Deep water generation of compressed hydrogen

a hydrogen production and deep water technology, applied in the field of renewable energy, can solve the problems of not being able to achieve a practical method or apparatus for hydrogen production, not being able to scale up to produce commercially useful quantities, and not being able to achieve the effect of hydrogen production ideas that are too complex, expensive to build, and not attractive to consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

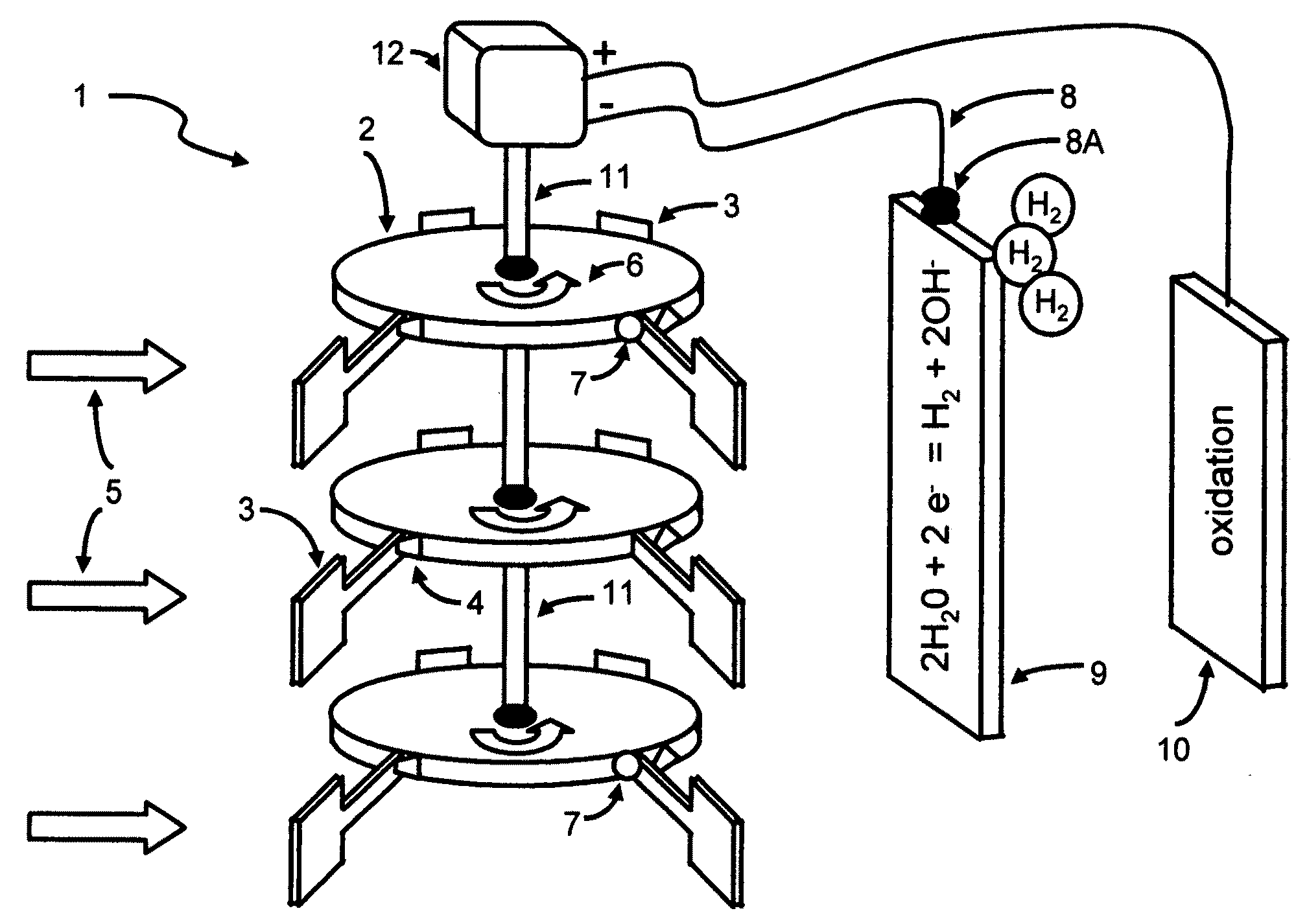

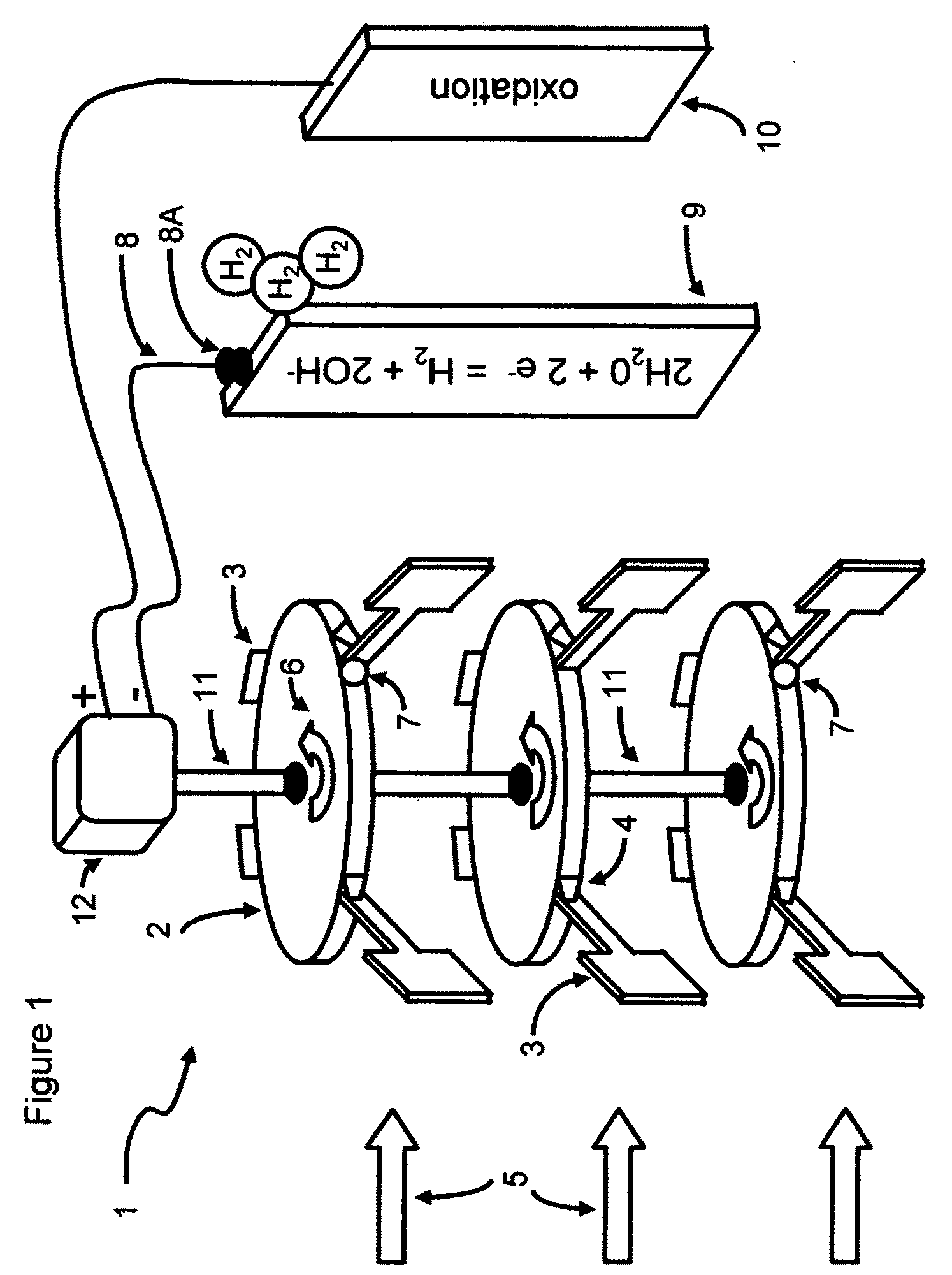

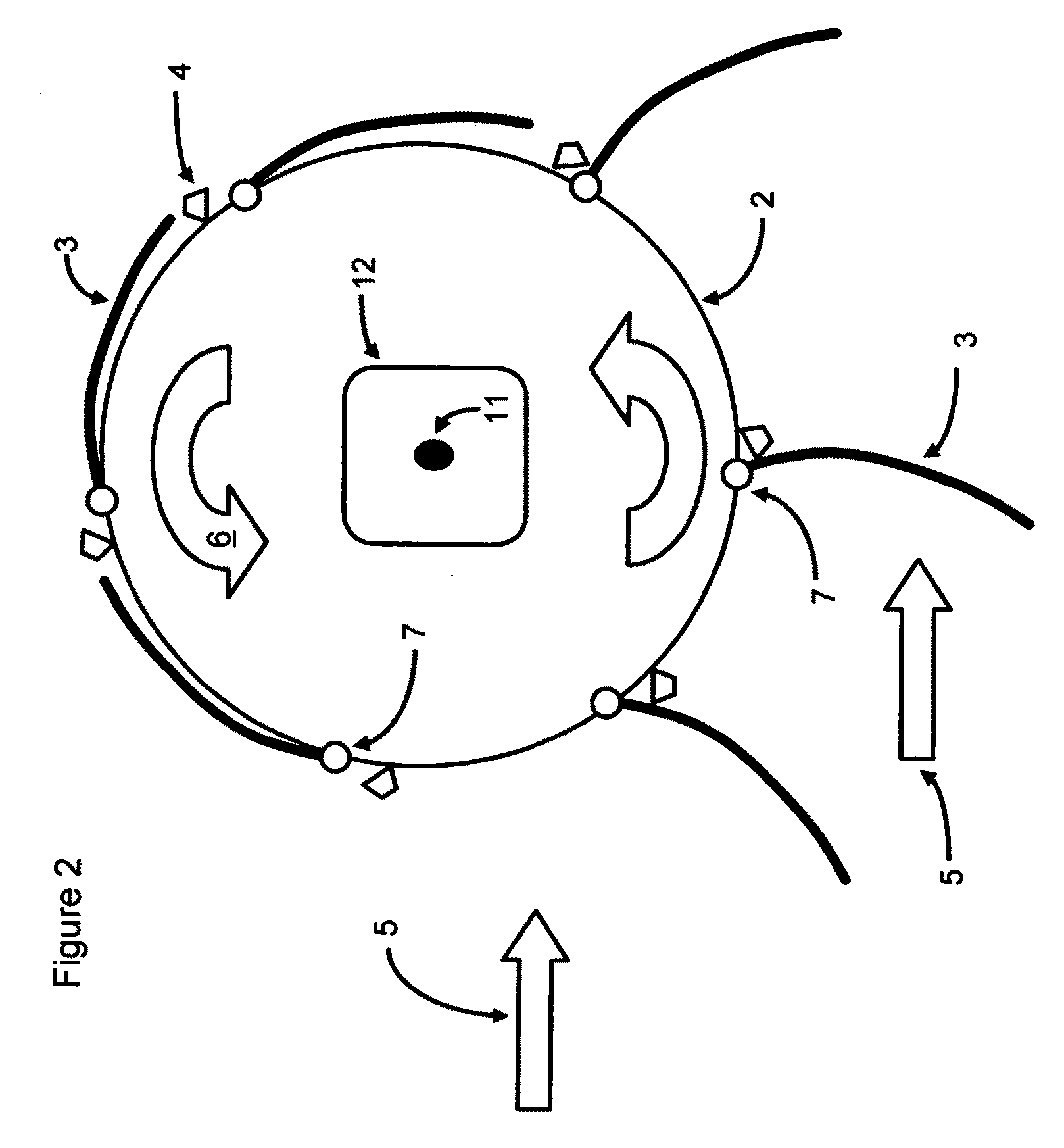

[0097]FIG. 1 shows a basic hydrogen production station 1. It includes one or more rotating disks 2 that rotate due to current catchers 3. Open current catchers 3 are held open by restraints 4 that hold the current catchers open only in one direction. When the restraints 4 are on the downstream side of the current catchers 3, the current catchers open, and are pushed by the ocean current 5. When the restraints 4 are on the upstream side of the current-catchers, the current catchers fold. Current catchers are not pushed by the ocean current 5 when they are folded. The result is a counter-clockwise rotation 6 when viewed from the top. Note that the ocean current 5 itself opens and folds the current catchers. At the start of energy capture, the ocean current 5 pushes the current catcher 3 open. At the end of energy capture, the ocean current5 folds the current catcher 3.

[0098]The restraints 4 shown in FIG. 1 are implemented as structural blocks with sufficient rigidity and size to stabi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com