Piston type pneumatic circulating gas pump

A circulating air pump, piston-type technology, applied in the field of piston-type pneumatic circulating air pump, can solve the problems of power consumption, waste of fuel safety, stack pressure fluctuations, etc., and achieve the effects of no hydrogen loss, improved comfort, and no power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

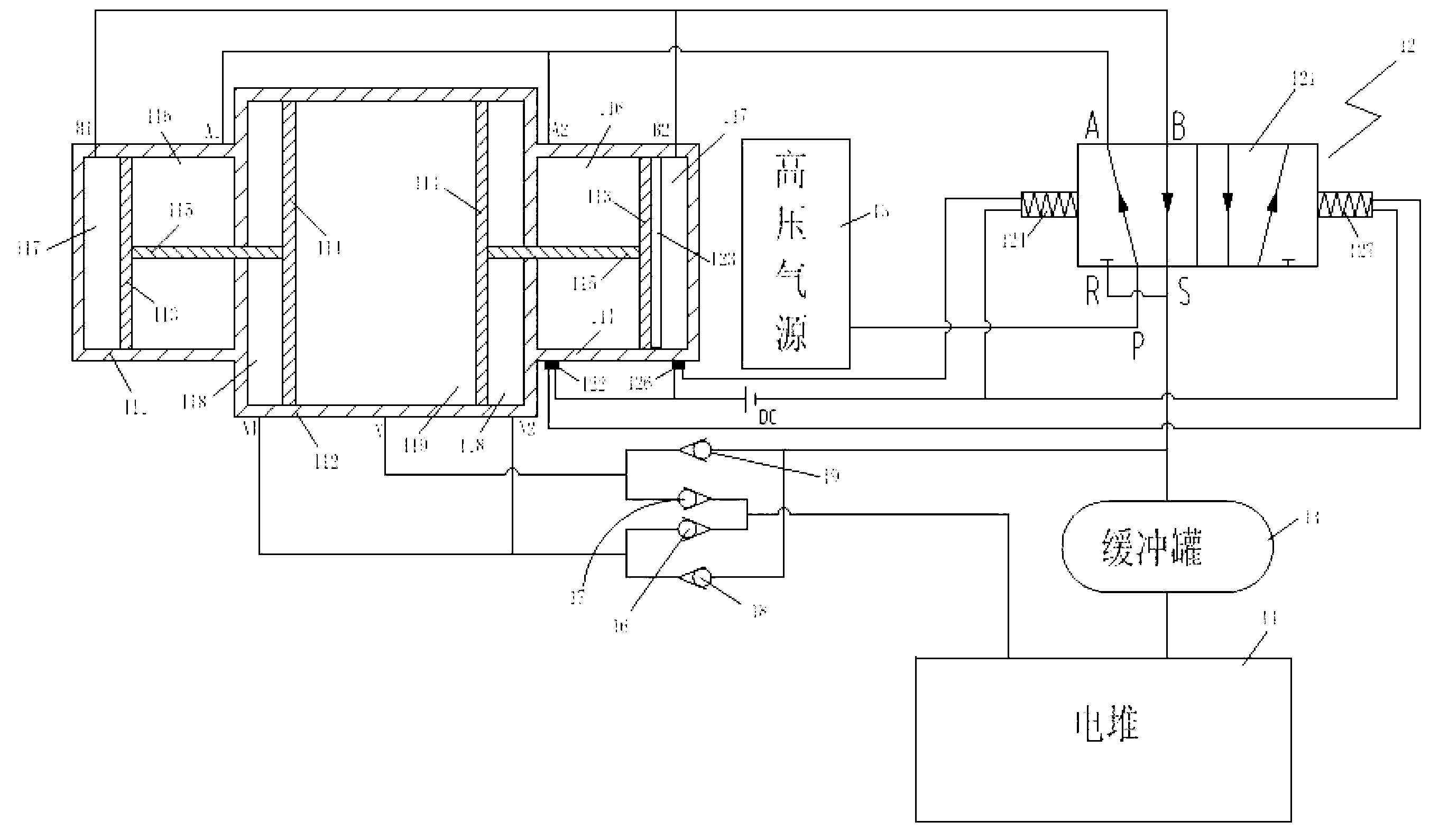

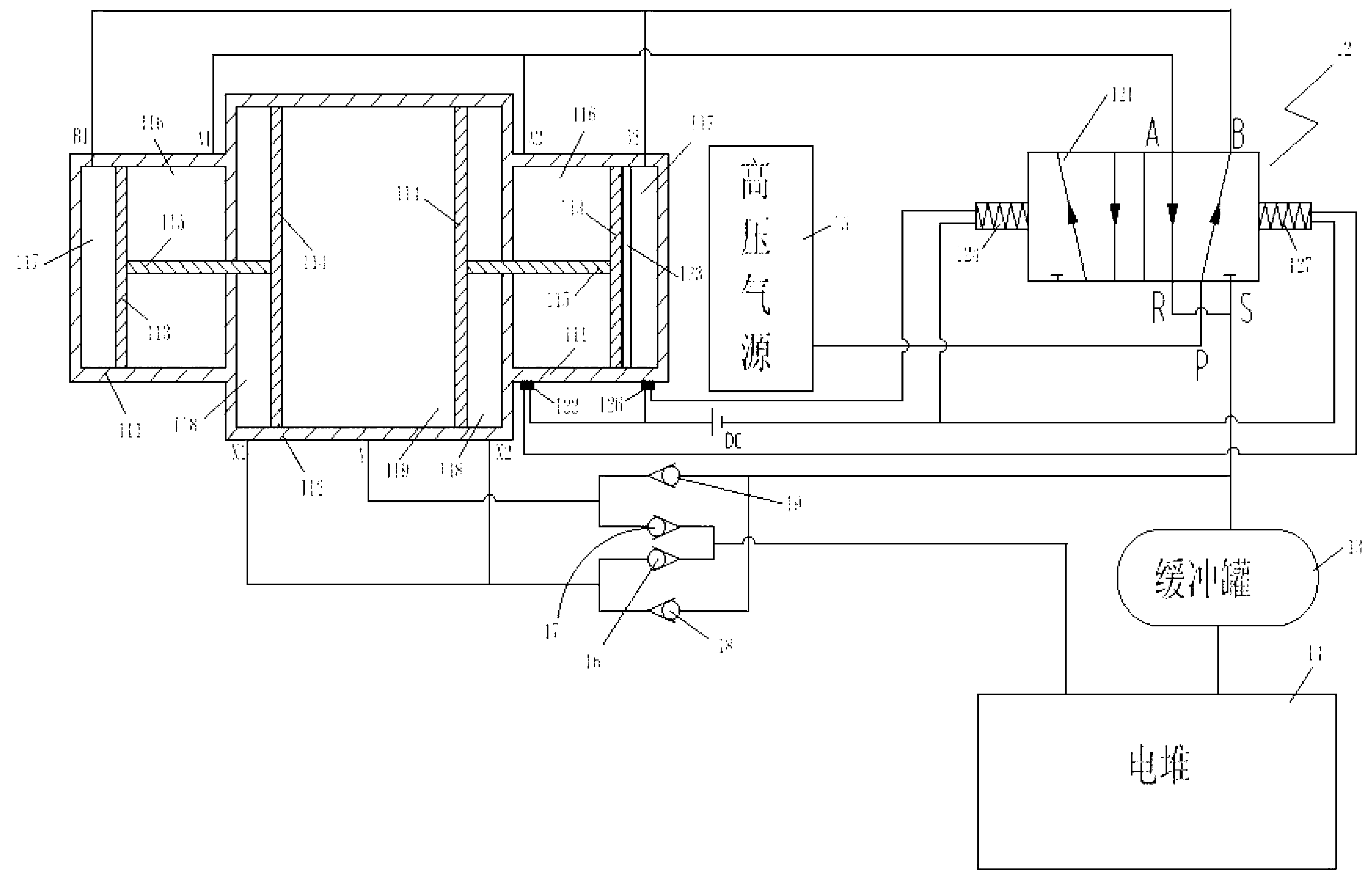

[0029] see figure 1 , figure 2 A piston-type pneumatic circulating air pump shown includes a circulating air pump pump body, a gas reversing mechanism 12, a buffer tank 13 and an electric stack 14,

[0030] The pump body of the circulating air pump includes two small cylinders 111 and a large cylinder 112 arranged horizontally on the same axis. The two small cylinders 111 are symmetrically arranged on both sides of the large cylinder 112. Each small cylinder 111 is respectively equipped with a small piston 113. 1. Two large pistons 114 are arranged in the large cylinder 112, and the large piston 114 and the small piston 113 are connected by corresponding piston rods 115; A first chamber 116 is formed between the partition wall and the small piston, and the other is a second chamber 117; the large piston 114 divides the large cylinder 112 into two chambers, wherein the partition wall of the large and small cylinders and the large piston A third cavity 118 is formed, and the ...

Embodiment 2

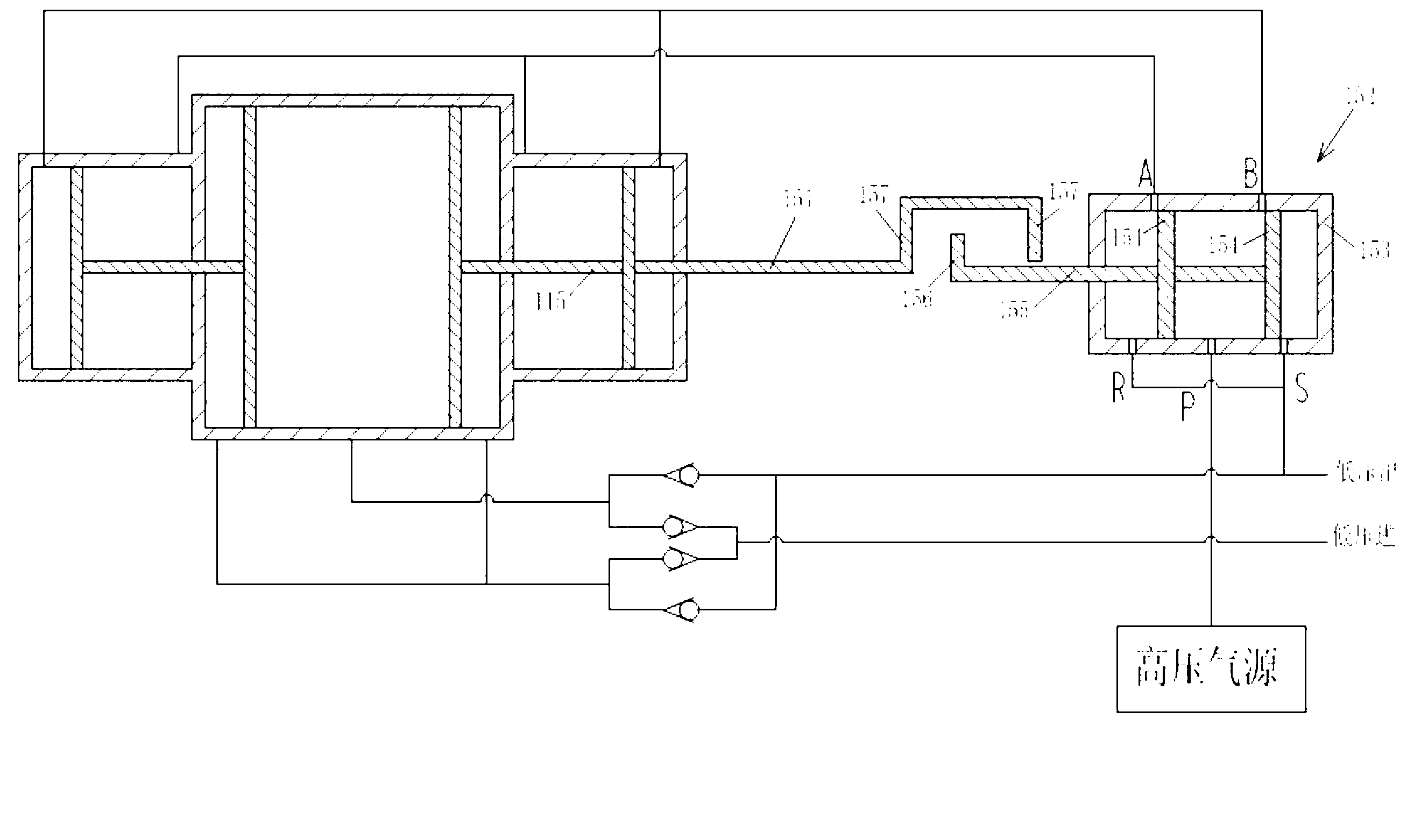

[0043] see you again image 3 As shown, the difference between this embodiment and Embodiment 1 is that the switching mechanism includes a shifting lever 151, the two-position five-way reversing valve is a mechanical two-position five-way reversing valve 152, and the inner end of the shifting rod 151 is connected to the The piston rod 115 is connected and fixed, and the outer end of the driving rod 151 has a concave structure; the mechanical 2-position 5-way reversing valve 152 includes a valve body 153, two spools 154 and a driven rod 155, and the spool 154 is set on the valve In the body 153, the inner end of the driven rod 155 is connected to the spool 154, and the outer end of the driven rod 155 is provided with a protrusion 156, and the protrusion 156 extends into the concave outer end of the driving rod 151, and the piston rod 115, The axes of the driving rod 151 and the driven rod 155 coincide;

[0044] Both sides of the concave outer end are respectively provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com