Micro-interface reaction system and method for preparing ethylene glycol by gas-phase catalytic hydration method

A gas-phase catalyzed water and hydration reaction technology, which is applied in the preparation of hydroxyl compounds, organic compounds, hydrolysis, etc., can solve problems such as inappropriateness, achieve the effects of reducing temperature and pressure, reducing dependence, and improving mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

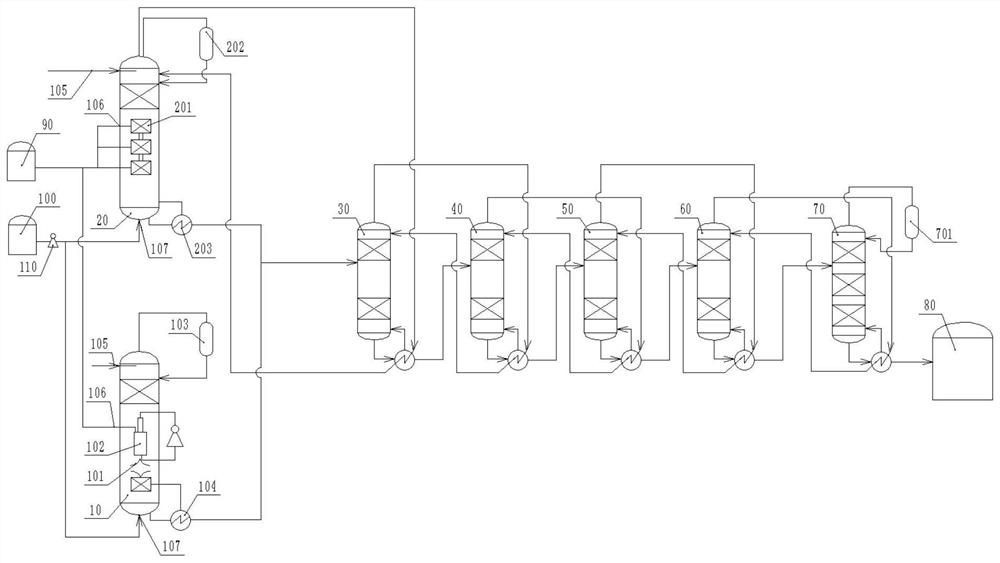

[0061] refer to figure 1 As shown, this embodiment provides a micro-interface reaction system for preparing ethylene glycol by gas-phase catalytic hydration, including: a first hydration reaction rectifier 10, a second hydration reaction rectifier 20, a first evaporation tower 30, The second evaporation tower 40, the first dehydration tower 50, the second dehydration tower 60 and the refining tower 70; the first hydration reaction rectifier 10 is connected in parallel with the second hydration reaction rectifier 20; the first hydration reaction rectification device 10 is connected with The second hydration reaction rectifier 20 is connected to the first evaporation tower 30 respectively.

[0062] The first evaporation tower 30 is connected to the second evaporation tower 40, the first dehydration tower 50 and the second dehydration tower 60 in sequence; the material coming out from the bottom of the first evaporation tower 30 enters the second evaporation tower 40, the first d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com