Micro-interface reaction system and method for hydrofining crude terephthalic acid

A crude terephthalic acid and reaction system technology, which is applied in the field of refining crude terephthalic acid, can solve the problems of large catalyst loss, small gas-liquid interface area, and reduced safety, so as to improve product purity and improve reaction efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

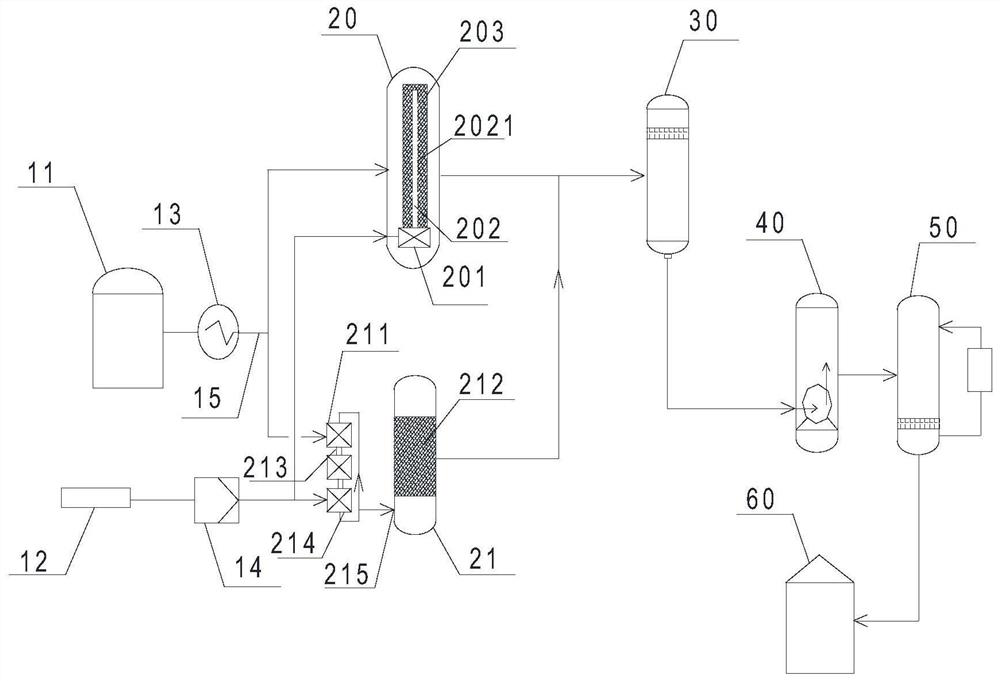

[0055] refer to figure 1 As shown, the micro-interface reaction system for crude terephthalic acid hydrogenation and refining provided in the embodiment of the present invention mainly includes a crude terephthalic acid storage tank 11, a hydrogen gas inlet pipeline 12, a hydrogenation reactor 20, a bubbling Tower reactor 21 , crystallization tower 30 , centrifugal separator 40 , drier 50 and collection tank 60 . The crude terephthalic acid storage tank 11 is connected with the hydrogenation reactor 20 and the bubble column reactor 21 through a crude terephthalic acid pipeline 15, and a raw material preheater is also arranged on the crude terephthalic acid pipeline 15 13. The crude terephthalic acid can be preheated to the reaction temperature. The hydrogen gas inlet pipe 12 directly leads into the hydrogen micro-interface generator 201 inside the hydrogenation reactor 20 and the external micro-interface generator 211 at the bottom of the external micro-interface unit 214, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com