Patents

Literature

161 results about "Compressed hydrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compressed hydrogen (CH₂, CGH₂ or CGH2) is the gaseous state of the element hydrogen kept under pressure. Compressed hydrogen in hydrogen tanks at 350 bar (5,000 psi) and 700 bar (10,000 psi) is used for mobile hydrogen storage in hydrogen vehicles. It is used as a fuel gas.

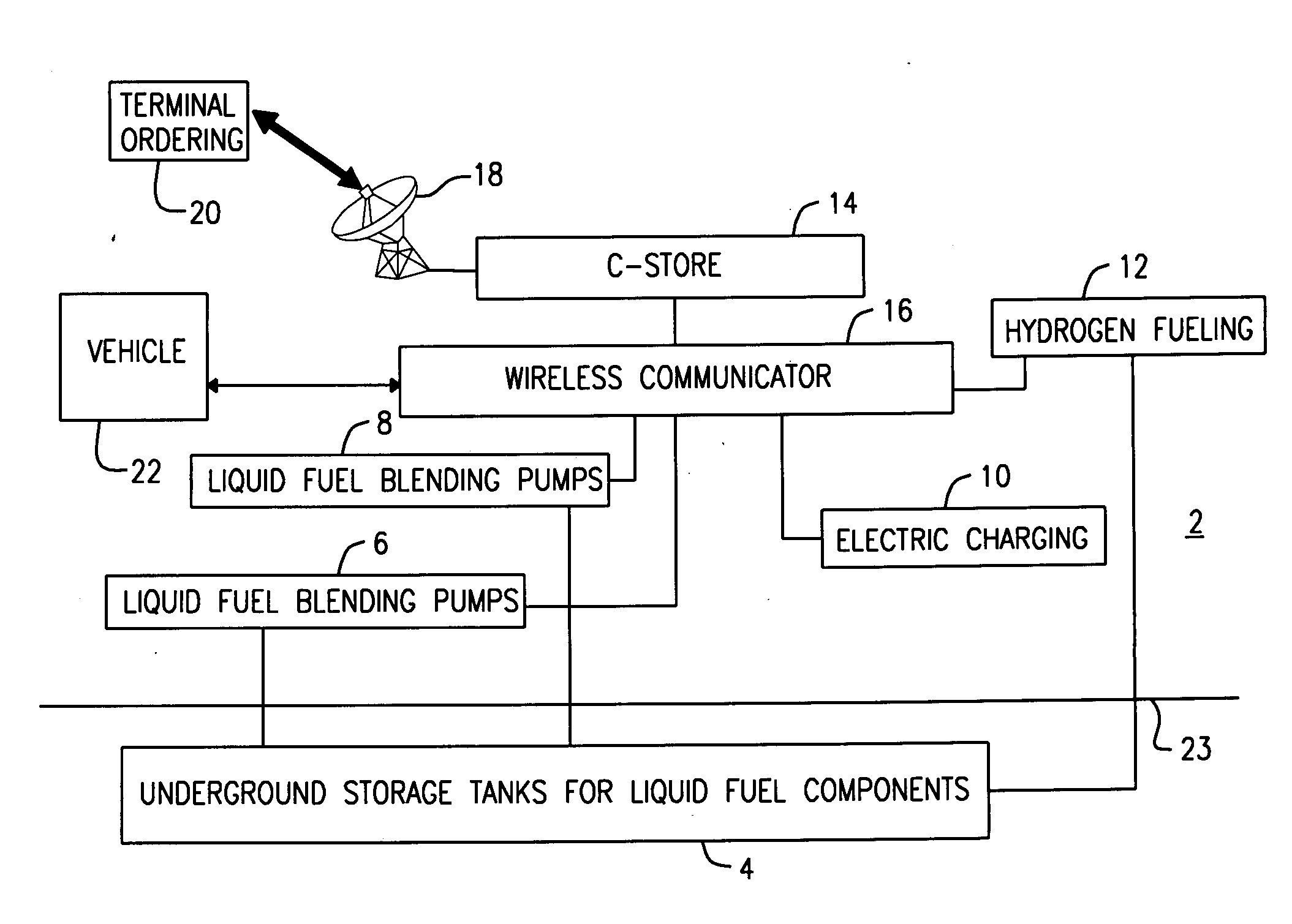

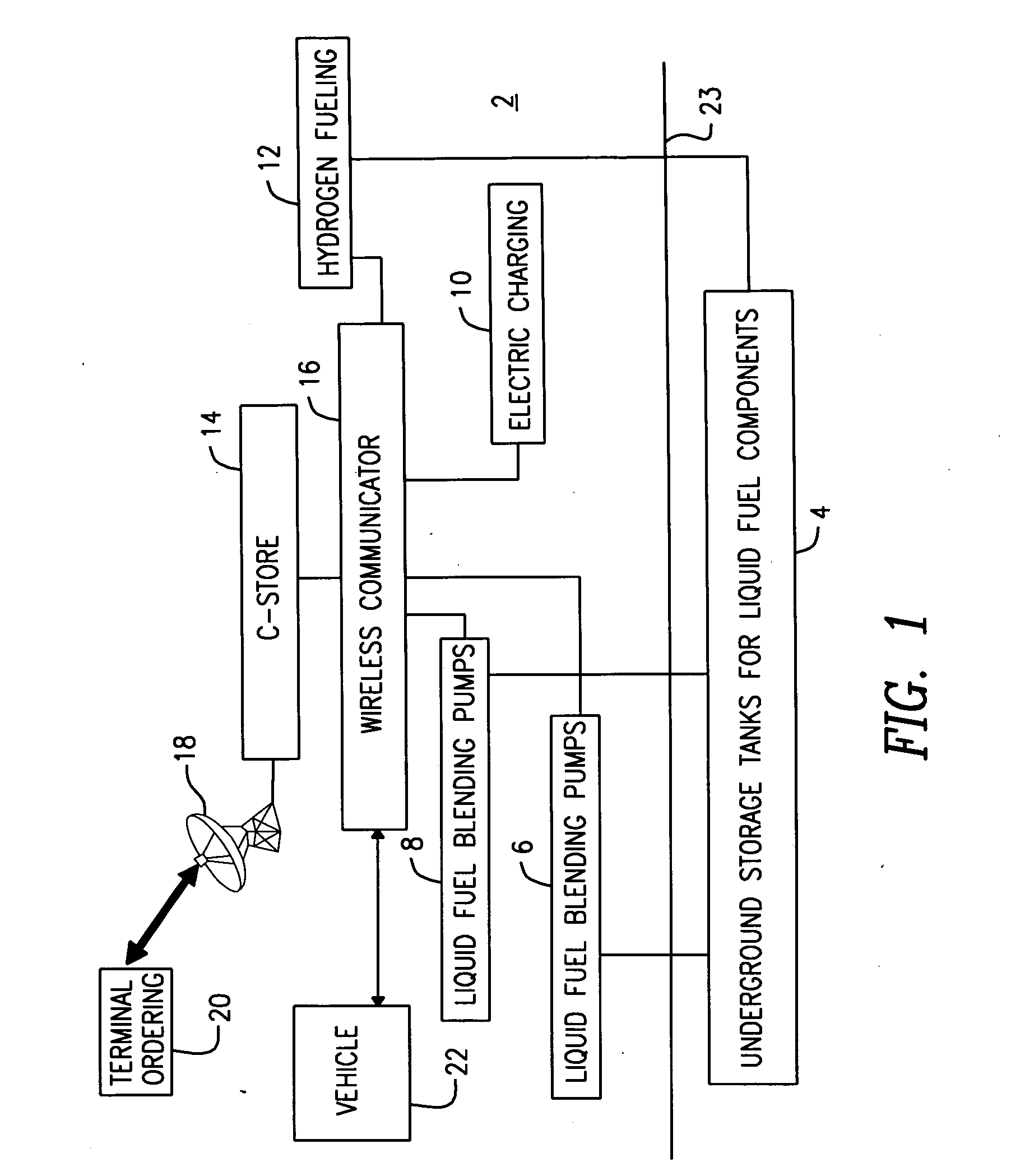

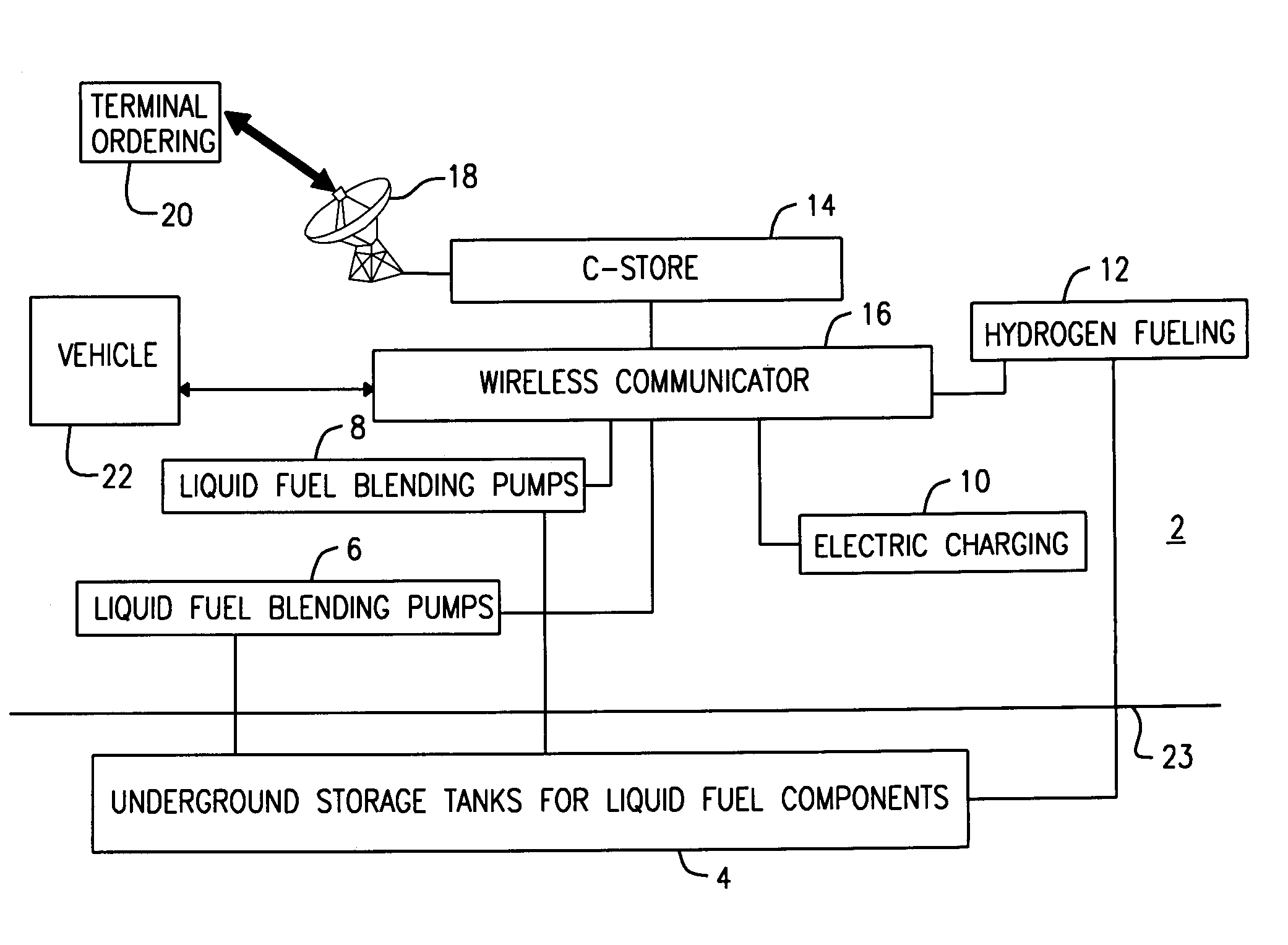

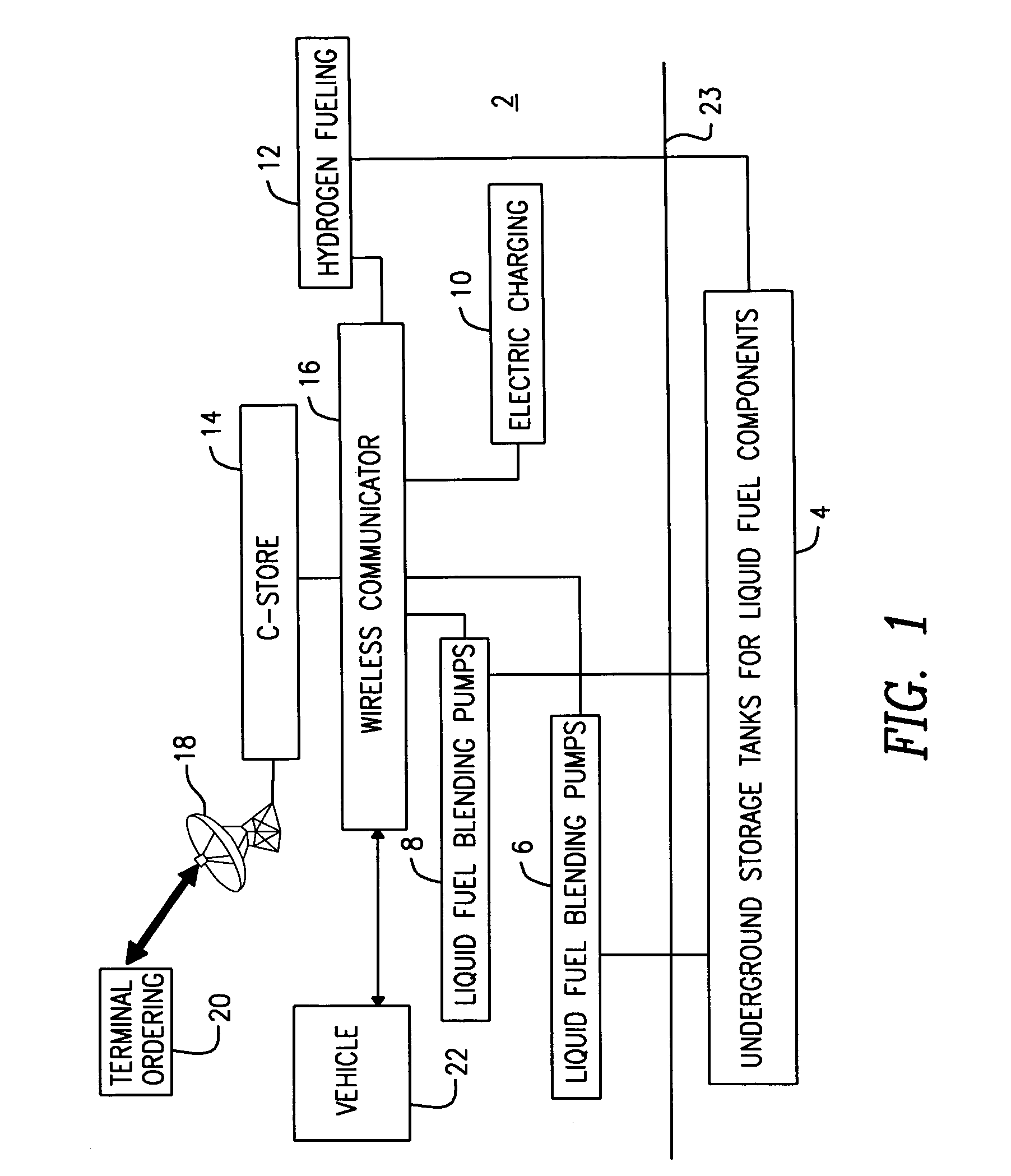

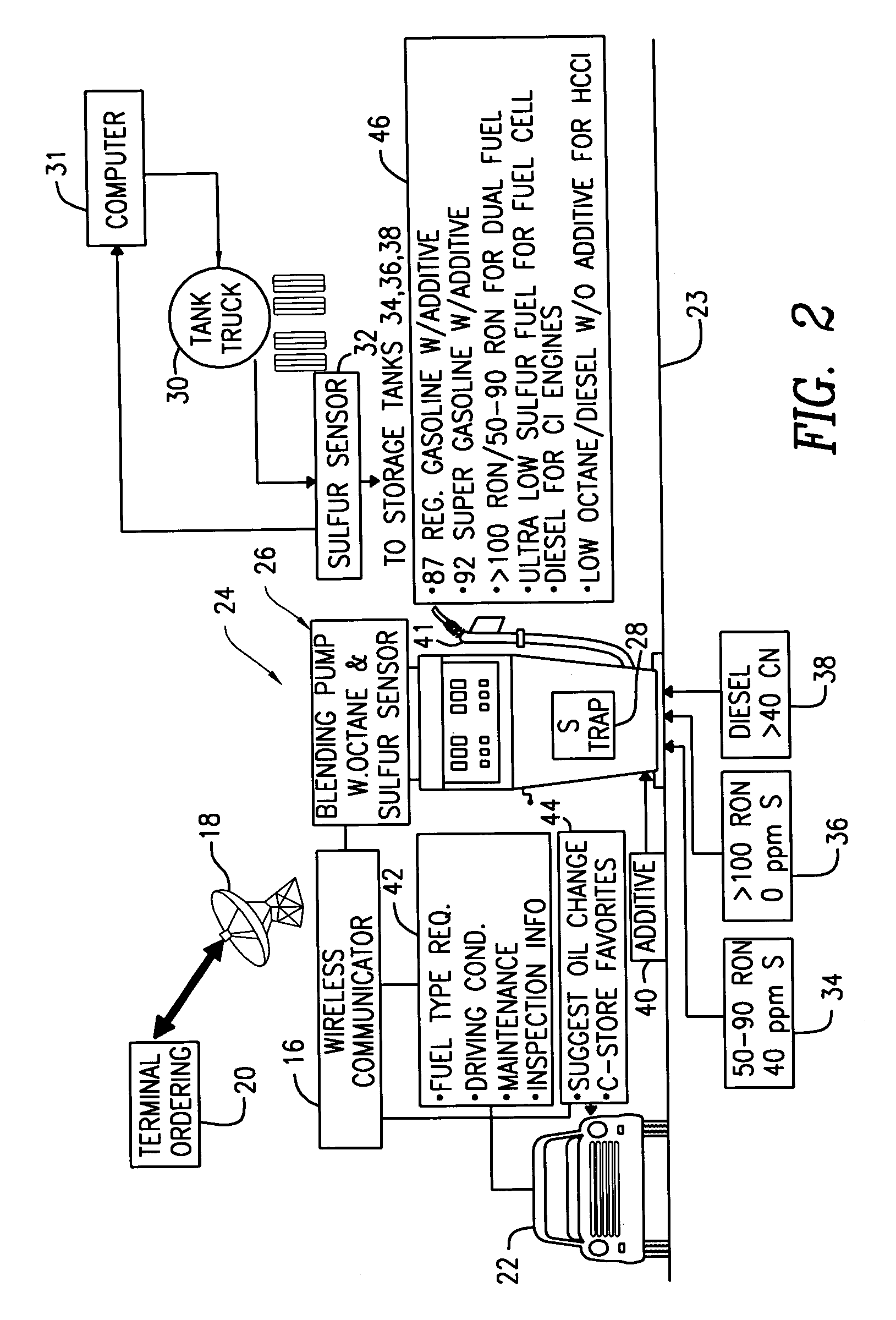

Service station for serving requirements of multiple vehicle technologies

InactiveUS20070144605A1Prevent fueling errorAvoid mistakesLiquid fillingData processing applicationsFuel cellsGasoline

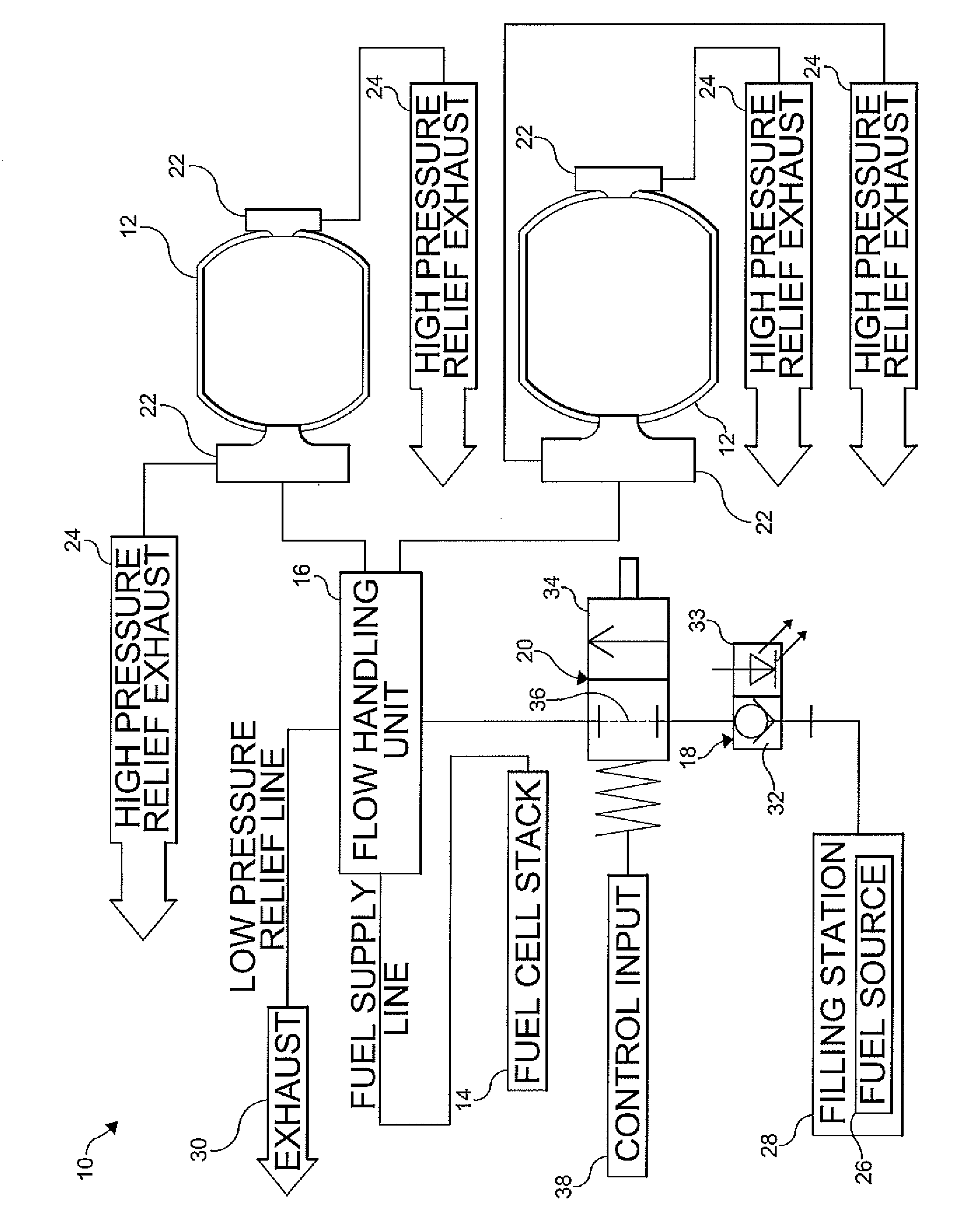

A service station is provided with a plurality of vehicle servicing islands including liquid fuel blending pumps for dispensing and blending fuel components from underground tanks for refueling standard gasoline engine driven vehicles, standard diesel engine vehicles, vehicles with engines requiring dual fuels, vehicles with HCCI engines requiring low octane gasoline blended with standard diesel fuel, and fuel cell powered vehicles having onboard reformers. Other service islands include pumps for dispensing compressed hydrogen to fuel cell powered vehicles that do not include onboard reformers. In addition, service islands are provided for recharging the batteries of pure electric powered vehicles.

Owner:EXXON RES & ENG CO

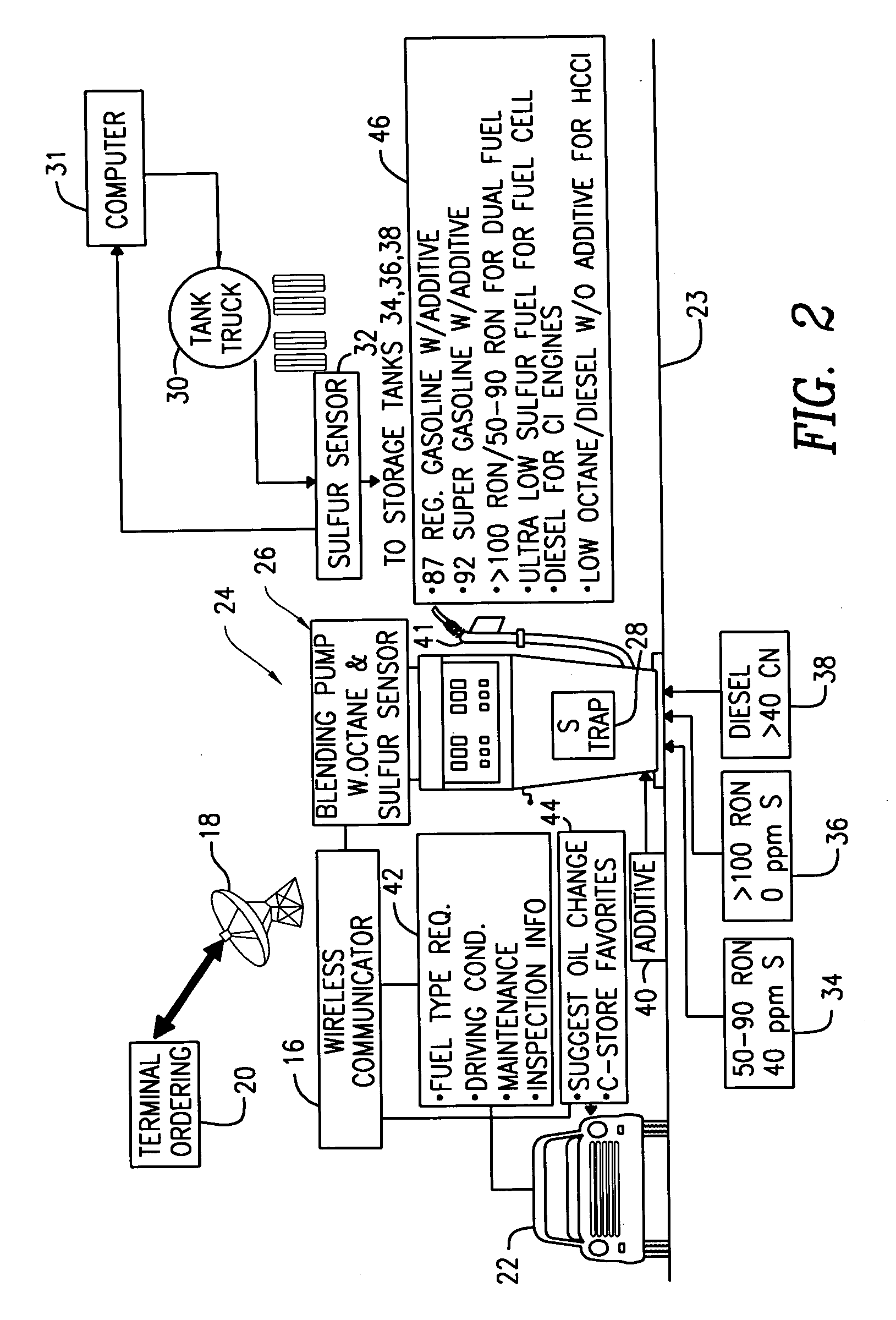

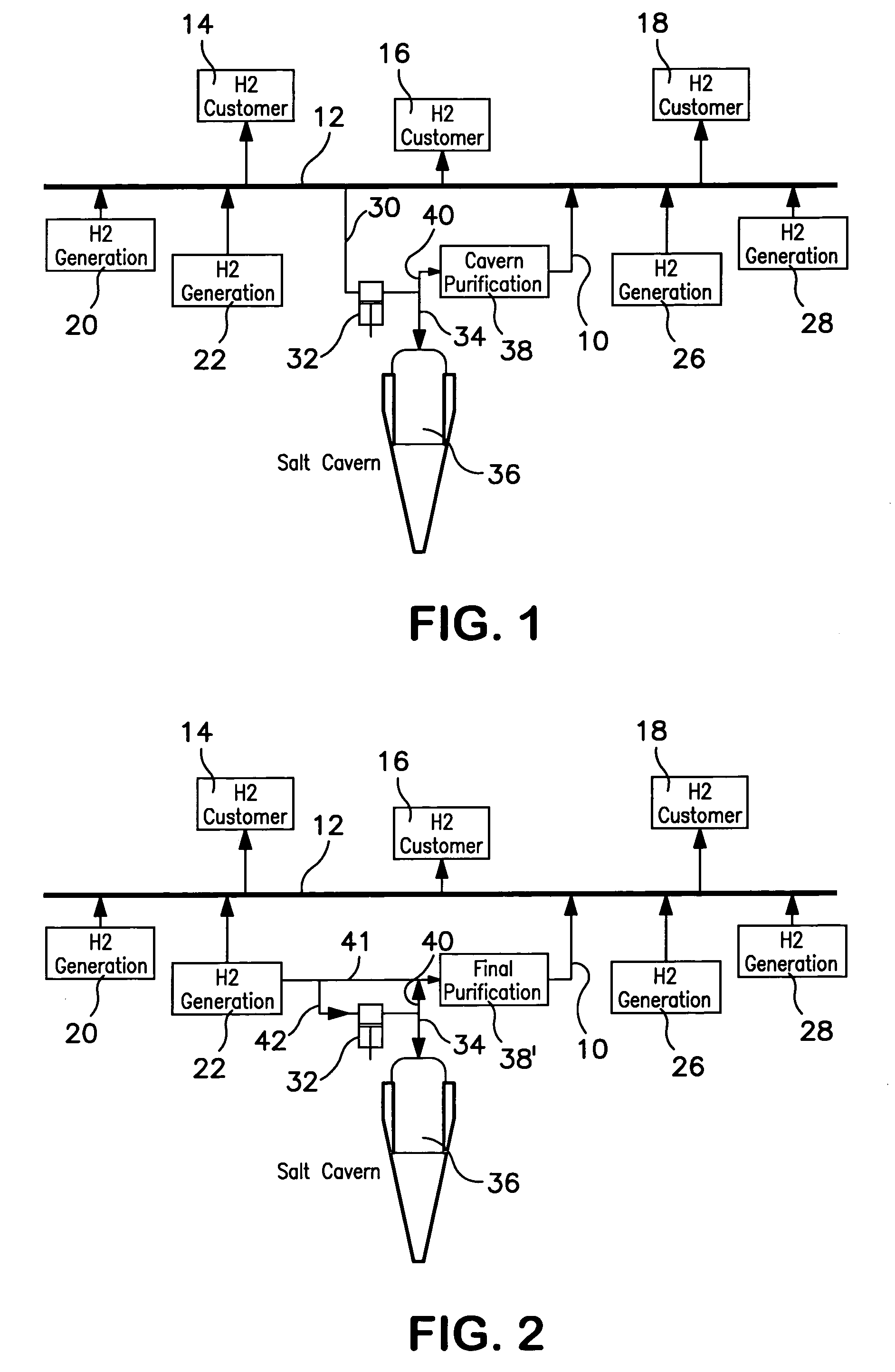

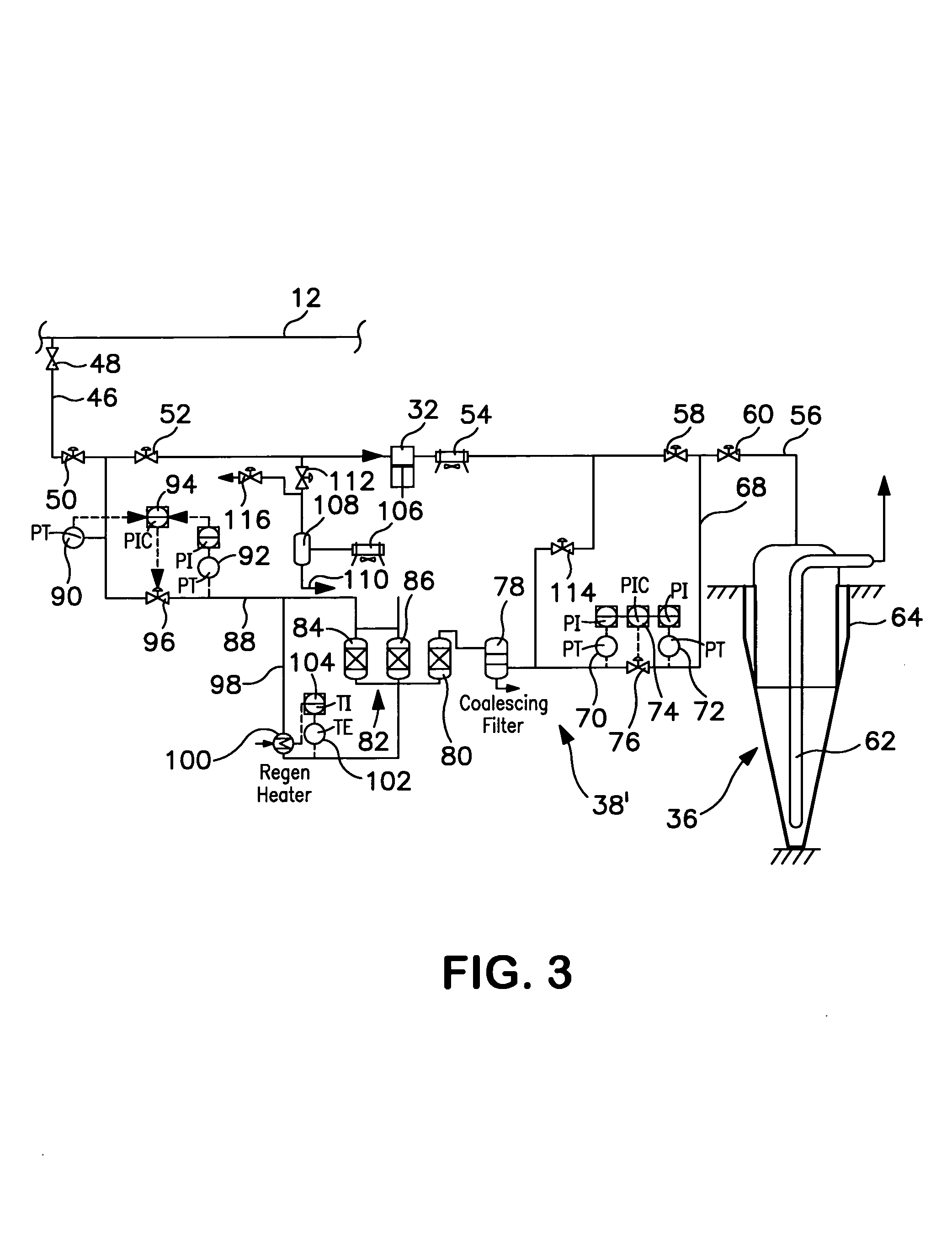

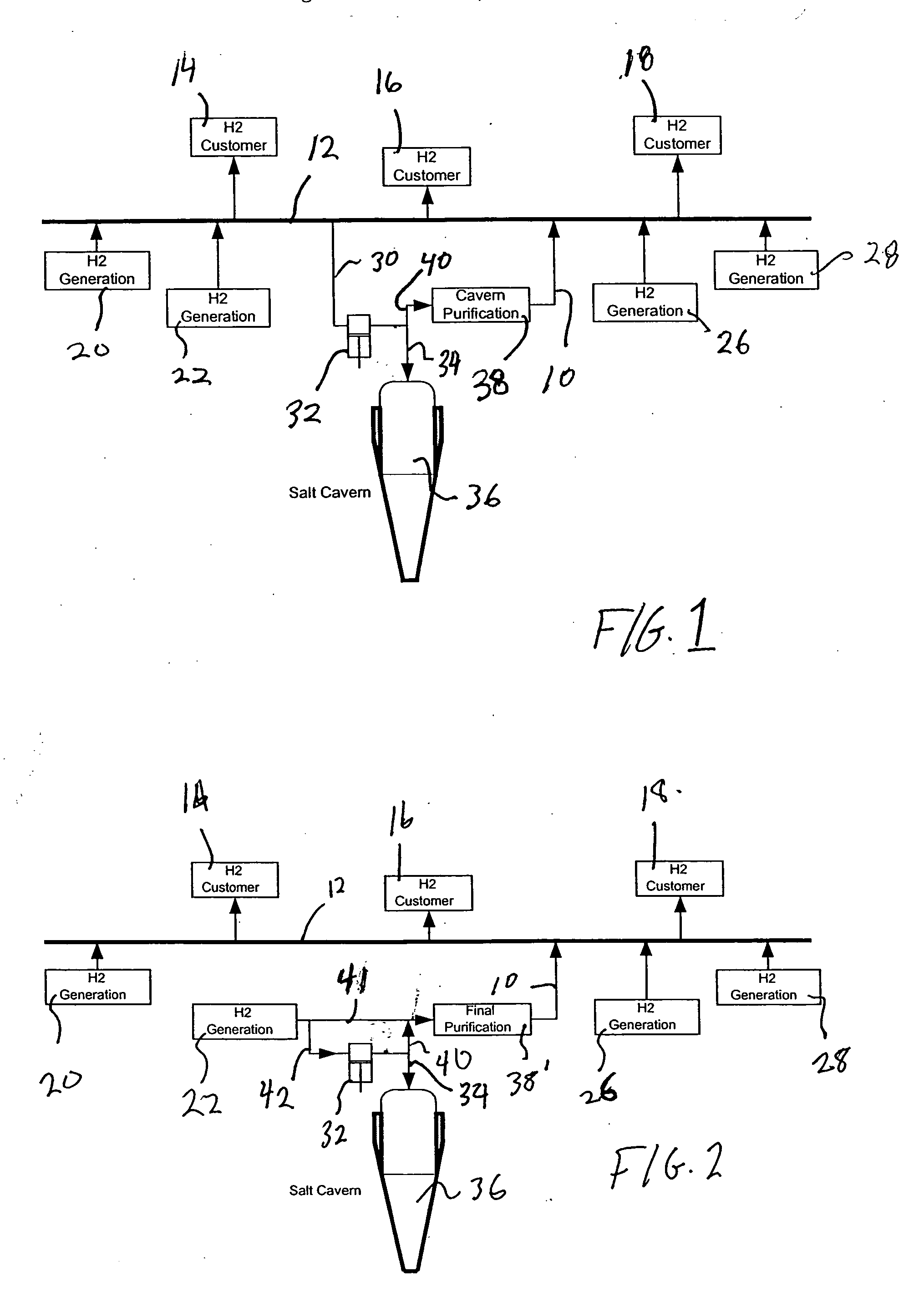

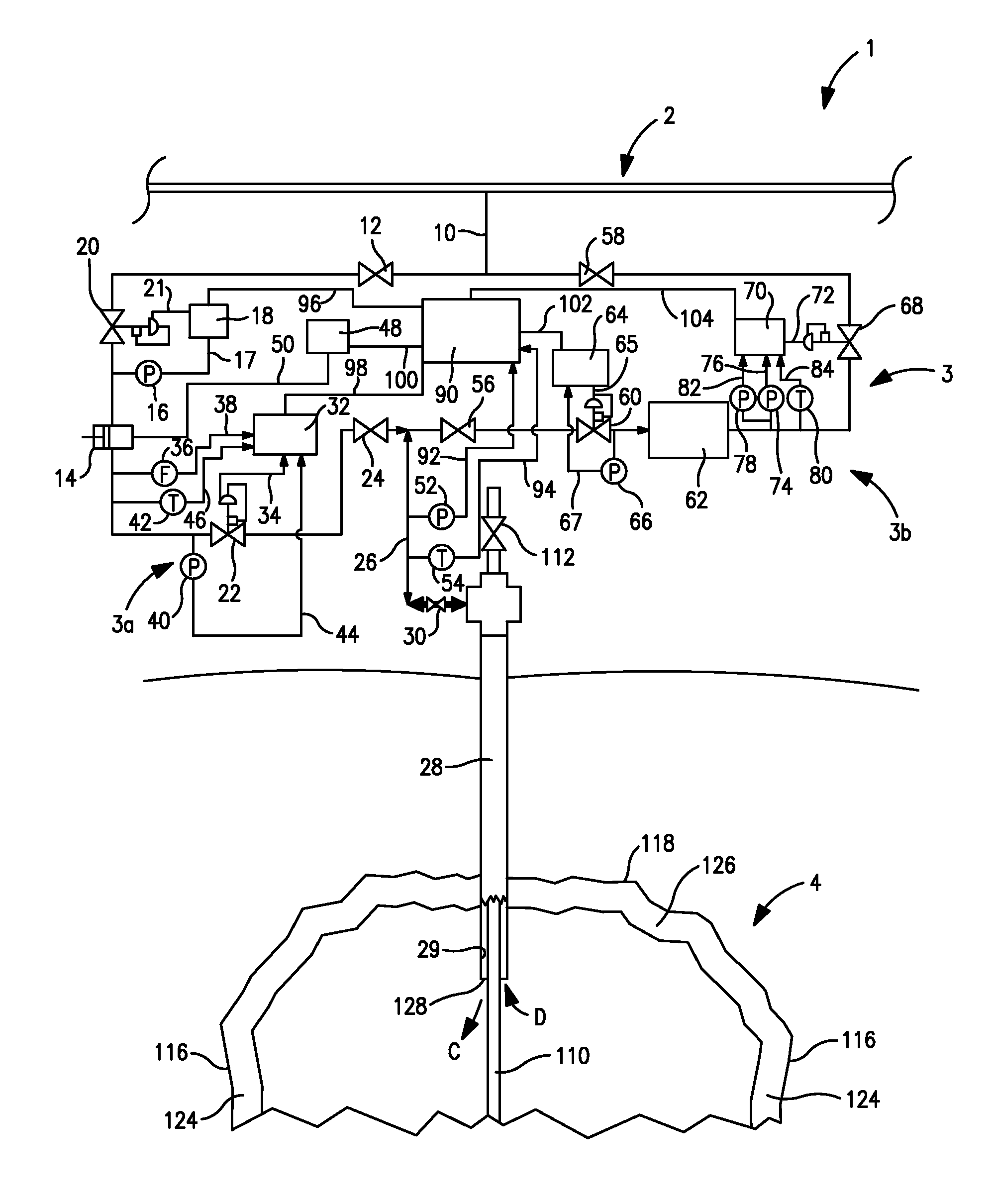

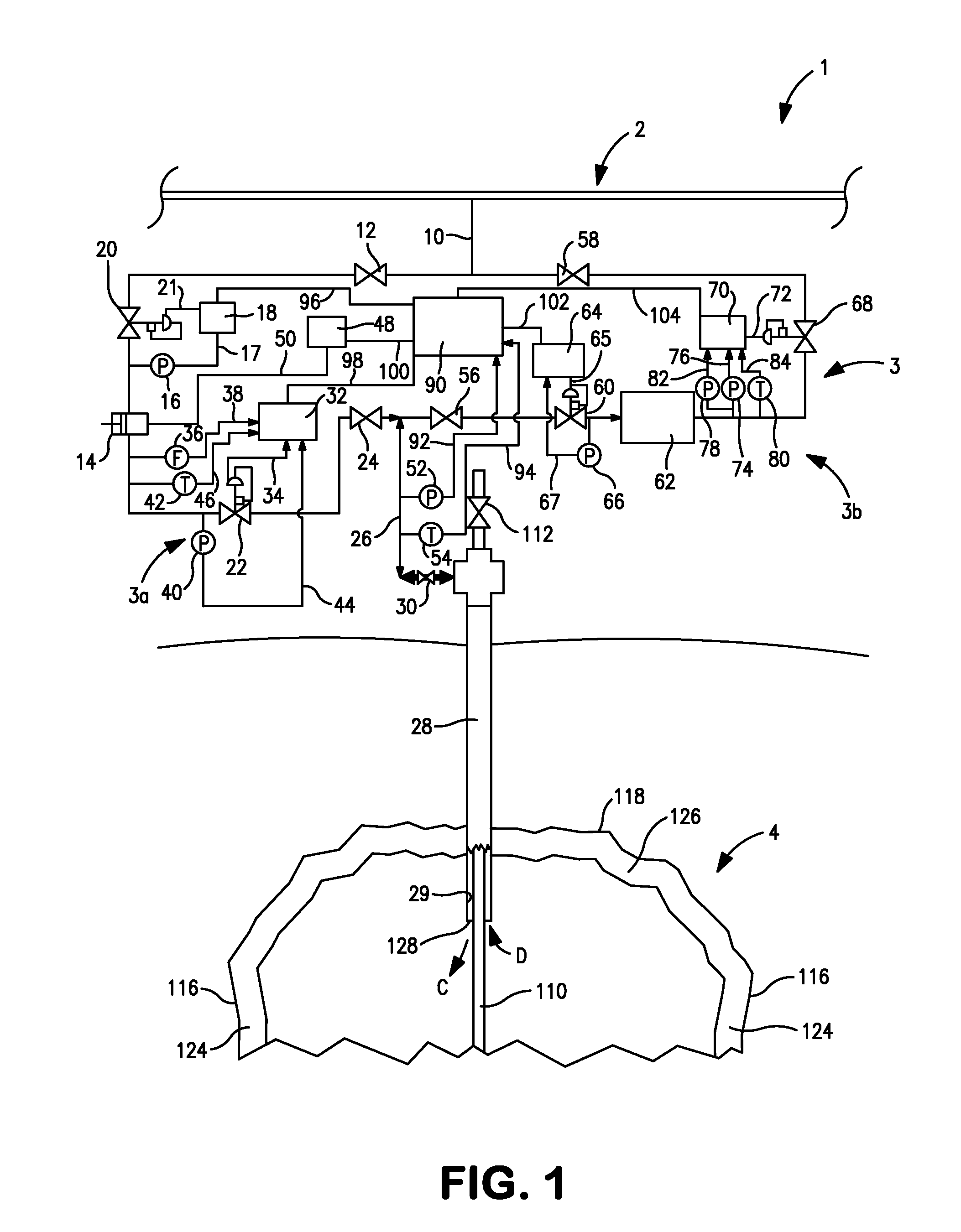

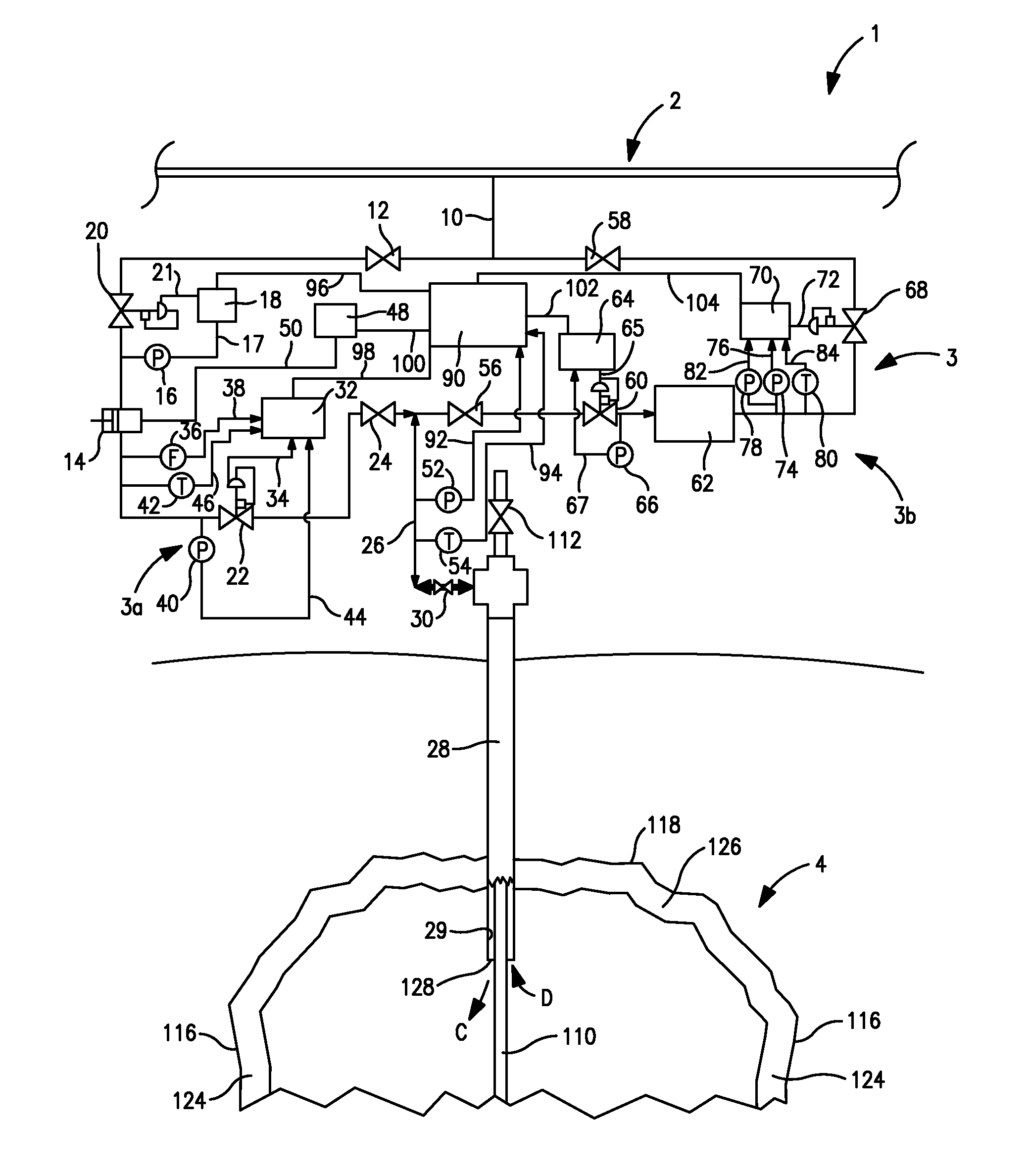

Method of storing and supplying hydrogen to a pipeline

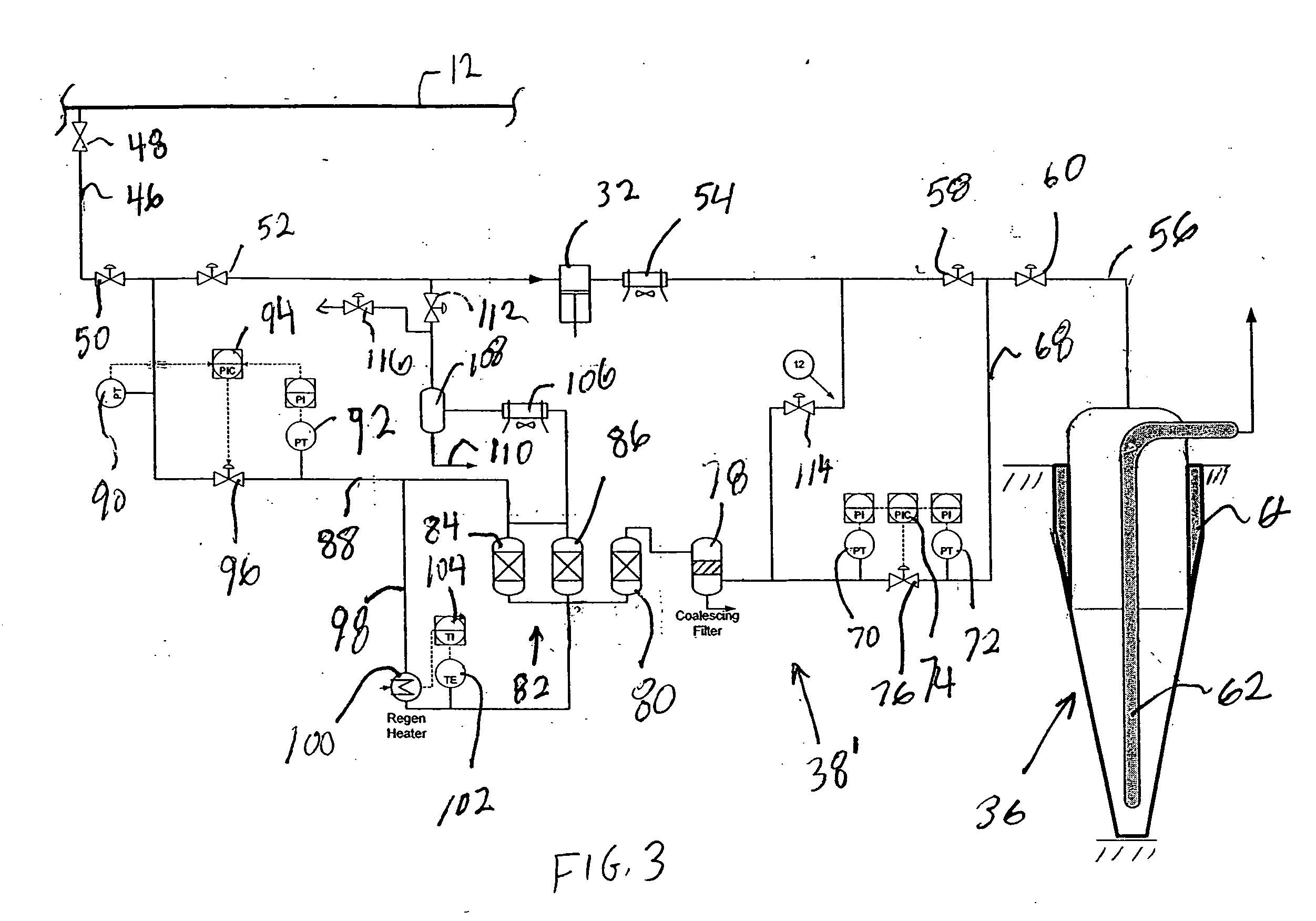

A method of storing and supplying a gaseous hydrogen product to a pipeline under a product purity specification in which a hydrogen stream made up of gaseous hydrogen is compressed to form a compressed hydrogen stream and introduced into a salt cavern for storage. A crude hydrogen stream, contaminated from storage in the salt cavern is recovered and purified by sufficiently removing at least carbon dioxide and water vapor to produce a hydrogen product stream having an impurity level at or below the product purity specification. The hydrogen product stream is supplied back to the pipeline. Alternatively, during periods of low demand, hydrogen produced by a production facility is both purified and supplied to the pipeline and stored in the salt cavern. During high demand period, both the output of the production facility and hydrogen retrieved from the salt cavern are purified and supplied to the pipeline.

Owner:PRAXAIR TECH INC

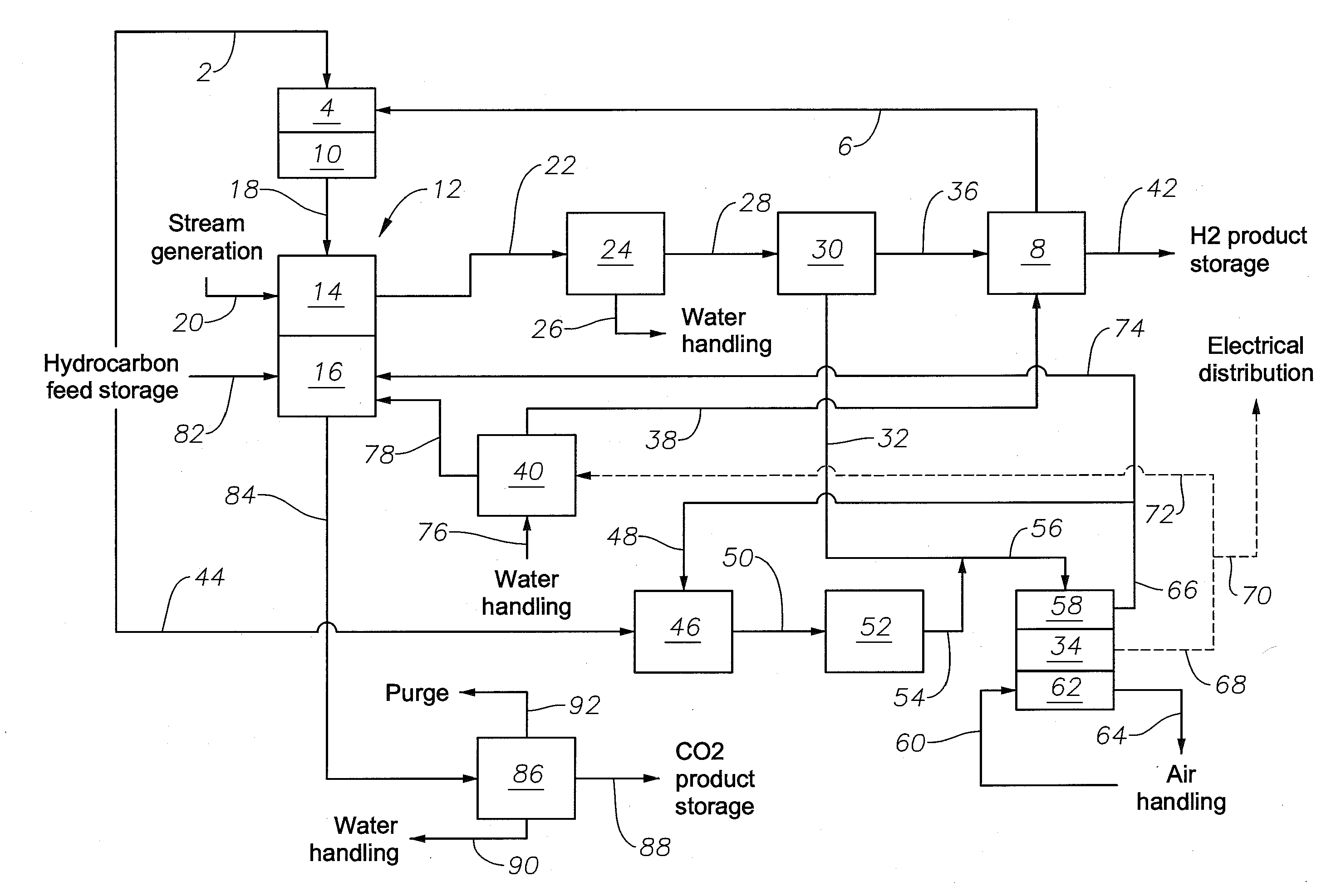

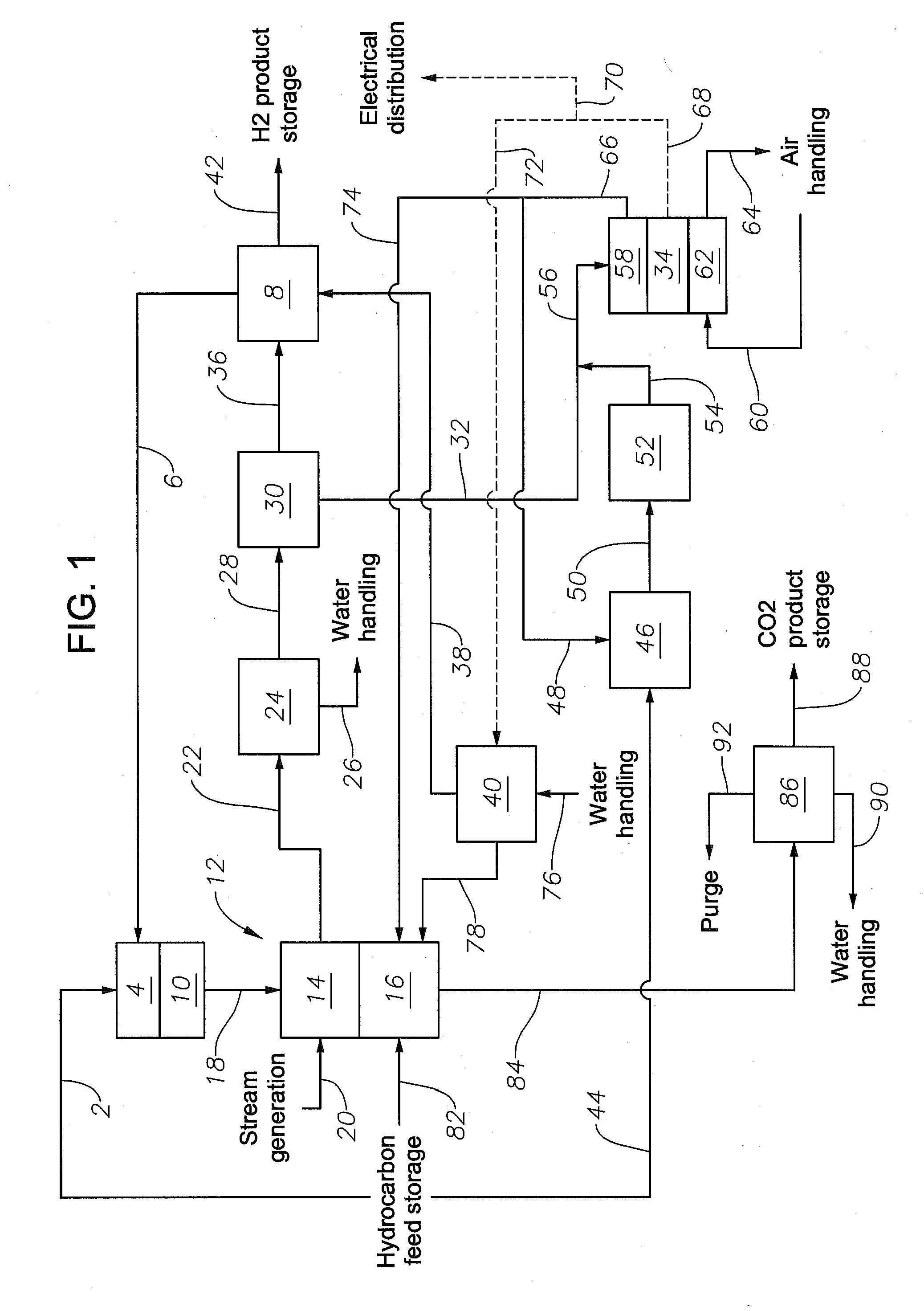

Method and a system for combined hydrogen and electricity production using petroleum fuels

ActiveUS20130126038A1Reduce decreasePrevents carbon dioxide emissionHydrogen/synthetic gas productionVehicular energy storageElectricityCombustion chamber

A SOFC system for producing a refined carbon dioxide product, electrical power and a compressed hydrogen product is presented. Introducing a hydrocarbon fuel and steam to the SOFC system, operating the SOFC system such that the steam-to-carbon molar ratio in the pre-reformer is in a range of from about 3:1 to about 4:1, the oxygen in the reformer combustion chamber is in excess, greater than 90% of the carbon dioxide produced during the process forms the refined carbon dioxide product are steps in the process. An alternative fueling station having a SOFC system is useful for fueling both electrical and hydrogen alternative fuel vehicles. Introducing steam and a hydrocarbon fuel, operating the alternative fueling station, coupling the alternative fuel vehicle to the alternative fueling station, introducing an amount of alternative fuel and decoupling the alternative fuel vehicle are steps in the method of use.

Owner:SAUDI ARABIAN OIL CO

Service station for serving requirements of multiple vehicle technologies

A service station is provided with a plurality of vehicle servicing islands including liquid fuel blending pumps for dispensing and blending fuel components from underground storage tanks for refueling standard gasoline engine driven vehicles, standard diesel engine vehicles, vehicles with engines requiring dual fuels, vehicles with HCCL engines require low octane gasoline blended with standard diesel fuel, and fuel cell powered vehicles having onboard reformers. Other service islands include pumps for dispensing compressed hydrogen to fuel cell powered vehicles that do not include onboard reformers. In addition, service islands are provided for recharging the batteries of pure electric powered vehicles. A service station is further provided with a wireless communicator for receiving signals indicative of a vehicle's fuel requirements and transmitting signals to direct the vehicle to a service island capable of servicing the vehicle.

Owner:EXXON RES & ENG CO

Method of storing and supplying hydrogen to a pipeline

A method of storing and supplying a gaseous hydrogen product to a pipeline under a product purity specification in which a hydrogen stream made up of gaseous hydrogen is compressed to form a compressed hydrogen stream and introduced into a salt cavern for storage. A crude hydrogen stream, contaminated from storage in the salt cavern is recovered and purified by sufficiently removing at least carbon dioxide and water vapor to produce a hydrogen product stream having an impurity level at or below the product purity specification. The hydrogen product stream is supplied back to the pipeline. Alternatively, during periods of low demand, hydrogen produced by a production facility is both purified and supplied to the pipeline and stored in the salt cavern. During high demand period, both the output of the production facility and hydrogen retrieved from the salt cavern are purified and supplied to the pipeline.

Owner:PRAXAIR TECH INC

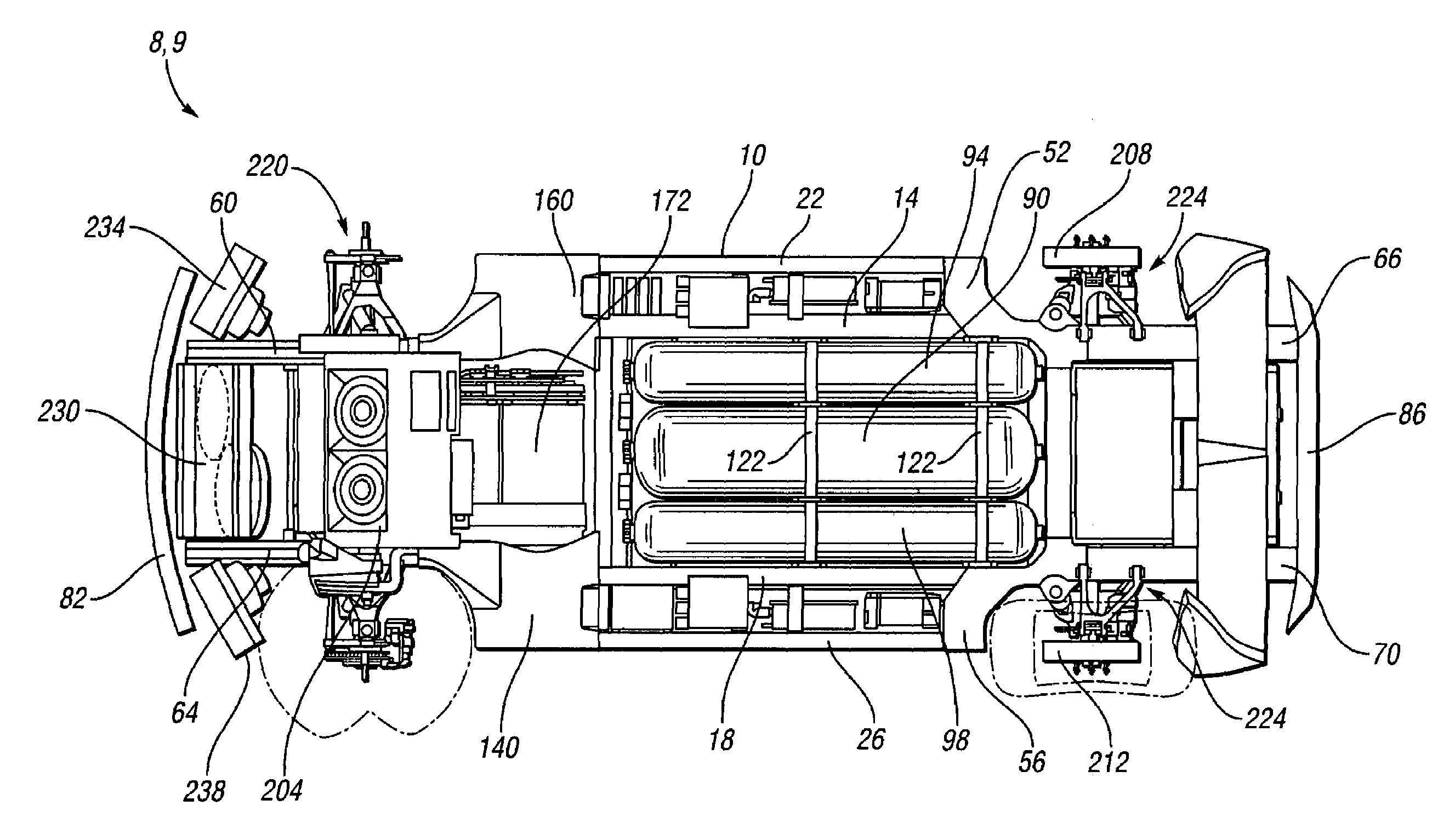

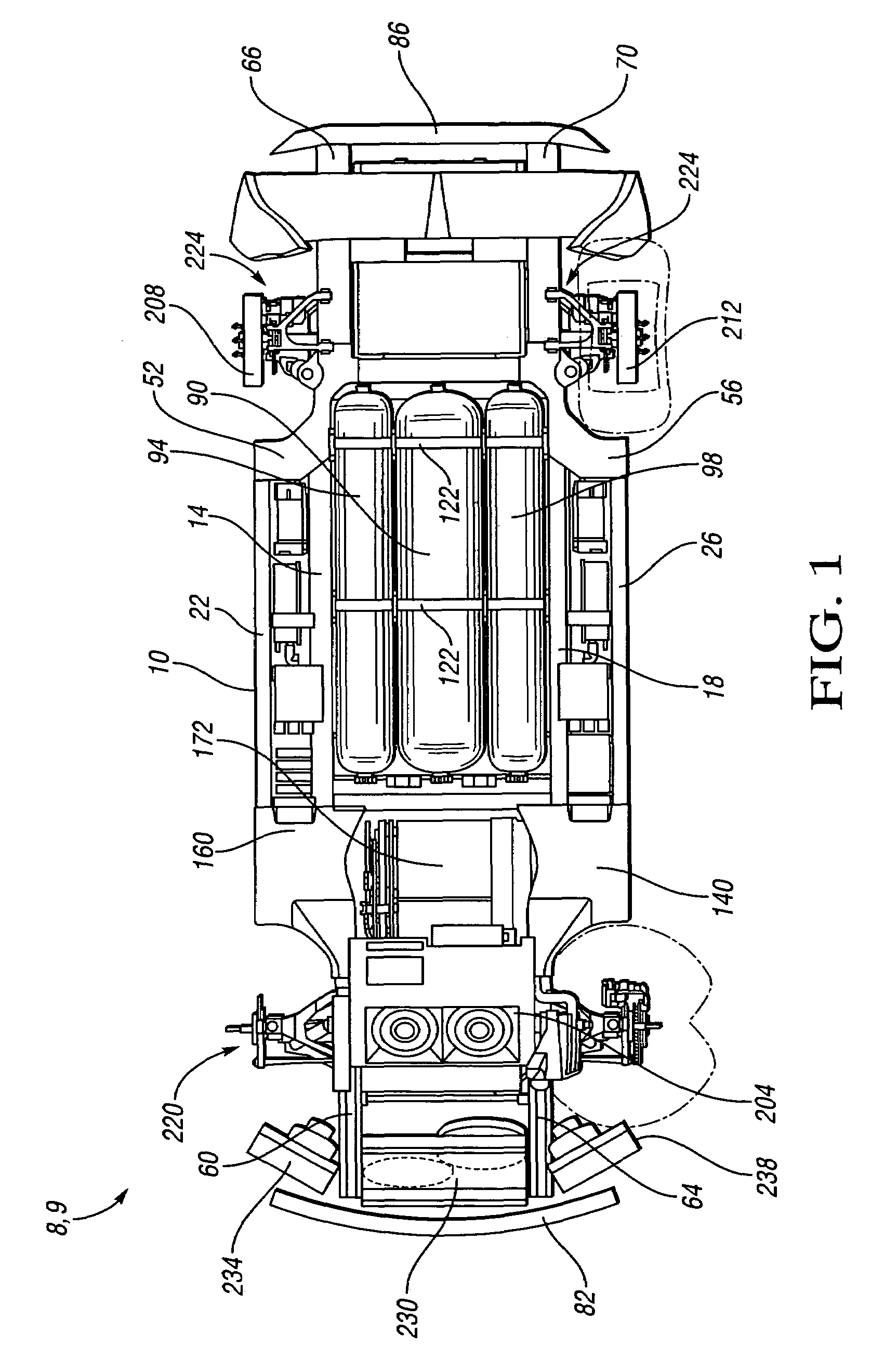

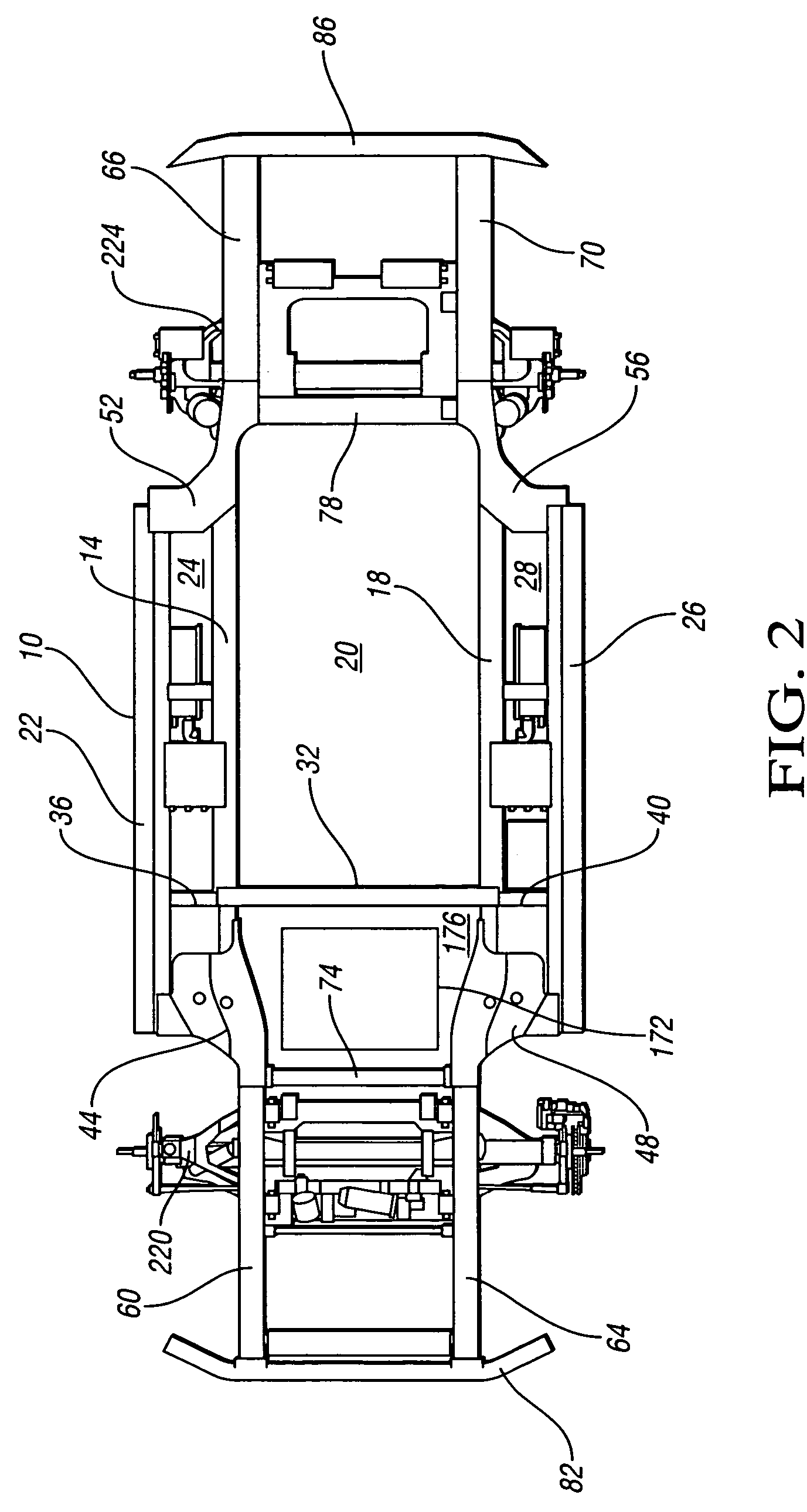

Fuel cell vehicle architecture

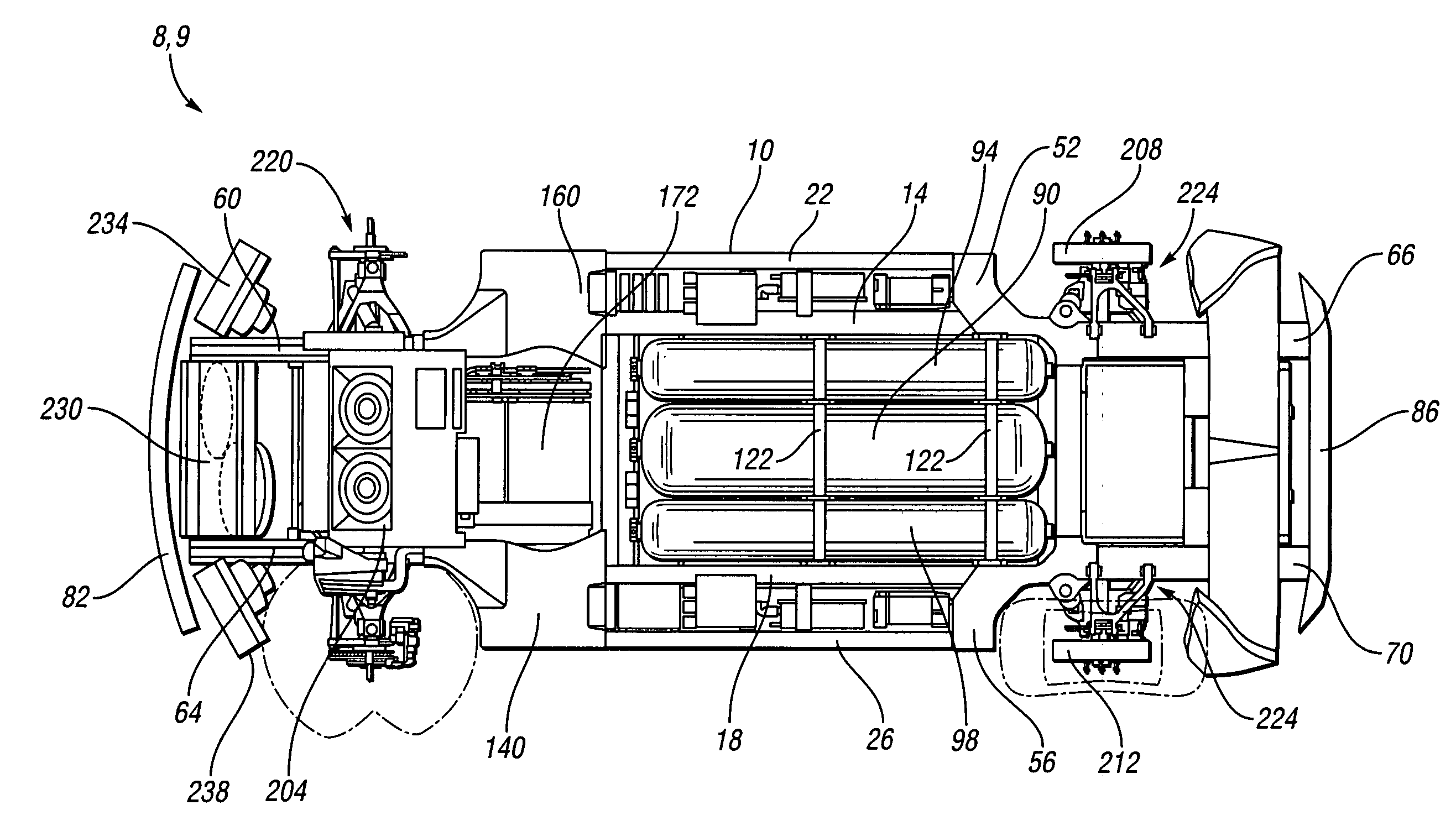

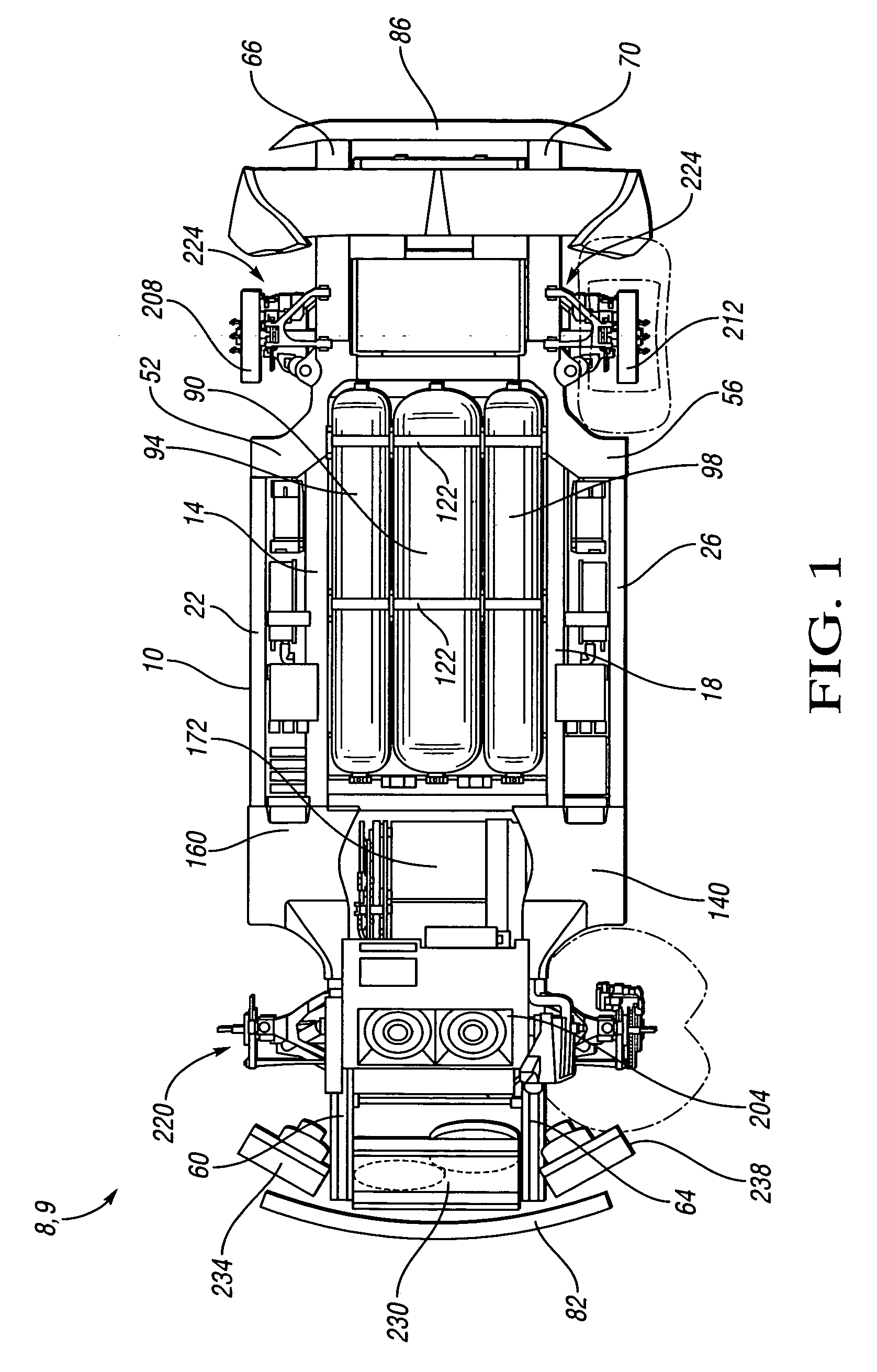

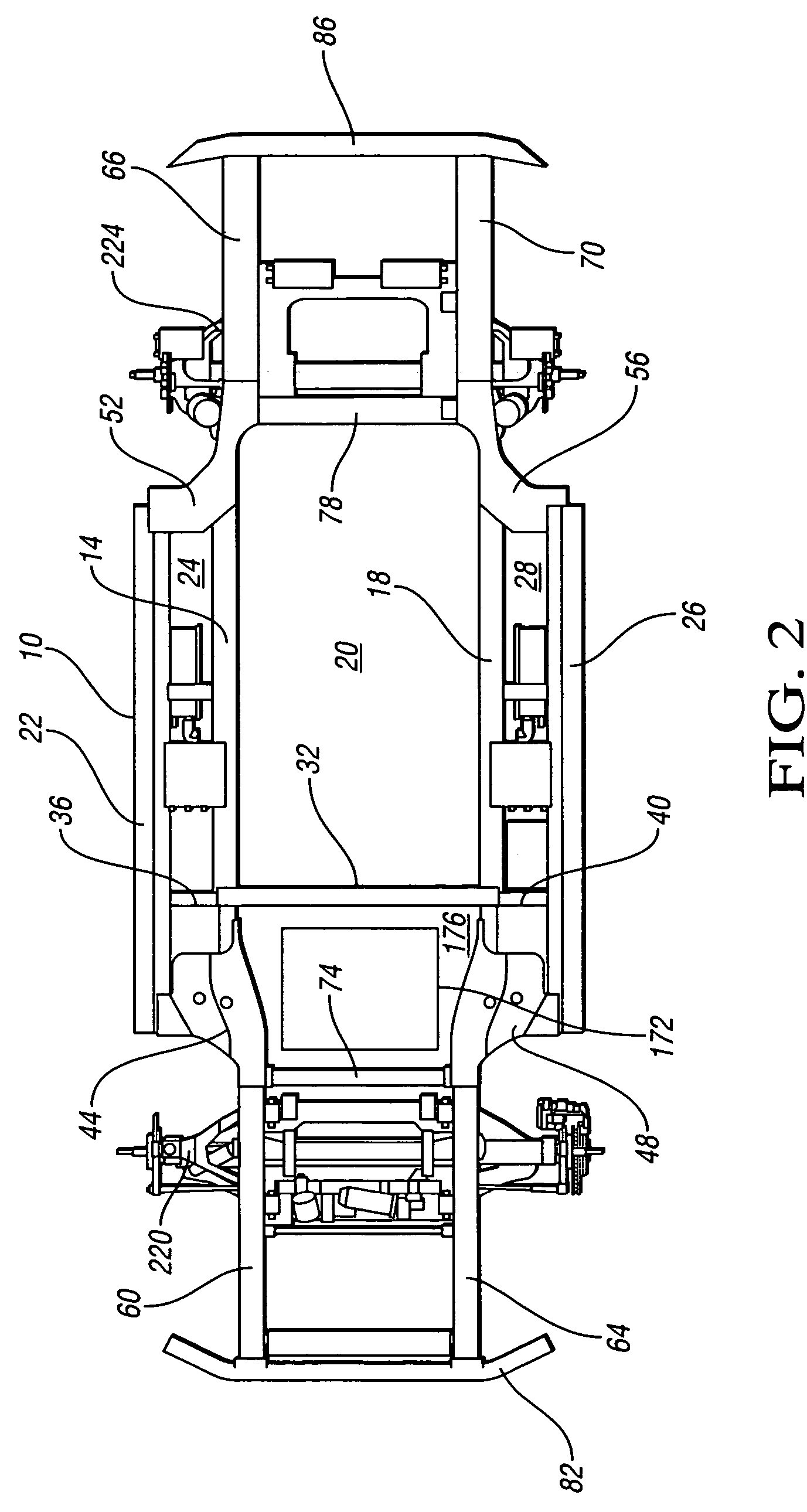

InactiveUS20060027406A1Decrease in fuel tank sizeIncrease in fuel cell stack sizeReactant parameters controlTank vehiclesFuel cellsHydrogen

A vehicle chassis includes a frame defining a cavity, and a tank configured to store compressed hydrogen gas. The tank is at least partially located within the cavity, and is longitudinally oriented with respect to the frame to maximize the fuel-storage capability of the vehicle chassis. In an exemplary embodiment, a floorpan includes a concavity to accommodate at least a portion of the tank, with a corresponding protuberance in the passenger compartment floor surface of the vehicle chassis.

Owner:GM GLOBAL TECH OPERATIONS LLC

Hydrogen storage method and system

A method and system for storing and supplying hydrogen to a hydrogen pipeline in which a compressed hydrogen feed stream is introduced into a salt cavern for storage and a stored hydrogen stream is retrieved from the salt cavern and reintroduced into the hydrogen pipeline. A minimum quantity of stored hydrogen is maintained in the salt cavern to produce a stagnant layer having a carbon dioxide content along the cavern wall and the top of a residual brine layer located within the salt cavern. The compressed hydrogen feed stream is introduced into the salt cavern and the stored hydrogen stream is withdrawn without disturbing the stagnant layer to prevent carbon dioxide contamination from being drawn into the stored hydrogen stream being reintroduced into the hydrogen pipeline. This allows the stored hydrogen stream to be reintroduced into the hydrogen pipeline without carbon dioxide removal.

Owner:PRAXAIR TECH INC

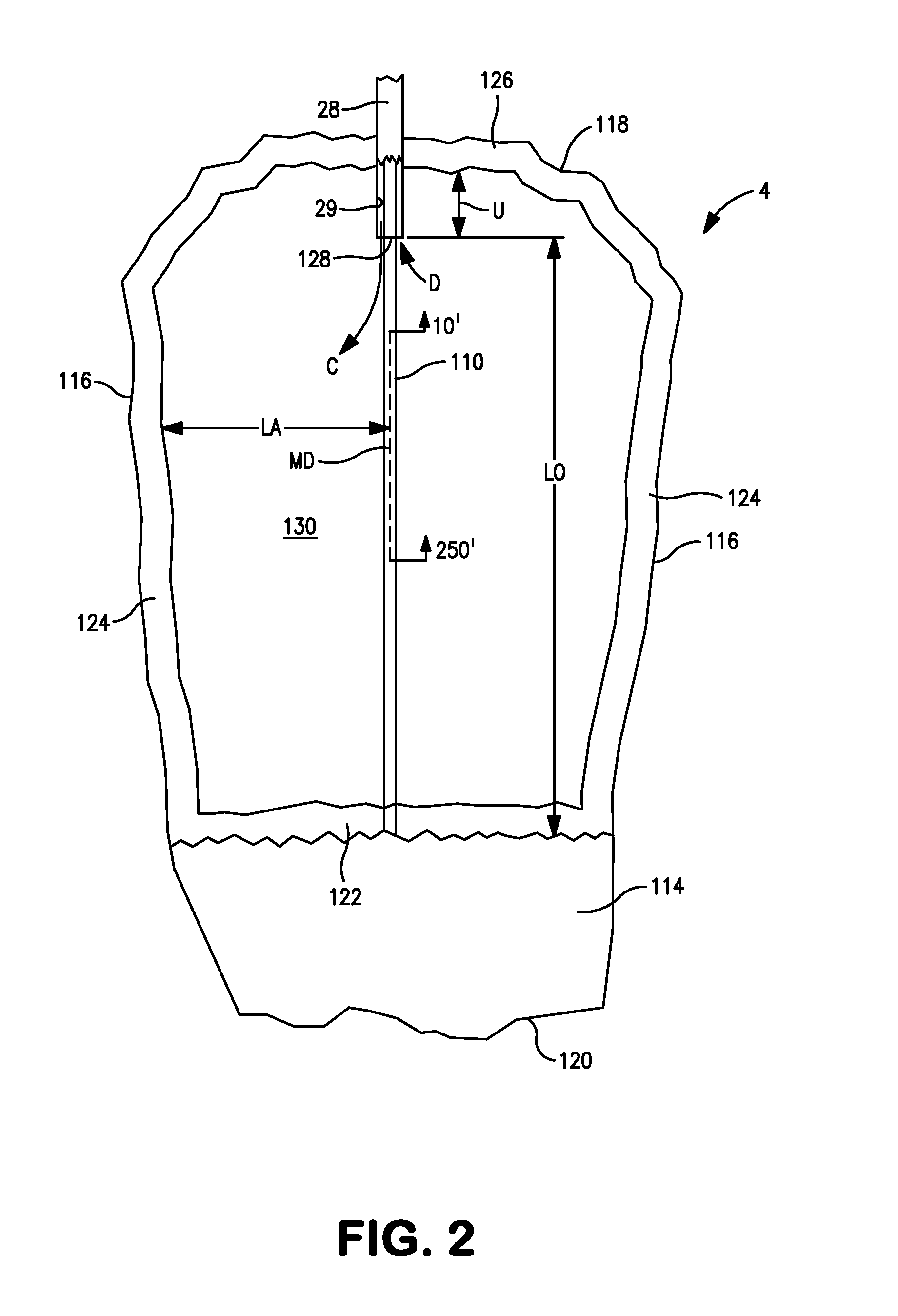

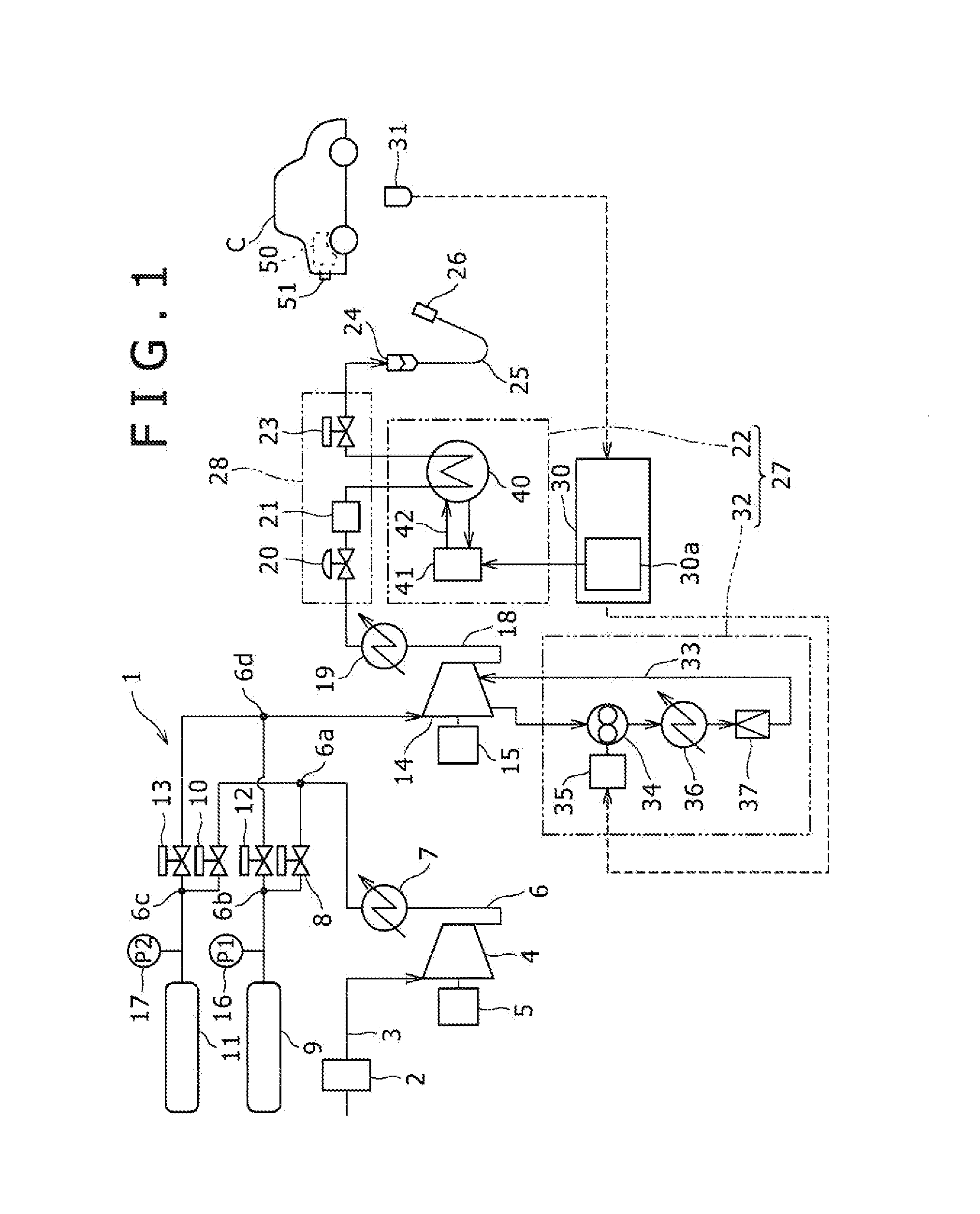

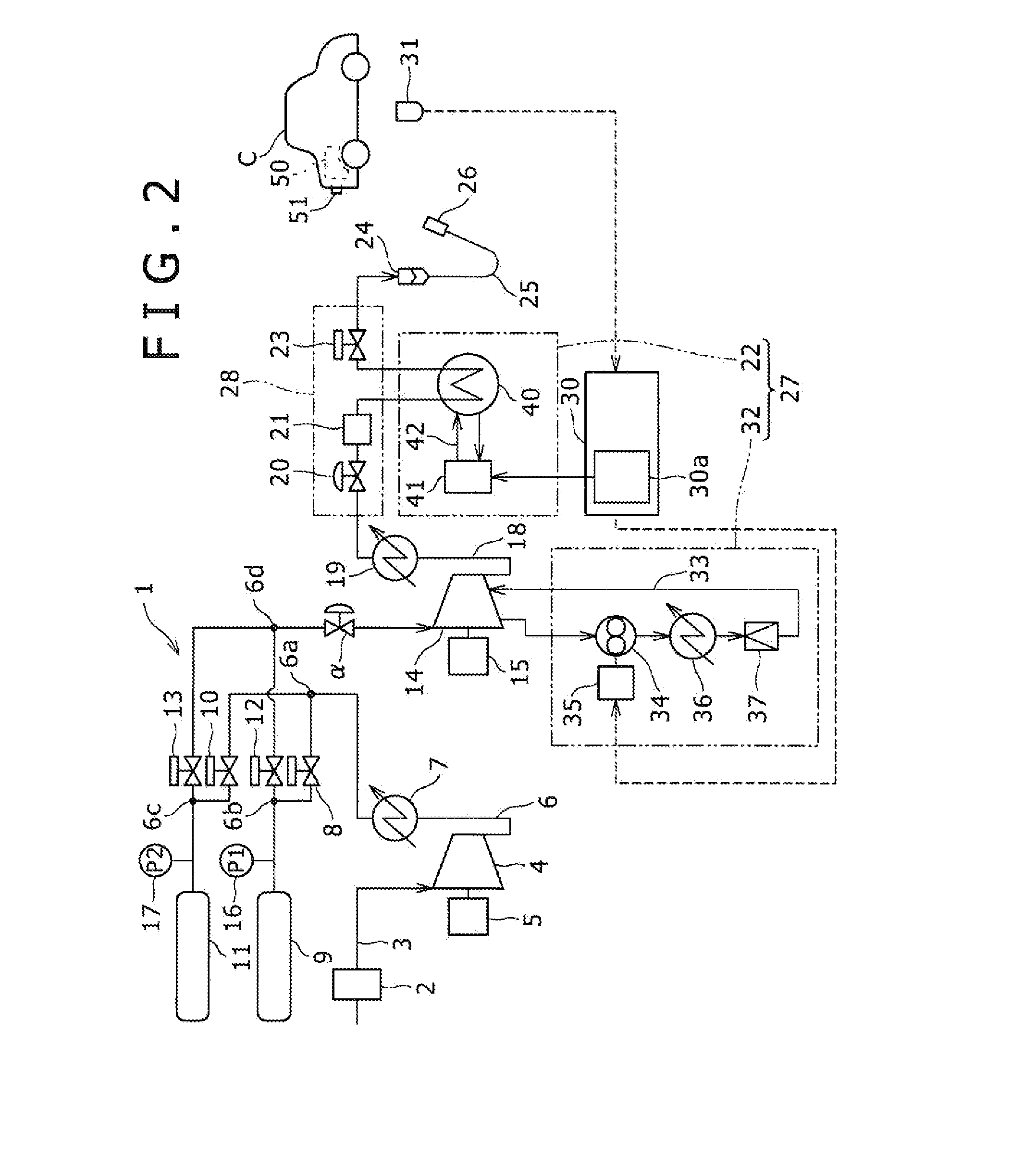

Hydrogen station

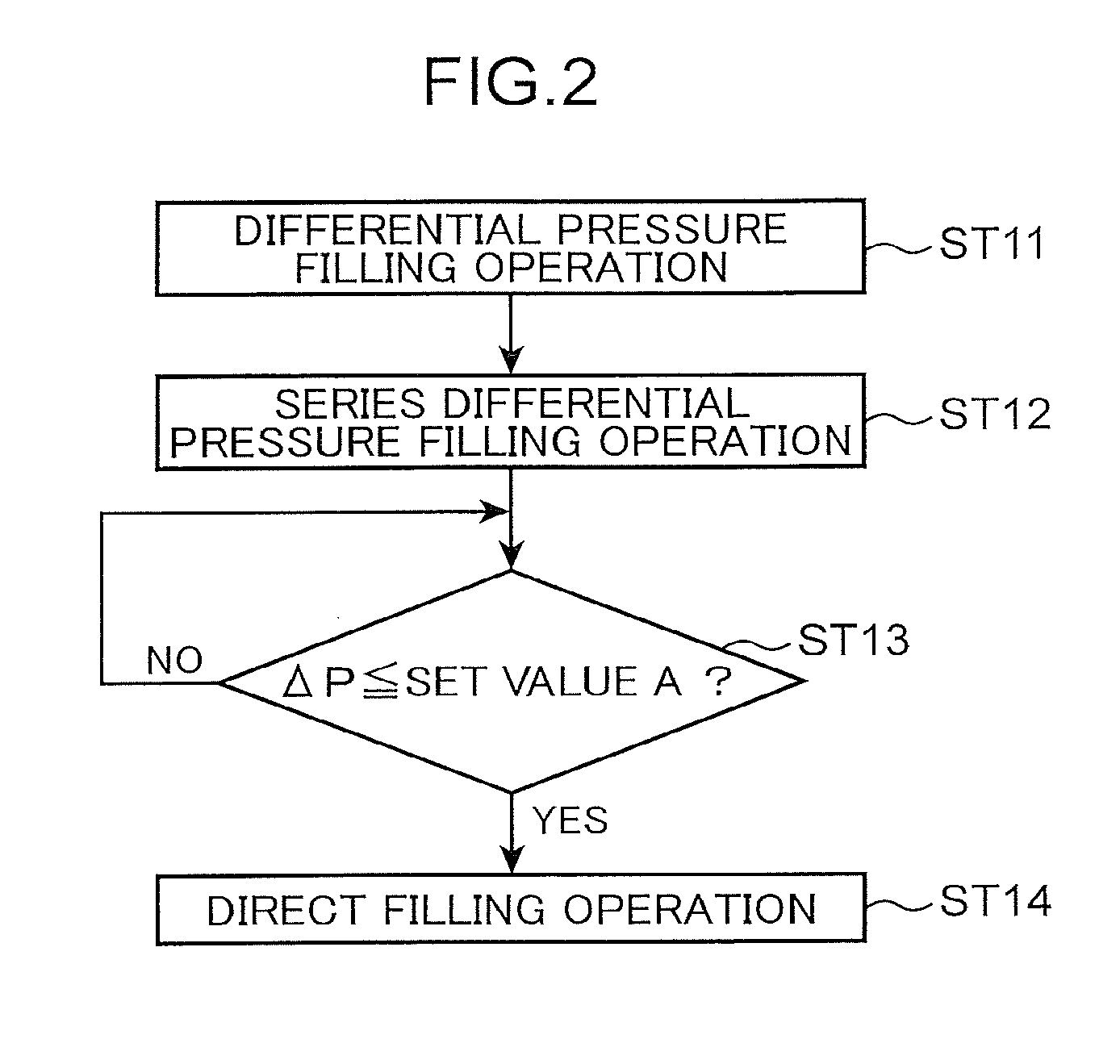

ActiveUS20140102587A1Reduce the necessary timeIncrease power consumptionReactant parameters controlSecondary cellsProcess engineeringHydrogen tank

Provided is a hydrogen station that is used to charge hydrogen to a hydrogen tank mounted on a vehicle, the hydrogen station including: a compressor that compresses hydrogen; a lubricant cooling unit that cools the lubricant of the compressor while circulating the lubricant; a hydrogen cooling unit that is capable of cooling hydrogen which is not charged to the hydrogen tank mounted on the vehicle yet and is compressed by the compressor; a sensor that detects whether the vehicle approaches or reaches the hydrogen station; and a startup unit that starts up at least one of the lubricant cooling unit and the hydrogen cooling unit by a signal from the sensor.

Owner:KOBE STEEL LTD

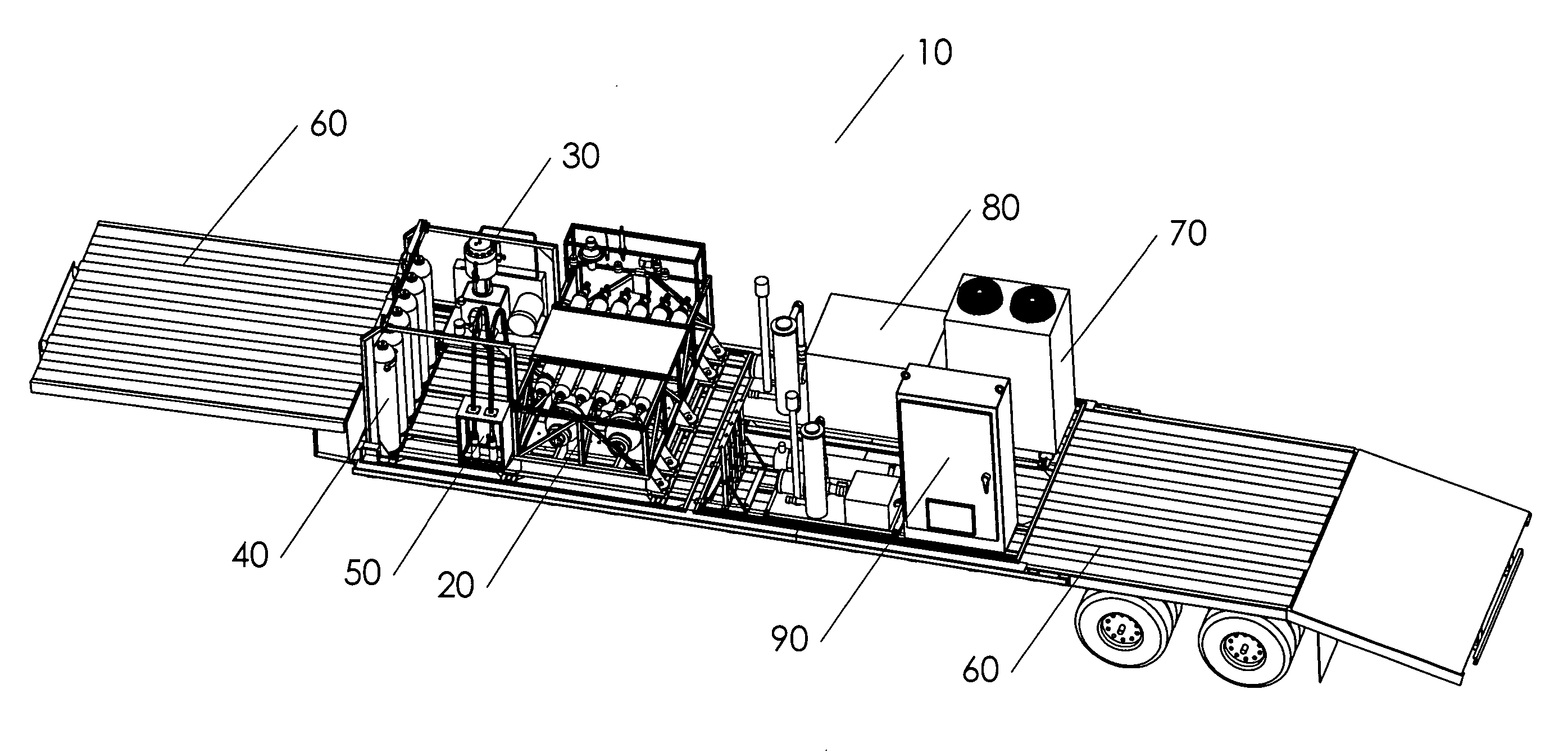

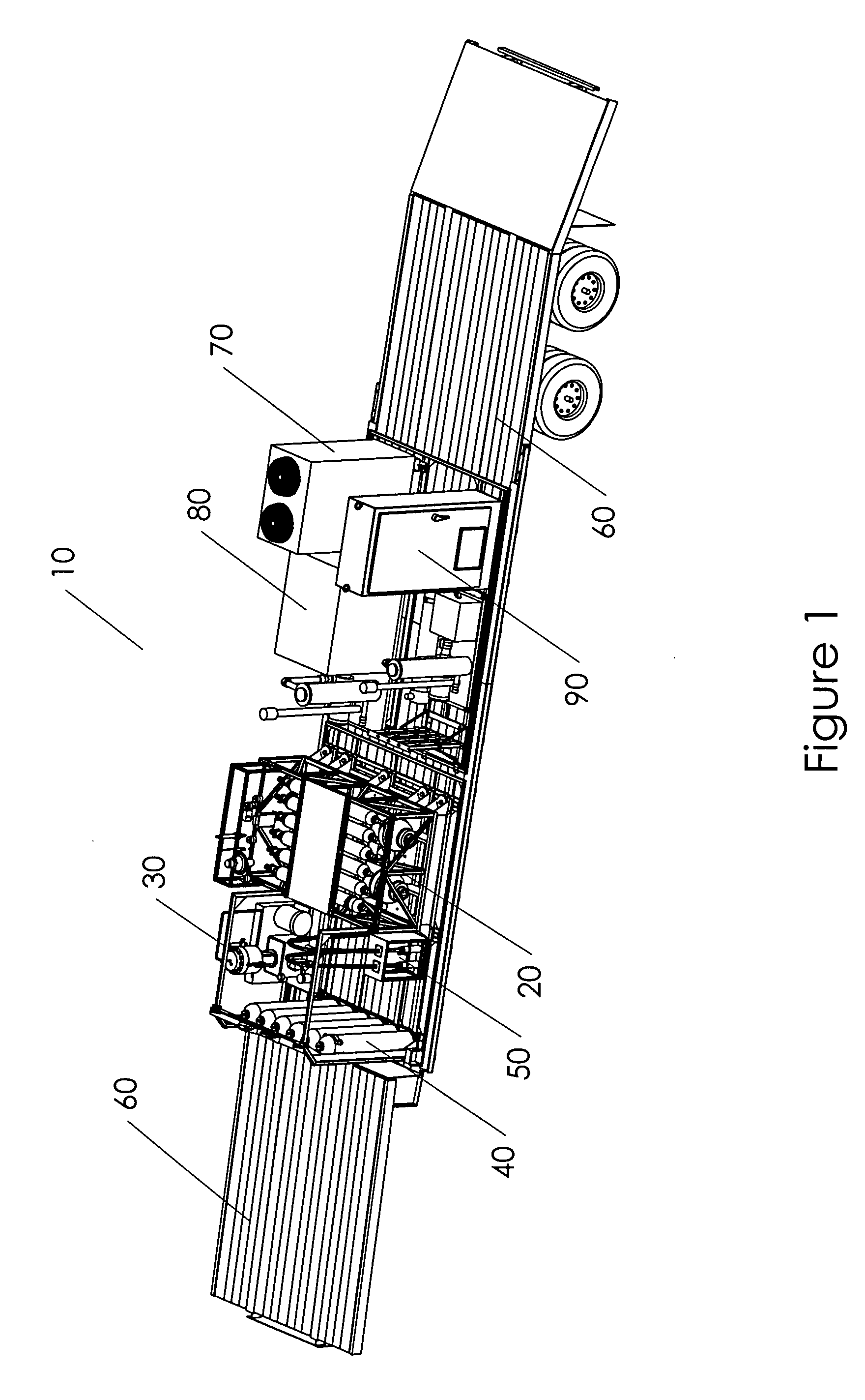

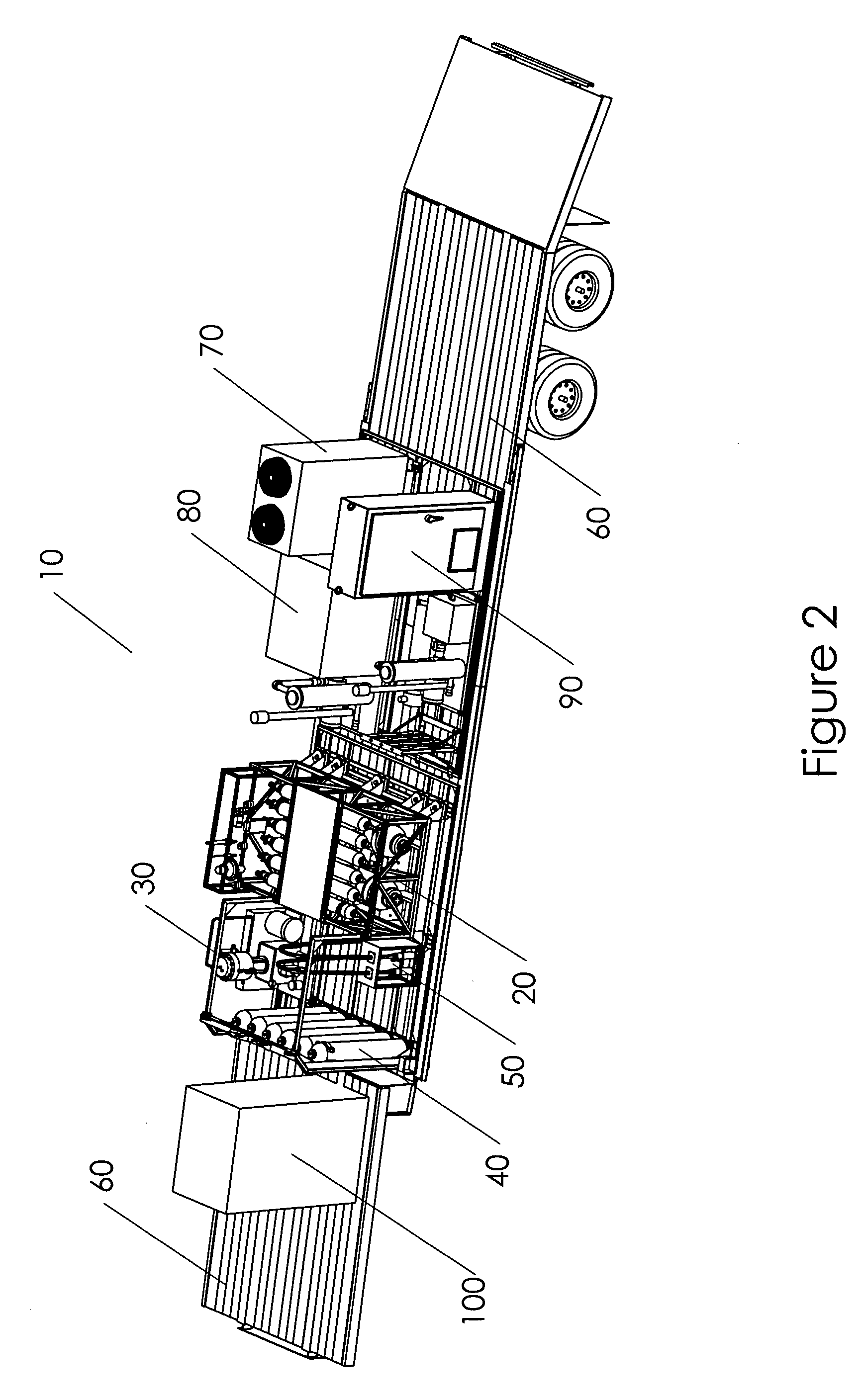

Mobile hydrogen delivery system

A mobile hydrogen delivery system for delivering a compressed stream of hydrogen at pressures up to 15000 psig. The mobile hydrogen delivery system includes a hydrogen compression system, a gaseous hydrogen storage system, and a delivery system for supplying hydrogen to end users. A mobile platform supports the hydrogen compression system, the gaseous hydrogen storage system, and the dispensing system. The mobile platform may be any platform, such as a trailer, capable of being pulled, pushed, or supported by any type of vehicle, such a truck, train, boat, tractor, etc.

Owner:HARNYSS IP LLC +1

Fuel cell vehicle architecture

InactiveUS7303211B2Small sizeIncrease in sizeReactant parameters controlTank vehiclesHydrogenFuel cells

Owner:GM GLOBAL TECH OPERATIONS LLC

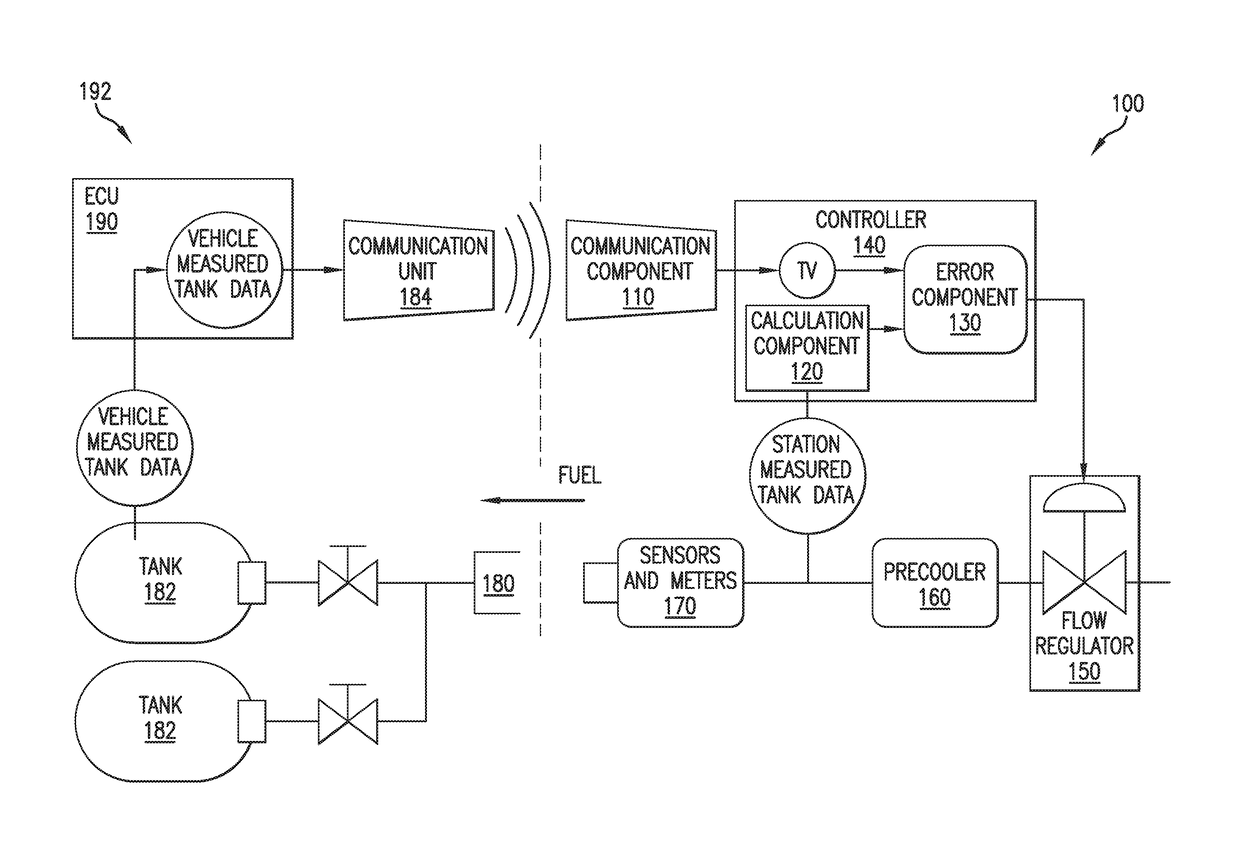

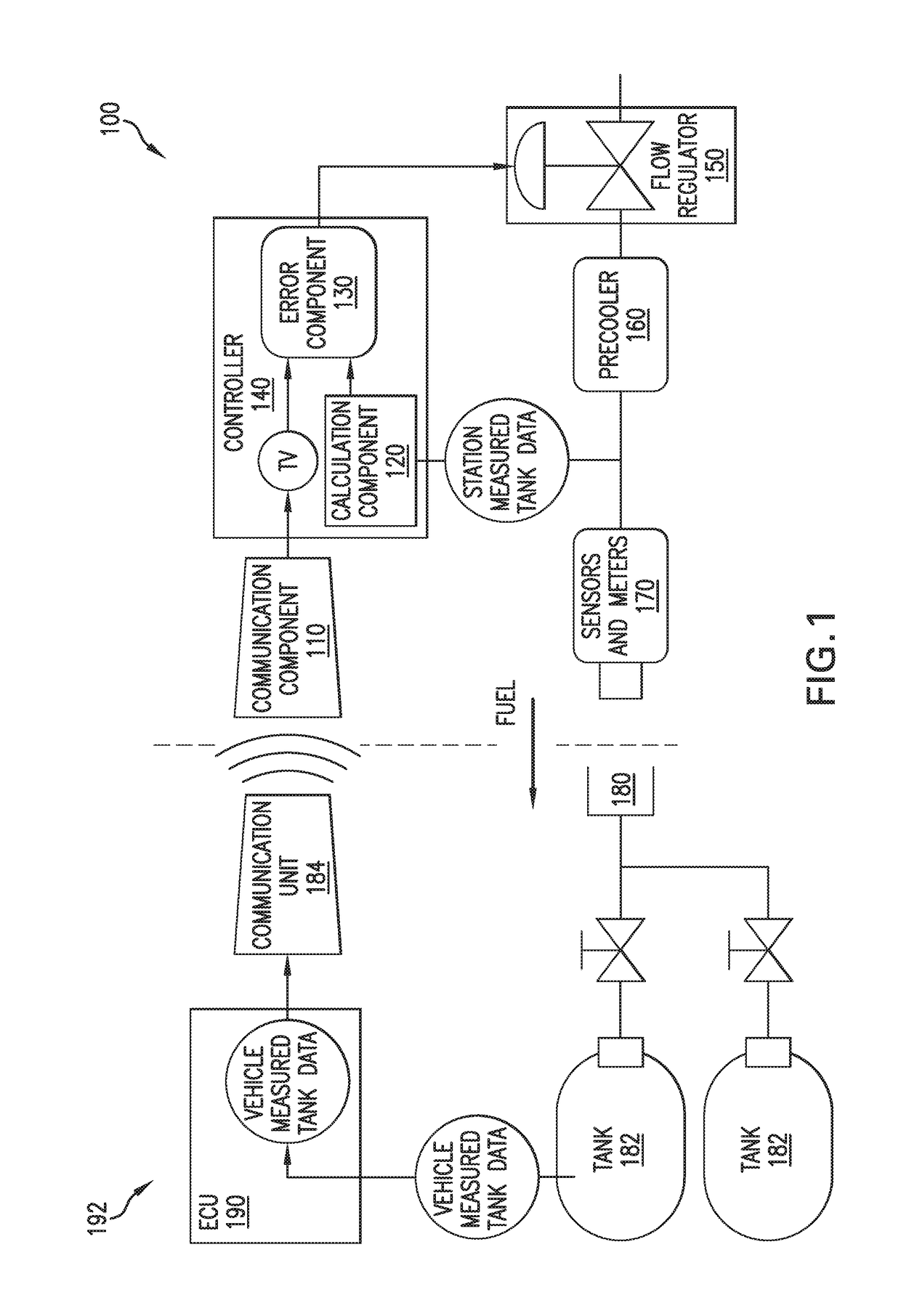

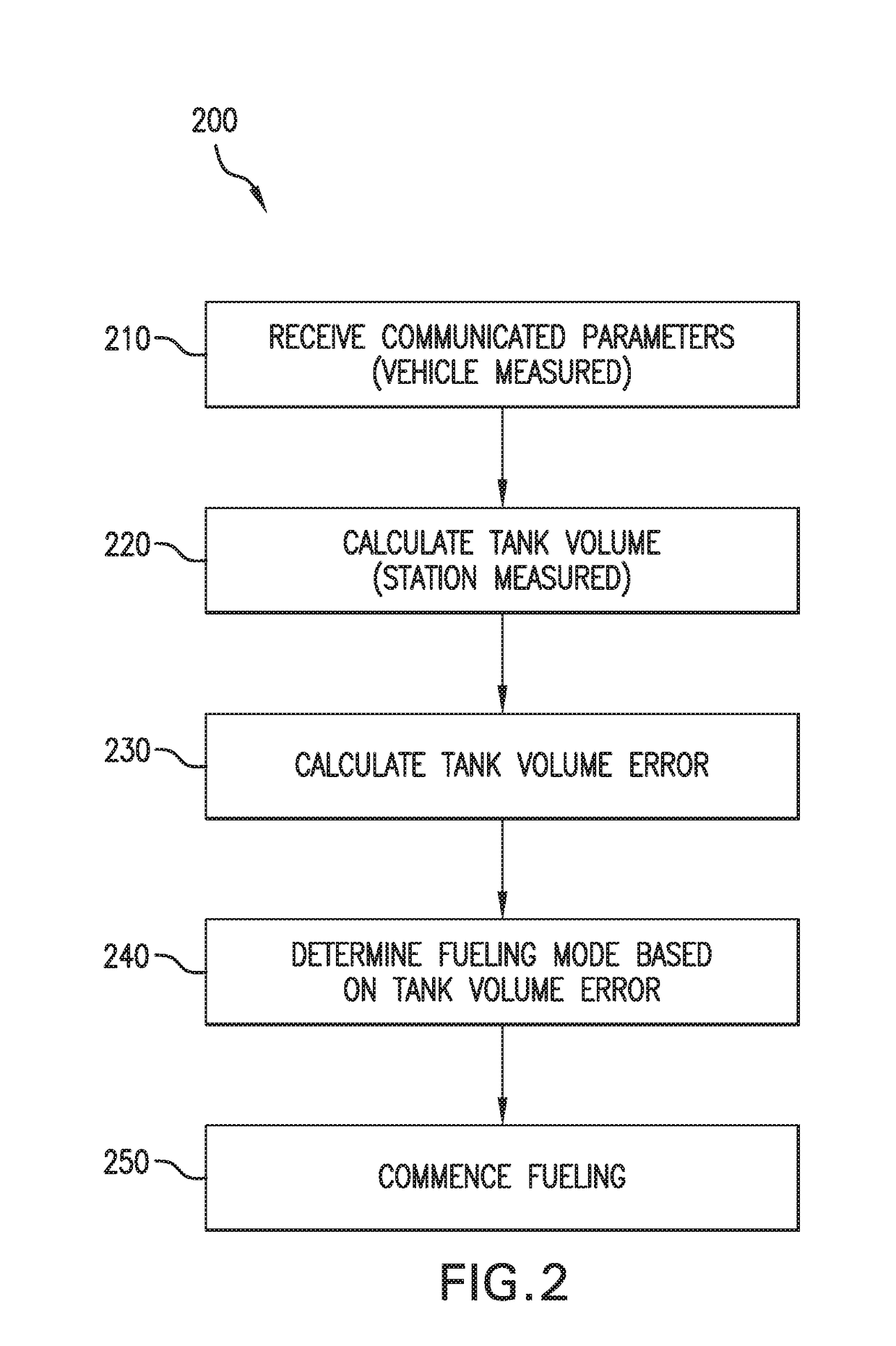

Hydrogen fueling with integrity checks

ActiveUS20170074707A1Vessel mounting detailsVolume measurement apparatus/methodsOn boardHydrogen fuel

According to one or more aspects, systems and techniques for hydrogen fueling with integrity checks are provided herein. Communicated parameters measured by on-board sensors of a vehicle may be cross-referenced against calculated parameters measured by sensors of a fueling station. For example, communicated parameters relating to a compressed hydrogen storage system (CHSS) tank of a vehicle to be fueled may be received at different time intervals. Calculated parameters may be calculated based on a mass of hydrogen fuel dispensed by a hydrogen fueling station from a reference point to one of the time intervals and densities of the CHSS tank of the vehicle at respective time intervals. An error may be calculated between the communicated parameters and the calculated parameters. A fueling mode, such as a conservative fueling mode or a non-conservative fueling mode, may be determined based on the calculated error.

Owner:HONDA MOTOR CO LTD

Hydrogen storage method and system

A method and system for storing and supplying hydrogen to a hydrogen pipeline in which a compressed hydrogen feed stream is introduced into a salt cavern for storage and a stored hydrogen stream is retrieved from the salt cavern and reintroduced into the hydrogen pipeline. A minimum quantity of stored hydrogen is maintained in the salt cavern to produce a stagnant layer having a carbon dioxide content along the cavern wall and the top of a residual brine layer located within the salt cavern. The compressed hydrogen feed stream is introduced into the salt cavern and the stored hydrogen stream is withdrawn without disturbing the stagnant layer to prevent carbon dioxide contamination from being drawn into the stored hydrogen stream being reintroduced into the hydrogen pipeline. This allows the stored hydrogen stream to be reintroduced into the hydrogen pipeline without carbon dioxide removal.

Owner:PRAXAIR TECH INC

Integrated marine vessel hull for energy storage

InactiveUS20060228960A1Reduce spacingPropulsion power plantsRegenerative fuel cellsHull structureMarine engineering

A hull structure is provided for a marine vessel having an inner hull and an outer hull. An energy storage device is provided between the inner hull and outer hull. The energy storage device has one or more hollow tubes, or has a honeycomb structure. Hydrogen or oxygen can be stored and placed within the hollow tubes or honeycomb structure. A metal hydride, or liquid hydrogen or compressed hydrogen gas, as well as liquid oxygen or compressed oxygen gas can also be stored inside the hollow tubes or honeycomb structure. The dual use of the hull structure provides for an energy storage apparatus and propulsion generation system that conserves space within the marine vessel, and adds less weight to the marine vessel.

Owner:LOCKHEED MARTIN CORP

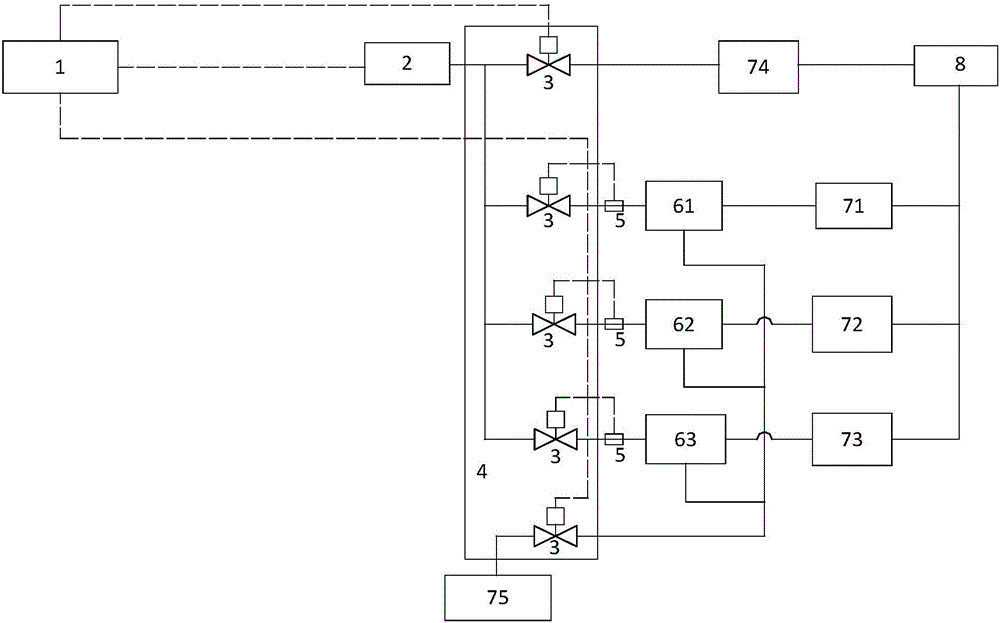

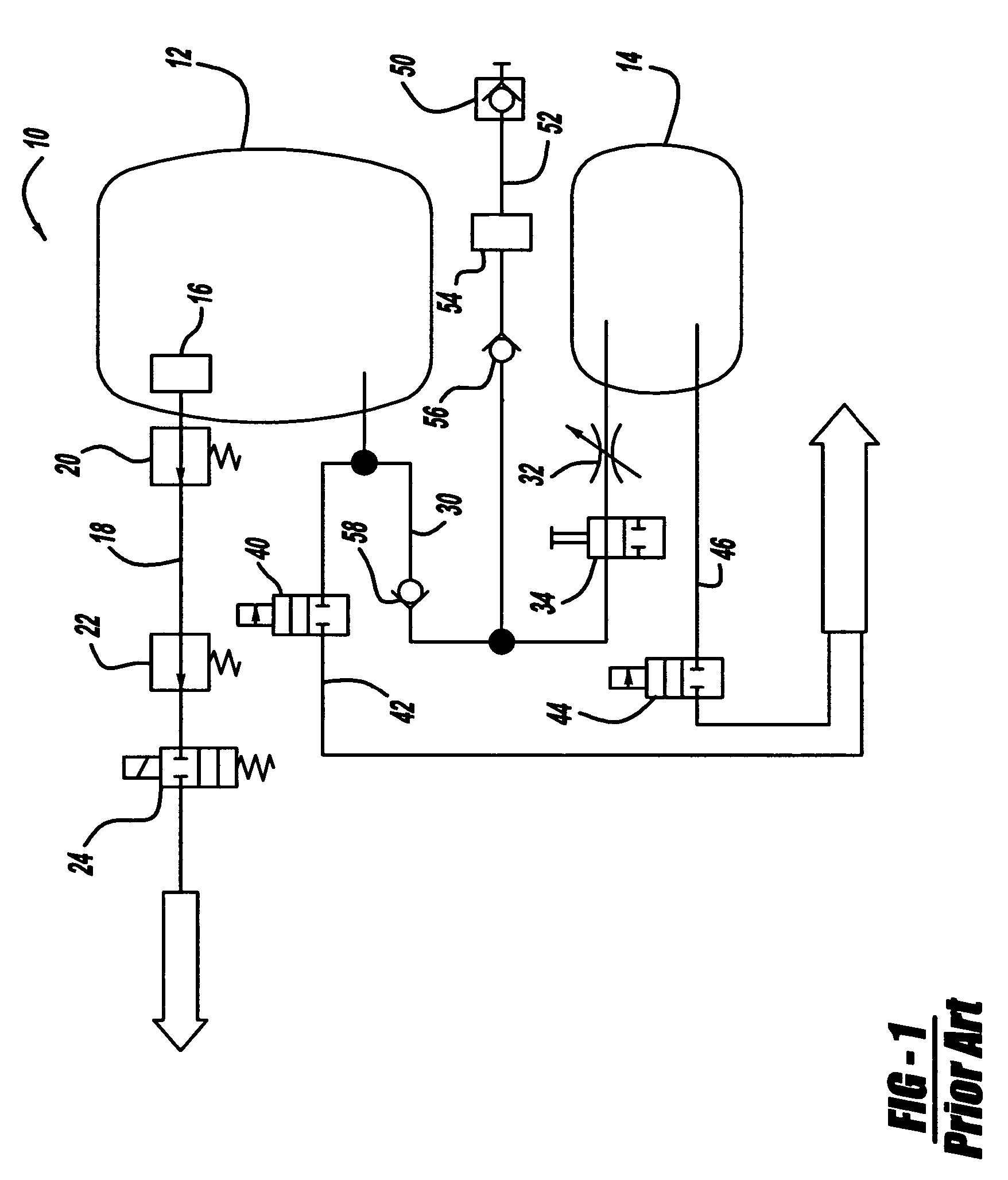

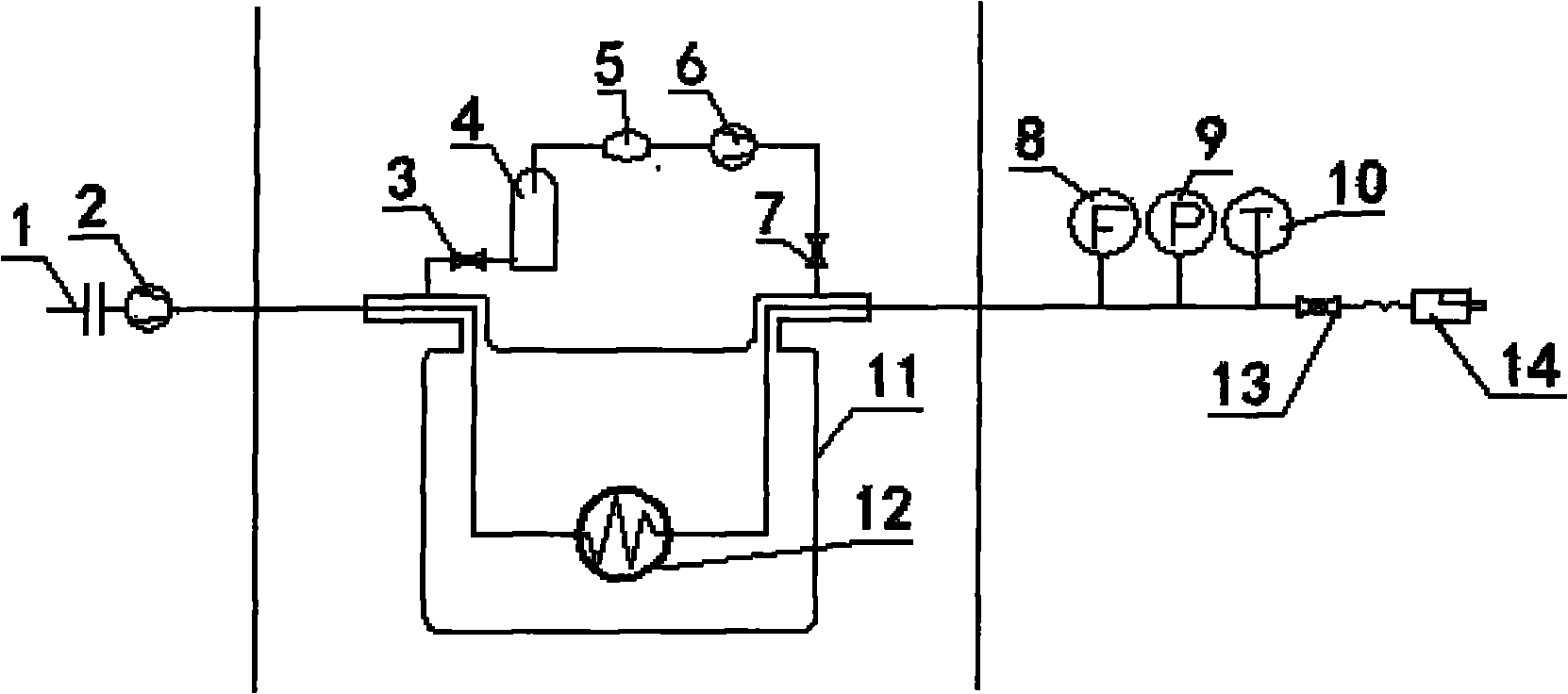

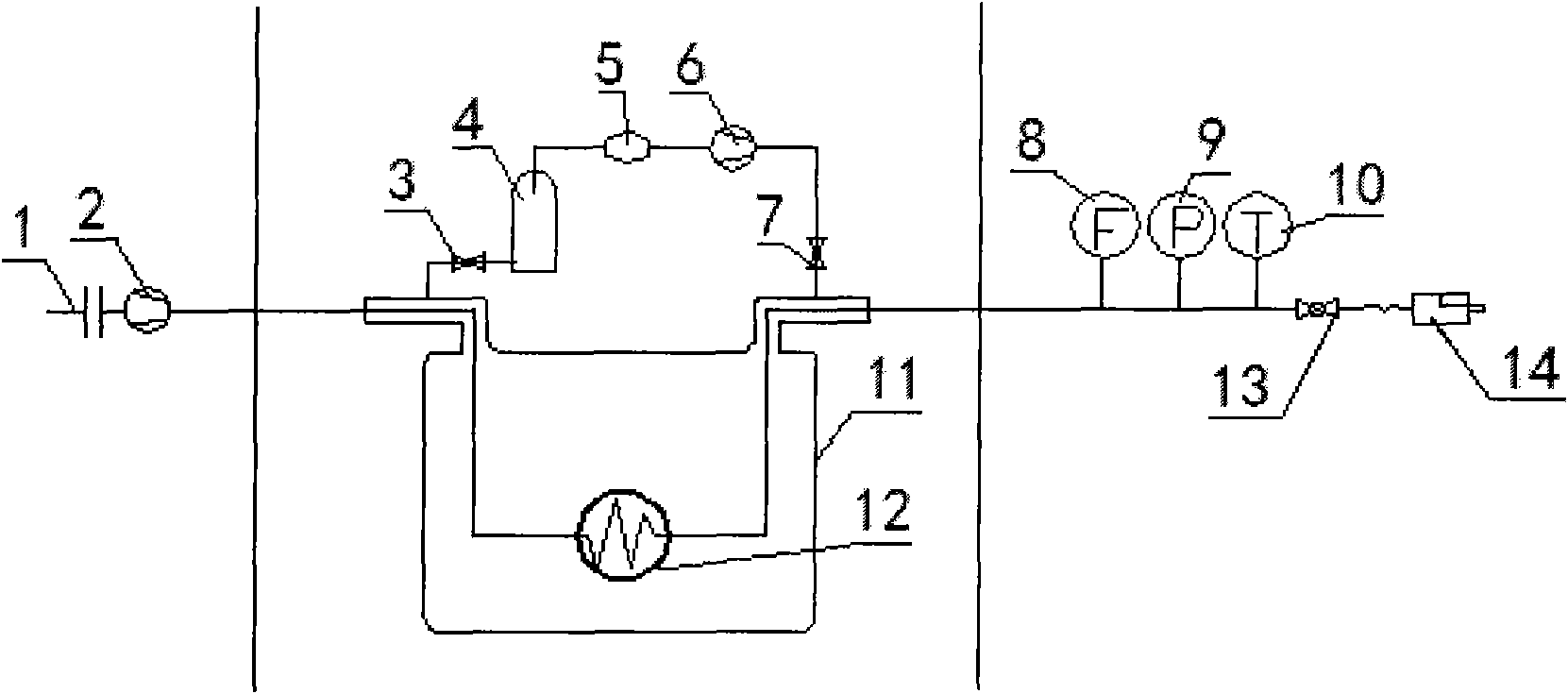

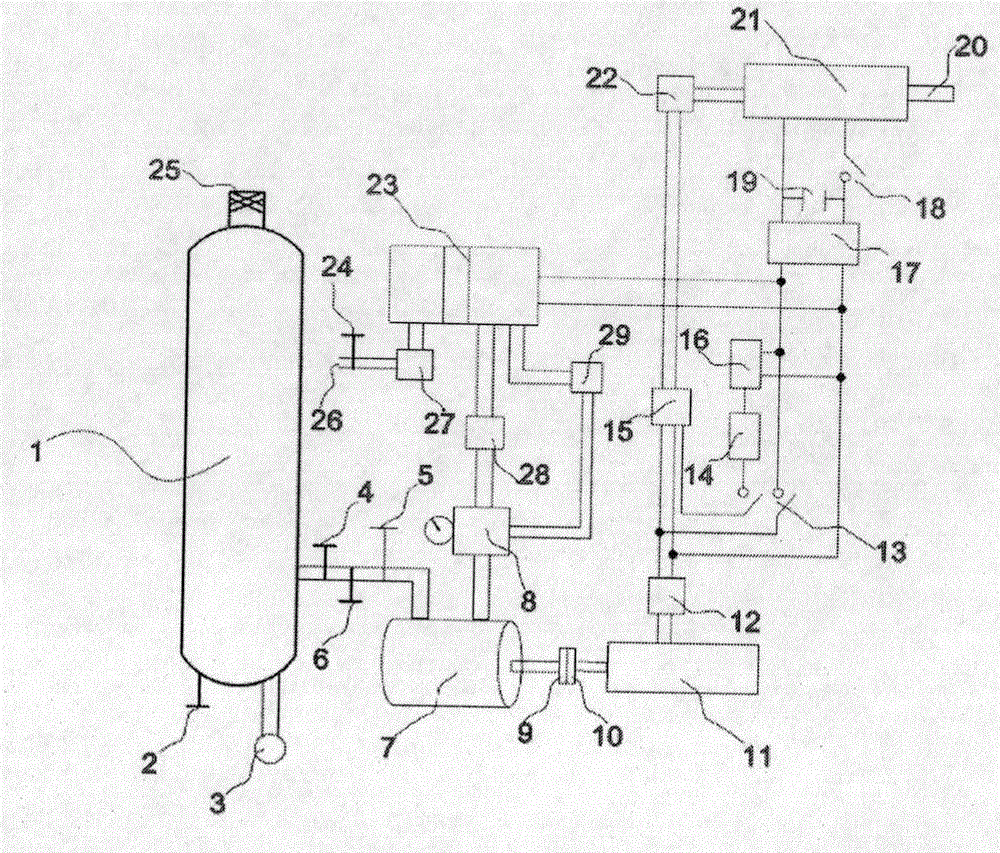

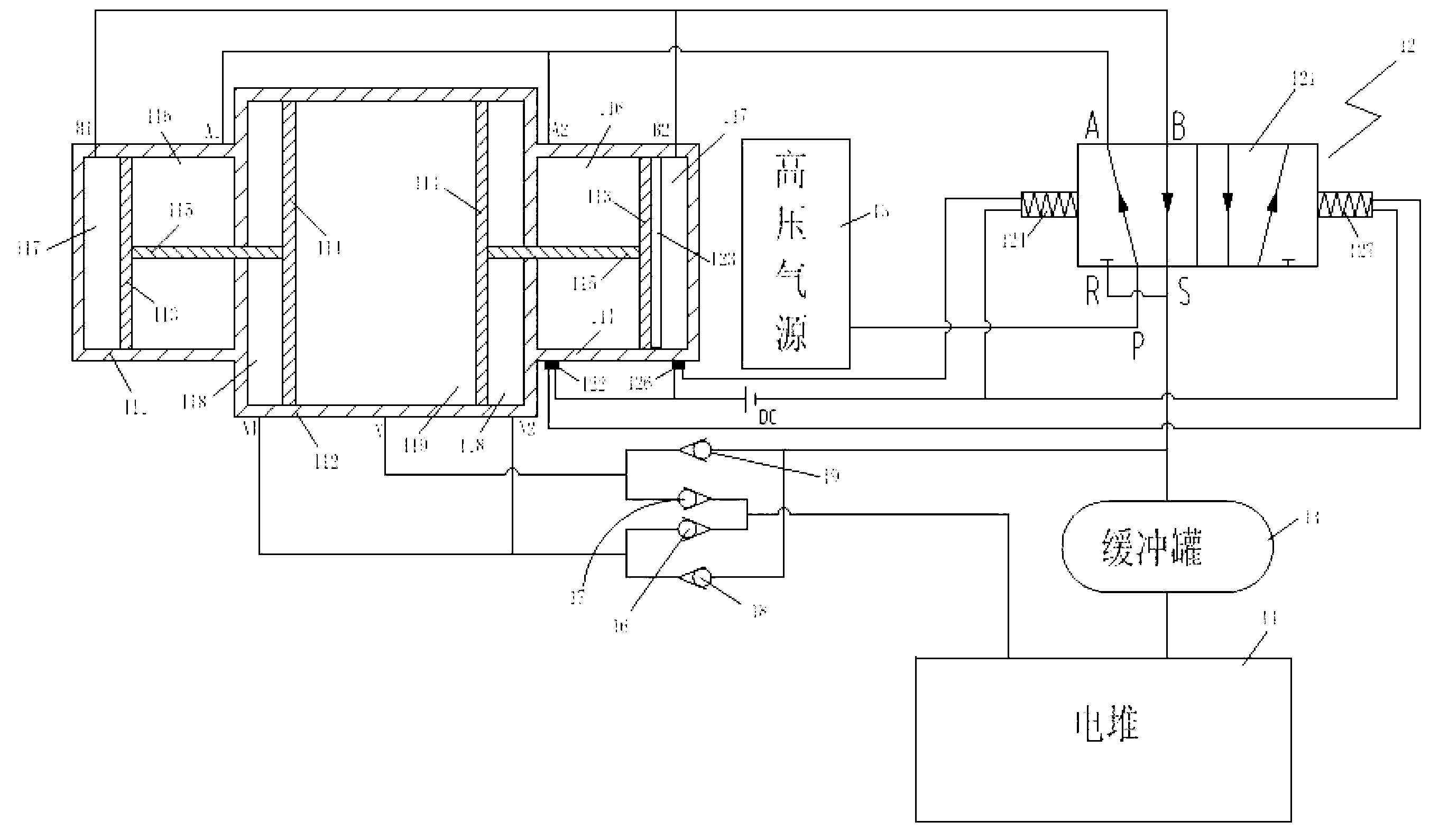

Compressed hydrogen storage and charging system of hydrogen refueling station

InactiveCN106015926ARealize intelligent controlFluid transferredFluid handling accessoriesGas cylinderHydrogen fuel

The invention proposes a compressed hydrogen storage and charging system of a hydrogen refueling station. A compressor is respectively connected with a high-pressure gas storage cylinder, a medium-pressure gas storage cylinder, a low-pressure gas storage cylinder and a direct charging pipeline by control valve pipelines; the high-pressure gas storage cylinder, the medium-pressure gas storage cylinder and the low-pressure gas storage cylinder are respectively connected with a high-pressure gas charging pipeline, a medium-pressure gas charging pipeline and a low-pressure gas charging pipeline by pipelines, and are all connected with a release pipeline by pipelines; a gas inlet side pipeline of the release pipeline is connected with a control valve; pipelines on gas intake sides of the high-pressure gas storage cylinder, the medium-pressure gas storage cylinder and the low-pressure gas storage cylinder are all connected with pressure sensors; and a data controller is in signal connection with the pressure sensors and the compressor. The system has the following beneficial effects: the system not only can charge vehicle-mounted gas storage cylinders of hydrogen fuel vehicles through the gas storage cylinder set, but also can directly charge the vehicle-mounted gas storage cylinders of the hydrogen fuel vehicles so as to realize intelligent control of compressed hydrogen storage and charging of the hydrogen refueling station.

Owner:CHINA PETROLEUM & CHEM CORP +1

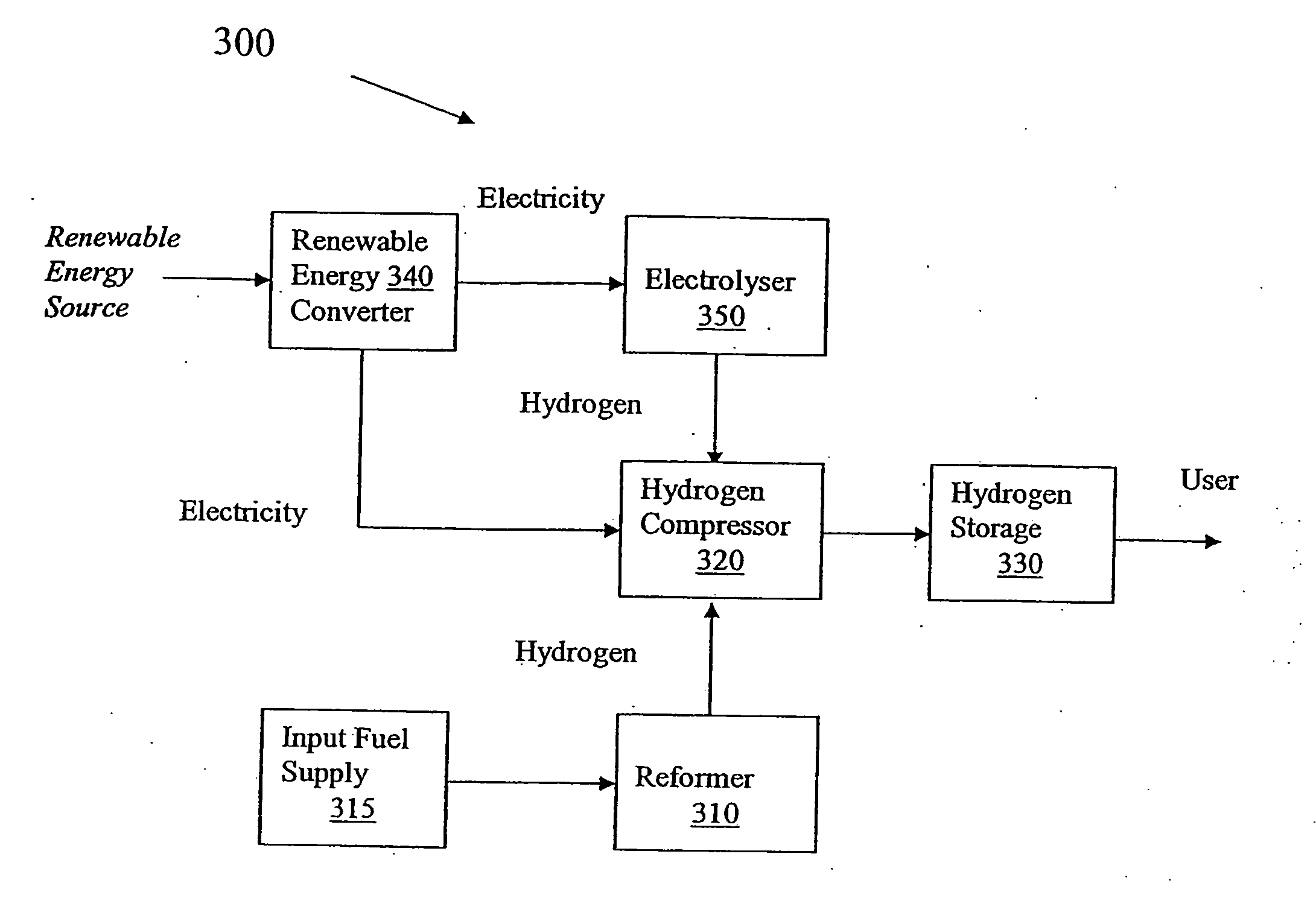

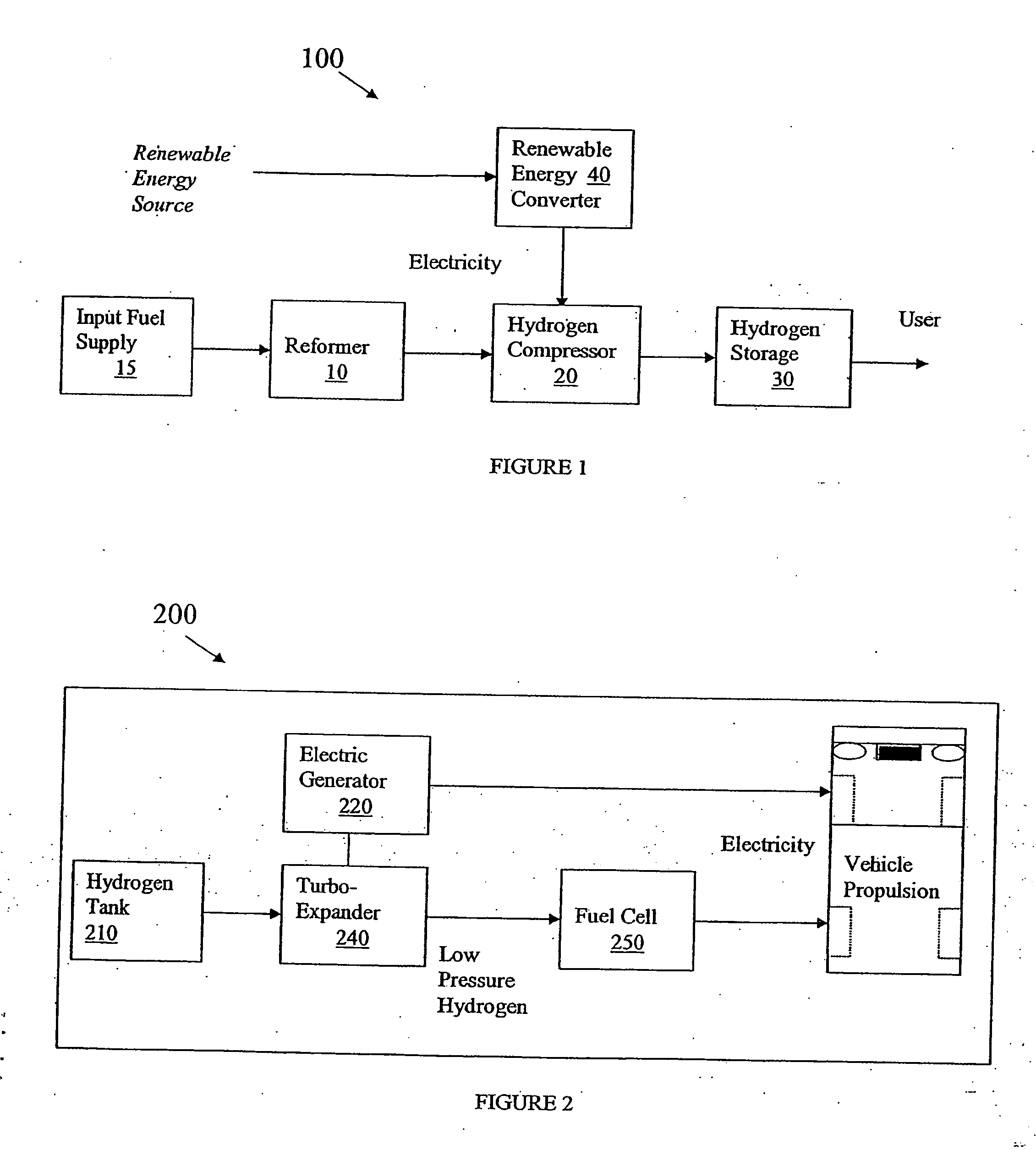

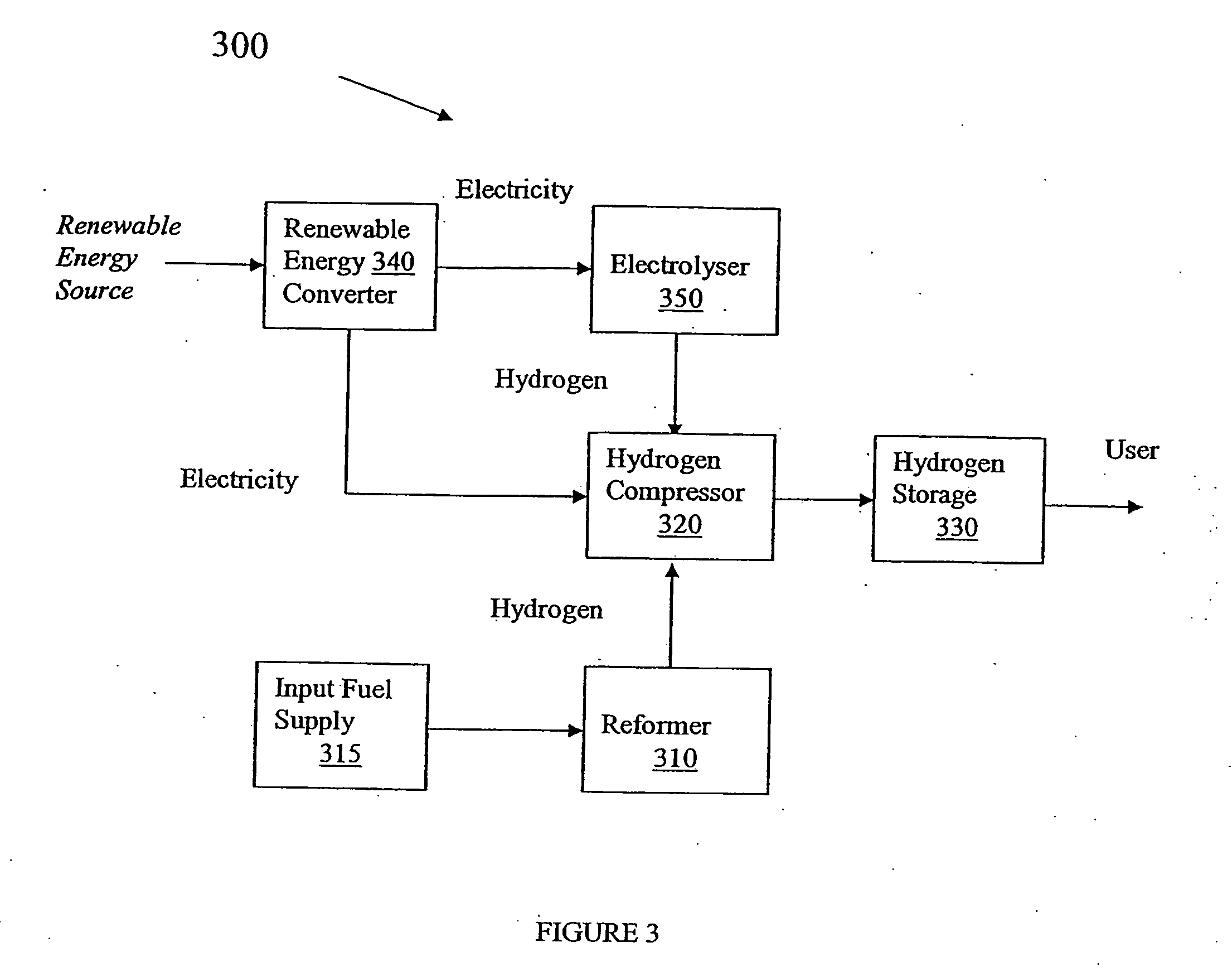

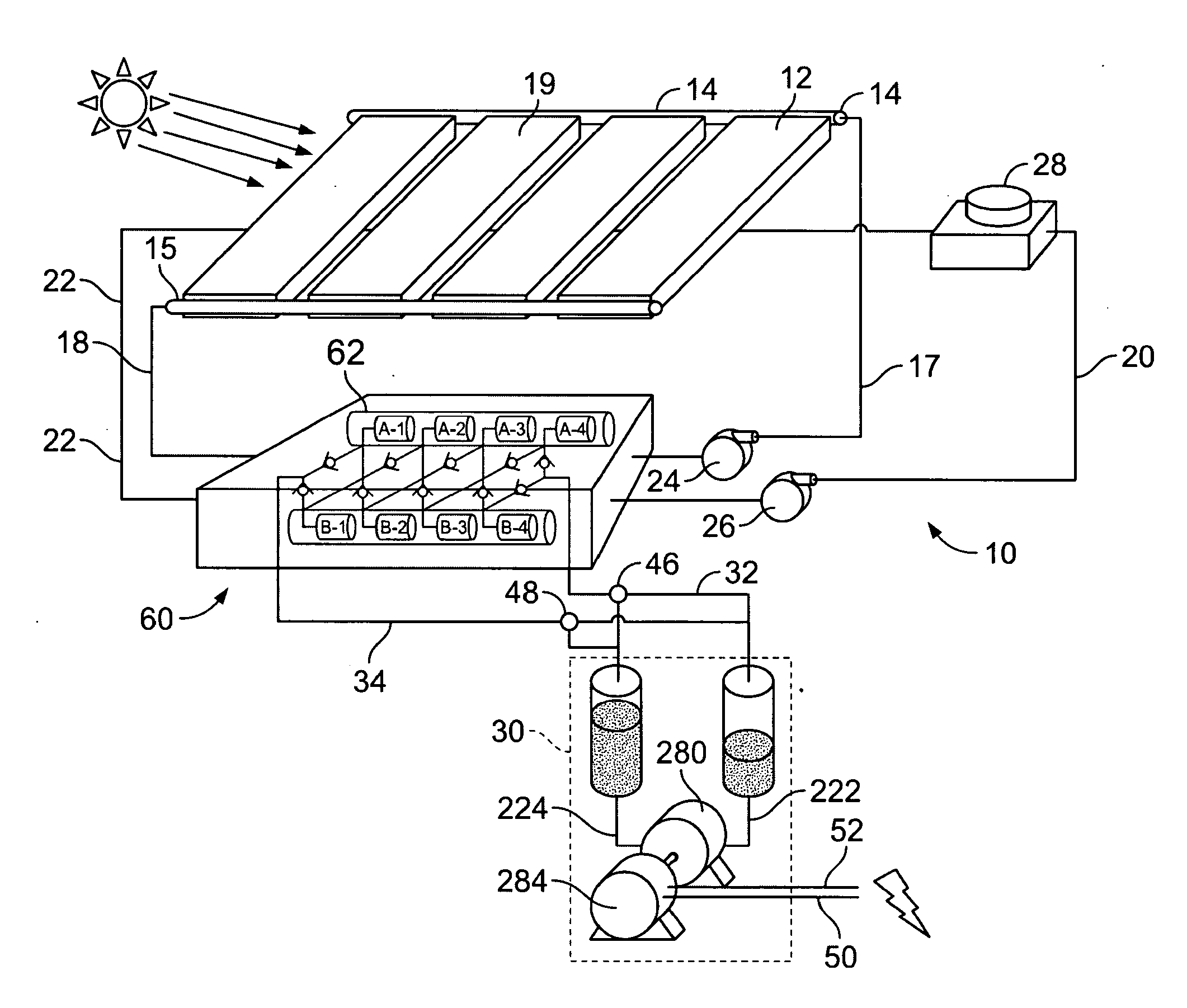

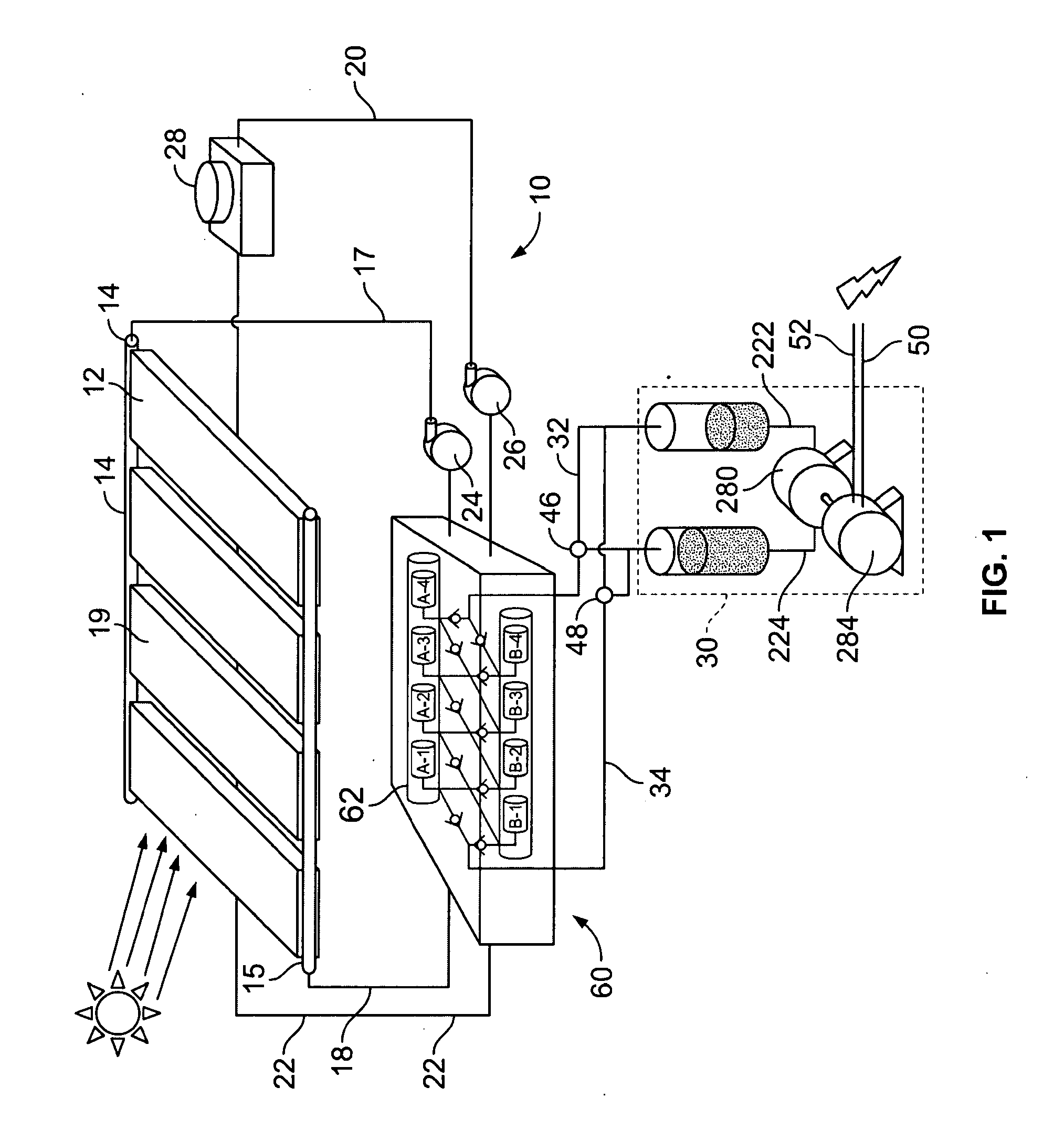

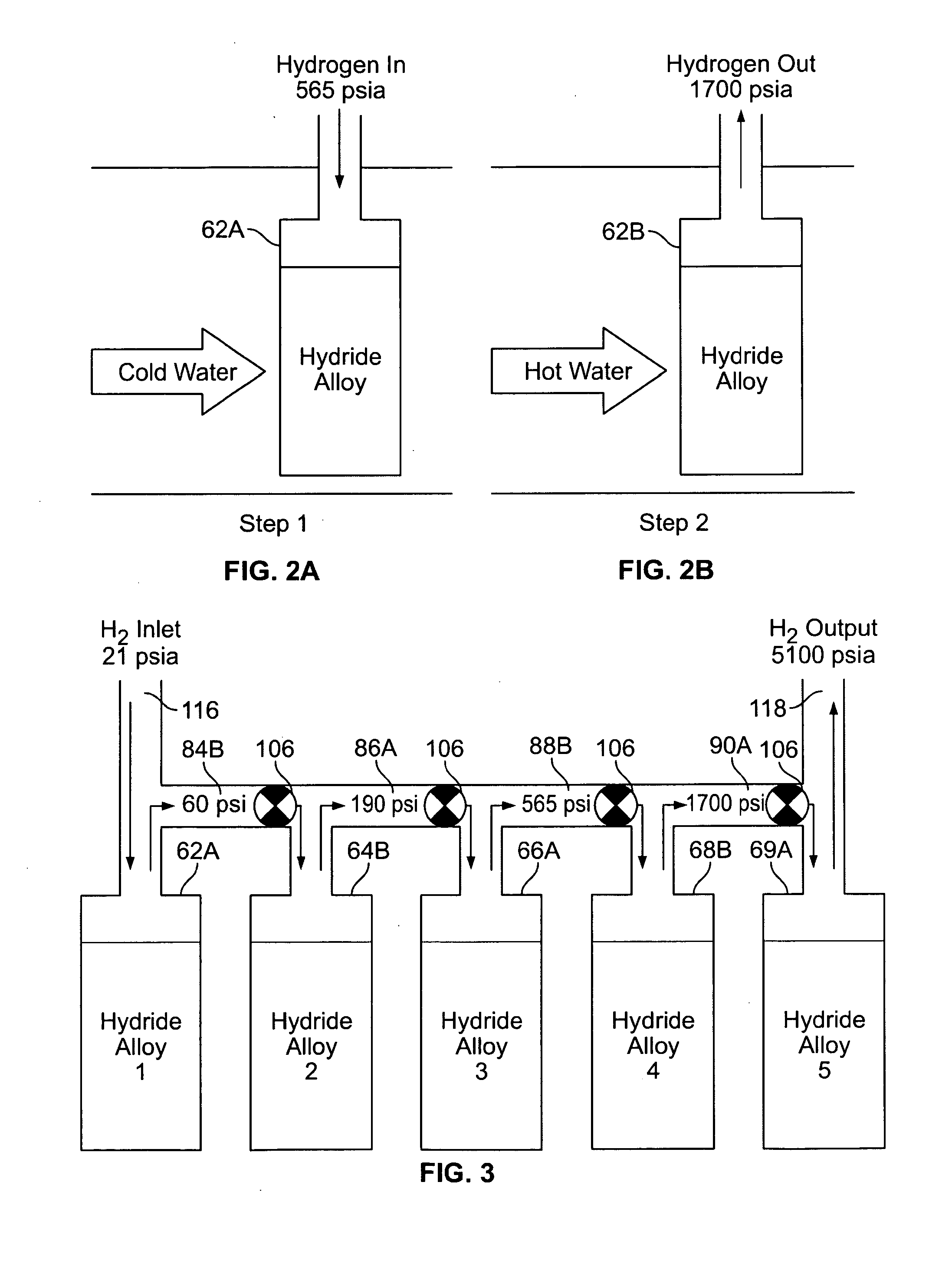

Renewable energy operated hydrogen reforming system

An application applying mixed use of conventional hydrocarbon fuel with renewable energy sources for hydrogen production presents an optimal balance between economics and environmental benefits for any long-range implementations. A hydrogen production system incorporates the use of electricity from renewable sources in hydrogen reforming plants for various functions to achieve better environmental performance. The hydrogen production system includes the compression of hydrogen for high-pressure storage and an electrical heating supply for an endothermic reforming process of producing hydrogen from an input fuel. The compressed hydrogen, produced using renewable energy sources, also provides a means of stored mechanical energy, Another hydrogen production system utilizes a conventional chemical reforming process to provide leveled hydrogen generation together with electrolysis from the fluctuating renewable energy sources, which also provides low cost hydrogen generation, good environmental performance and commercial dependability.

Owner:ZTEK

Heatable hydrogen pressure regulator

ActiveUS20060081290A1Avoid temperatureVessel mounting detailsValve members for heating/coolingHydrogen pressureEngineering

A compressed hydrogen tank system that includes a heatable hydrogen pressure regulator. Hydrogen is removed from the compressed tank through a suitable pipe where the pressure drop of the hydrogen is controlled by the pressure regulator. The high pressure side of the regulator is typically at a relatively low temperature as the hydrogen is being removed from the tank, and the low pressure side of the regulator is typically at a relatively high temperature as the hydrogen is removed from the tank. A heat source is provided to heat the pipe on the high pressure side of the regulator to prevent the hydrogen from becoming cold as the hydrogen is being removed from the tank, thus preventing the temperature of the hydrogen within the tank from decreasing.

Owner:GM GLOBAL TECH OPERATIONS LLC

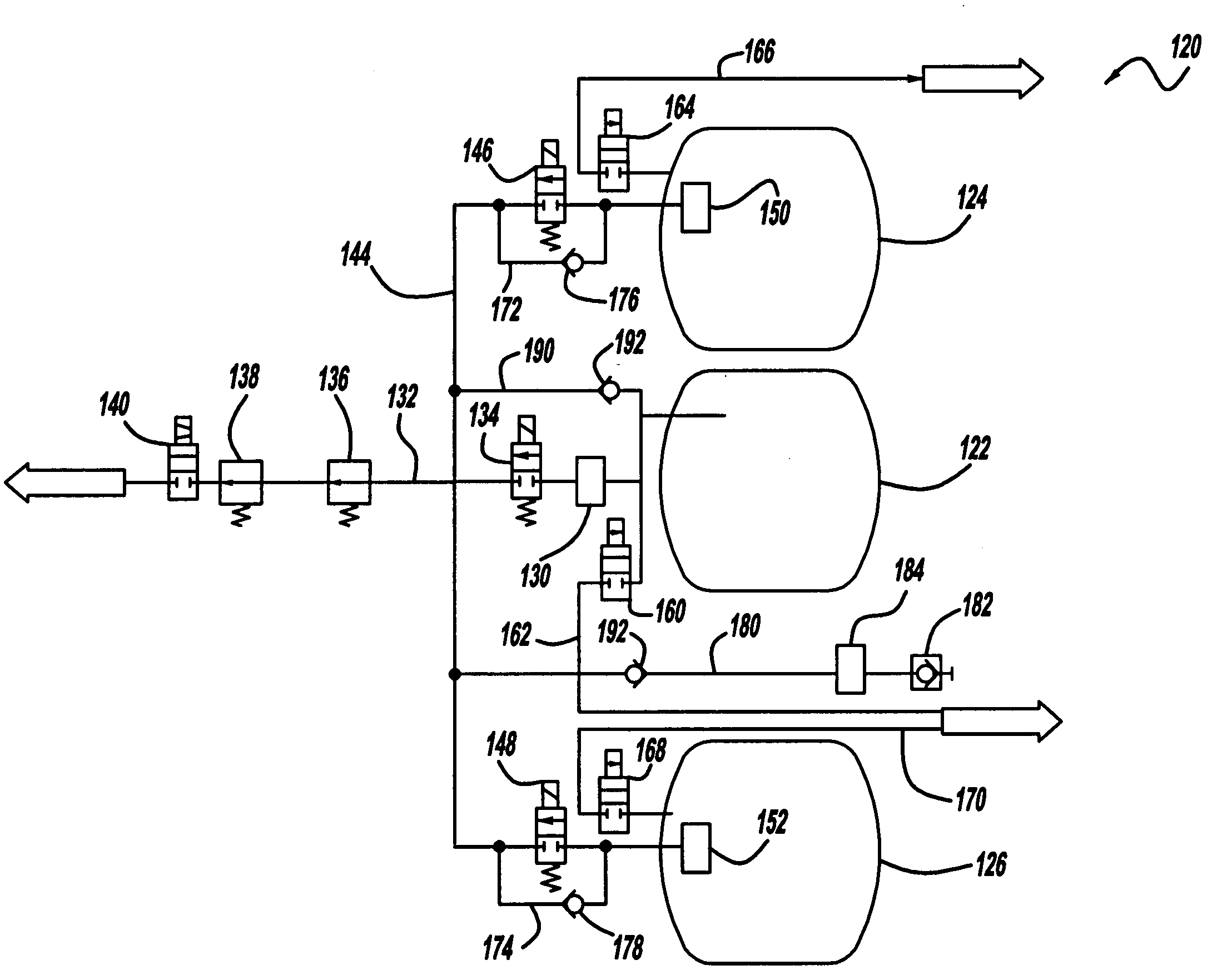

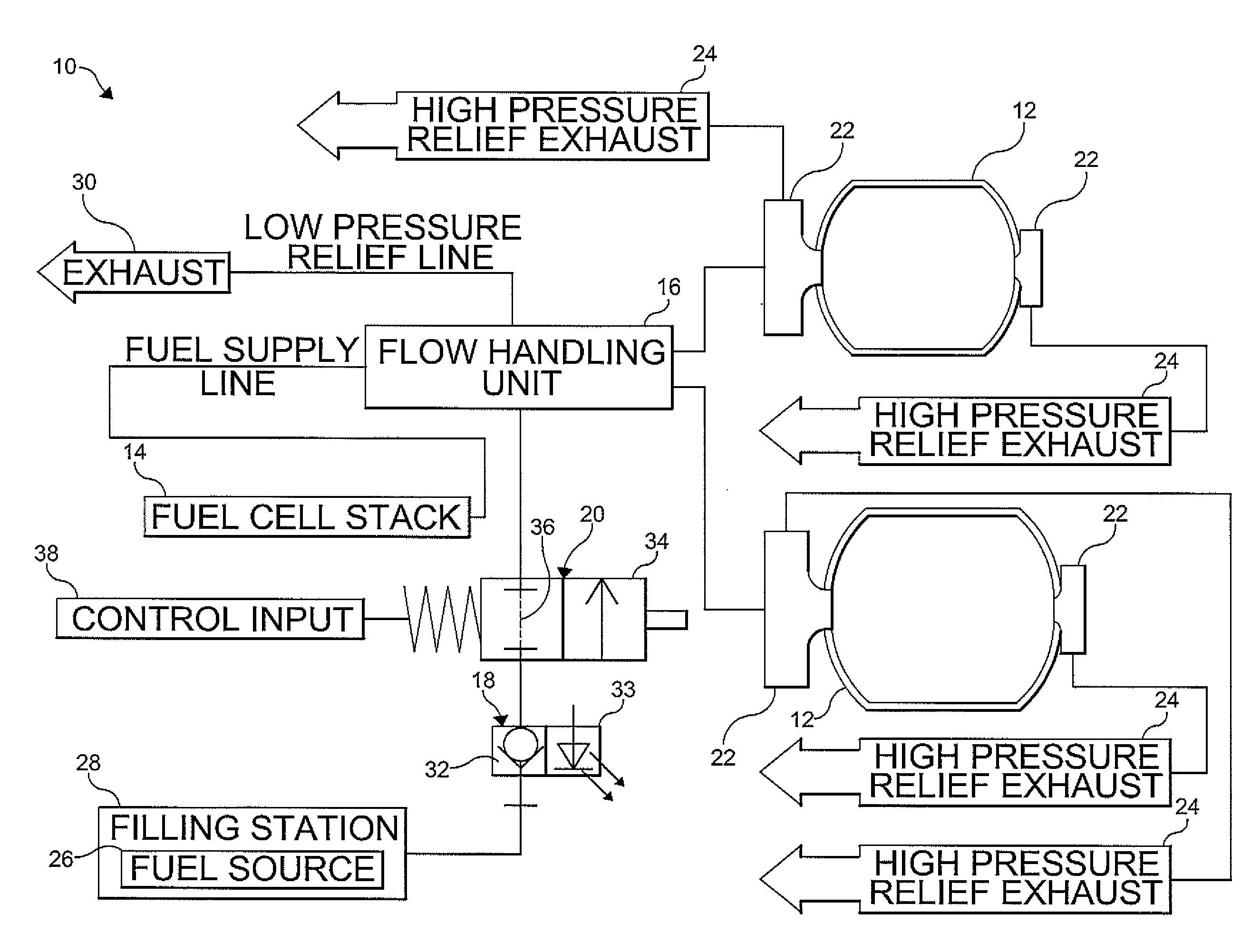

Method of discharging high pressure storage vessels

InactiveUS7426935B2Minimum of electrical energyReduce differential pressureContainer filling methodsGas handling applicationsElectricityHydrogen

A master / slave tank system for storing a compressed hydrogen gas, where the system employs an electrically driven shut-off valve for each tank in the system. The tank system includes a master tank and a slave tank for storing the gas. A first line is coupled to the master tank for providing the gas stored therein to a fuel cell stack. A master tank shut-off valve is positioned in the first line between the master tank and a pressure regulator. A second line is coupled to the slave tank for providing the gas stored therein to the master tank as the pressure difference between the slave tank and the master tank changes. An electrically driven slave tank shut-off valve is positioned within the second line, where the slave tank shut-off valve automatically closes the second line in response to an increase in the differential pressure across the slave tank valve.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for producing methane chloride by using dilute hydrochloric acid

ActiveCN101440015AResolve disposal issuesAvoid safety and environmental hazardsHalogenated hydrocarbon preparationGas phaseChloride

The invention provides a method for producing monochloro methane by using dilute hydrochloric acid. The method comprises the following steps: 15 to 22 weight percent of the dilute hydrochloric acid and 40 to 52 percent of calcium chloride solution are mixed in a mixer and then enter into a hydrochloric acid analysis tower, the hydrochloric acid solution breaks a azeotropic point under boiling breaking action of calcium chloride, hydrogen chloride gas escapes from the top of the analysis tower, and the dilute calcium chloride solution is dewatered at a temperature of between 125 and 145 DEGC and a pressure of between 0.02 and 0.1MPa; compressed hydrogen chloride gas and vaporized methanol are superheated by a super-heater and enter a reactor to generate a mixture of monochloro methane, methane, ethyl chloride and methylene chloride; and the generated mixture enters a chilling machine, a gas phase enters a sulphuric acid drying system after the mixture is chilled and separated, and the gas phase is compressed to prepare the monochloro methane. The method effectively solves treatment problem of the dilute hydrochloric acid; the produced hydrogen chloride has high purity and little organic impurity; and the method reduces generating amount of heavy components in subsequent reaction, and improves the quality of the monochloro methane.

Owner:SHANDONG DONGYUE FLUO SILICON MATERIALS CO LTD

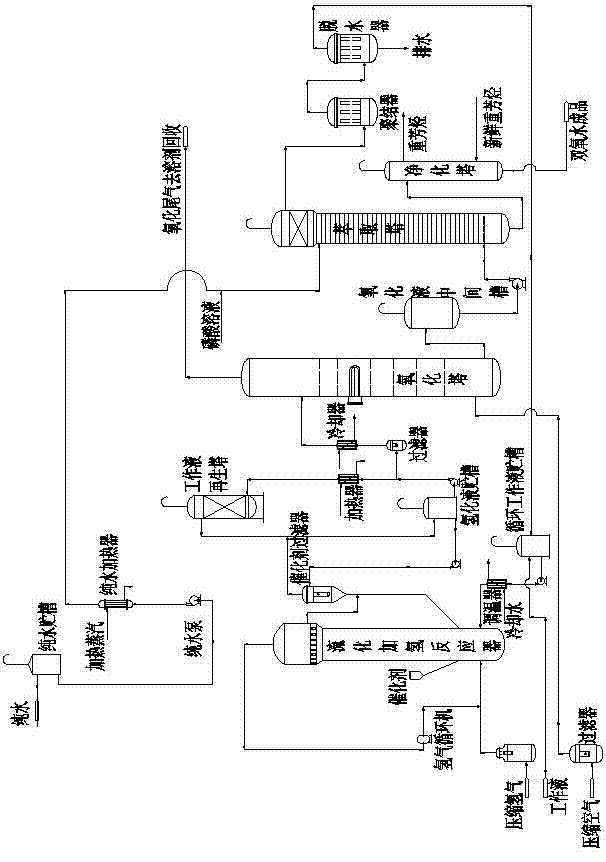

Production method of hydrogen peroxide

InactiveCN103588176ALow investment costImprove hydrogenation efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHigh concentrationPhosphate

Relating to the technical field of large-scale high concentration hydrogen peroxide production technologies, particularly to hydrogen peroxide production technologies by an anthraquinone process, the invention provides a production method of hydrogen peroxide. The method includes: taking heavy aromatics, tetrabutylurea and trioctyl phosphate as solvents, adopting 2-ethylanthraquinone as a reaction material, adding a well prepared working solution into a circulating working solution storage tank, making use of a circulating working solution pump to send the working solution into a working solution thermoregulator, using circulating cooling water to lower the temperature of the working solution to about 35DEG C, then bringing the working solution to the bottom of a fluidization hydrogenation reactor, adding a hydrogenation catalyst into the fluidization hydrogenation reactor in advance through a catalyst adding groove, at the same time, passing compressed hydrogen through a hydrogen buffer filter to filter out impurities, then letting the compressed hydrogen enter the bottom of the fluidization hydrogenation reactor, using the compressed hydrogen to blow and stir the catalyst and the working solution so as to undergo hydrogenation reaction at a temperature of about 50DEG C, under a pressure of about 0.26mPa, and at hydrogenation efficiency of about 13g / L.

Owner:YANGZHOU RONGXIANG CHEM TECH DEV DESIGN

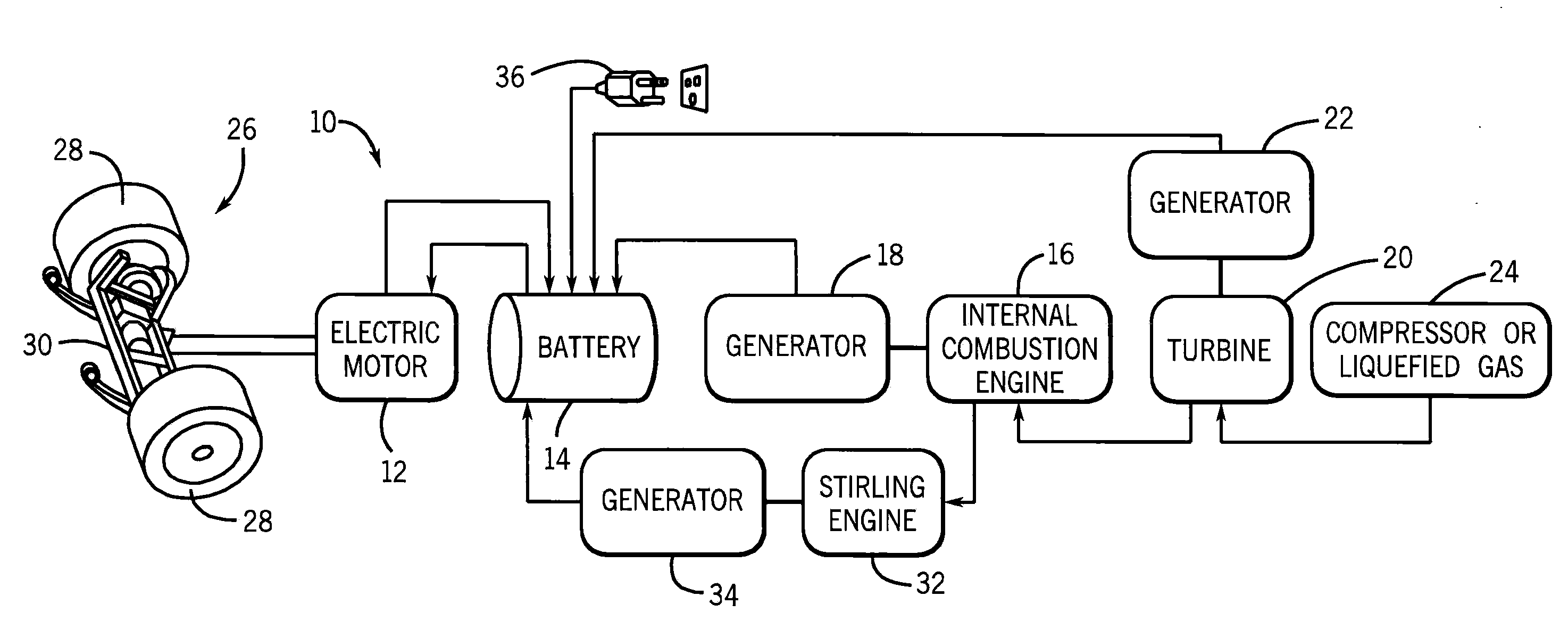

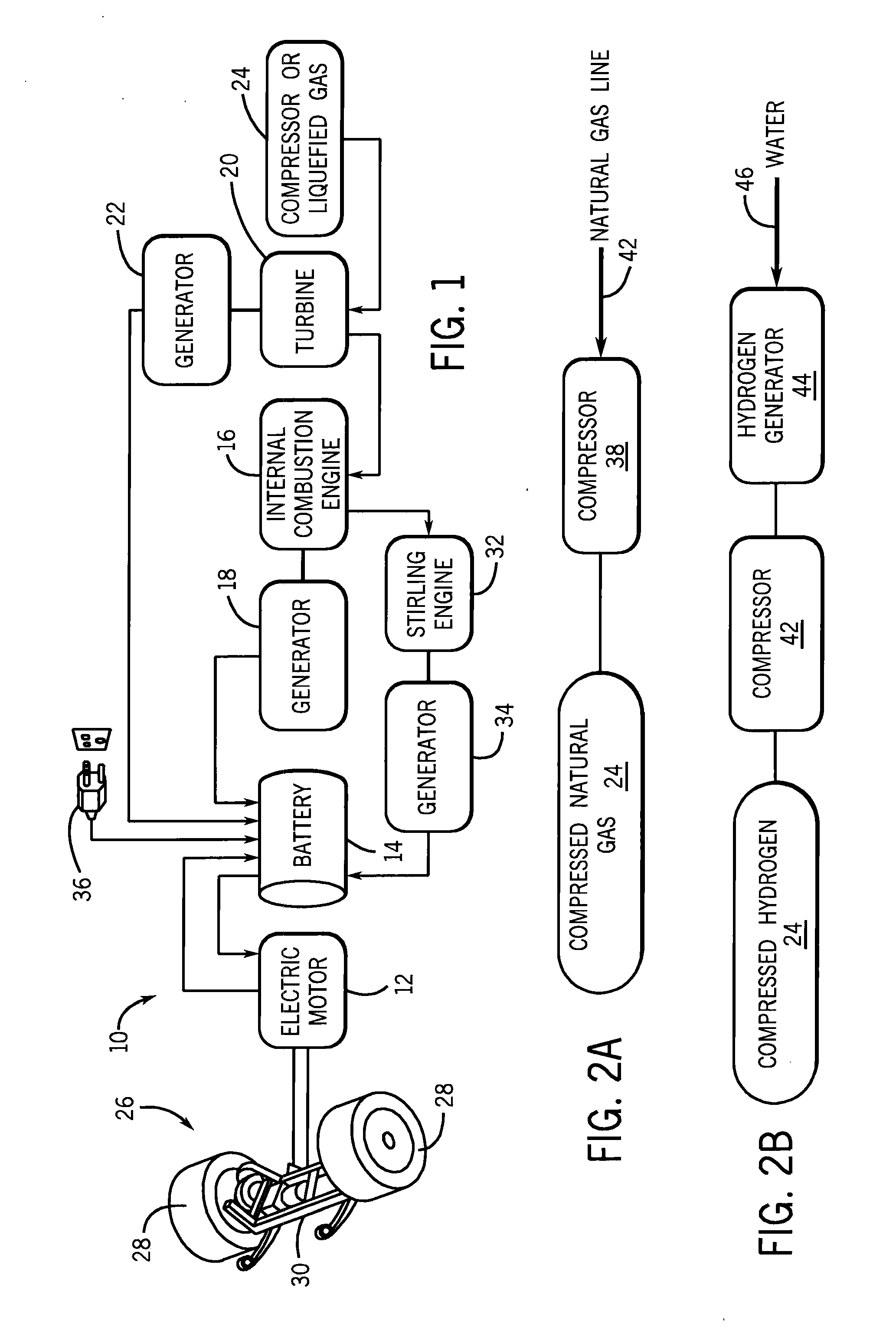

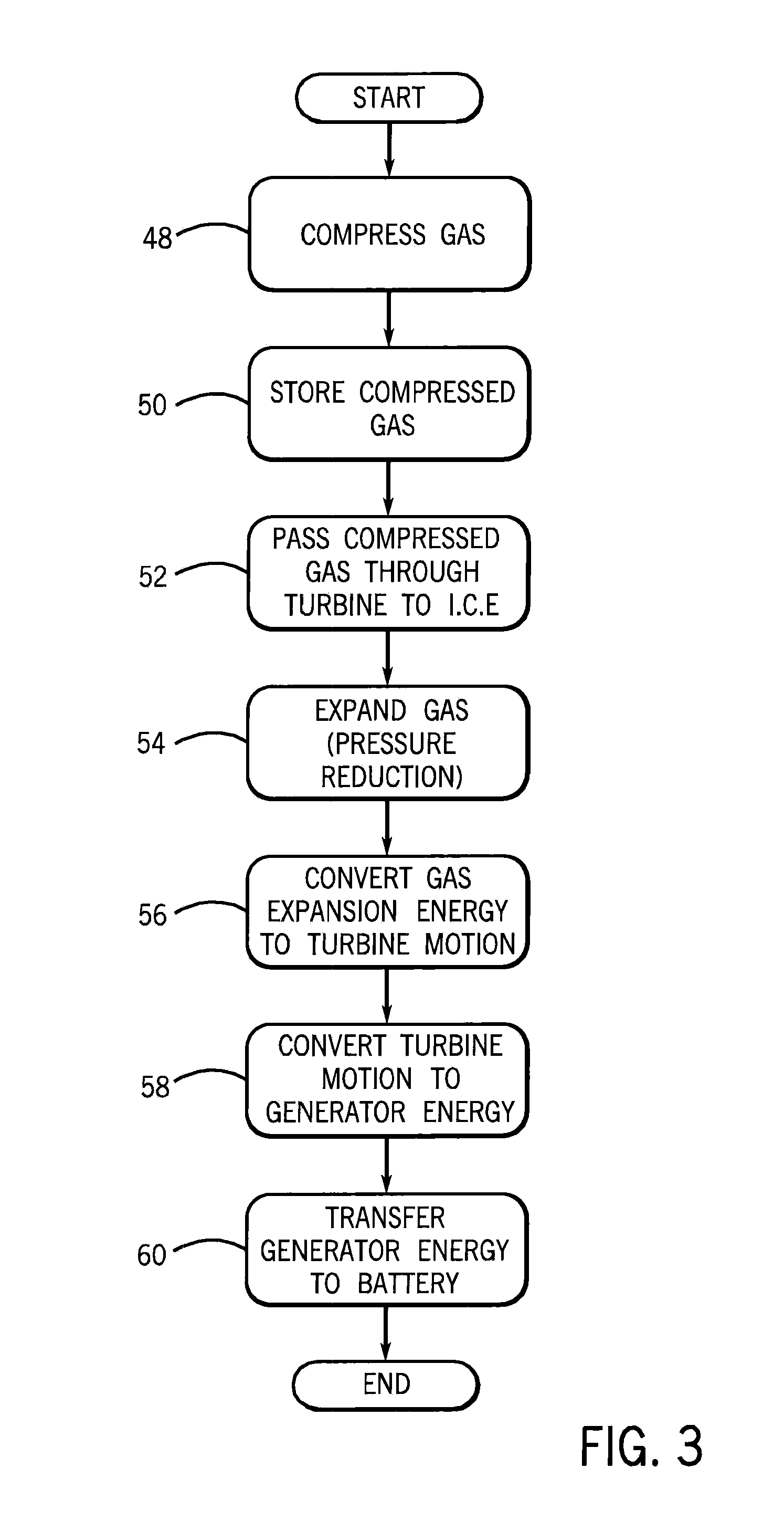

System And Method For Energy Recovery In A Hydrogen Or Natural Gas Engine

InactiveUS20130319359A1Reduce pressureHybrid vehiclesInternal combustion piston enginesHydrogenNatural gas storage

A method and system for energy recovery in a hydrogen or natural gas hybrid electric vehicle includes a turbine positioned between a compressed hydrogen or natural gas storage cylinder and an internal combustion engine. The turbine receives the compressed gas from the storage cylinder, reduces the pressure of the compressed gas, and supplies the compressed gas at a reduced pressure to the internal combustion engine. The turbine is connected to a generator and uses energy extracted from the pressure reduction of the compressed gas to drive the generator. The generator is further connected to a battery of the hybrid electric vehicle and acts as a power source for the battery.

Owner:EVANS DALE MICHAEL

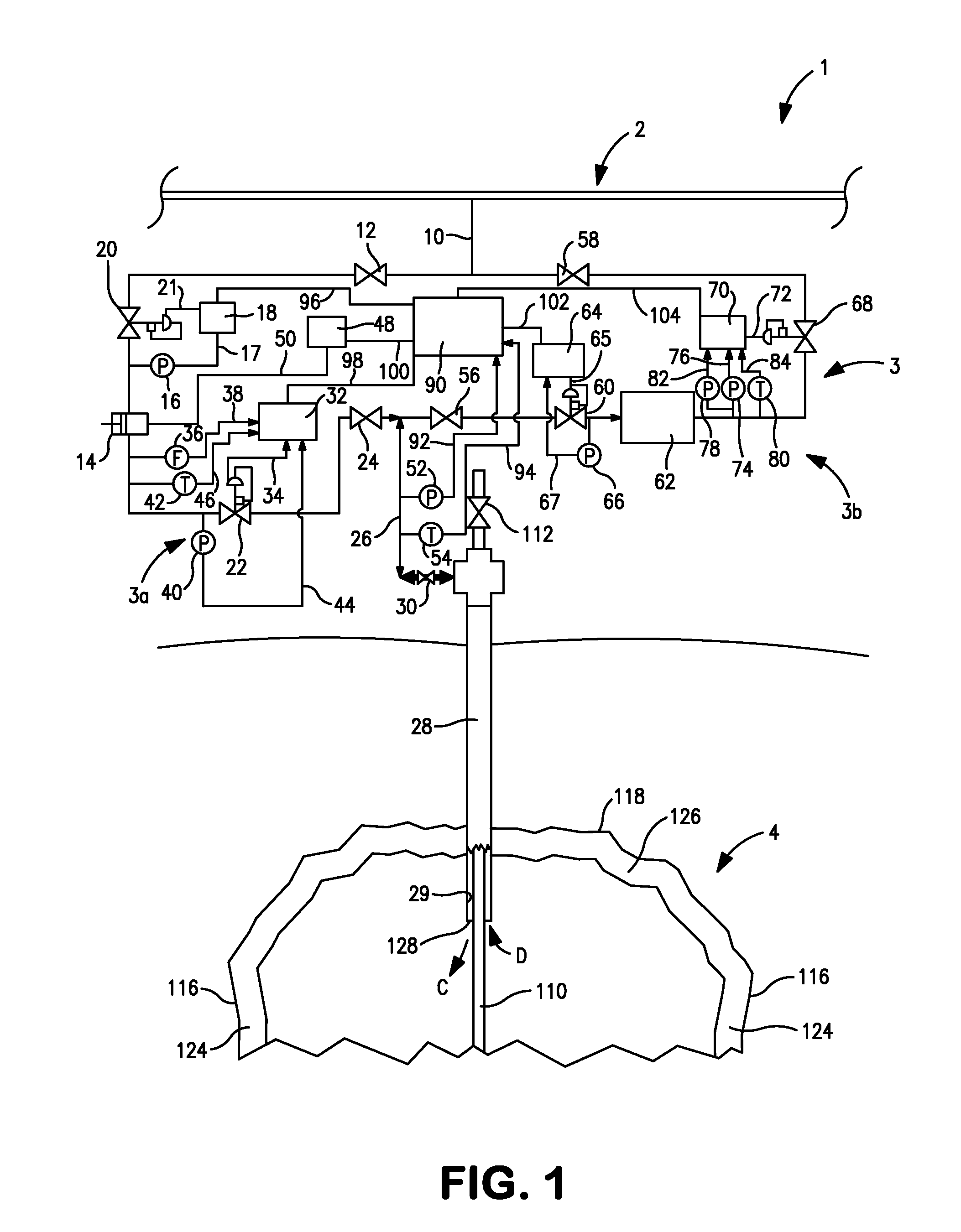

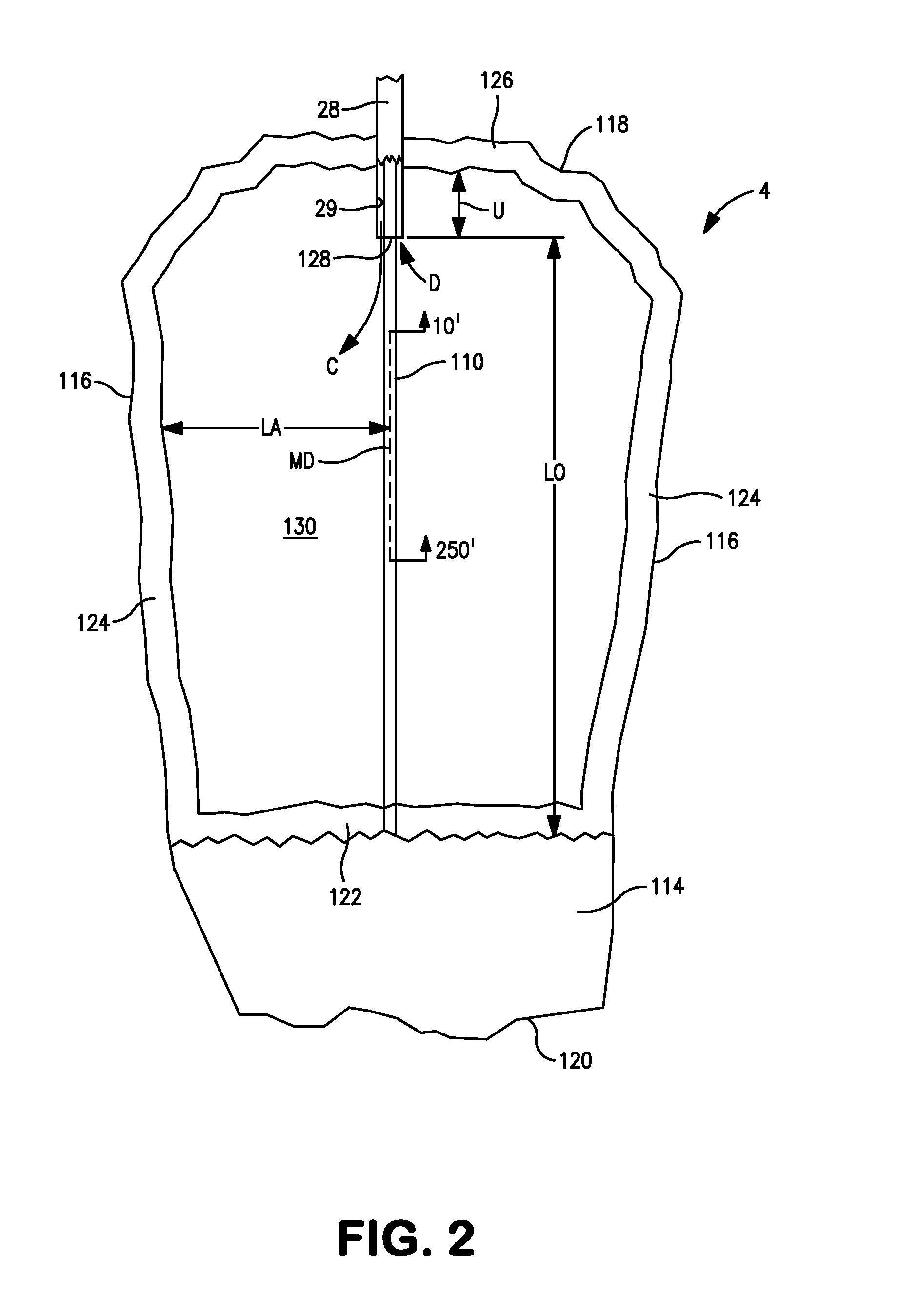

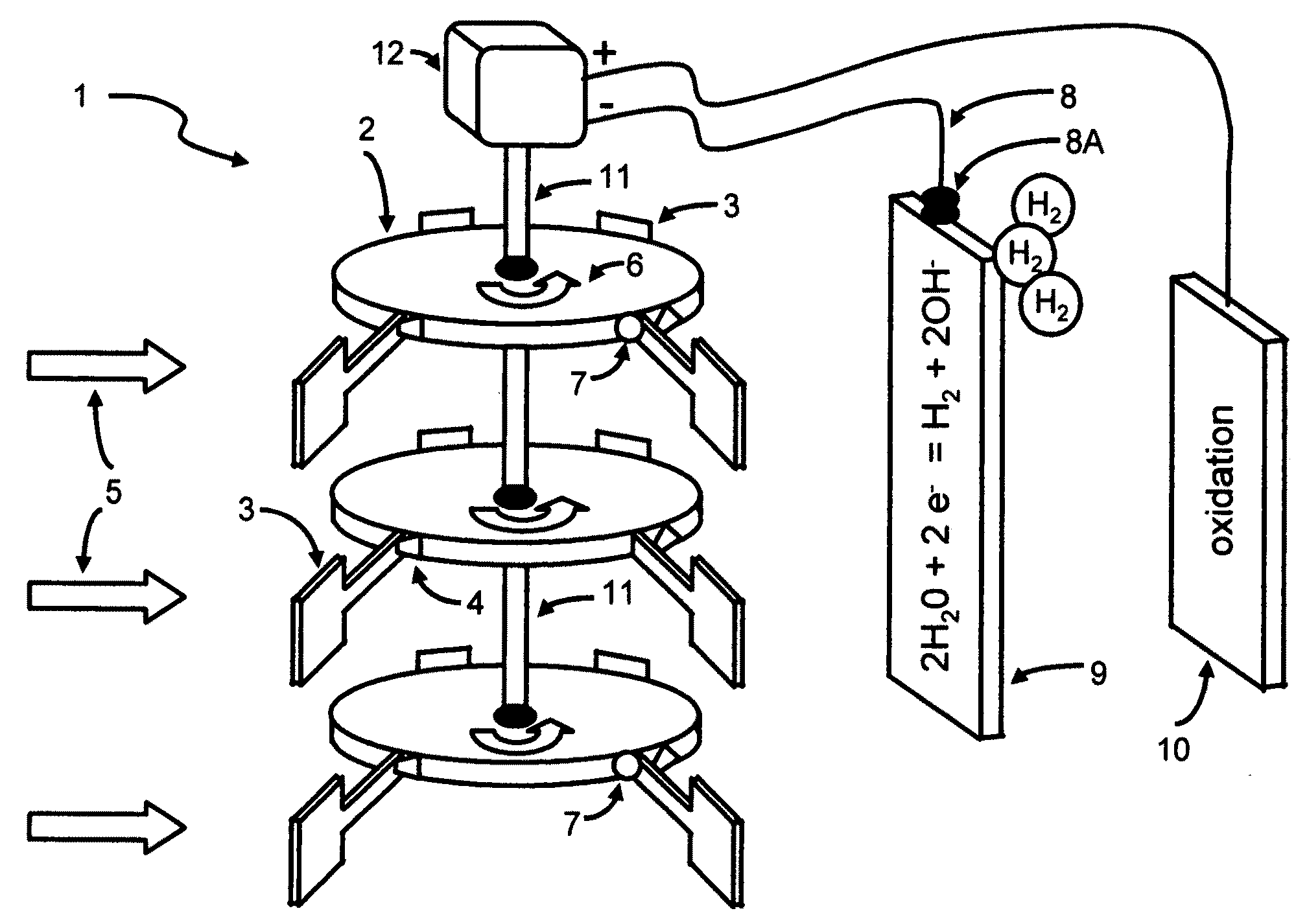

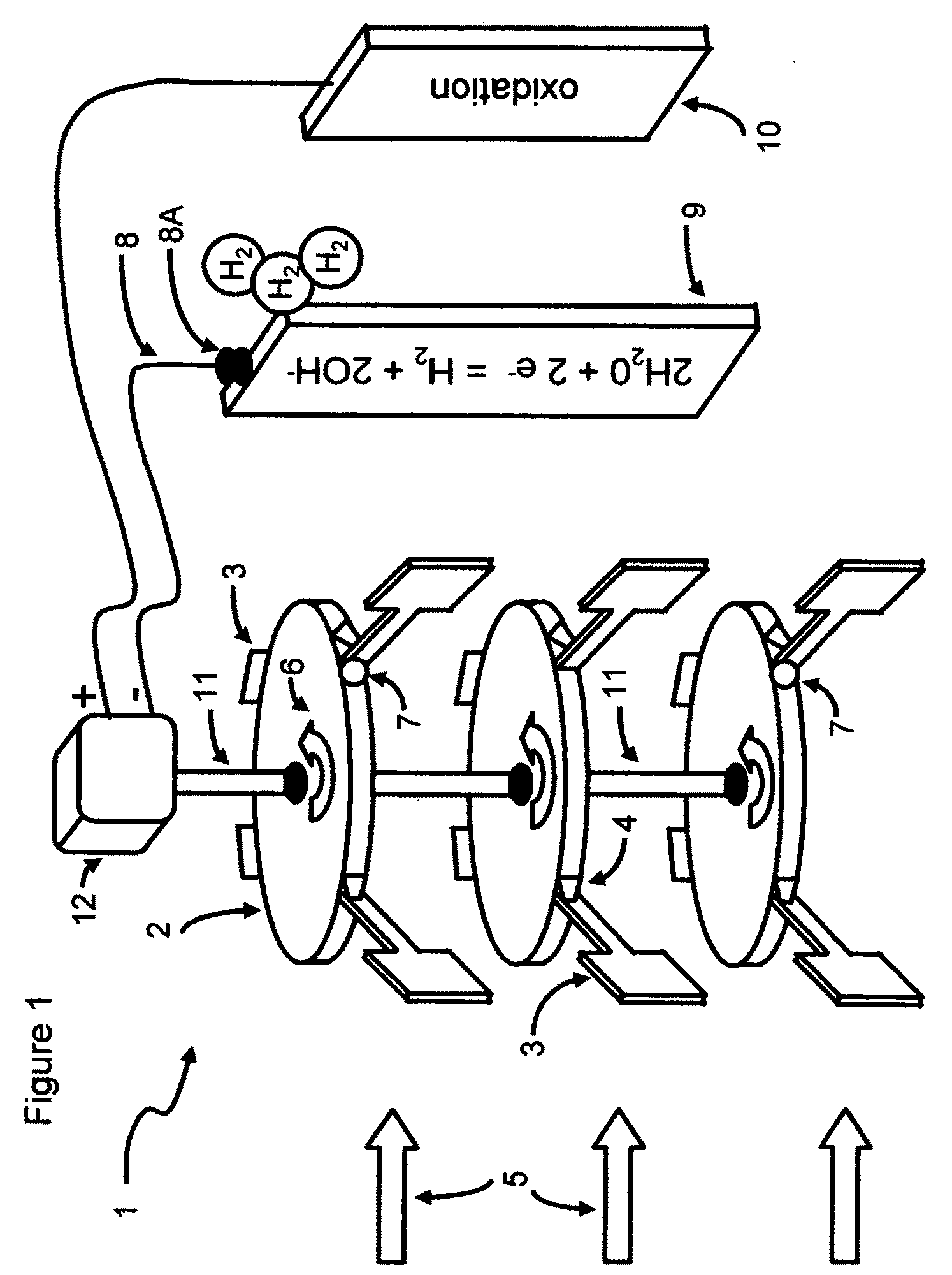

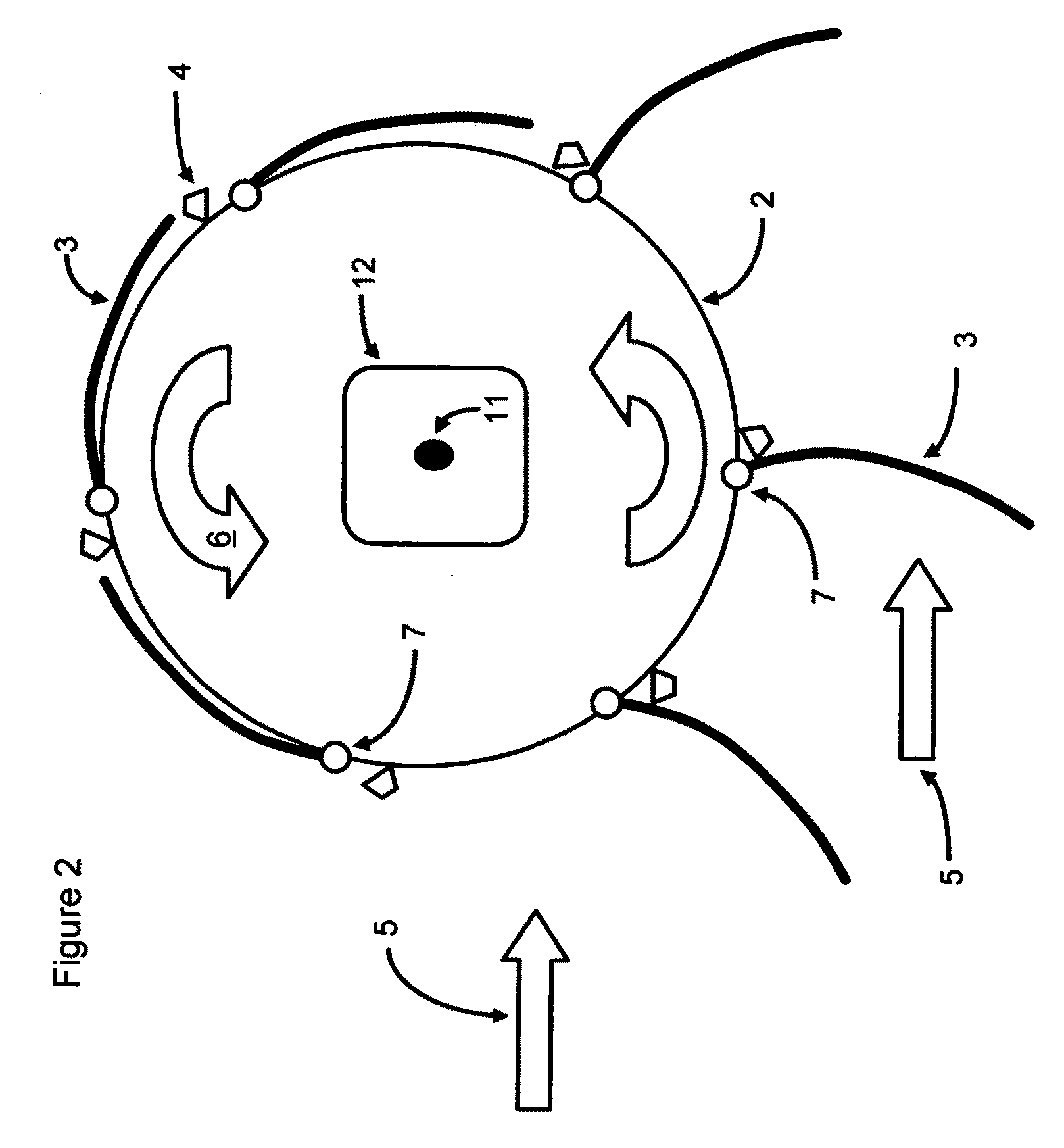

Deep water generation of compressed hydrogen

InactiveUS20100089766A1Market acceptance of hydrogen cars will be facilitatedCellsElectrical-based auxillary apparatusElectrolysisHydrogen pressure

A hydrogen generation vessel within which a reduction plate generates hydrogen by electrolysis of sea water. The hydrogen generation vessel operates at deep ocean levels to provide unexpected advantages. The operating depth is not limited because the hydrogen generation vessel includes openings at or near the bottom, and no pressure differential exists across the vessel walls. Pressure inside and outside are the same, and are determined by the depth at which the hydrogen generation vessel is positioned. Electrolysis, collection, and storage (temporary) take place in the same container. Since the hydrogen pressure is the same as the water pressure at the same depth, the hydrogen is pumped by simply opening a valve.

Owner:MENEAR JOHN E

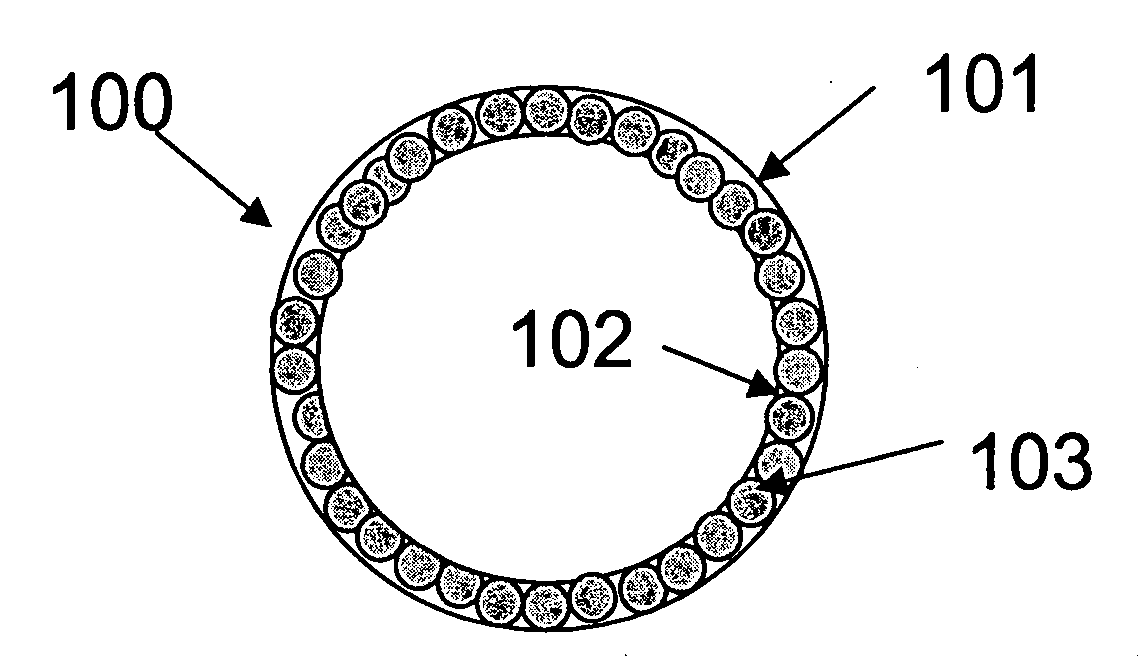

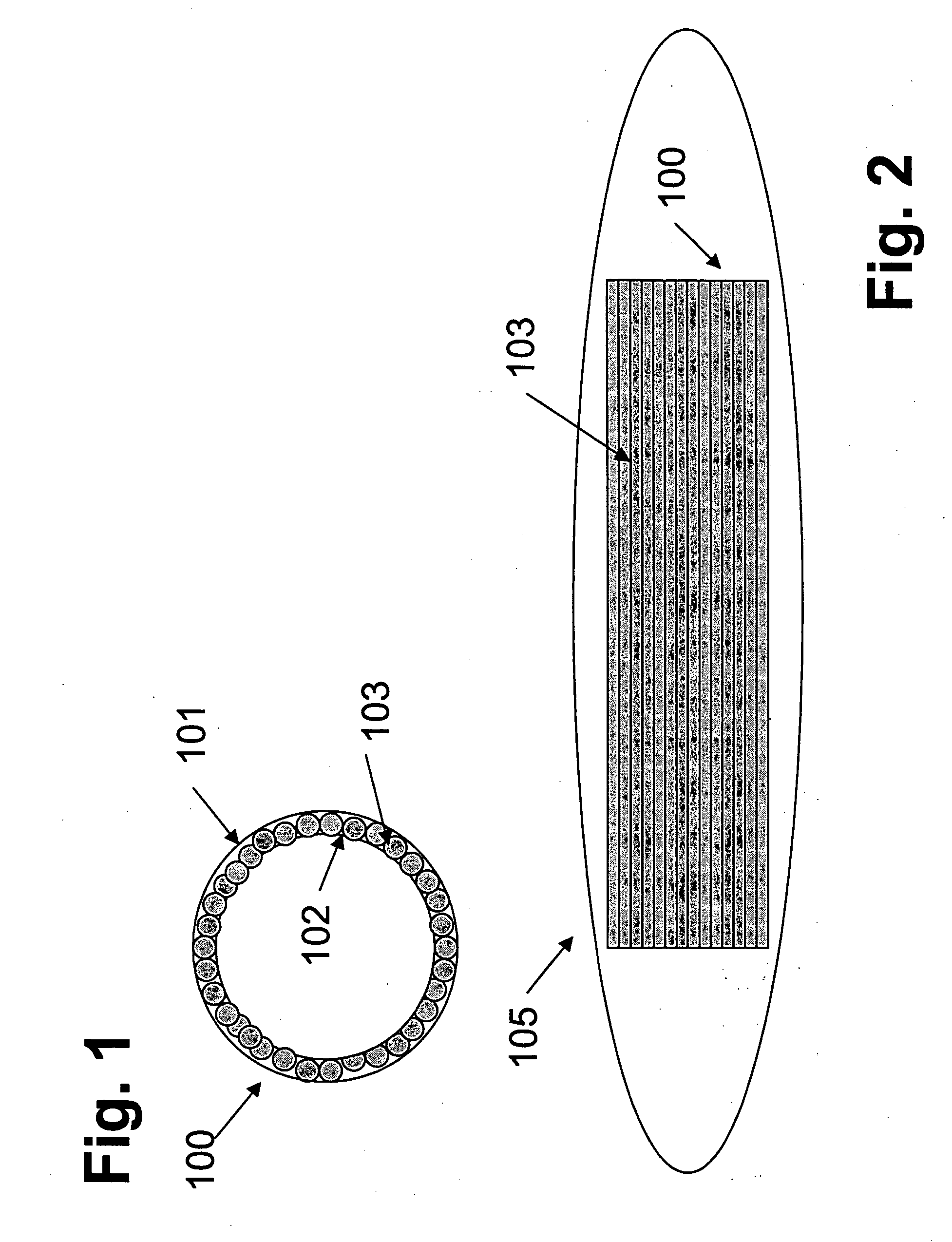

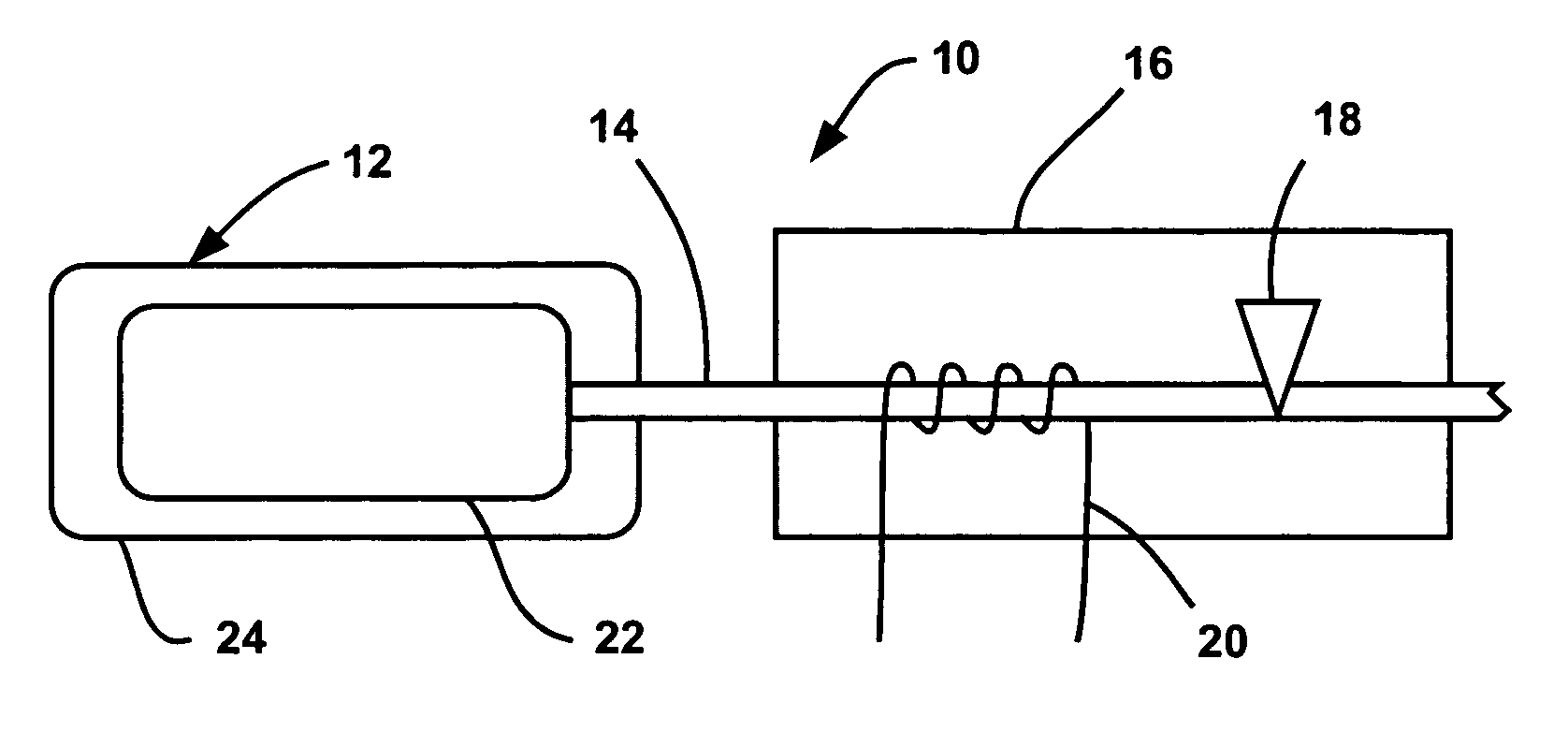

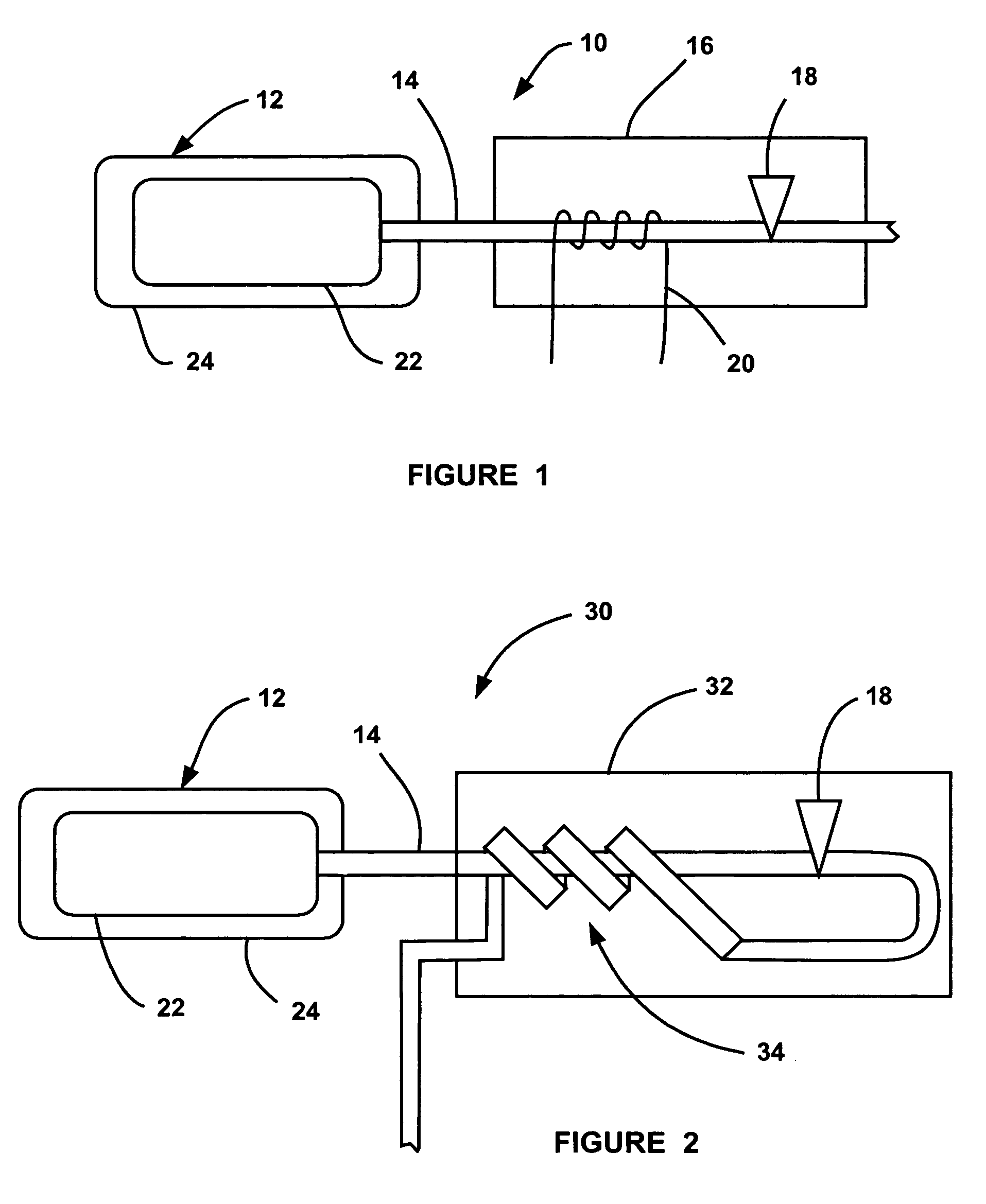

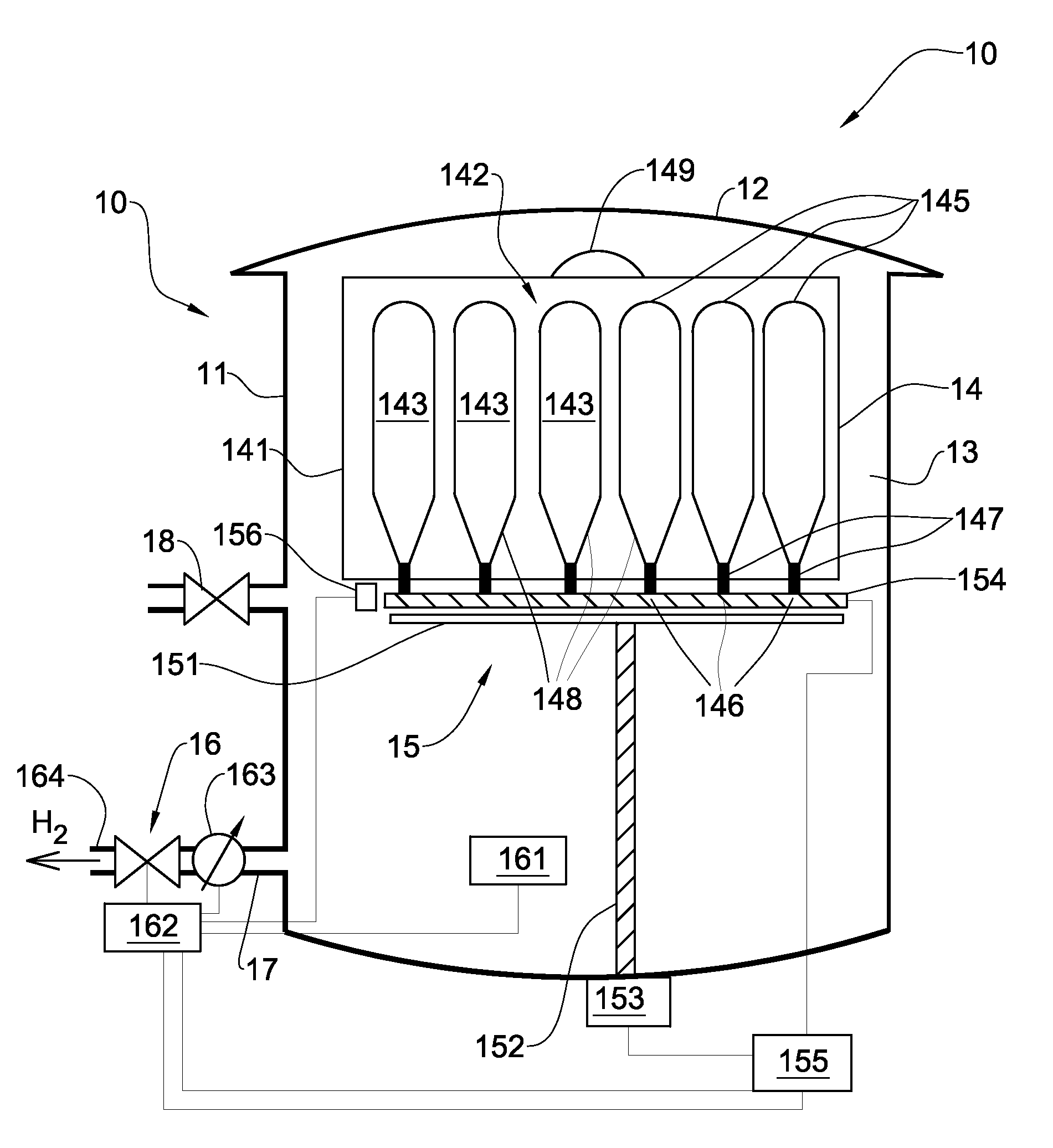

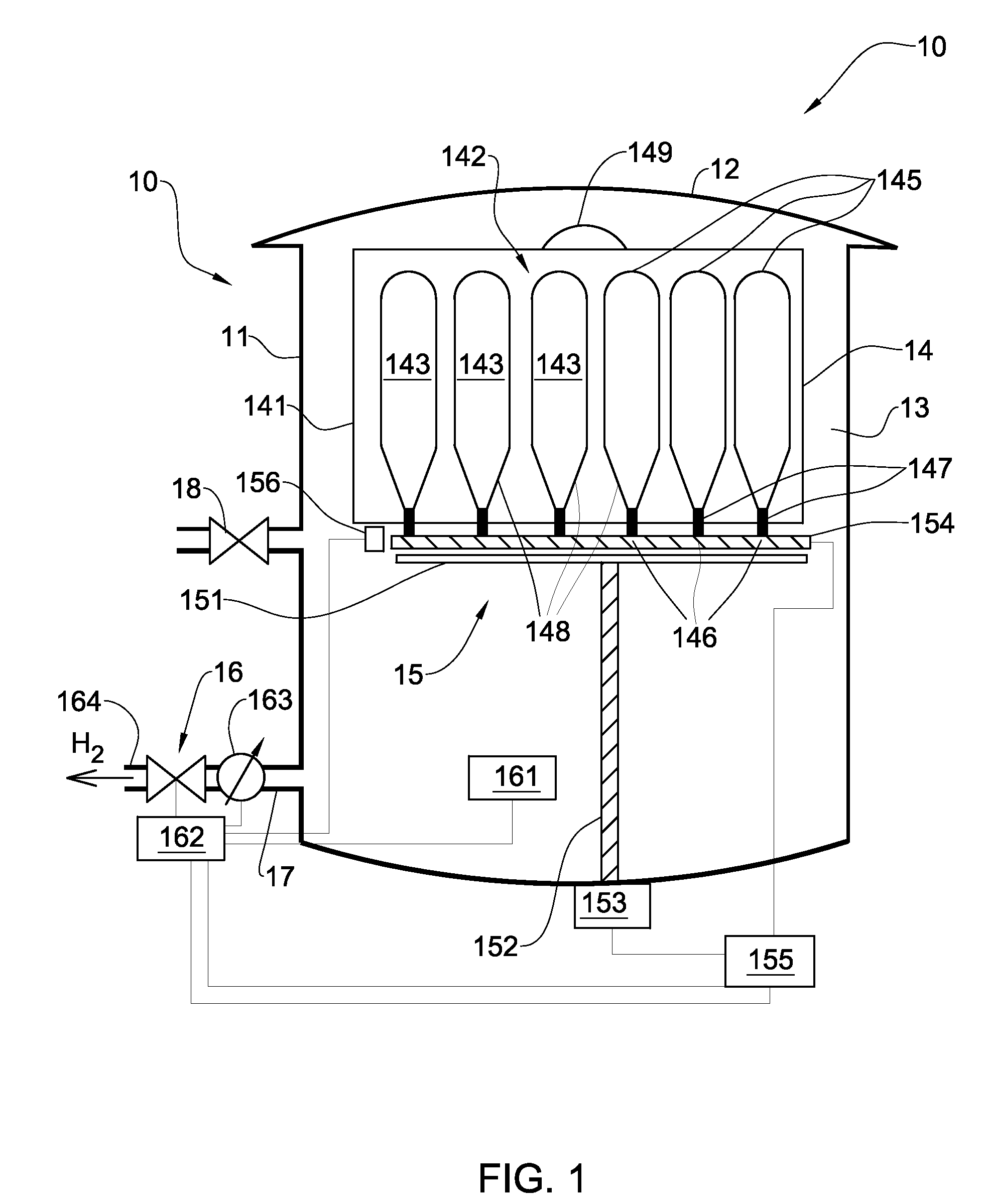

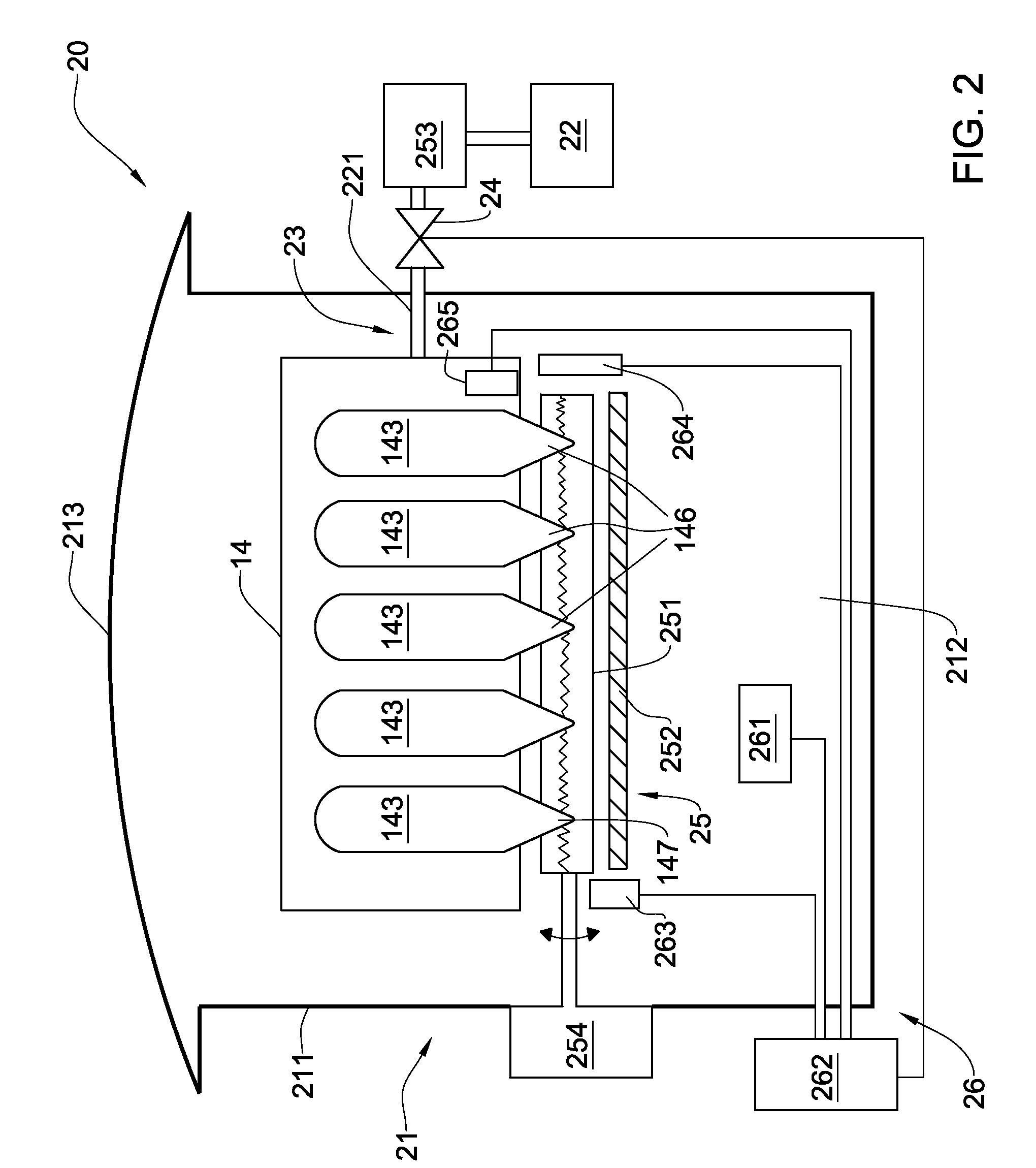

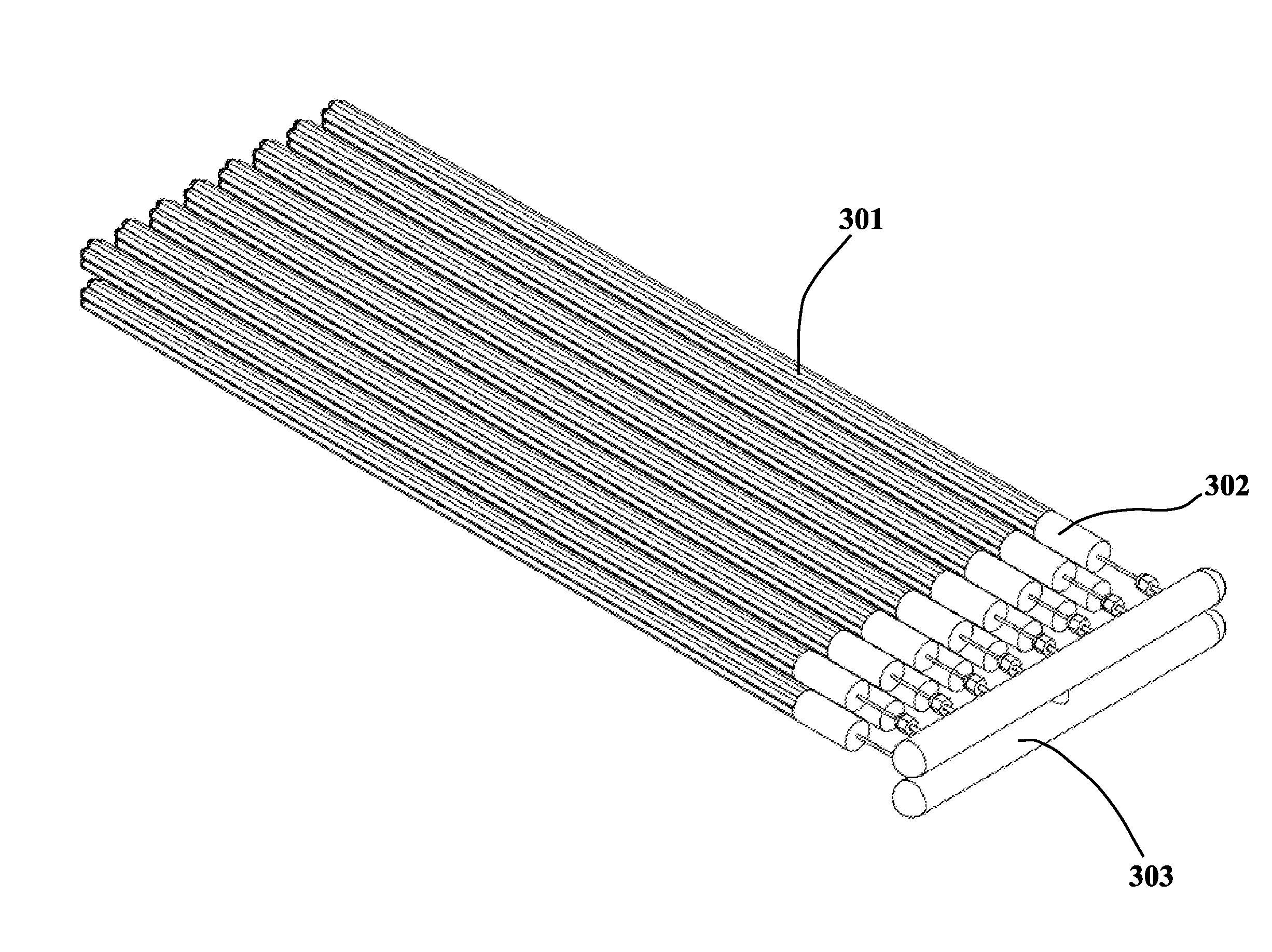

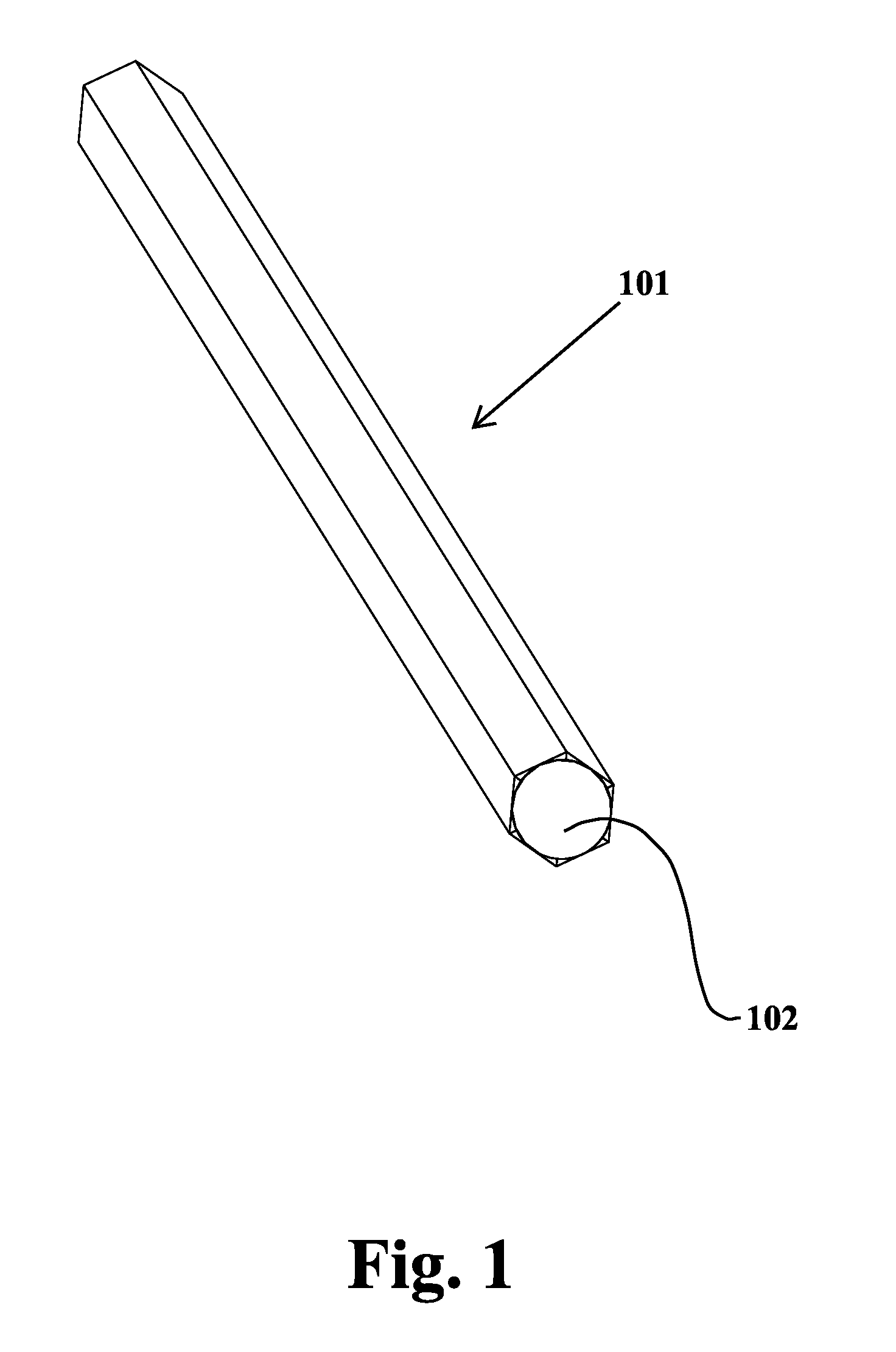

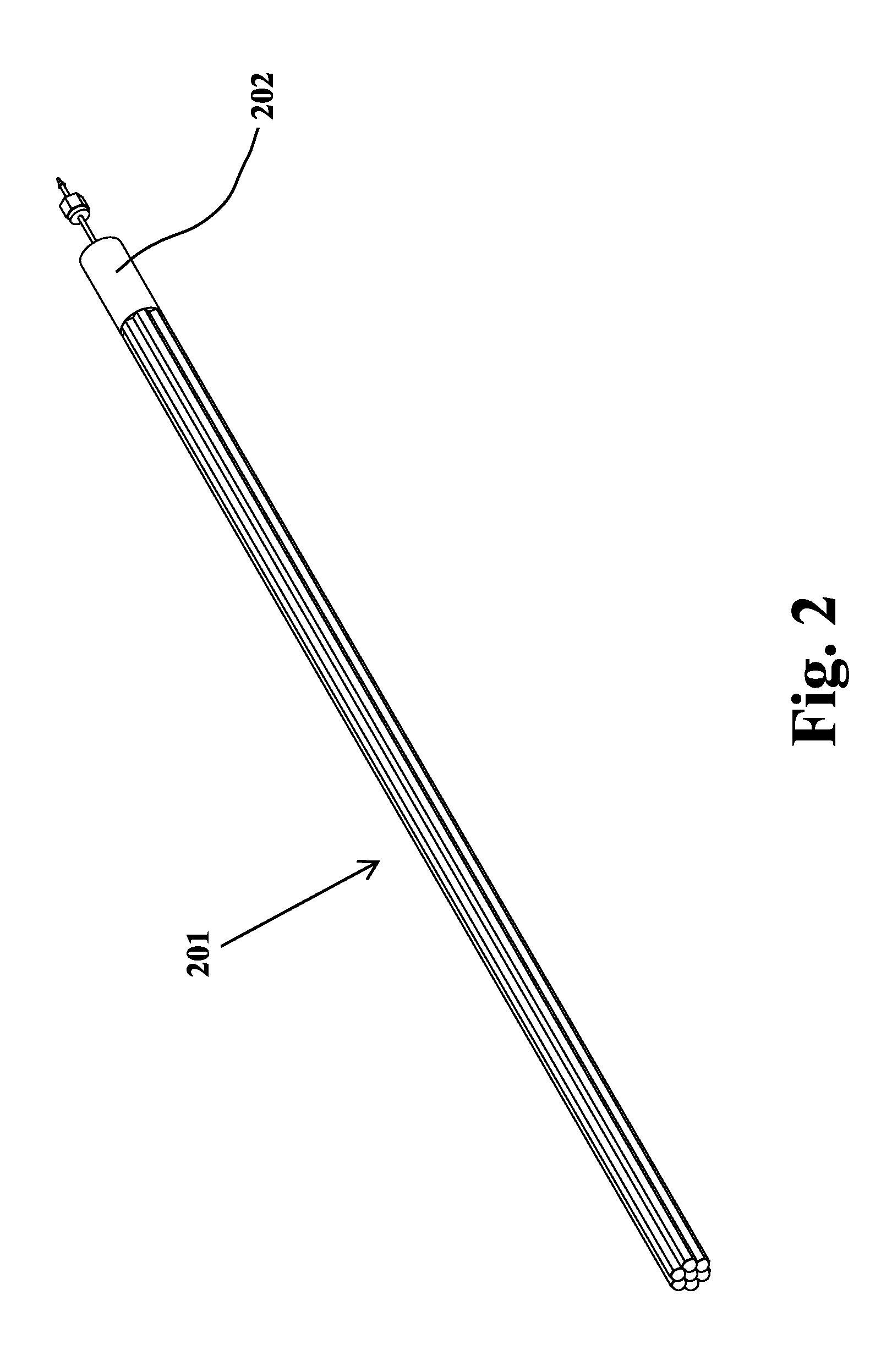

Apparatus for storage and liberation of compressed hydrogen gas in microcylindrical arrays and system for filling the microcylindrical arrays

ActiveUS20090120811A1Effective liberationEfficient loadingCapsContainer/bottle contructionHydrogenMicro column

An apparatus for storage and liberation of compressed hydrogen or other gases is provided. The apparatus includes a housing defining a chamber that includes a cartridge comprising an array of hollow microcylinders defining cavities for storage compressed gas. Each microcylinder has at least one end sealed with a plug made of an easily meltable alloy. The apparatus also includes a gas liberating tool configured for controllable liberating the gas from the cartridge into the chamber; and a control system operatively coupled to the discharge valve and liberating tool, and configured for controlling operation thereof. According to another aspect of the invention, there are provided a system and method for filling a cartridge having an array of hollow microcylinders having open ends. The filling includes placing the cartridge into a chamber of an autoclave, and compressing the gas in the chamber, thereby providing permeation of the gas through the open ends into cavities of the microcylinders. Thereafter, the open ends are sealed with plugs made of an easily meltable alloy.

Owner:CEN CO LTD +1

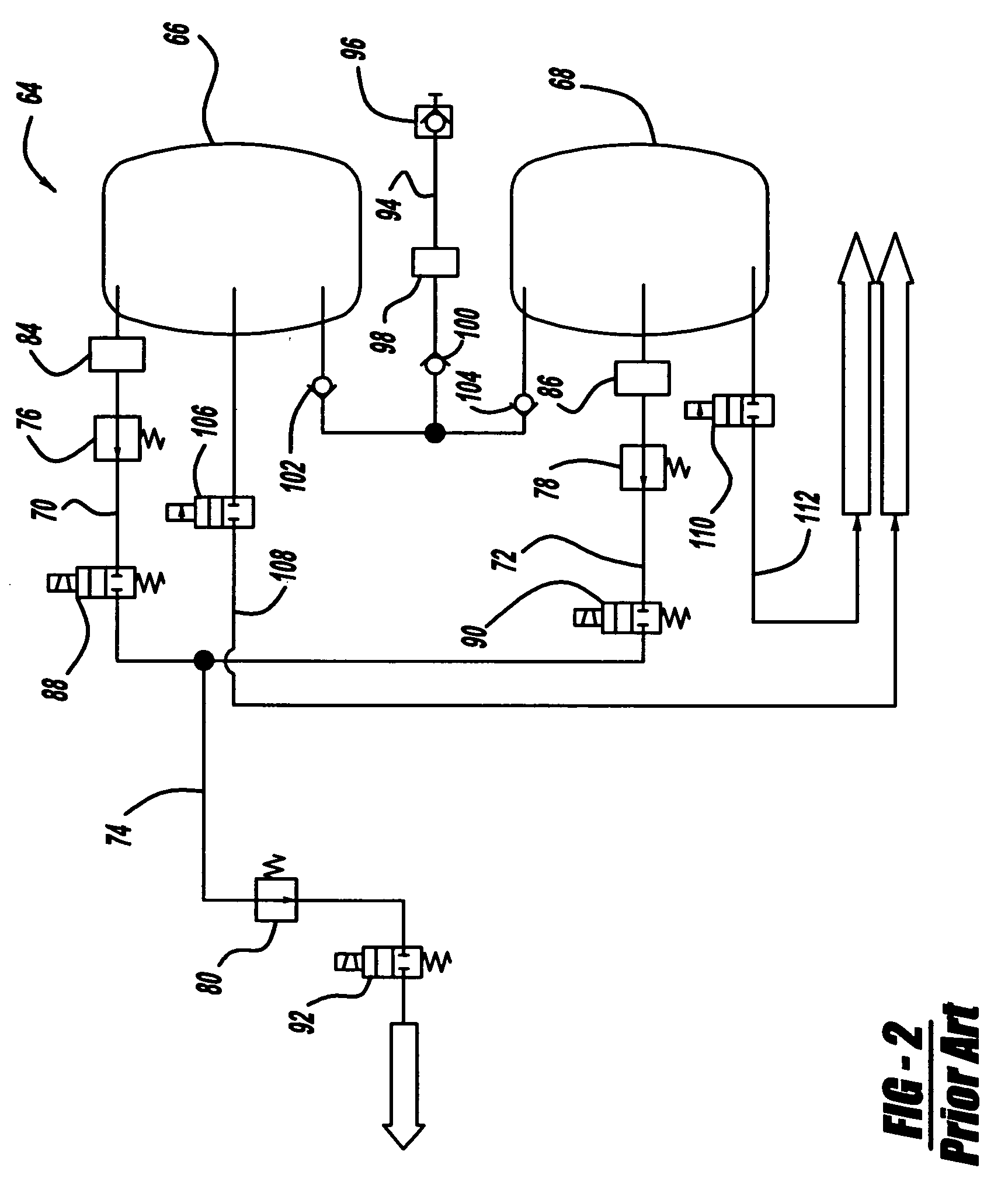

Compressed hydrogen fueling control valve

A fill control system includes a fuel storage vessel, a fuel inlet in fluid communication with the fuel storage vessel to provide fluid communication between a fuel source and the fuel storage vessel, and a fill control valve disposed between and in fluid communication with the fuel inlet and the fuel storage vessel, an actuation of the fill control valve causing a pressure level upstream thereof which emulates a full condition of the fuel storage vessel.

Owner:GM GLOBAL TECH OPERATIONS LLC

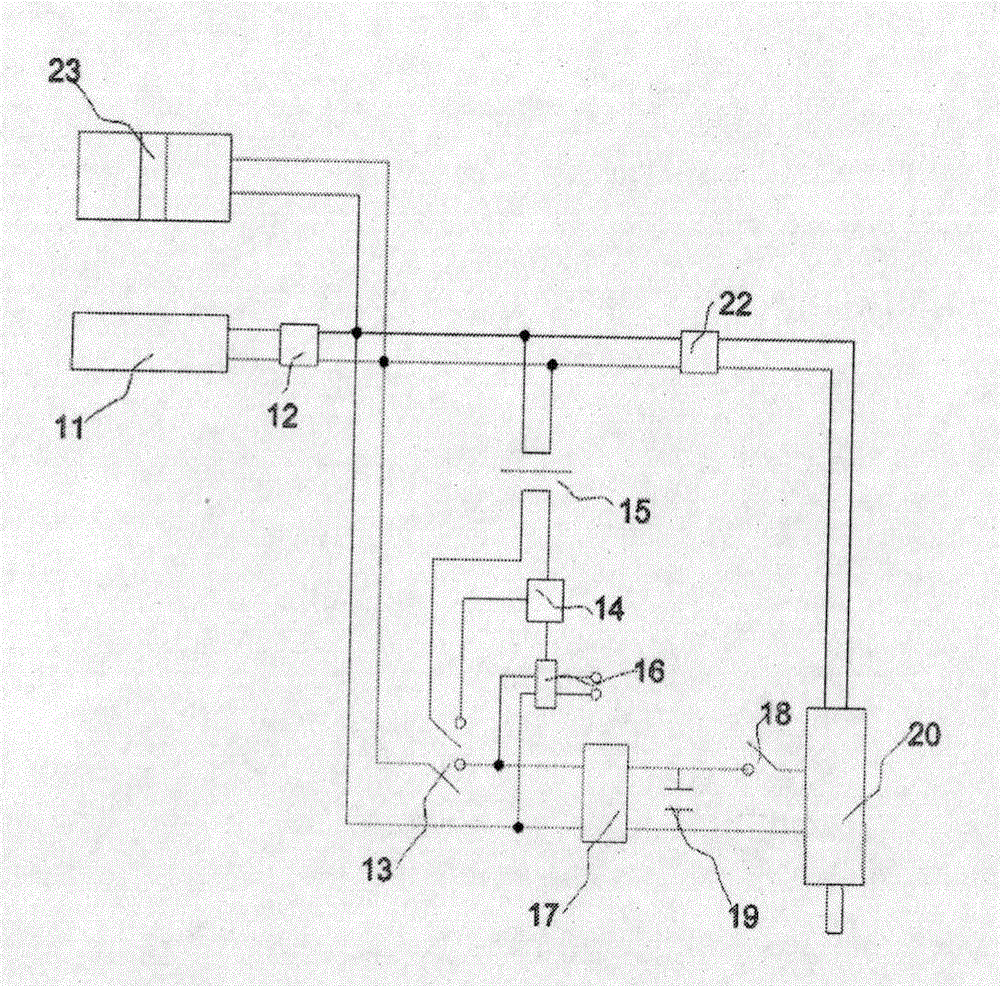

Cooling and filling method for hydrogen fuel used for vehicle

InactiveCN102104162AImprove high temperature conditionMeet fast filling needsFuel cell heat exchangeGas cylinderProcess engineering

The invention discloses a cooling and filling method for a hydrogen fuel used for a vehicle, and belongs to the technical field of gas fuel filling. The method is characterized by comprising the following steps of: (1) compressing and heating hydrogen from a hydrogen source by using a hydrogen compressor; (2) exchanging heat with a cooling pipeline through a heat exchange pipeline in a cooling heat exchange device to cool the compressed hydrogen in the heat exchange pipeline; and (3) connecting a filling gun of a filling and metering device with an on-vehicle hydrogen cylinder, and filling the compressed and cooled hydrogen into the on-vehicle hydrogen cylinder to finish filling. The method has the advantages that: not only the temperature of a gas cylinder can be controlled in a safety loading condition, but also the requirement on rapid filing of the vehicle can be met to ensure the safety of a filling process of the vehicle. The hydrogen filling time is short; and the safety and stability effects are very good. The method is not only suitable for the hydrogen filling of an on-vehicle gas cylinder under the pressure of 35 MPa, but also suitable for the hydrogen filling of the on-vehicle gas cylinder under the pressure of 70 MPa.

Owner:上海昆仑新奥清洁能源股份有限公司

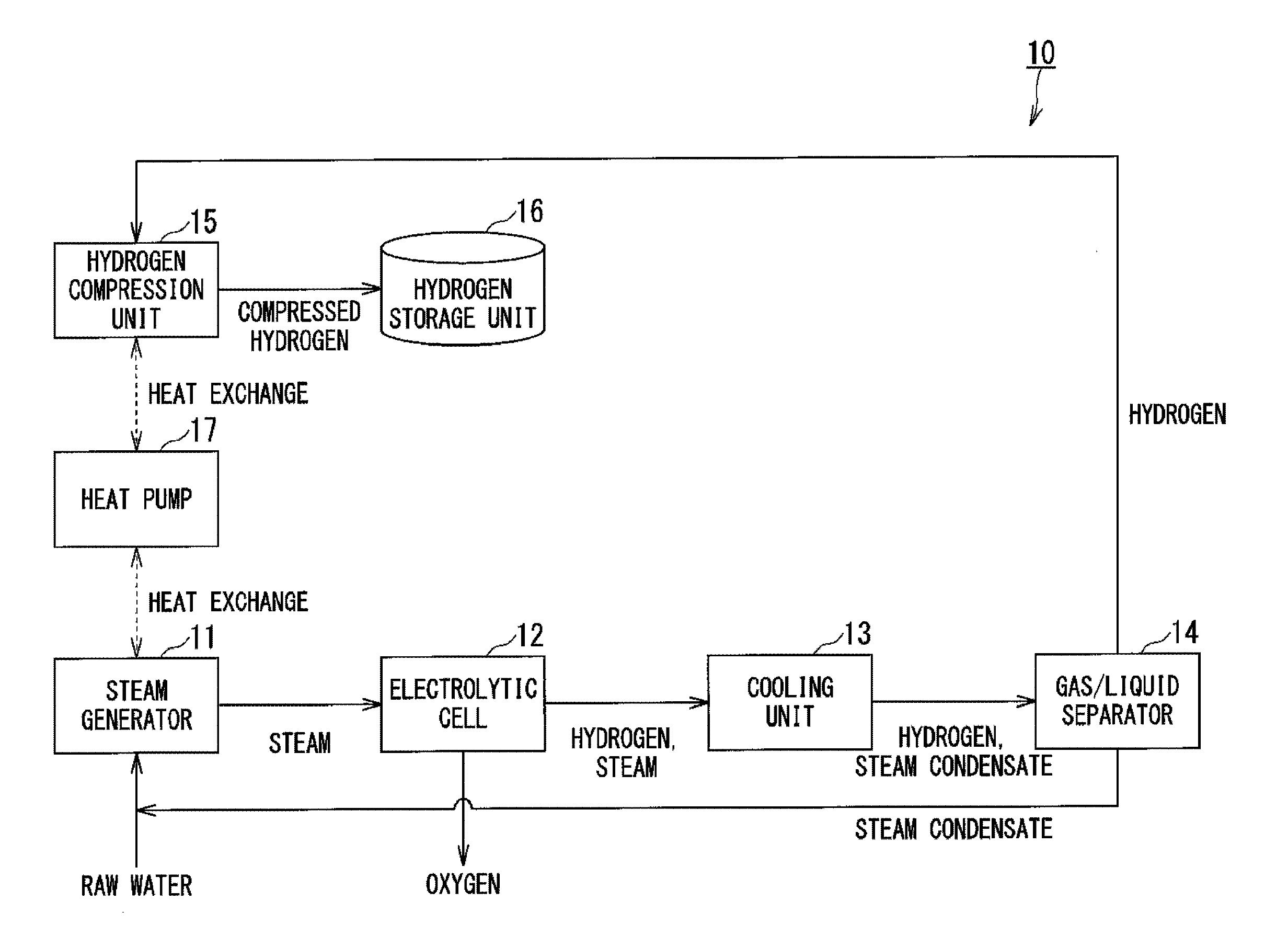

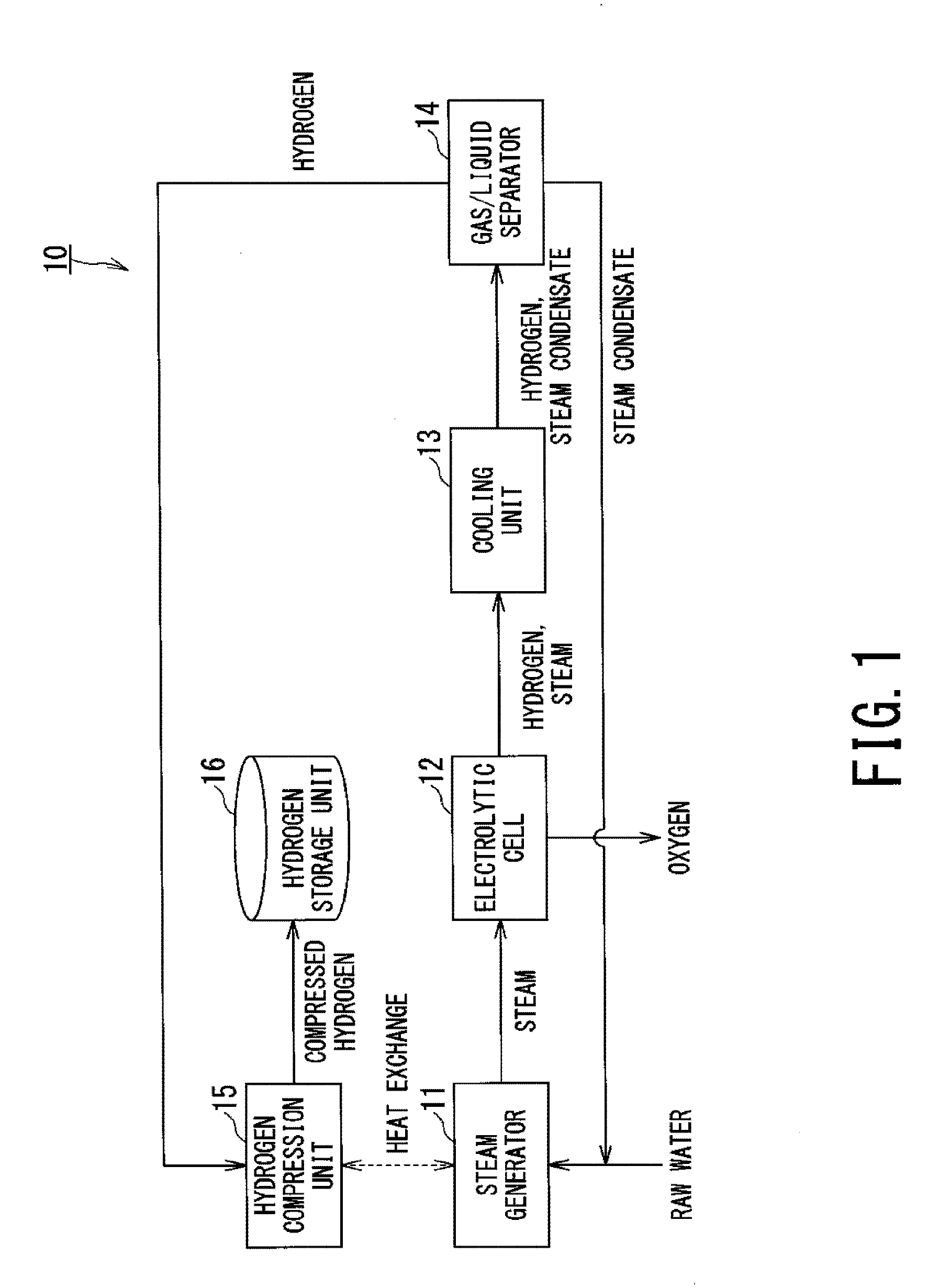

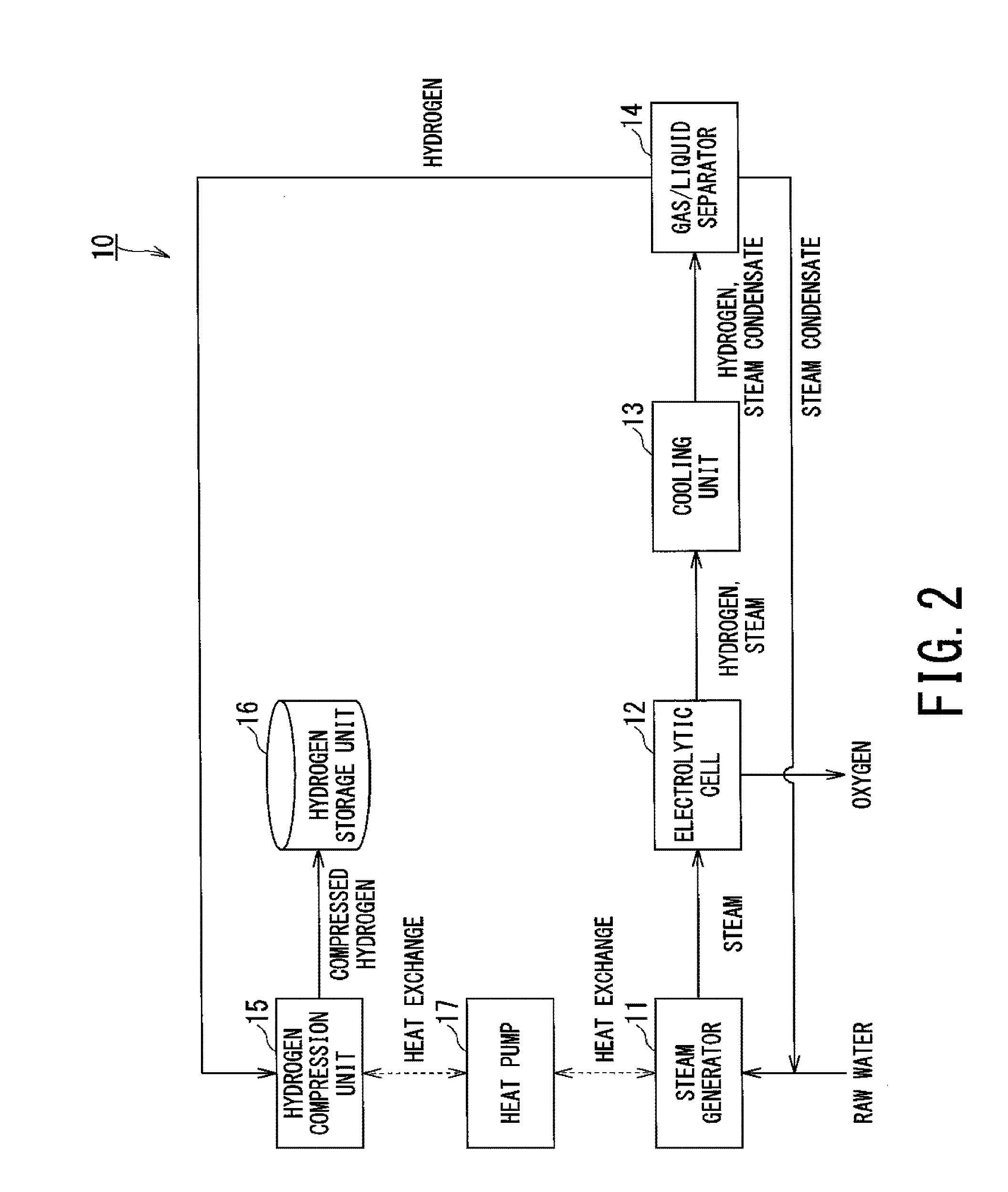

Hydrogen production system and method for producing hydrogen

ActiveUS20160122882A1Reduce heatImprove hydrogen production efficiencyCellsEnergy inputThermal energyHydrogen compression

A hydrogen production system includes: a steam generator heating supplied raw water and generating steam; an electrolytic cell receiving the steam and generating hydrogen and oxygen through a high temperature electrolysis; a cooling unit cooling an unreacted part of the steam in the high temperature electrolysis and changing the unreacted part of the steam into steam condensate; a gas / liquid separator performing gas / liquid separation on the generated hydrogen and the generated steam condensate; a hydrogen compression unit compressing the separated hydrogen and transmitting thermal energy generated when the hydrogen is compressed, to the raw water; and a hydrogen storage unit storing the compressed hydrogen.

Owner:KK TOSHIBA

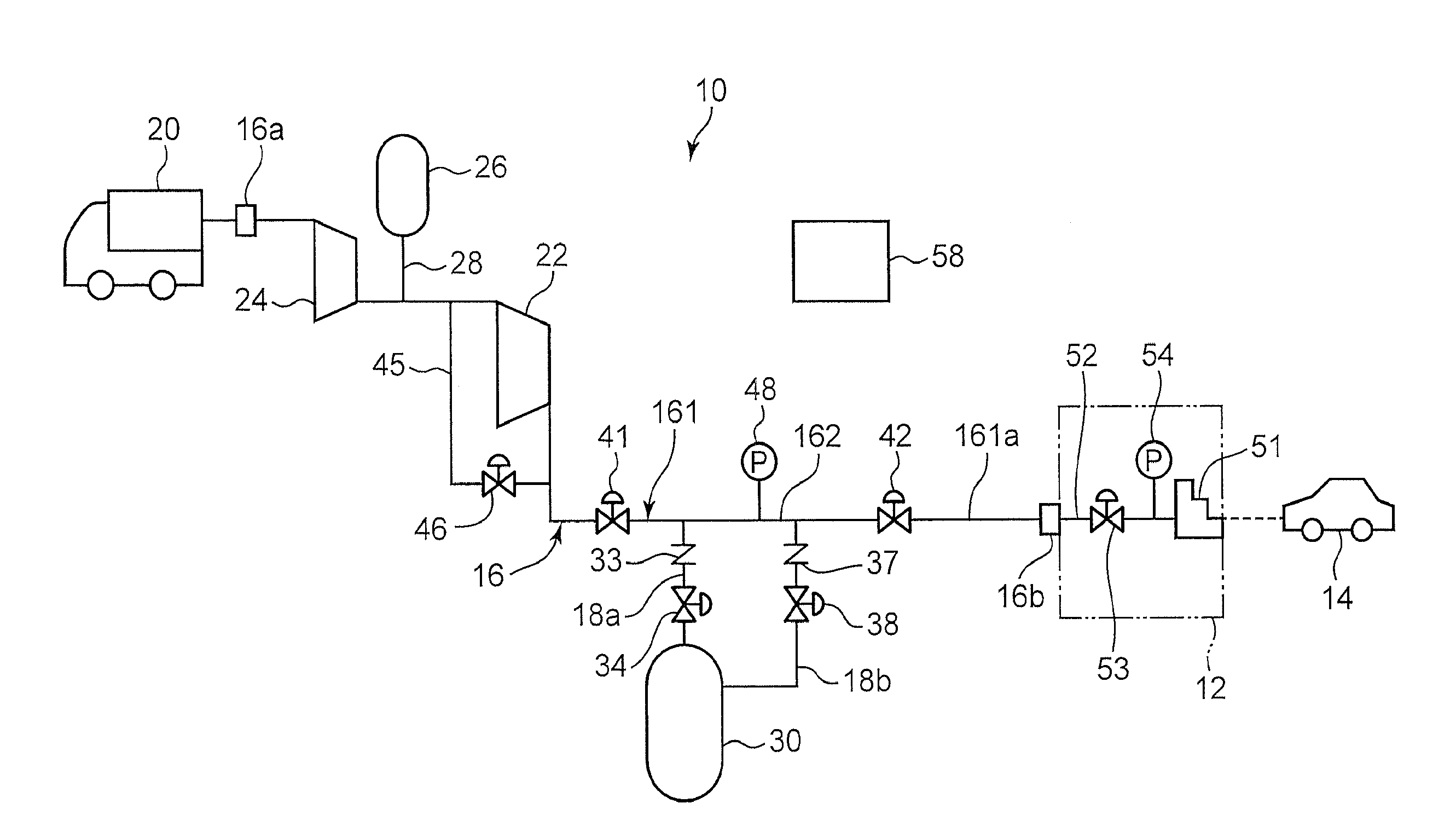

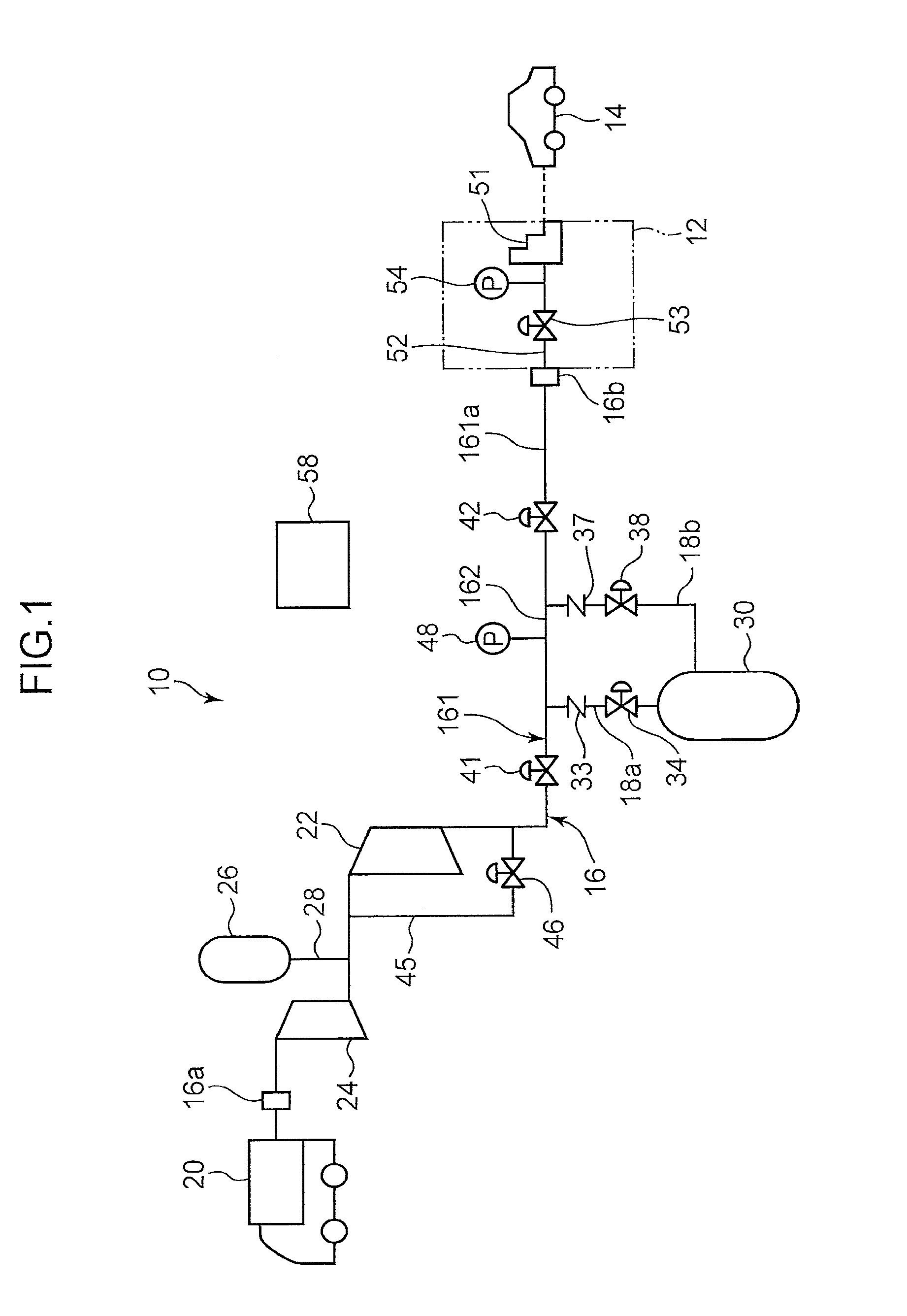

Gas supply device, hydrogen station, and gas supply method

A gas supply device includes a first compressor that compresses hydrogen gas, an accumulator disposed downstream of the first compressor and supplying the hydrogen gas to a dispenser that fills the hydrogen gas in a vehicle, and a gas flow passage that connects the first compressor, the accumulator, and the dispenser, and a control device. The gas flow passage includes a lead-in line for leading the hydrogen gas into the accumulator, a lead-out line for leading out the hydrogen gas from the accumulator, a lead-in side valve, and a lead-out side valve. The control device is capable of simultaneously bringing the lead-in side valve and the lead-out side valve into an open state.

Owner:KOBE STEEL LTD

Hydrogen energy recycling type automobile clean hybrid power system

ActiveCN106004504AExtended driving distanceNo polluting emissionsHybrid vehiclesGas pressure propulsion mountingCapacitanceHydrogen fuel cell

The invention provides an automobile hybrid power system. The automobile hybrid power system comprises a power generation part and a power part, wherein the power generation part comprises a compressed hydrogen power generation part, a hydrogen fuel cell power generation part, a super-capacitor and cell power generation part and a switching reluctance power generator; and the power part comprises a switching reluctance motor. The compressed hydrogen power generation part comprises a high-pressure hydrogen storage gas tank, a manual stop valve, an electromagnetic decompression valve, an electromagnetic stop valve-I, a pneumatic motor, a transmission wheel, a switching reluctance power generator and the like; the high-pressure hydrogen storage gas tank is provided with an external gas filling hole of the gas tank, a safety valve and a barometer; the high-pressure hydrogen storage gas tank is connected with the pneumatic motor through a pipeline-I; the pipeline-I is sequentially provided with the manual stop valve, the electromagnetic decompression valve and the electromagnetic stop valve-I; the pneumatic motor is connected with a rotary shaft of the switching reluctance power generator through the transmission wheel; the switching reluctance power generator is connected with the switching reluctance motor; and the switching reluctance motor is connected with an automobile transmission shaft. Compressed gas energy and contained hydrogen energy of hydrogen gas can be used for two times and energy utilization efficiency is extremely increased; the driving distance of an automobile is effectively expanded; and meanwhile, zero-pollution emission is realized.

Owner:PLA UNIV OF SCI & TECH

Method for Production of Carbon Dioxide and Apparatus Therefor

InactiveUS20120198884A1Easily supplyMinimize harmful effectsSolidificationLiquefactionThermal compressionProcess engineering

A system for conversion of waste and solar heat energy into a carbon sequestration device, including as a collector for collecting carbon dioxide gas from a carbon dioxide gas source, such as ambient air. The Joule Thompson effect is used to cool and thereby refrigerate / liquefy ambient air and then extracting carbon dioxide therefrom, comprising steps of and means for providing a hydride heat engine, operating the hydride heat engine utilizing hydride thermal compression technology to compress hydrogen gas and thereby to cool ambient air to a temperature rendering air into a refrigerated / liquefied state by use of a Joule-Thompson type process, and extracting carbon dioxide from the refrigerated / liquefied ambient air and collecting the carbon dioxide.

Owner:MPD TECH

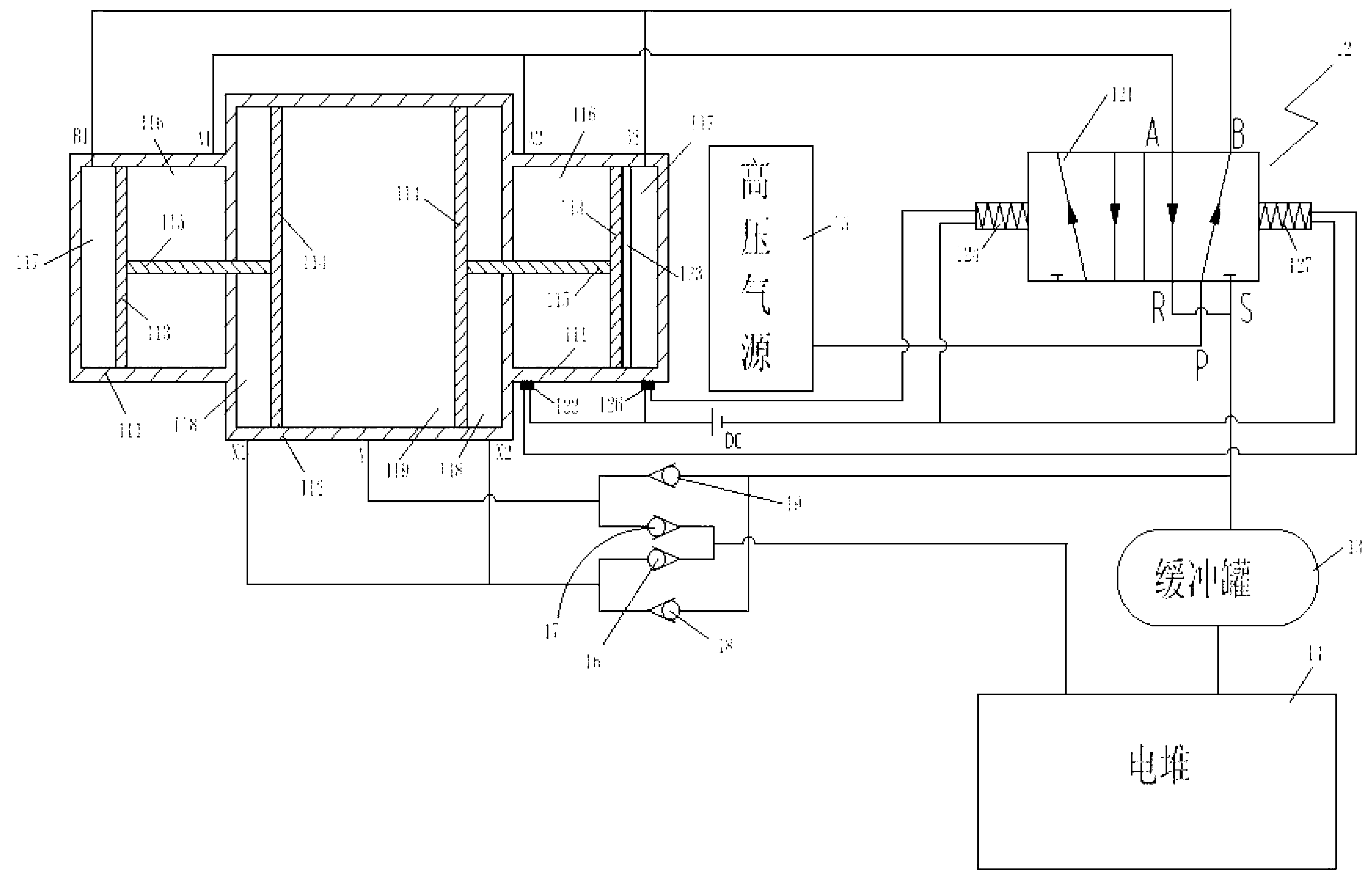

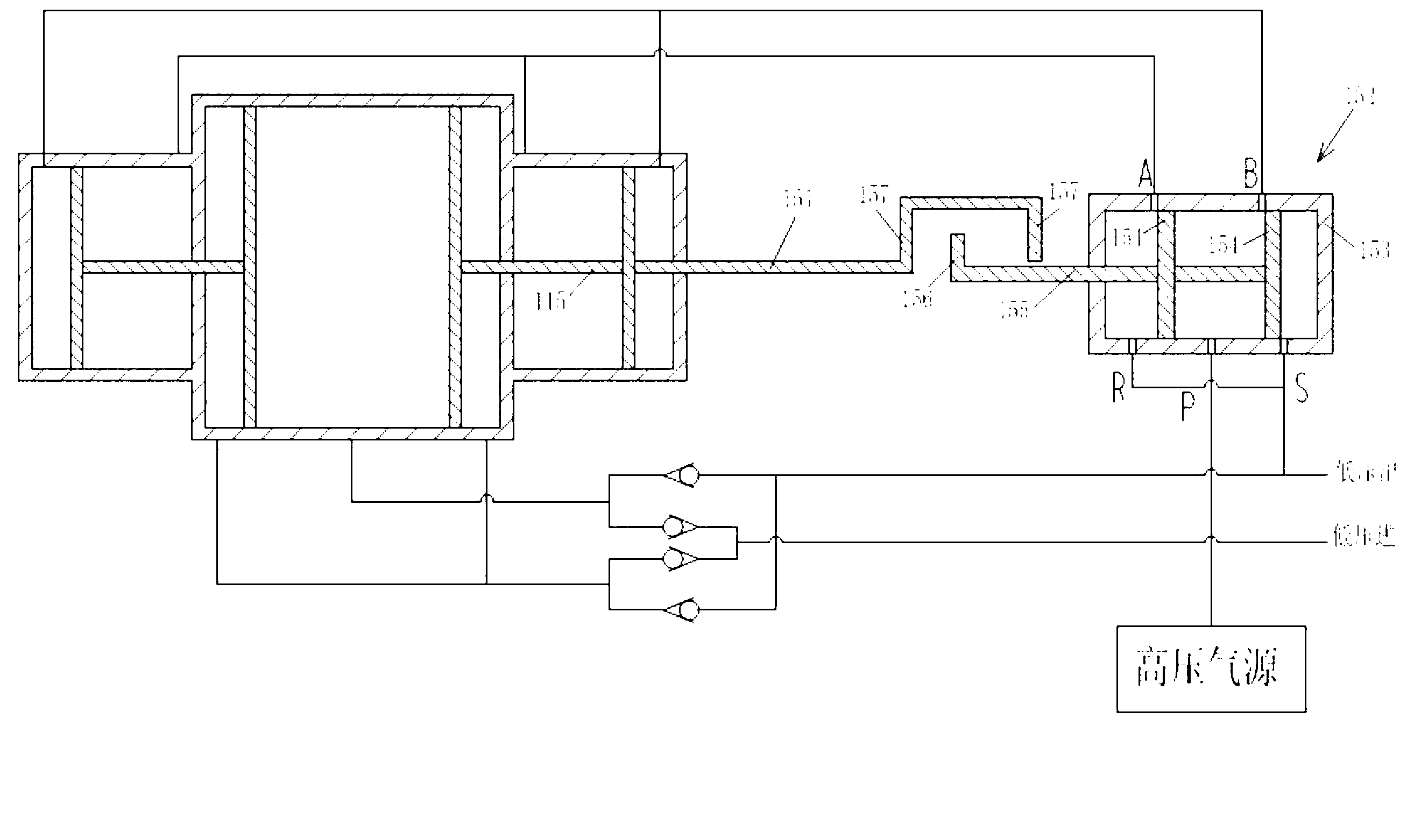

Piston type pneumatic circulating gas pump

The invention discloses a piston type pneumatic circulating gas pump which comprises a circulating gas pump body, a gas reversing mechanism, a buffering tank and an electric pile. The circulating gas pump body comprises a big cylinder and small cylinders, a big piston is arranged in the big cylinder and divides the big cylinder into two cavities, a small piston is arranged in each small cylinder and divides the corresponding small cylinder into two cavities, the gas reversing mechanism comprises a two-position five-way reversing valve and a replacing mechanism with one end connected with the circulating gas pump body and the other end connected with the two-position five-way reversing valve, a gas outlet of the electric pile is communicated with a third cavity in the big cylinder through a first check valve and further communicated with a fourth cavity in the big cylinder through a second check valve, the third cavity is communicated with a gas inlet of the buffering tank through a third check valve, and the fourth cavity is communicated with the gas inlet of the buffering tank through a fourth check valve. Circulatory flowing of hydrogen in the electric pile is realized through expansion work released during decompression of compressed hydrogen.

Owner:上海新源动力有限公司

Hydrogen Gas High Pressure Storage System

A device for the storage of compressed hydrogen gas comprises a plurality of glass capillary tubes each having a sealed extremity and an open extremity, wherein said plurality of glass capillary tubes is sheathed in an external tubular cover, and wherein the open end of a bundle of said tubular covers is housed in an adaptor, and wherein said adaptor is suitable to allow compressed hydrogen gas to be added to, and to prevent said hydrogen gas from escaping from, said glass capillary tubes.

Owner:CEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com