Renewable energy operated hydrogen reforming system

a hydrogen reforming and renewable energy technology, applied in the direction of combustible gas production, sustainable manufacturing/processing, greenhouse gas reduction, etc., can solve the problems of high cost of hydrogen fuel storage and transportation, lack of cost-effective hydrogen storage and transportation,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

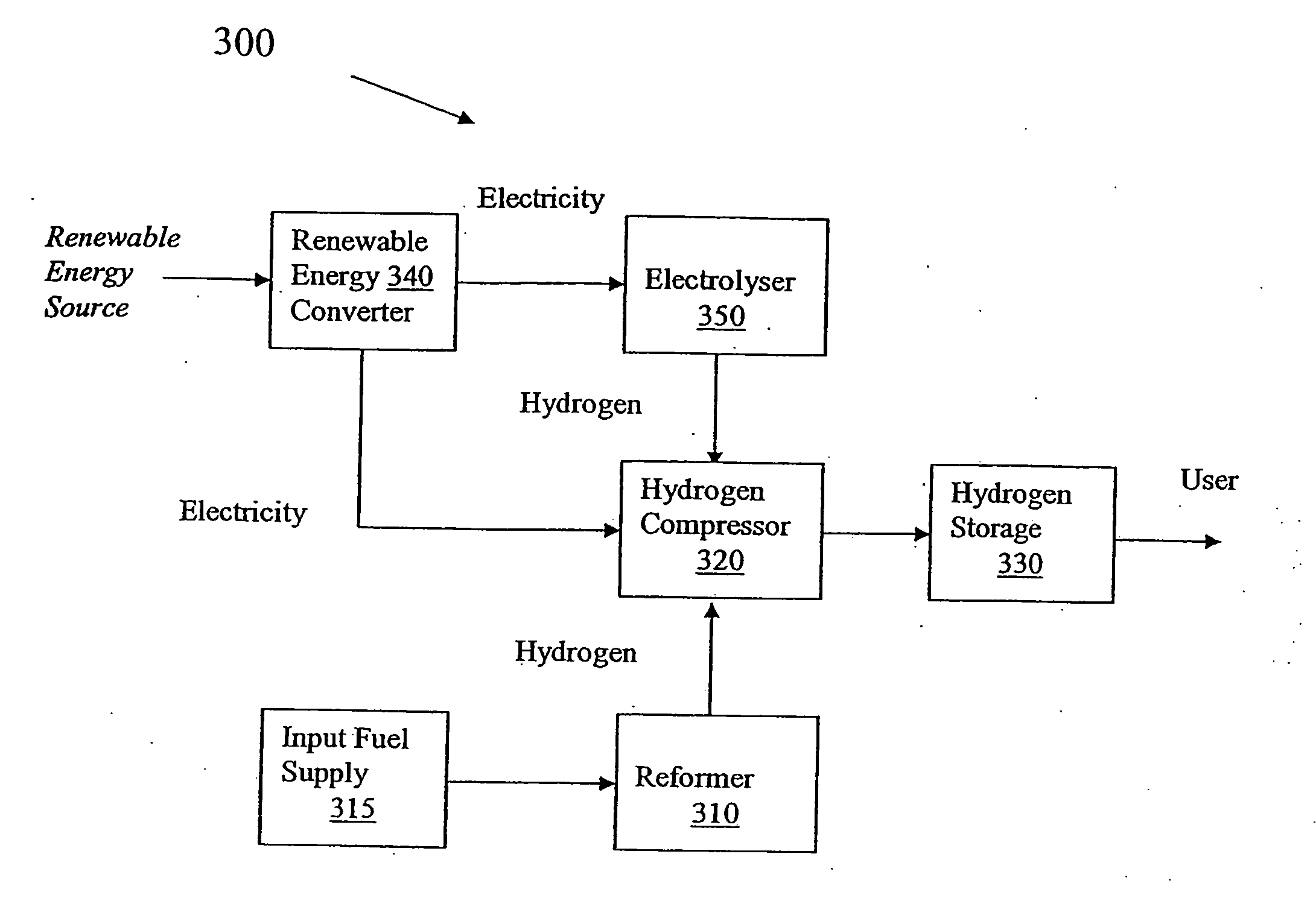

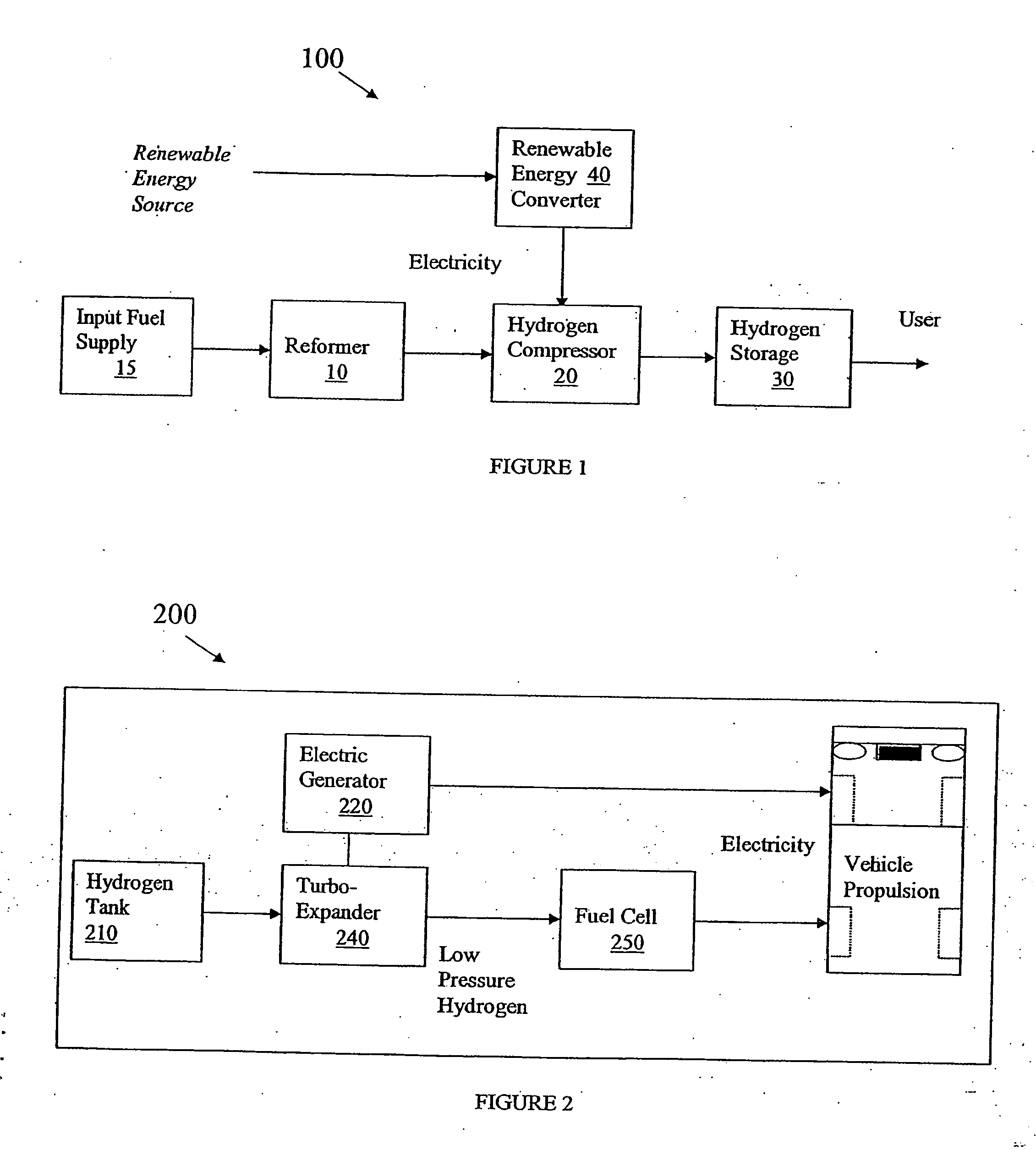

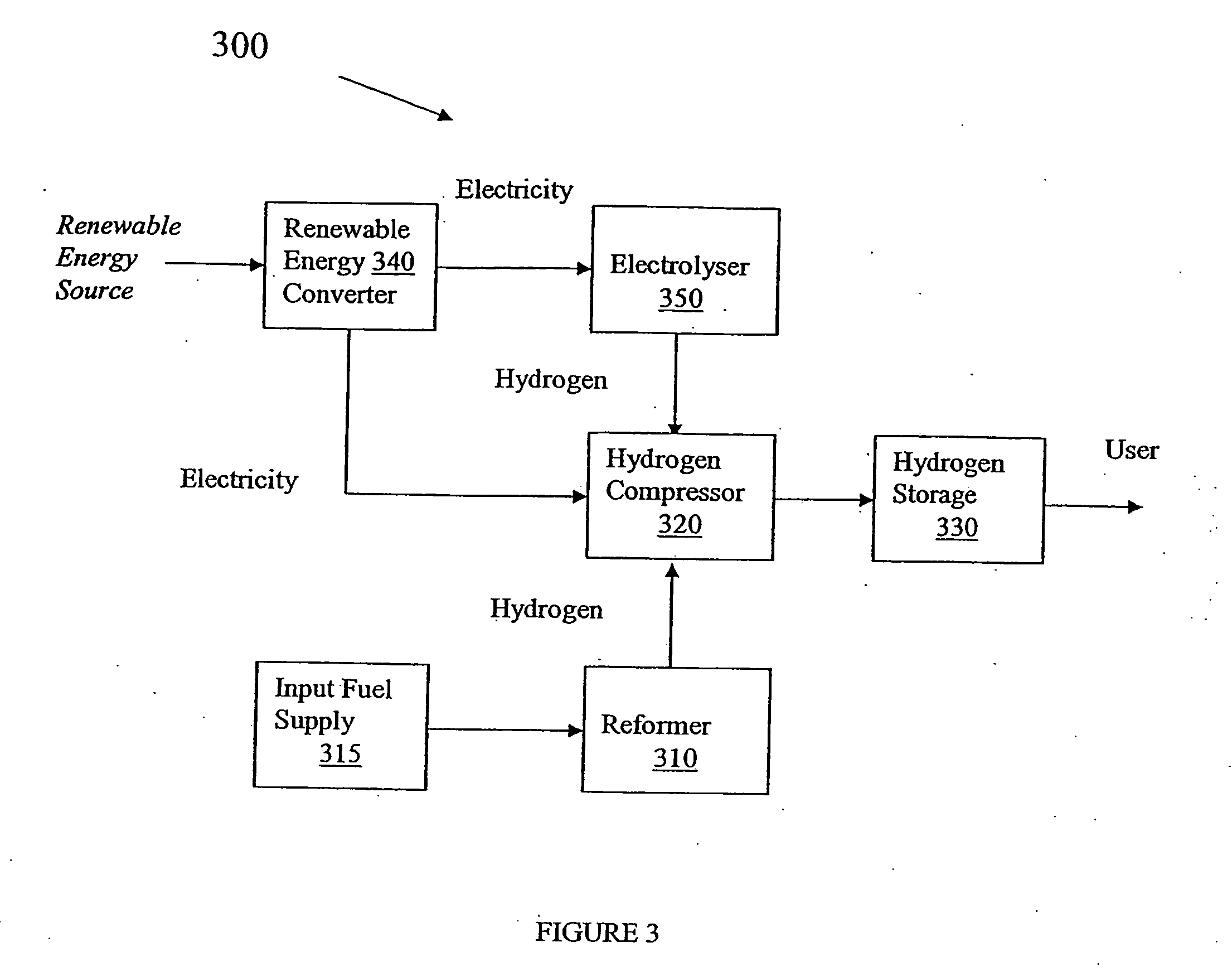

[0014] The present invention provides an efficient, low cost hydrogen production system that utilizes renewable energy sources. The invention will be described below relative to an illustrative embodiment. Those skilled in the art will appreciate that the present invention may be implemented in a number of different applications and embodiments and is not specifically limited in its application to the particular embodiment depicted herein.

[0015] As used herein, the term “renewable source” or “renewable energy source” refers to any energy source with a natural replenishment rate that augments its own stock (or biomass) at a non-negligible rate. Renewable resources are generally capable of being replenished at least as fast as the renewable resource is used, although this need not be the case. Renewable sources include, but are not limited to, wind, solar energy, geothermal energy, biomass, waste, wave energy and hydro energy. In contrast, nonrenewable energy sources draw on finite r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com