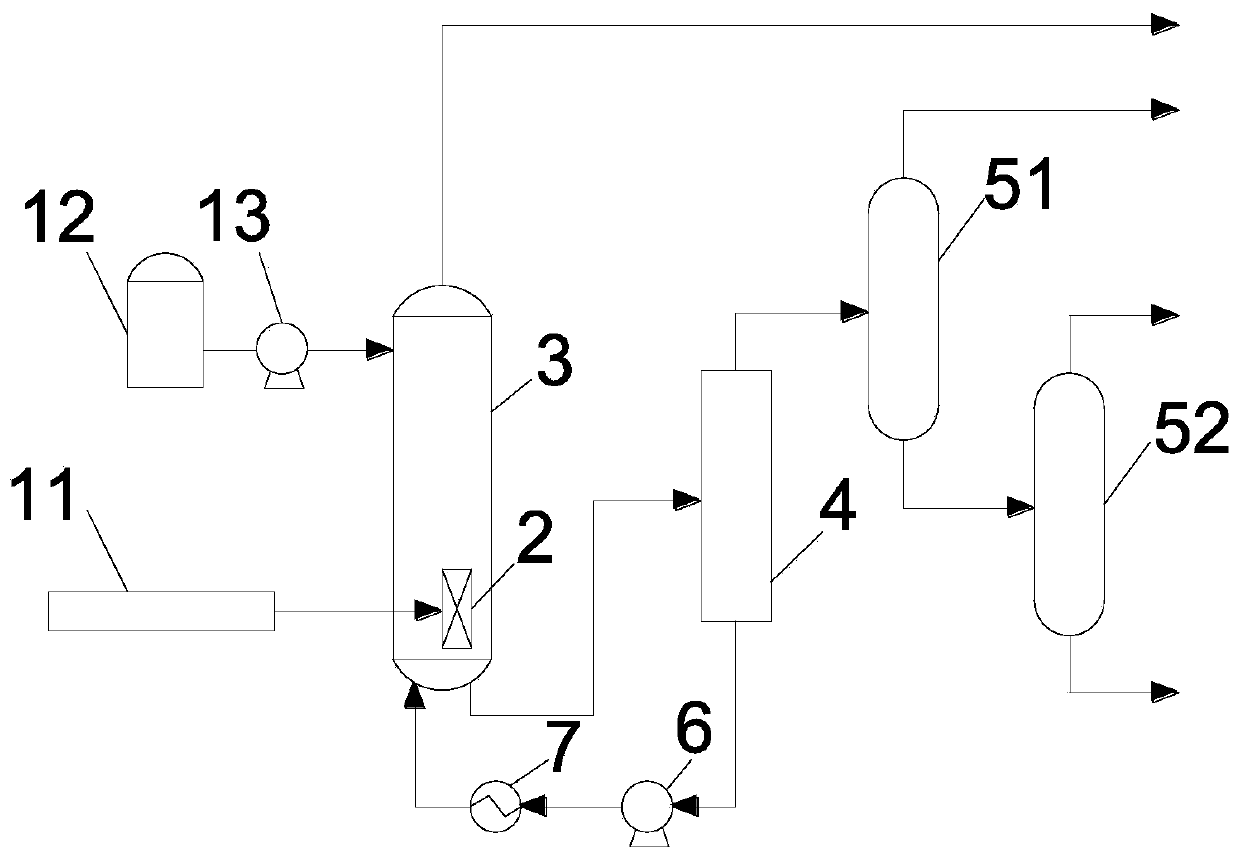

Preparation system and method of polyglycolic acid

PendingCN112058184AFully dispersed and brokenImprove hydrogenation reaction performanceChemical/physical processesHydrogenation reactionGlycolic acid

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

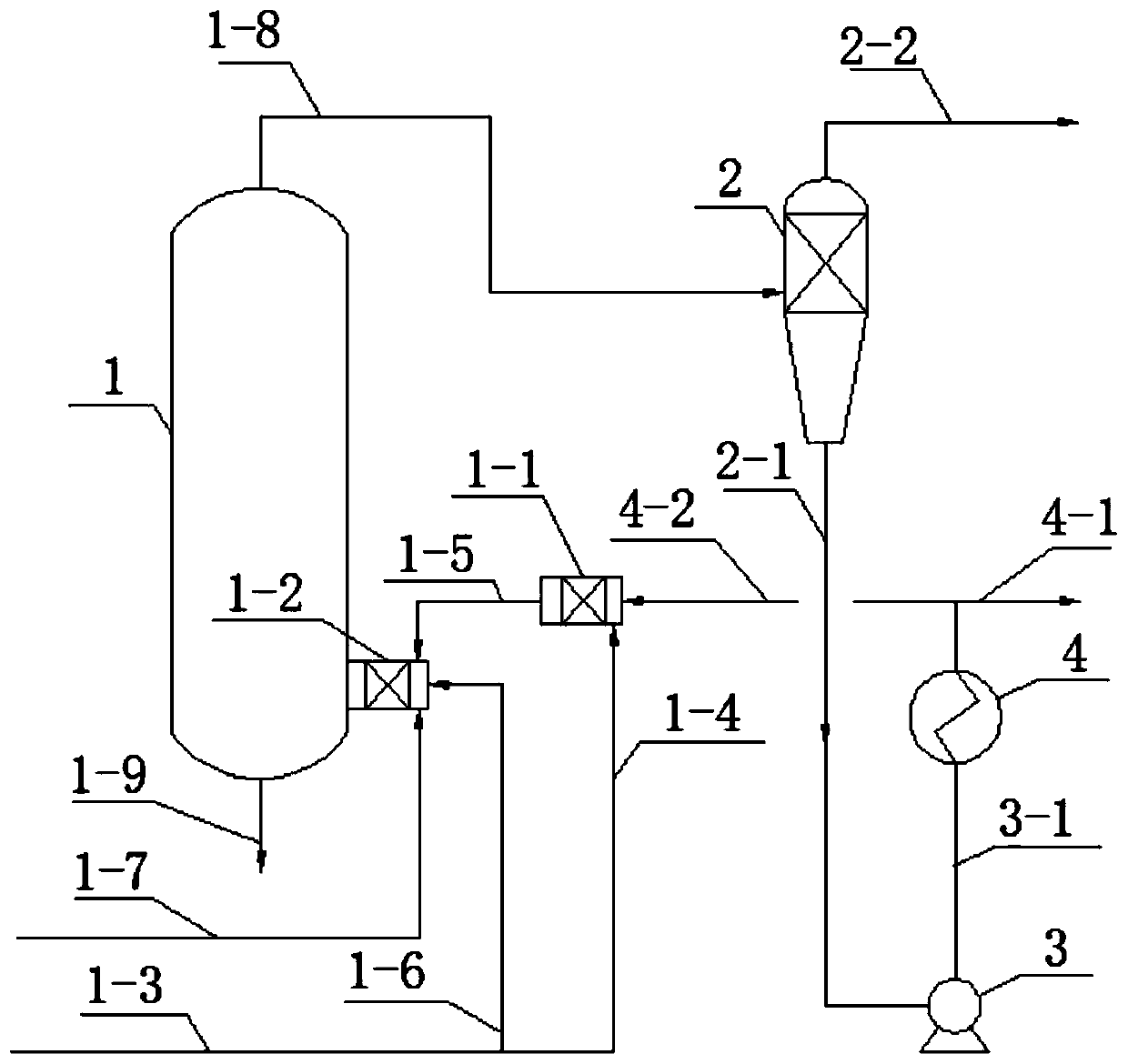

Micro-interface reaction system and method for hydrofining crude terephthalic acid

ActiveCN112774592AIncrease the mass transfer area of the phase boundaryImprove reaction efficiencyOrganic compound preparationChemical/physical/physico-chemical microreactorsInterfacial reactionPtru catalyst

The invention discloses a micro-interface reaction system for hydrofining crude terephthalic acid, which is characterized by comprising a hydrogenation reactor, wherein a hydrogen micro-interface generator for dispersing and breaking hydrogen is arranged in the hydrogenation reactor; the hydrogenation reactor is provided with a bubbling tower type reactor in parallel, and the bubbling tower type reactor is connected with an external micro-interface unit; and products obtained after reaction of the hydrogenation reactor and the bubbling tower type reactor are connected in parallel and sequentially enter a crystallization tower, a centrifugal separator and a dryer, and finally solid refined terephthalic acid is formed and enters a collecting tank. According to the reaction system, the mass transfer rate of the gas phase to the reaction liquid and the macroscopic hydrogenation rate are greatly improved, so that the original reaction pressure, reaction temperature and catalyst consumption can be reduced, and the reaction efficiency is improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD +1

Micro-interface oxidation system for preparing hydrogen peroxide and oxidation method thereof

PendingCN113387332AIncrease the mass transfer area of the phase boundaryHigh purityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAnthraquinonesEmulsion

The invention provides a micro-interface oxidation system for preparing hydrogen peroxide and an oxidation method thereof. The micro-interface oxidation system comprises an oxidation reaction tower; a liquid phase pipeline for conveying hydrogenated anthraquinone and a gas phase pipeline for conveying air are arranged on the side surface of the oxidation reaction tower; a mixed micro-interface unit is arranged in the oxidation reaction tower, the mixed micro-interface unit comprises an upper micro-interface generator and a lower micro-interface generator which are communicated up and down, and a long and narrow gas-liquid emulsion channel is arranged between the upper micro-interface generator and the lower micro-interface generator; and the gas-liquid emulsion channel is connected with a gas-liquid emulsion outlet, the gas-liquid emulsion outlet clings to the upper side wall of the lower micro-interface generator, and the top of the upper micro-interface generator is provided with an entrainment pipe for entrainment of air at the top in the tower. By adopting the micro-interface oxidation system, the utilization rate of oxygen can be increased, the occupied area is small, and the operation is simple and convenient.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

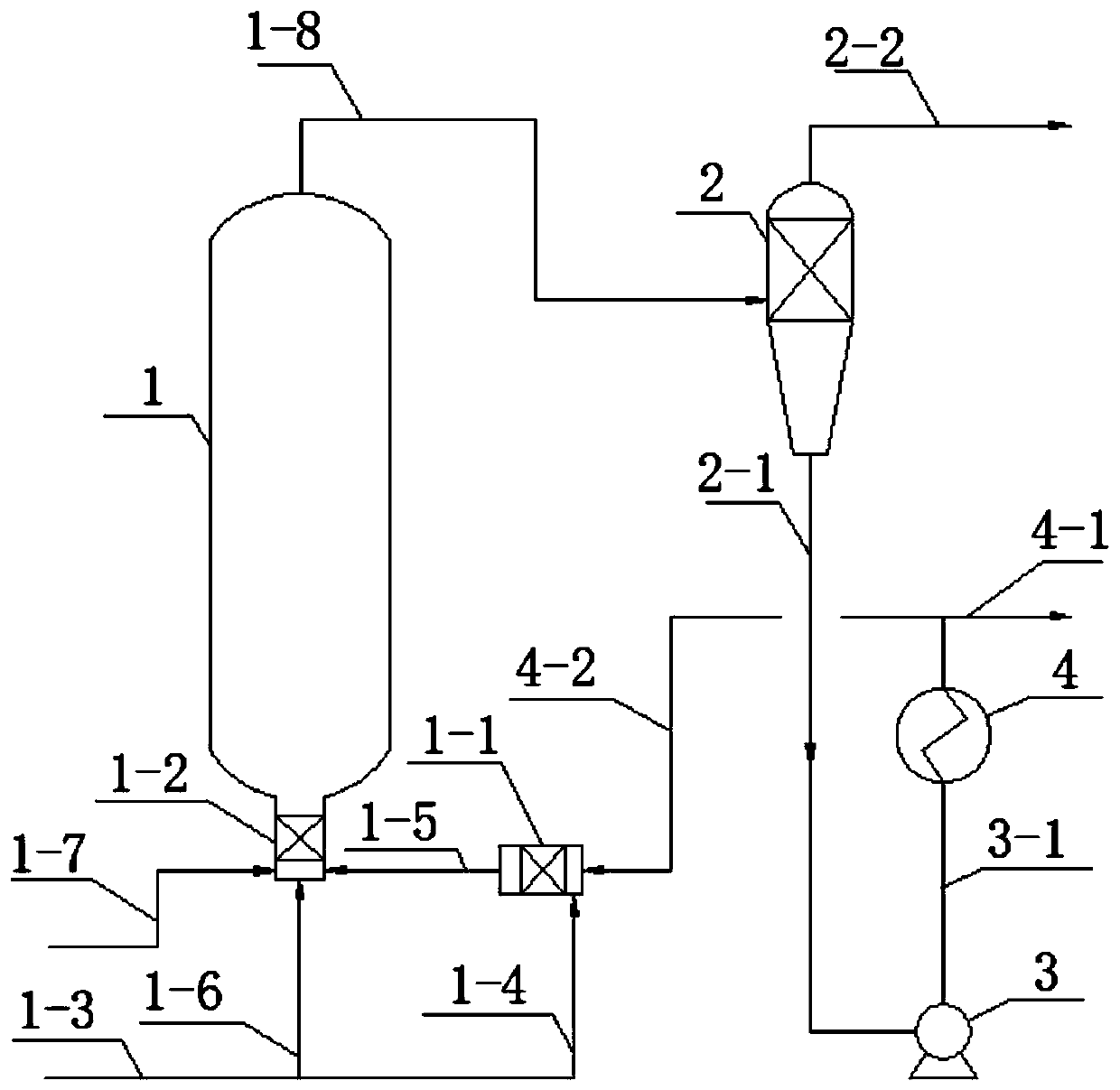

Ammonium sulfite oxidation enhanced micro-interface reaction system and method

PendingCN112755768AIncrease the mass transfer area of the phase boundaryTake advantage ofGas treatmentMixing methodsPhysical chemistryReaction system

The invention relates to an ammonium sulfite oxidation enhanced micro-interface reaction system which comprises an ammonium sulfite storage tank, an oxygen inlet pipeline, external micro-interface generators and a first oxidation reactor; a hydraulic micro-interface generator and a first oxygen micro-interface generator are arranged in the first oxidation reactor; a micro-interface unit is arranged on the side surface of the first oxidation reactor, consists of a plurality of external micro-interface generators, and is connected with the ammonium sulfite storage tank and the oxygen inlet pipeline; the first oxidation reactor and a second oxidation reactor are connected in parallel, the second oxidation reactor is internally provided with a second oxygen micro-interface generator and a liquid ejector, the oxygen inlet pipeline is connected with the second oxygen micro-interface generator, and the ammonium sulfite storage tank is connected with the liquid ejector. The reaction system provided by the invention ensures full utilization of gas, and improves the gas content and the reaction efficiency.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

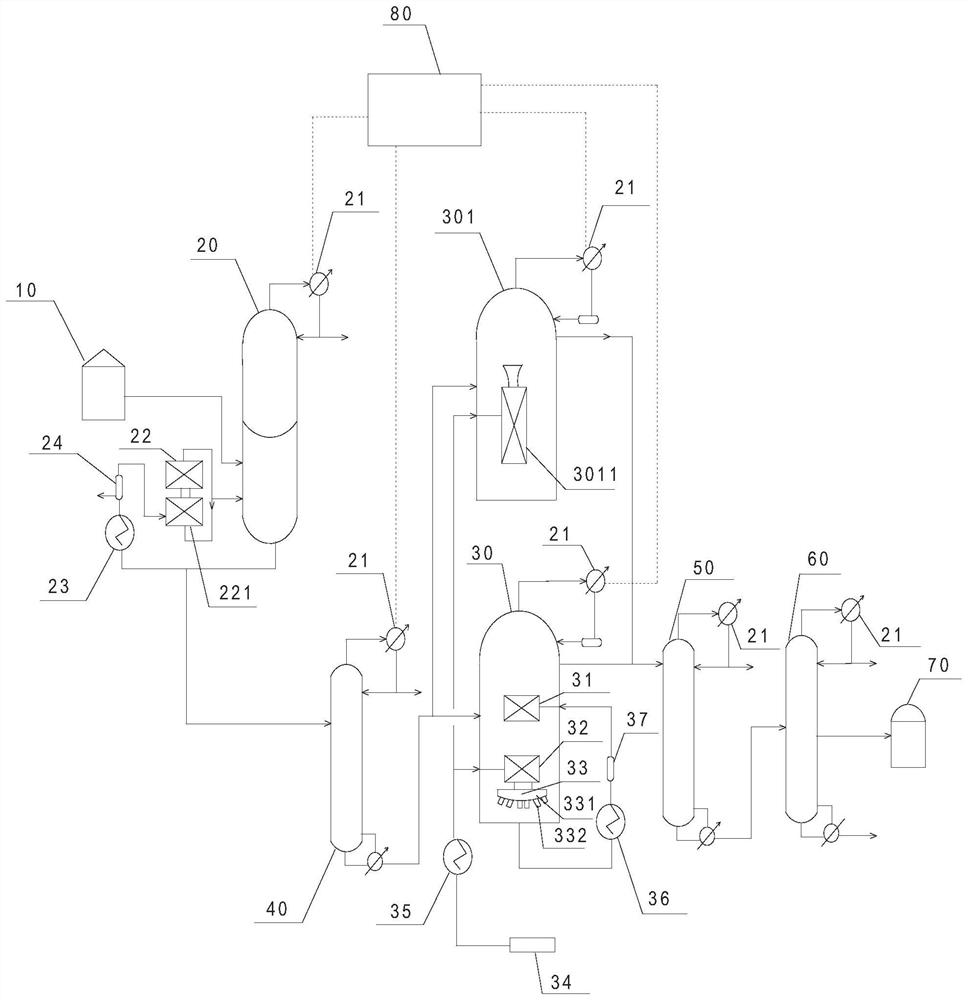

Enhanced micro-interface reaction system and method for preparing lactide from lactic acid

InactiveCN112934139AIncrease the mass transfer areaReduce reaction temperature and catalyst usageChemical/physical/physico-chemical microreactorsDistillation separationMaterials scienceLactic acid

The invention provides an enhanced micro-interface reaction system for preparing lactide from lactic acid. The enhanced micro-interface reaction system comprises a lactic acid raw material tank and an oligomerization rectification reactor, wherein the lactic acid raw material tank is connected with the oligomerization rectification reactor; an external micro-interface unit is arranged in the oligomerization rectification reactor; a second reboiler is arranged at the bottom of the first lactide rectification reactor, and materials discharged from the bottom of the first lactide rectification reactor are gasified by the second reboiler and then are introduced into a first micro-interface generator in the first lactide rectification reactor; a second micro-interface generator is arranged below the first micro-interface generator; the first lactide rectification reactor is connected in parallel with a second lactide rectification reactor; and a hydraulic micro-interface generator is arranged in the second lactide rectification reactor. The reaction system provided by the invention can reduce reaction temperature and improve reaction efficiency.

Owner:TOWERSMASTER NANJING

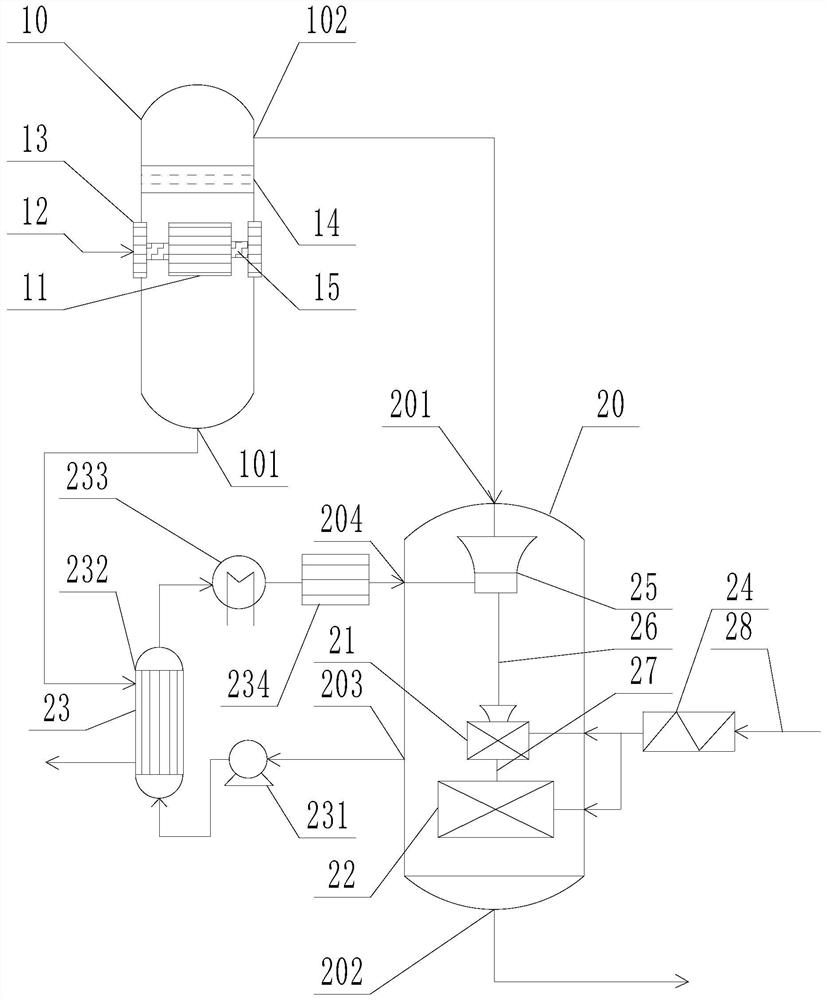

Enhanced micro-interface reaction system and method for preparing ethylene glycol by ethylene oxide method

PendingCN112723996AIncrease the mass transfer area of the phase boundaryHigh purityOrganic compound preparationTransportation and packagingEthylene oxidePhysical chemistry

The invention provides an enhanced micro-interface reaction system and method for preparing ethylene glycol by an ethylene oxide method, the enhanced micro-interface reaction system comprises a first reactor, a second reactor and a stirring kettle, and the stirring kettle is filled with a NaHCO3 agent material; a micro-interface unit is arranged on the outer side of the stirring kettle and is formed by arranging a plurality of external micro-interface generators; a main pipeline introduced into the micro-interface unit is connected with an ethylene oxide feeding pipeline and two branch pipelines of a water source pipeline at the same time, ethylene oxide is introduced into the micro-interface unit from the gas source conveying pipeline, and a water source enters the micro-interface unit to be used for breaking ethylene oxide gas into micron-sized micro-bubbles; the micro-interface units are arranged on the outer side of the stirring kettle and in the reactor, so that ethylene oxide is crushed into micro-bubbles before reacting with the water source, and the phase boundary mass transfer area between the ethylene oxide and the water source is increased.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

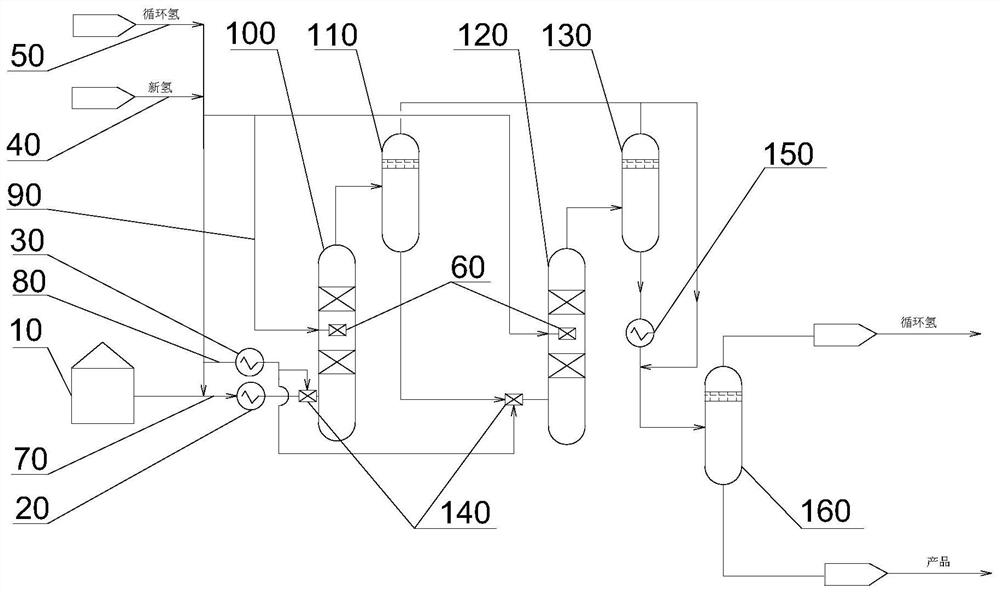

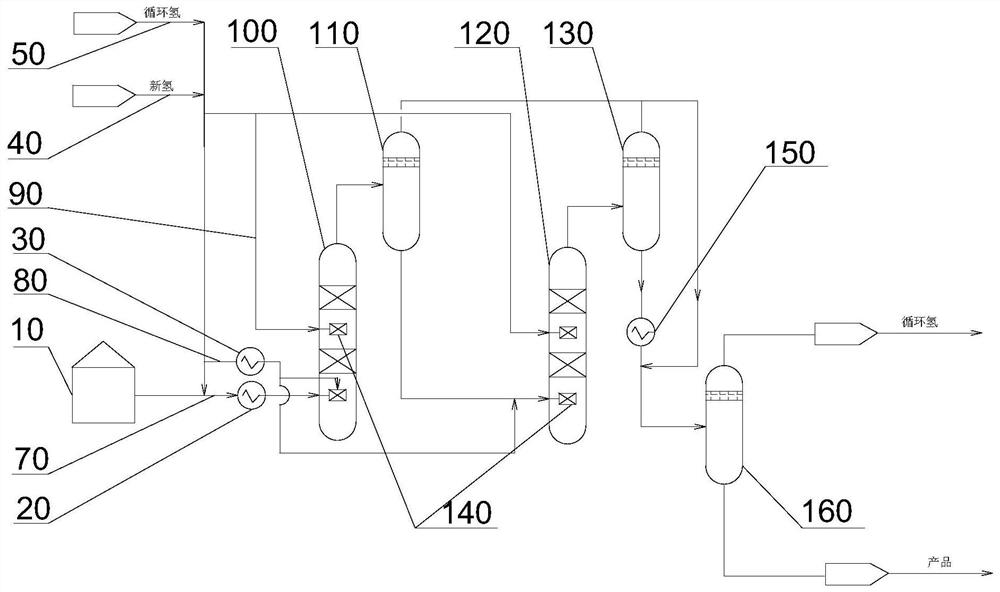

Micro-interface enhanced reaction system and method for petroleum resin hydrogenation

InactiveCN112011365AIncrease the mass transfer area of the phase boundarySolve the problem of reduced reaction efficiencyTransportation and packagingMixing methodsThermodynamicsPtru catalyst

The invention provides a micro-interface enhanced reaction system and method for petroleum resin hydrogenation. The micro-interface enhanced reaction system comprises a pre-hydrogenation reactor provided with two catalyst bed layers, a circulating hydrogen channel and a new hydrogen channel, a built-in micro-interface generator is arranged between the two catalyst bed layers, and an external micro-interface generator is arranged on the side surface of the pre-hydrogenation reactor. After the micro-interface enhanced reaction system provided by the invention is combined with the micro-interfacegenerator, the energy consumption is reduced, the reaction temperature is reduced, the reaction yield is improved, the utilization rate of raw materials is improved, particularly the utilization rateof hydrogen is improved, and meanwhile, the productivity is effectively improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Reaction system and method for hydrofining crude terephthalic acid

InactiveCN112707811AIncrease the mass transfer area of the phase boundarySolve the problem of reduced reaction efficiencyOrganic compound preparationChemical/physical processesPtru catalystHydrogenation reaction

A reaction system for hydrofining crude terephthalic acid comprises a hydrogenation reactor, and a hydrogen micro-interface generator used for dispersing broken hydrogen is arranged in the hydrogenation reactor. The side wall of the hydrogenation reactor is communicated with a crude terephthalic acid pipeline and a hydrogen inlet pipeline, and the hydrogen inlet pipeline penetrates through the side wall of the hydrogenation reactor and is led into the hydrogen micro-interface generator. A product purified terephthalic acid obtained after reaction in the hydrogenation reactor sequentially enters a crystallization tower, a centrifugal separator and a dryer, and finally solid purified terephthalic acid is formed and enters a collection tank. According to the reaction system, the mass transfer rate and the macroscopic hydrogenation rate of the gas phase to the reaction liquid are greatly improved, so that the original reaction pressure, reaction temperature and catalyst consumption can be reduced, and the reaction efficiency is improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Micro-interface reaction system and method for petroleum resin hydrogenation

InactiveCN112011366AImprove mass transfer effectImprove the effect of dispersion and crushingTransportation and packagingMixing methodsPhysicsInterfacial reaction

The invention provides a micro-interface reaction system and method for petroleum resin hydrogenation. The micro-interface reaction system comprises a pre-hydrogenation reactor provided with two catalyst bed layers, a circulating hydrogen channel and a new hydrogen channel, wherein a raw material inlet and a hydrogen inlet are respectively formed in the side wall of the pre-hydrogenation reactor,and micro-interface generators are respectively arranged between the two catalyst bed layers and the bottom of the pre-hydrogenation reactor. After the micro-interface reaction system provided by theinvention is combined with the micro-interface generator, the energy consumption is reduced, the reaction temperature is reduced, the reaction yield is improved, the utilization rate of raw materialsis improved, particularly the utilization rate of hydrogen is improved, and meanwhile, the productivity is effectively improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Intelligent micro-interface reaction system and method for preparing lactide from lactic acid

InactiveCN112933630AIncrease the mass transfer area of the phase boundaryReduce usageOrganic chemistryDistillation regulation/controlReaction temperatureOrganic chemistry

The invention provides an enhanced micro-interface reaction system for preparing lactide from lactic acid. The enhanced micro-interface reaction system comprises a lactic acid raw material tank and an oligomerization rectification reactor, wherein the lactic acid raw material tank is connected with the oligomerization rectification reactor; an external micro-interface unit is arranged in the oligomerization rectification reactor; a second reboiler is arranged at the bottom of a first lactide rectification reactor, and materials discharged from the bottom of the first lactide rectification reactor are gasified by the second reboiler and then are introduced into a first micro-interface generator in the first lactide rectification reactor; a second micro-interface generator is arranged below the first micro-interface generator; the first lactide rectification reactor is connected in parallel with a second lactide rectification reactor; and a hydraulic micro-interface generator is arranged in the second lactide rectification reactor. The reaction system provided by the invention can reduce reaction temperature and improve reaction efficiency.

Owner:TOWERSMASTER NANJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com